Underwater vector propulsion type ultrasonic drilling robot and using method thereof

A vector propulsion and vector propulsion technology, which is applied in the field of underwater vector propulsion ultrasonic drilling robots, can solve the problems of large size, low work efficiency, and reduced exploration efficiency, and achieves a wide working temperature range, high propulsion efficiency, and flexible movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0038] The working principle of the ultrasonic drill of the present invention is to utilize the inverse piezoelectric effect of the piezoelectric material.

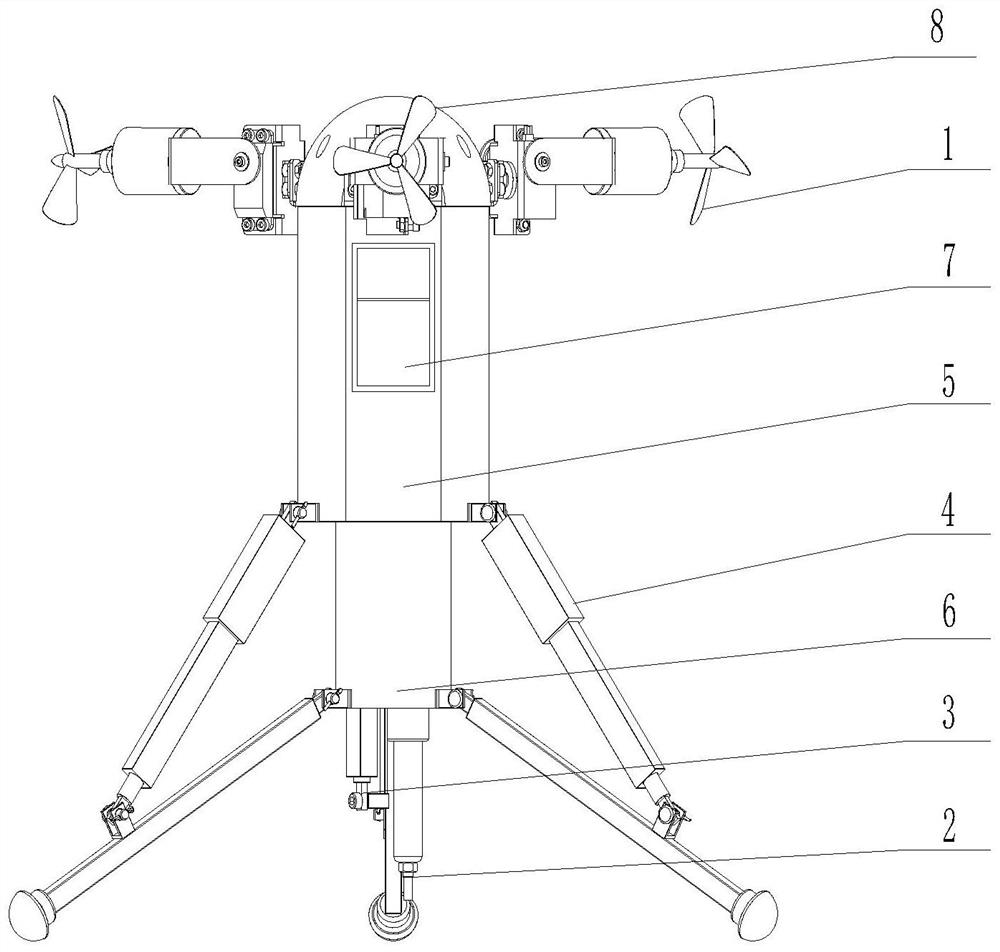

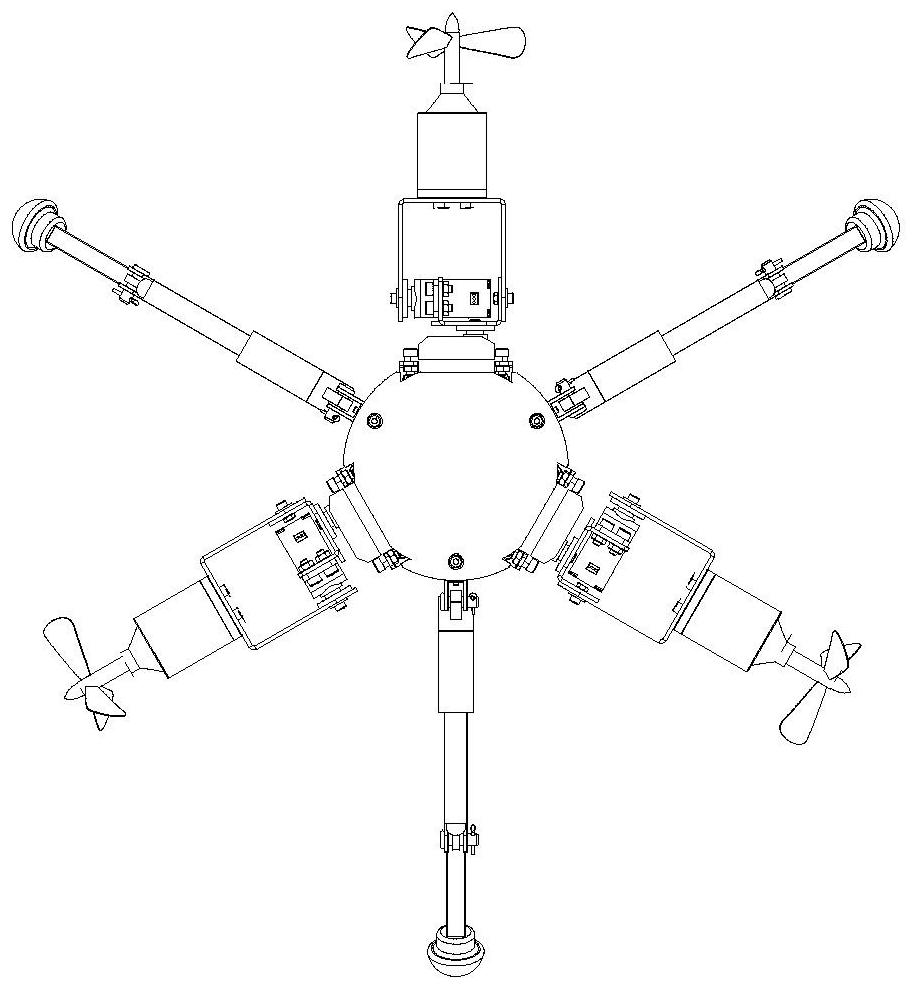

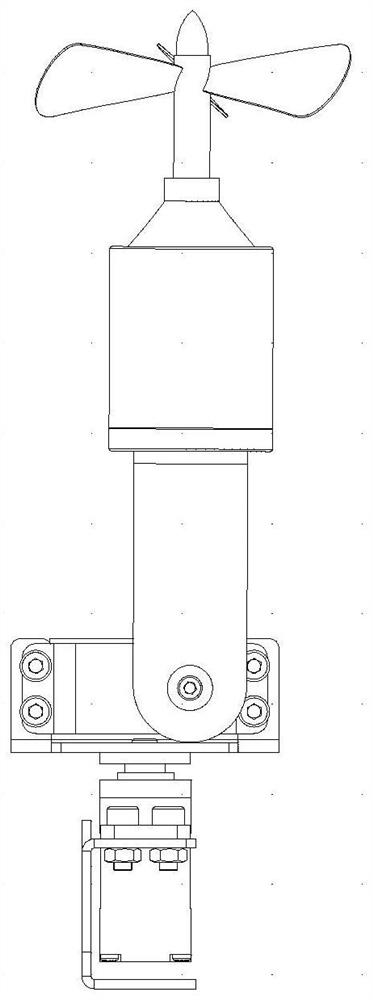

[0039] like Figure 1-9 As shown, an underwater vector-propelled ultrasonic drilling robot includes a vector thruster 1, an ultrasonic drill 2, a drill fixing device 3, a base support adjustment mechanism 4, a sealed cabin 5, a hollow cylindrical shell 6, and a lithium battery 7 and a hemispherical casing 8, a hemispherical casing 8 is provided on the top of the sealed cabin body 5, and three groups of vector thrusters 1 evenly arranged are installed on the side of the spherical casing 8, and each group of vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com