Hard-brittle material large-depth-diameter-ratio tiny-special-shaped-hole precise ultrasonic drilling

A technology of hard and brittle materials and depth-to-diameter ratio, which is applied in metal processing and other directions, can solve problems such as inaccurate positioning, inability to process large depth-to-diameter ratio holes, and punching defects, so as to achieve high processing accuracy and benefit the roughness of the hole wall The effect of controlling and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

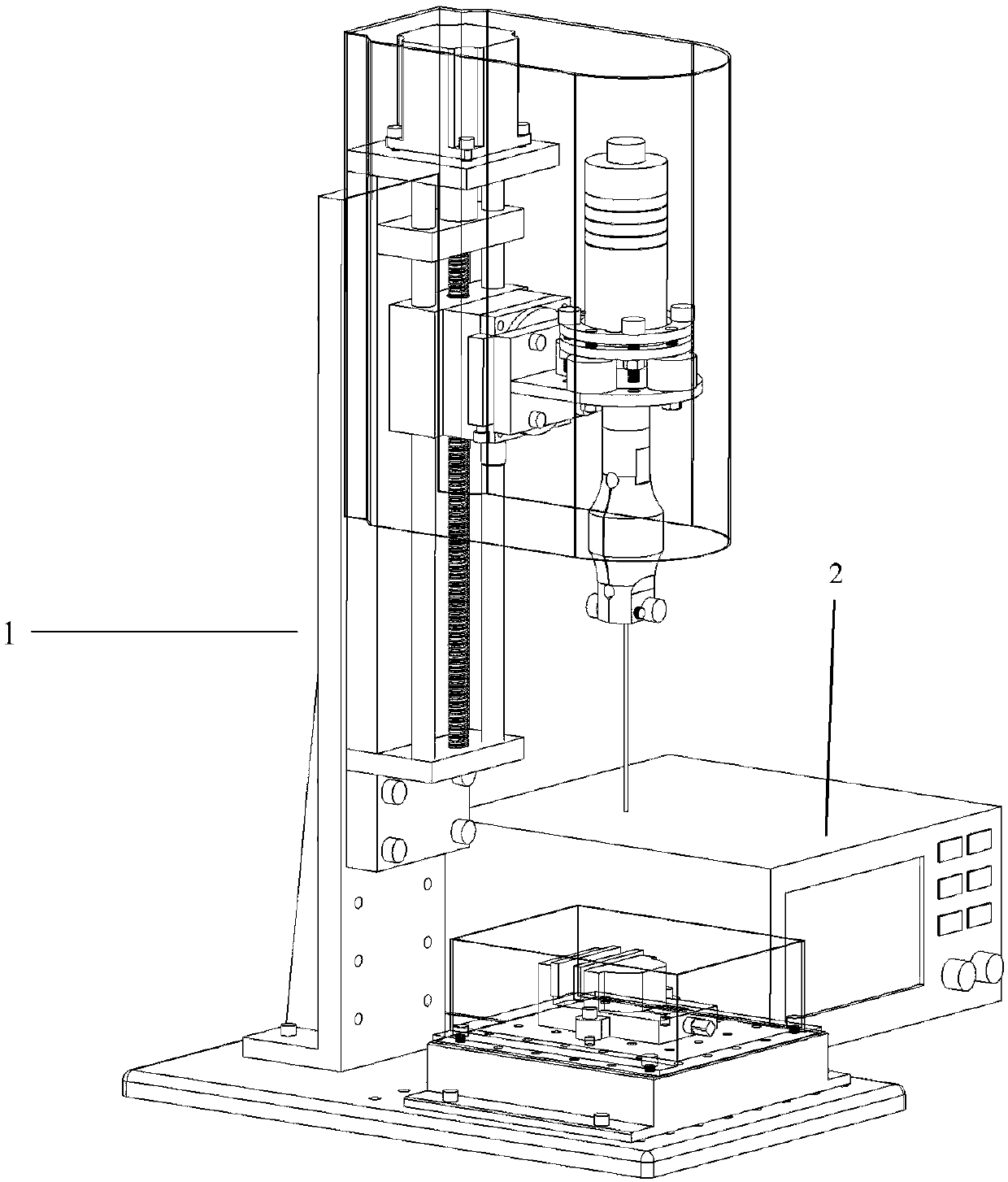

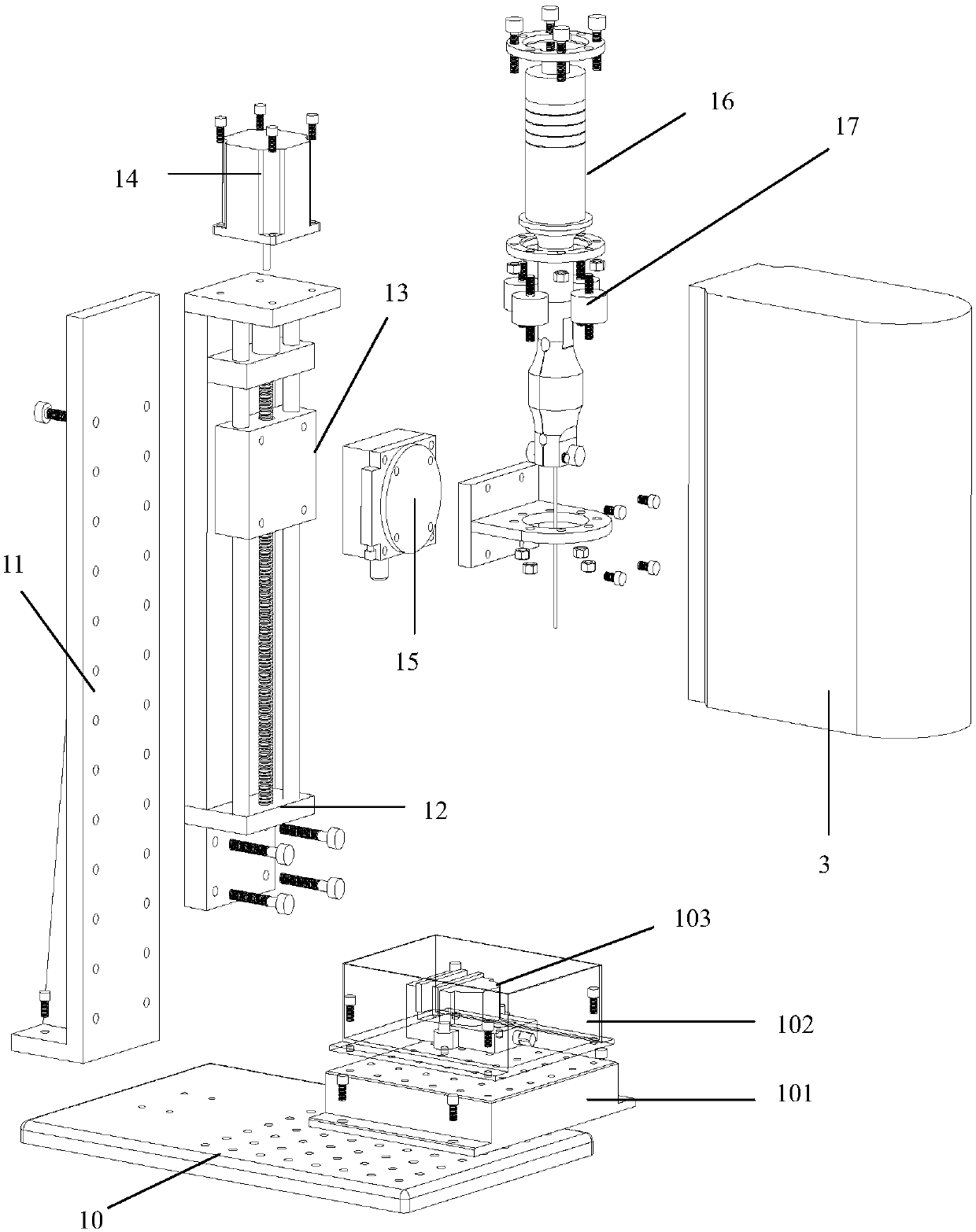

[0021] Please check figure 1 and figure 2 , a precision ultrasonic drilling machine with large depth-to-diameter ratio and small special-shaped holes for hard and brittle materials, including a machine tool body 1 and a control system 2, the machine tool body 1 includes a workbench 10, a column 11, a slide rail 12, and a slider 13 and stepping motor 14.

[0022] In this embodiment, the column 11 is vertically and fixedly installed on one side of the workbench 10, the slide rail 12 is fixed on the column 11, and the slider 13 is slid on the slide rail 12. The stepper motor 14 is connected with the slider 13 and can drive the slider 13 to move up and down along the slide rail 12 , and the control system 2 controls the moving amount of the slider 13 by connecting the stepper motor 14 .

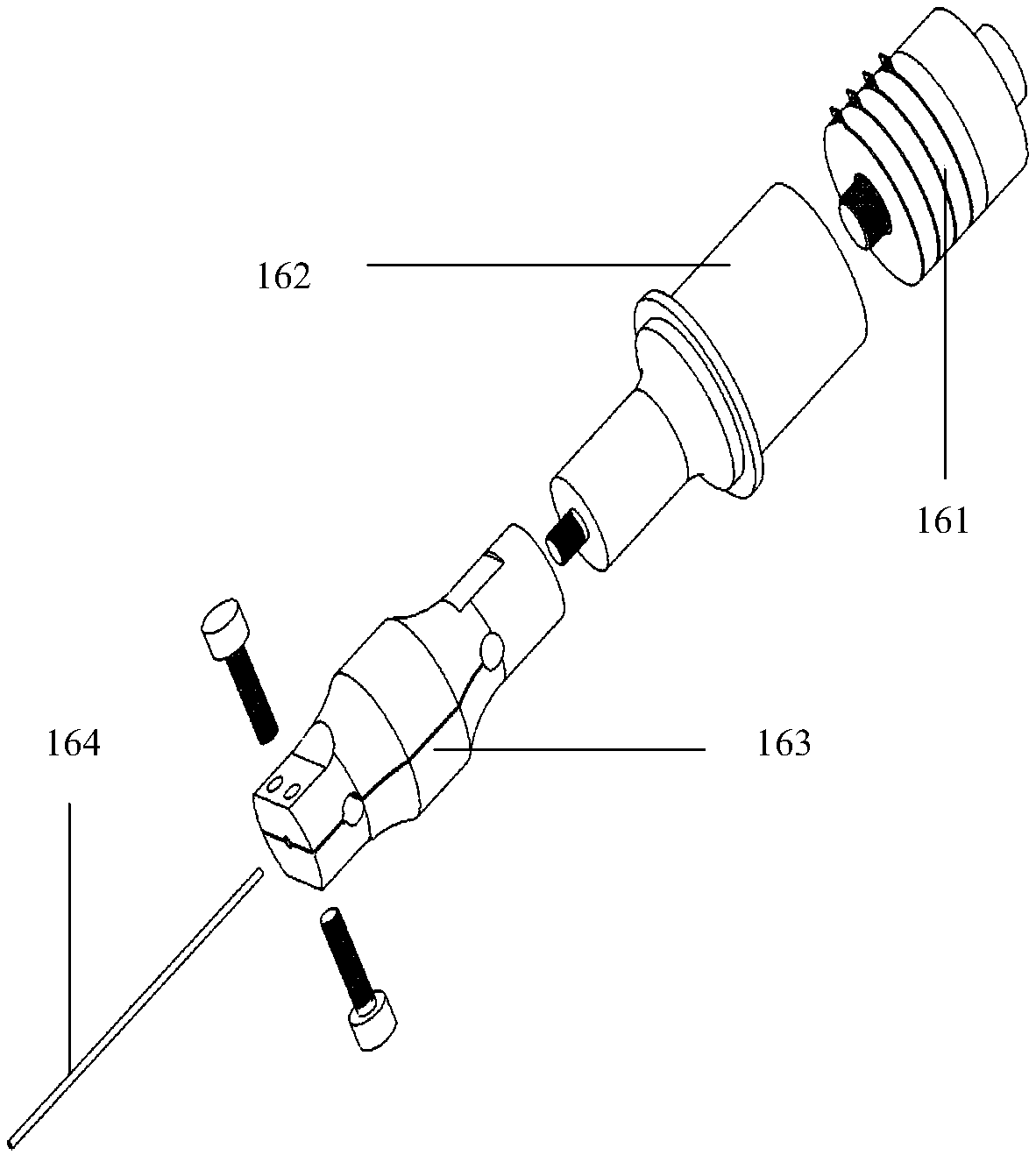

[0023] An angle adjustment device 15 is also mounted on the slider, and the angle adjustment device 15 can rotate left and right relative to the slider 13 . An ultrasonic vibrating device 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com