Test bench for testing comprehensive performances of ultrasonic drilling device

A comprehensive performance testing, ultrasonic technology, applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve the problems of inability to measure the quality of ultrasonic drills, loading spring stiffness, restoring spring stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

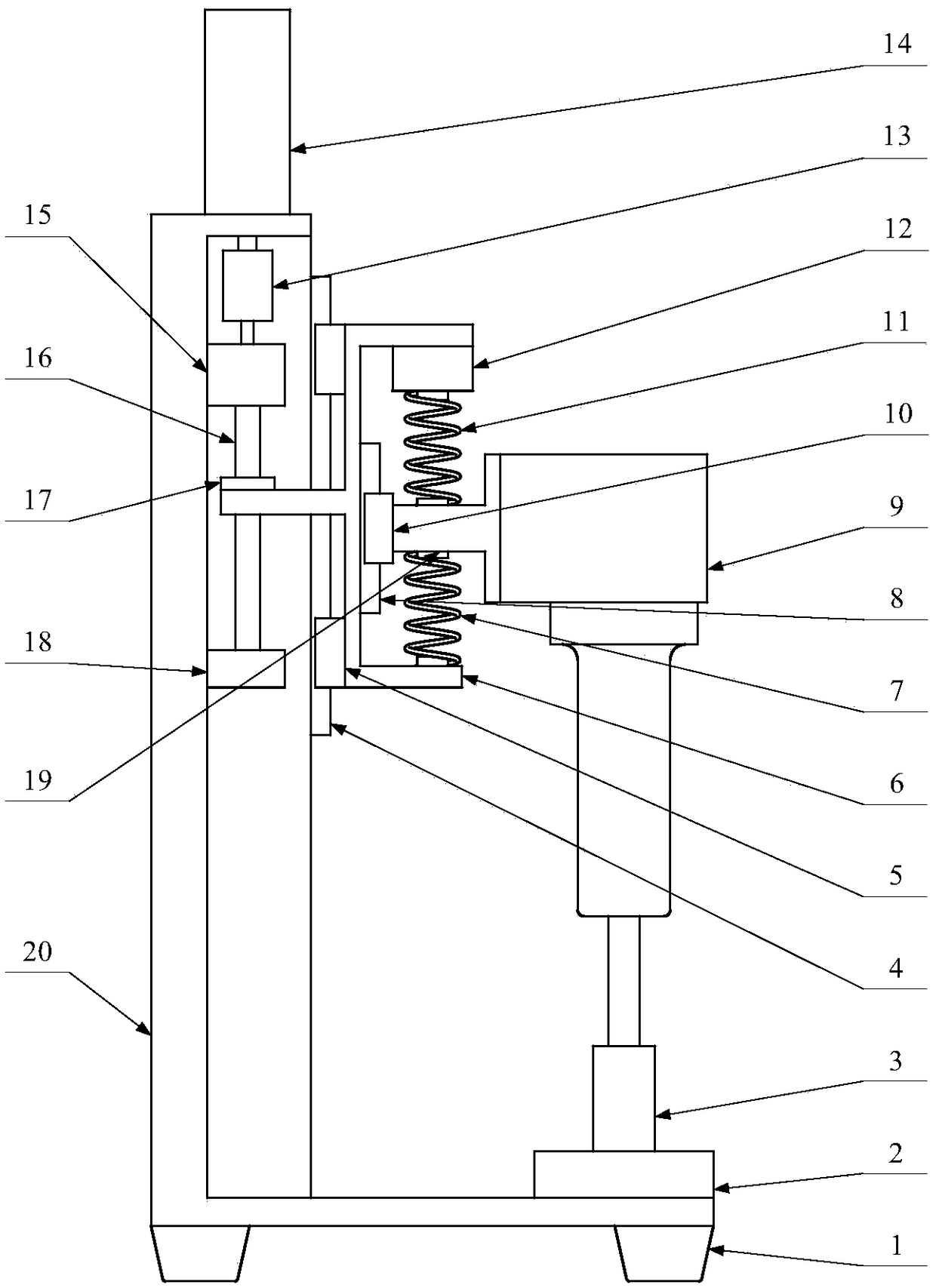

[0019] Specific implementation mode one: see figure 1 This embodiment will be described. An ultrasonic drill comprehensive performance test bench described in this embodiment includes an impact sensor 2, an ultrasonic drill 9, an adjustment mechanism, a shaft coupling 13, a rotary motor 14, a screw fixed end support 15, a ball screw 16. Lead screw nut 17, lead screw movable end support 18, loading platform 19 and frame 20;

[0020] The frame 20 is in an "L" shape, and the bottom plane of the frame 20 is equipped with an impact force sensor 2 for real-time measurement of the impact force of the rock sample 3, and the rock sample 3 is fixedly mounted on the impact force sensor 2. The ultrasonic drill 9 is vertically placed on the upper surface of the rock sample 3, the ultrasonic drill 9 is fixedly connected to the loading platform 19, and the loading platform 19 is fixedly connected to the adjustment mechanism;

[0021] The rotary motor 14 is installed on the column of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com