One-way ultrasonic vibration platform with adjustable clamps and operation method for one-way ultrasonic vibration platform

An ultrasonic vibration and platform technology, which is used in manufacturing tools, grinding machines, grinding/polishing equipment, etc., to achieve the effect of good work stability, wide application range, fast positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

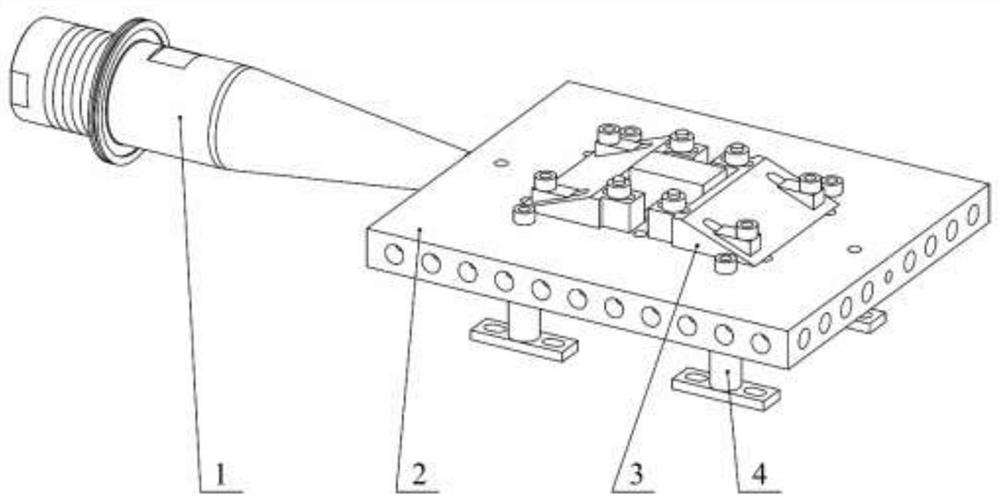

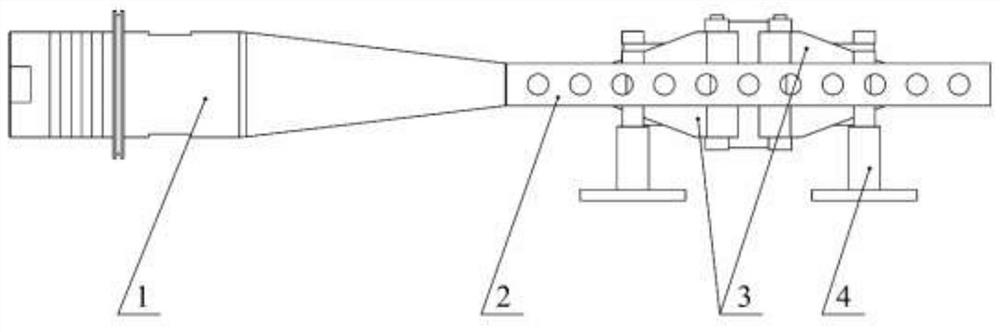

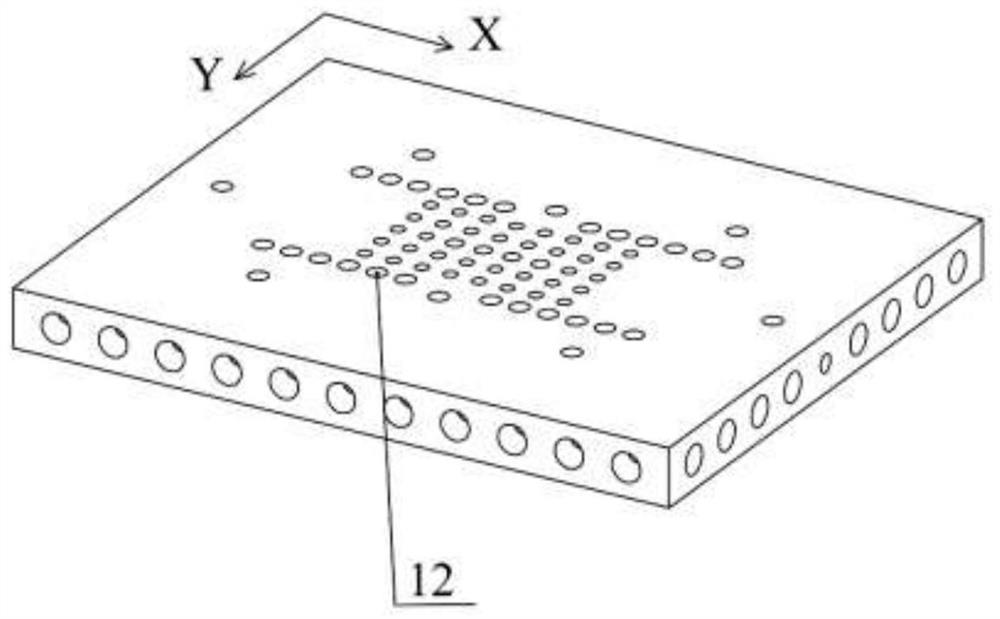

[0046] Such as Figure 1-5 As shown, a unidirectional ultrasonic vibration platform with adjustable clamps includes: an ultrasonic transducer 1 , a two-dimensional porous ultrasonic vibration platform 2 , an adjustable clamp 3 , and fixed feet 4 . Wherein the adjustable clamp includes a trapezoidal slider 5, a nut 6, a long bolt 7, a wedge 8, and a short bolt 9, and the fixed leg includes a leg 10 and a bolt 11. The two sets of adjustable fixtures are connected by bolts and nuts and pressed against the bearing surface of the two-dimensional porous ultrasonic vibration platform. The foot base fixes the two-dimensional porous ultrasonic vibration platform on the processing platform of the machine tool, and one side of the two-dimensional porous ultrasonic vibration platform is connected to the ultrasonic transducer by studs.

[0047] The ultrasonic transducer is installed at the center of one side of the two-dimensional porous ultrasonic vibration platform. The ultrasonic powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com