Rotary-impact-type ultrasonic drilling device without free mass block

A quality block and impact type technology, which is applied in the direction of drilling equipment, earthwork drilling, rotary combined drilling, etc., can solve problems such as energy loss, and achieve the effect of light weight, no need for lubrication, and high energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

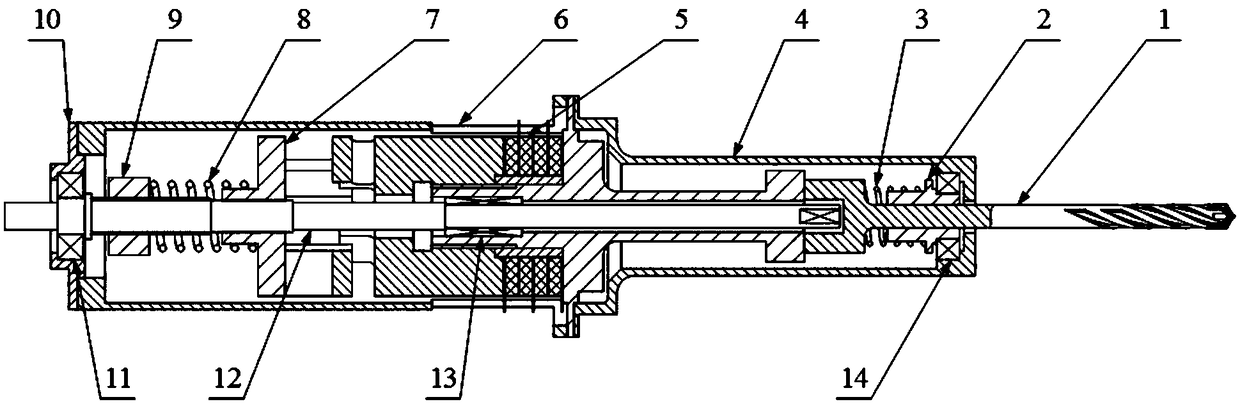

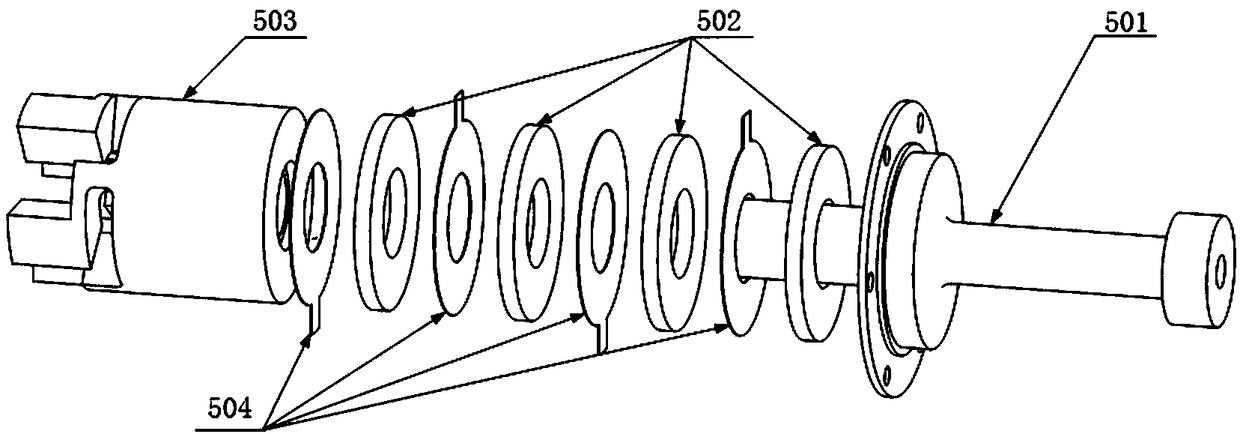

[0024] Specific implementation mode one: see figure 1 This embodiment will be described. A rotary impact ultrasonic drill without free mass described in this embodiment includes a sampling drilling tool 1, a return spring 2, a rotary shaft sleeve 3, a front housing 4, and a longitudinal-longitudinal torsion composite piezoelectric transducer Device 5, rear housing 6, rotor 7, loading spring 8, nut 9, rear bearing cover 10 and transmission shaft 12;

[0025] The transmission shaft 12 is fixedly connected with the sampling drilling tool 1, and the outer periphery of the transmission shaft 12 is covered with a longitudinal-longitudinal torsion composite piezoelectric transducer 5. The front housing 4, the rear housing 6 and the rear bearing end The cover 10 is sequentially connected to form a housing, and the front end of the transmission shaft 12, the longitudinal-longitudinal torsion composite piezoelectric transducer 5 and the tail end of the sampling drill 1 are located insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com