Processing method of rare earth ion doped optical fiber perform

A rare earth ion doped optical fiber technology, which is applied in the field of optical fiber manufacturing to achieve the effects of improving processing accuracy, reducing the stressed area, and weakening damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the same industry, the features of the present invention and other related features will be further described below through embodiments in conjunction with the accompanying drawings.

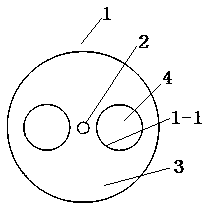

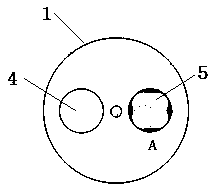

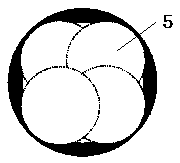

[0019] Such as figure 1 As shown, a method for processing a rare-earth ion-doped optical fiber preform, the steps are as follows: In the first step, a preform 1 containing a rare-earth ion-doped core layer is deposited using an MCVD process.

[0020] In the second step, after the deposition is completed, the rare earth ion-doped optical fiber preform 1 is removed, the preform is cut off at a predetermined position, and the cross section of the preform 1 is ground and fixed on a punching machine.

[0021] In the third step, according to the performance index requirements of the rare earth ion-doped polarization-maintaining optical fiber, combined with the thermal expansion coefficient and geometric parameters of the core 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com