Pile measuring hole obstacle clearing device based on ultrasonic drill bit

A cleaning device, ultrasonic technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., to achieve the effect of strengthening hardness, good cleaning effect and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

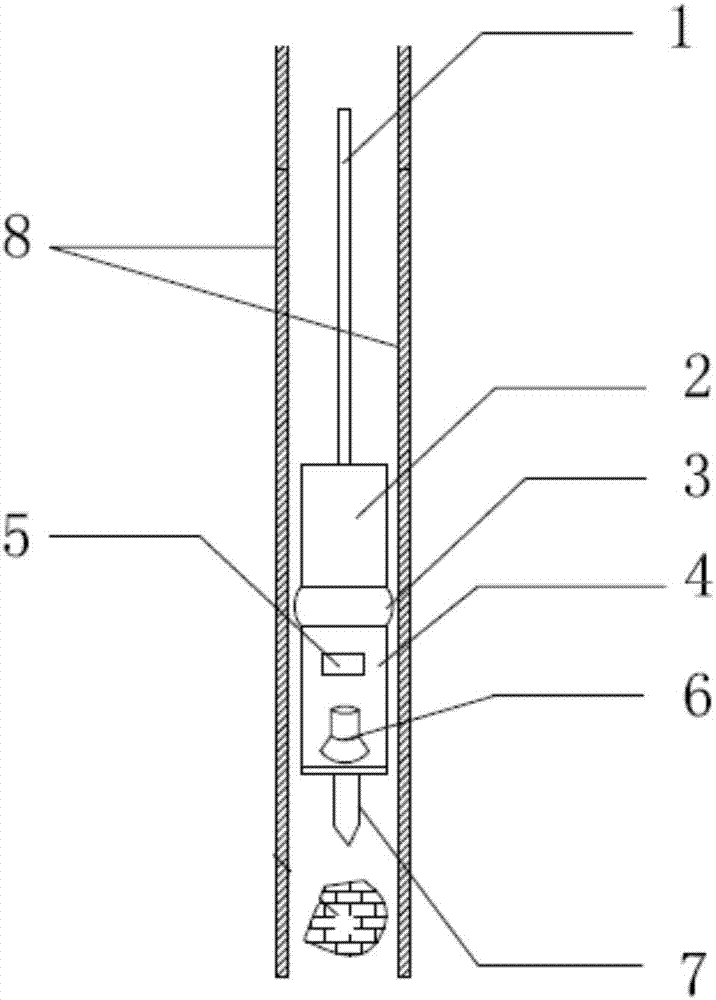

[0021] Embodiment: a kind of measuring pile hole obstacle cleaning device changer based on ultrasonic drill bit, such as figure 1 As shown, it includes a cable 1, a counterweight 2 and an ultrasonic drill 4. The front end of the ultrasonic drill 4 is provided with an ultrasonic drill 7, and the inside of the ultrasonic drill is provided with an ultrasonic generator 5 and a piezoelectric ceramic ultrasonic transducer. 6. The ultrasonic generator 5 is electrically connected to the cable 1, and the ultrasonic generator is electrically connected to the piezoelectric ceramic ultrasonic transducer 6 through a control circuit;

[0022] The cables, the counterweight and the ultrasonic drill are all located in the pile measuring hole 8 .

[0023] The piezoelectric ceramic ultrasonic transducer is arranged at the ultrasonic drill and is closely attached to the inner wall of the ultrasonic drill.

[0024] The counterweight 2 is connected to the ultrasonic drill 4 through a buffer device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com