Scraping plate for filter and matched filter plate

A filter plate and filter technology, which is used in mobile filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problem of low filtration efficiency, easy damage to filtration equipment, production efficiency, and adjustment of the content of particles that cannot be discharged at a speed. problem, to achieve the effect of speeding up the efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

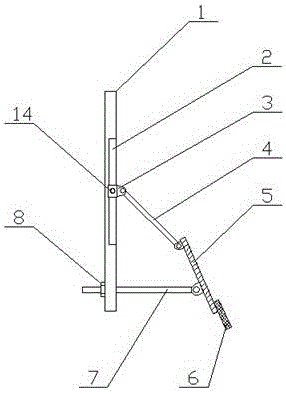

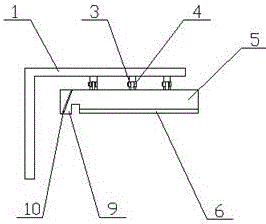

[0023] Embodiment 1: as Figure 1~4 Shown: a scraping device for a filter and a matching filter plate, including a scraper 5 and a mounting bracket 1, the scraper 5 is an arc-shaped structure with the scraper surface protruding outward; the scraper 5 is installed through an arc adjustment device and an angle adjustment device On the mounting frame, it is arranged above the filter plate 11 in an inclined manner.

[0024] The angle adjustment device includes three angle adjustment rods 4 arranged horizontally and corresponding sliders 3. The slider 3 is installed on the slide rail 2 of the mounting bracket 1 in a manner that can move up and down. It is hinged with the upper part of the scraper 5 , and the slider 3 is provided with a locking screw 14 for fixing with the mounting bracket 1 . By adjusting the slider 3 up and down, the angle adjusting rod 4 can be driven to move up and down, thereby adjusting the inclination angle of the scraper 5 .

[0025] The arc adjustment dev...

Embodiment 2

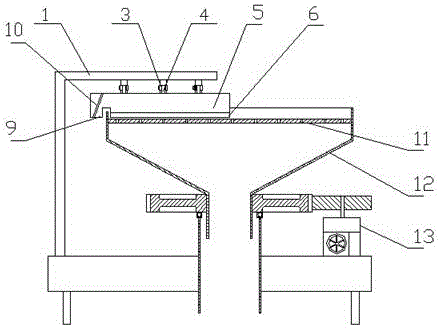

[0029] Embodiment 2: as Figure 5 Shown: compared with embodiment 1, the difference between a kind of filter scraping device and the matching filter plate of this embodiment is that the filter plate 11 is a conical structure that protrudes upwards in the middle, and the filter plate 11 is set as The conical structure can speed up the discharge speed of silica particles and improve the efficiency of filtration and recovery.

[0030] Working principle and using method of the present invention:

[0031] When performing filtration and recovery, the scraping device and its supporting filter plate 11 are installed on the rotary filter, and the driving device 13 of the rotary filter drives the casing 12 and the filter plate 11 to rotate, and the aluminum fluoride solution containing silicon dioxide particles After falling into the filter plate 11, the aluminum fluoride solution is filtered through the filter plate 11, and the silica is left on the filter plate 11. As the filter plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com