Electromagnetic motor-assisted rotary impact type ultrasonic drilling device

An electromagnetic motor and percussion technology, applied in the direction of drill pipes, drill pipes, drilling tools, etc., can solve the problems of low drilling efficiency and poor chip removal performance of percussive ultrasonic drills, and achieve improved drilling efficiency and structural design. Scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

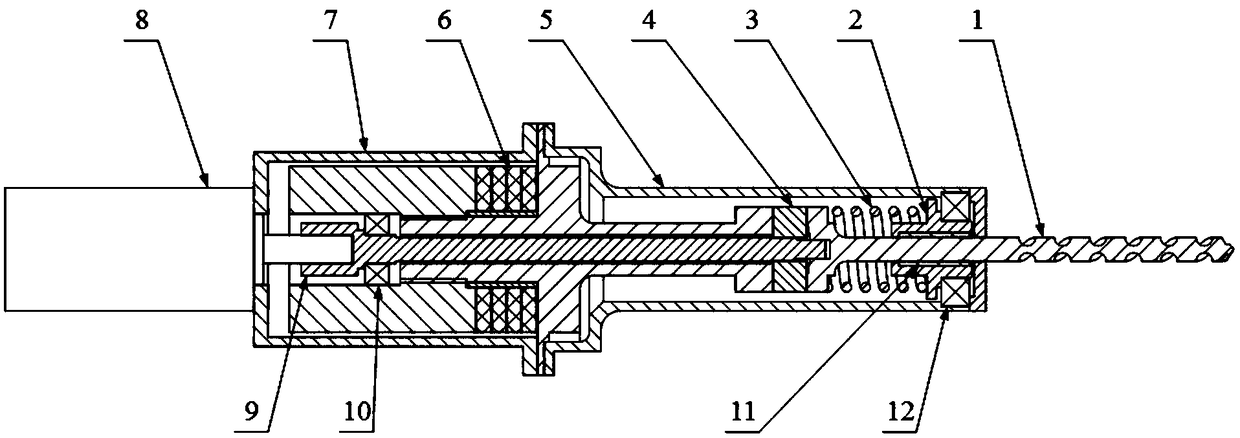

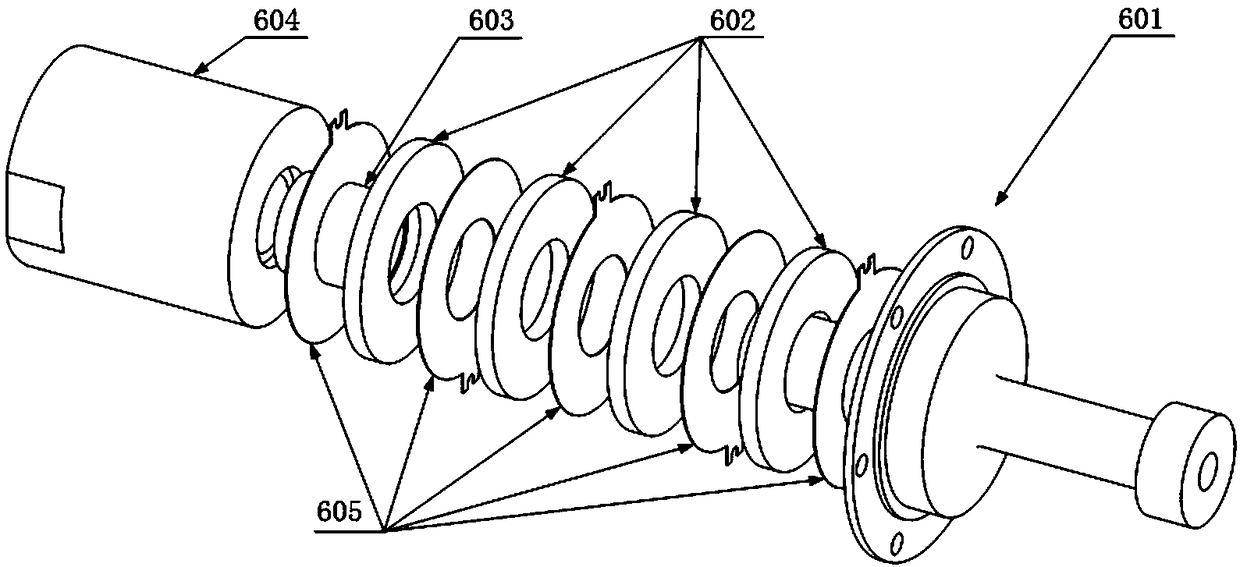

[0025] Specific implementation mode one: see Figure 1-Figure 2 This embodiment will be described. An electromagnetic motor-assisted rotary impact ultrasonic drill described in this embodiment includes a sampling drill 1, a bearing sleeve 2, a return spring 3, a free mass 4, a front housing 5, and a sandwich piezoelectric transducer 6 , rear housing 7, rotary motor 8 and transmission shaft 9;

[0026] The transmission shaft 9 is fixedly connected to the sampling drilling tool 1, and the outer circumference of the transmission shaft 9 is covered with a sandwich piezoelectric transducer 6 and a free mass block 4, and the free mass block 4 is positioned on the sandwich piezoelectric transducer. 6 and the sampling drill 1, the front housing 5 is connected to the rear housing 7 to form a housing, the transmission shaft 9, the sandwich piezoelectric transducer 6, the free mass 4 and the sampling drill 1 The tail end is located inside the housing, and the rotary motor 8 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com