Oil-pressure control device of automatic speed variator

A technology of automatic transmission and oil pressure control, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., to prevent sudden loss of torque and promote the effect of increasing oil viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

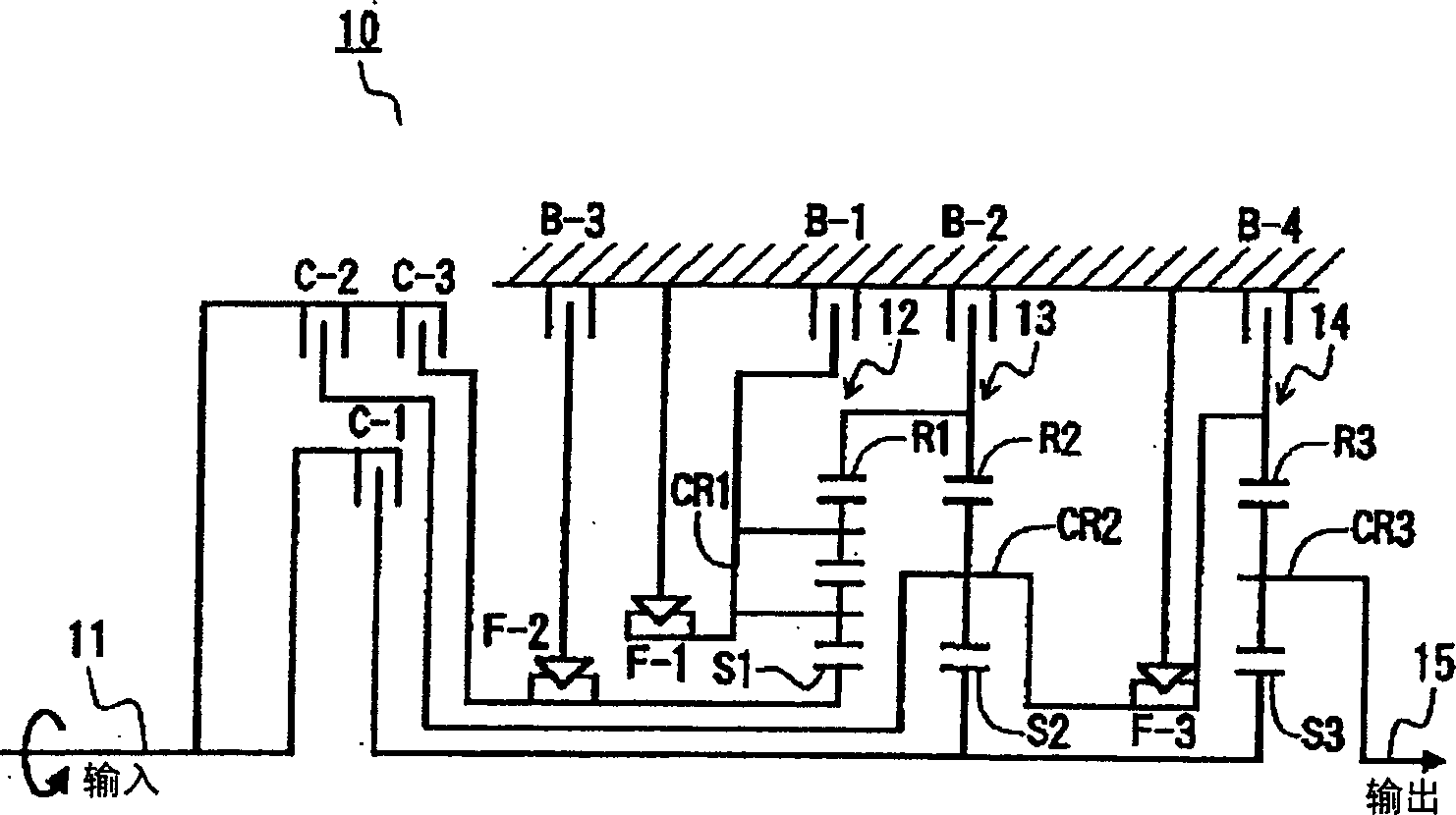

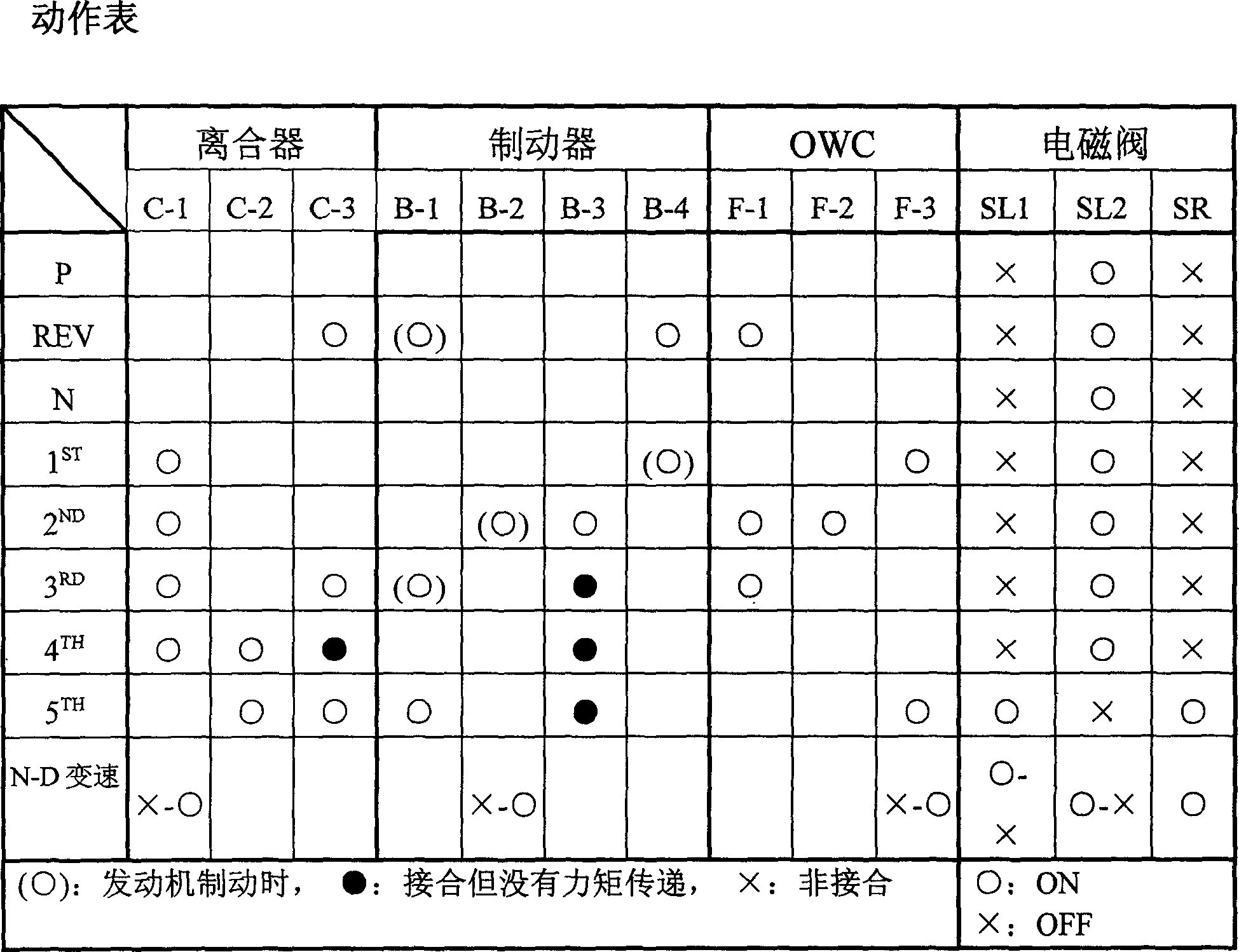

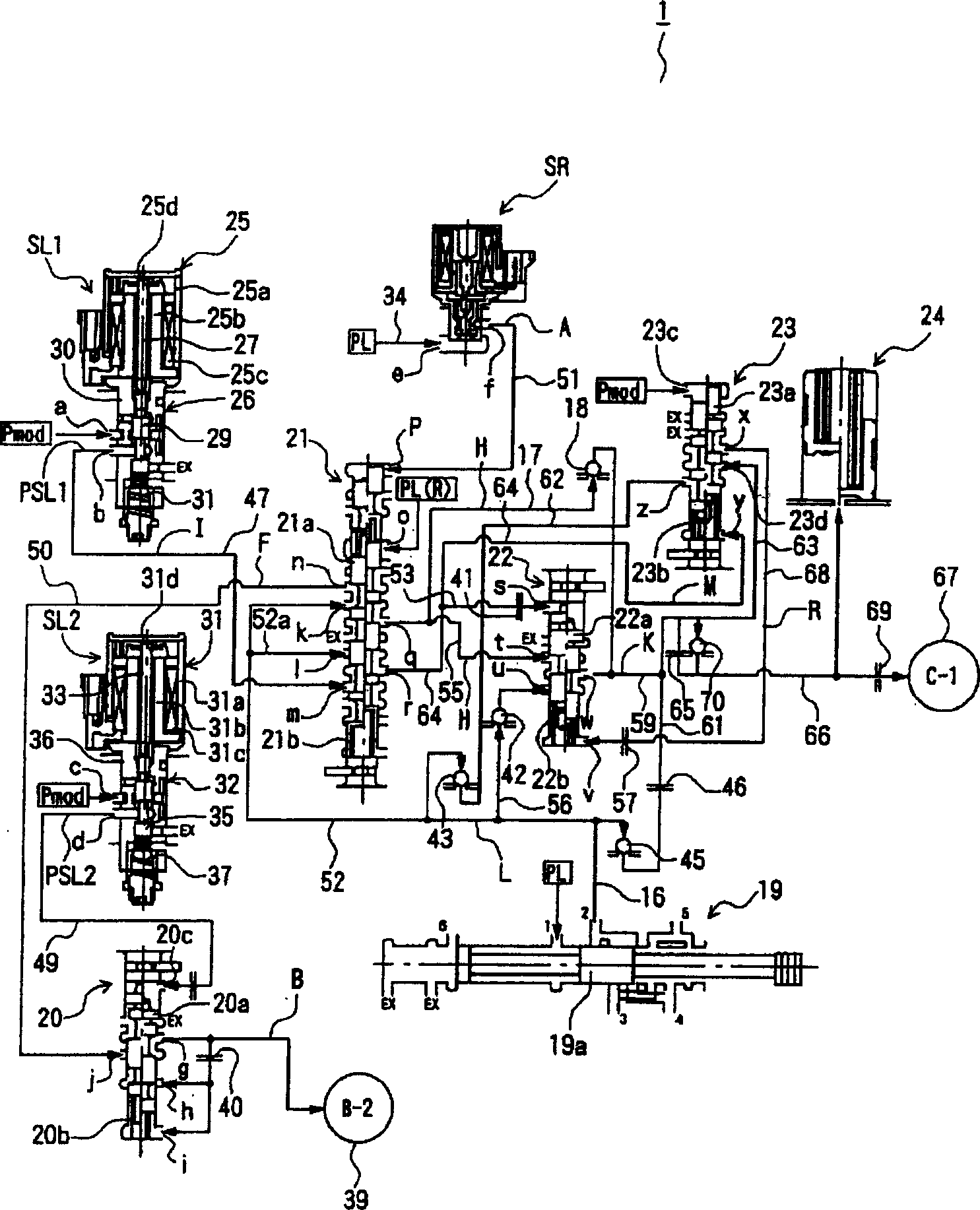

[0025] Embodiments of the present invention are described below with reference to the drawings. figure 1 is a schematic diagram showing an automatic transmission mechanism to which the present invention is applied, figure 2 is an operation table showing the engagement state of the frictional engagement elements in each gear, image 3 It is a schematic diagram showing the hydraulic control device of the present invention.

[0026] For example, in an automatic transmission disposed in a vehicle or the like, the oil pressure control device 1 of the present invention is included, and the oil pressure control by the oil pressure control device 1 is performed by controlling a plurality of friction engagement members (for example, clutches C-1 to C-1). -3. The engagement state of the brakes B-1 to B-4) is controlled to form, for example, an automatic transmission mechanism (gear mechanism) 10 with 5 forward speeds and 1 reverse speed.

[0027] Such as figure 1 As shown, the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com