Rotary type transducer main shaft device of supersonic vibrated drill

A spindle device and ultrasonic vibration technology, applied in the direction of fluid using vibration, etc., can solve the problems of difficulty in ensuring the rotation accuracy of the spindle and increase the complexity of the mechanism, and achieve the effect of simple structure, easy assembly and disassembly, and guaranteed rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

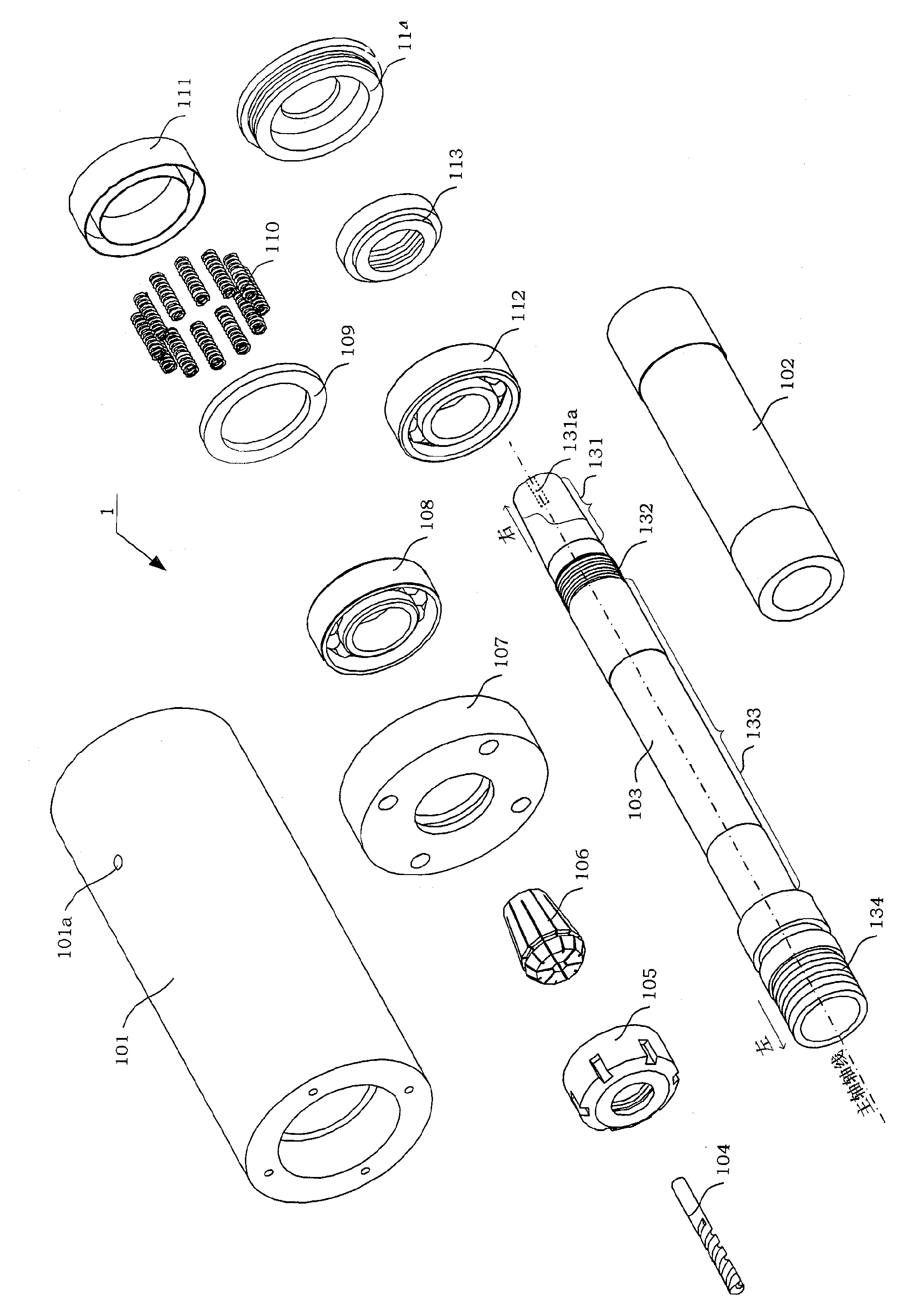

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

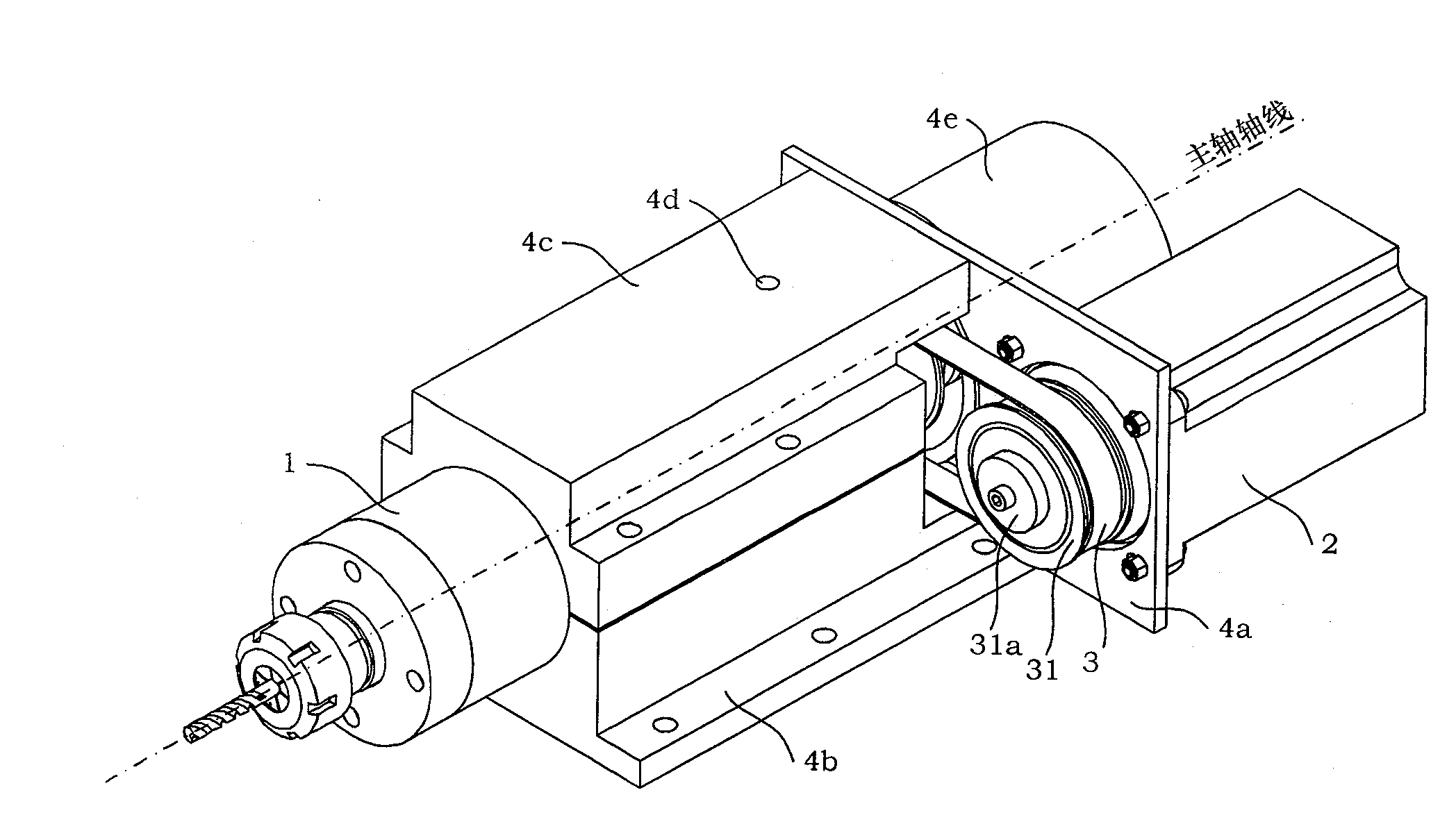

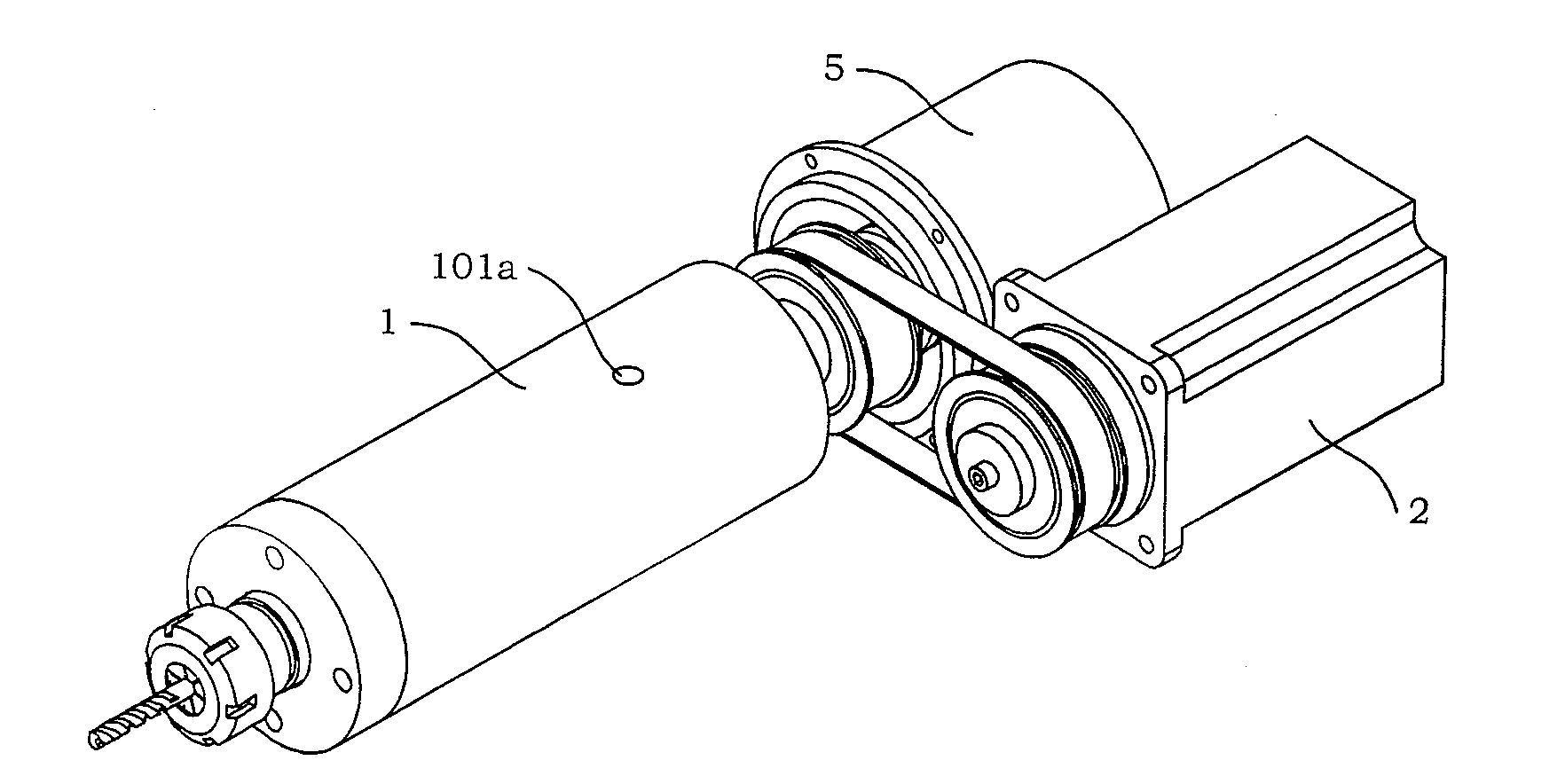

[0025] see figure 1 , Figure 1A , image 3 As shown, the present invention is a rotary transducer spindle device for ultrasonic vibration drilling. The rotary transducer spindle device is composed of a spindle assembly 1, a motor drive assembly, a transducer power supply assembly 5, and a housing assembly; The compression screw 510 of the transducer power supply assembly 5 is connected in the threaded hole 131a of the main shaft 103 of the main shaft assembly 1; the driven pulley 32 of the motor drive assembly is sleeved on the main shaft 103 of the main shaft assembly 1, and the driving pulley 31 It is connected with the driven pulley 32 through the transmission belt 3.

[0026] see figure 1 As shown, the housing assembly includes a motor connection plate 4a, an upper housing 4c, a lower housing 4b, and a transducer cover 4e; the main shaft assembly 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com