Laser-induced oxidation auxiliary micro milling method and device thereof

A micro-milling, laser-induced technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of poor surface integrity, low process controllability, low processing efficiency, etc., to improve surface integrity and process reliability. The effect of high controllability and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

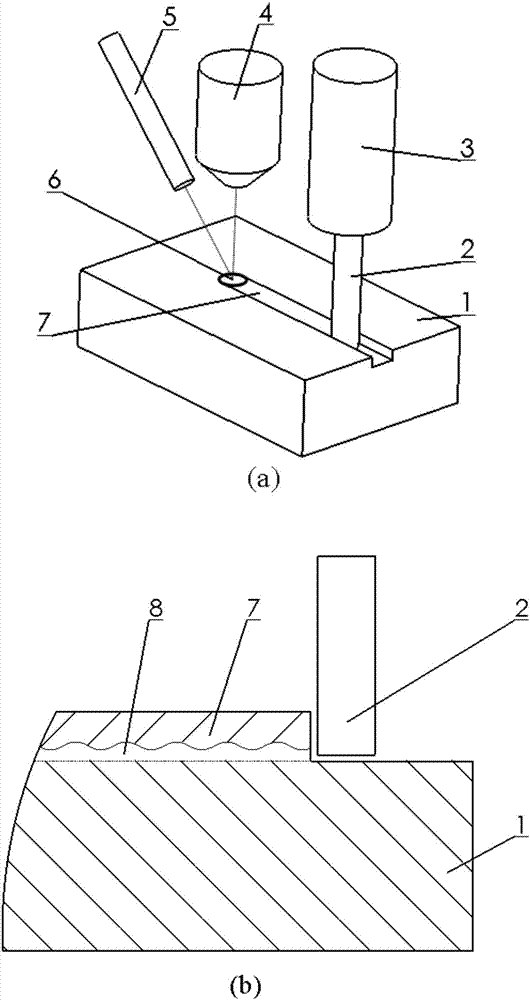

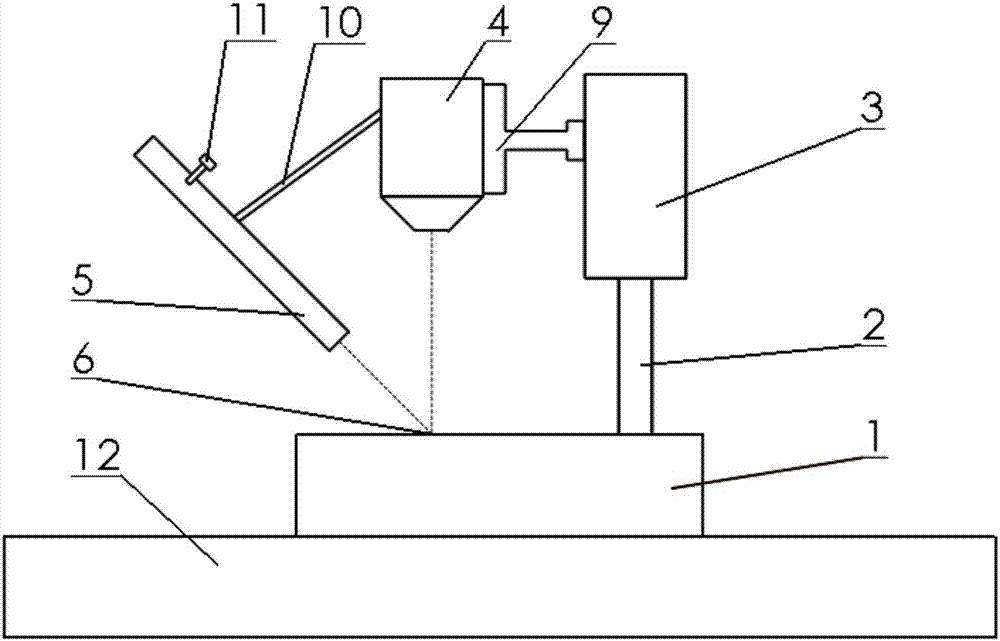

[0028] The laser-induced oxidation-assisted micro-milling processing device of the present invention mainly includes a workpiece 1 , a micro-milling cutter 2 , a spindle 3 , a laser 4 , an air jet 5 and a laser spot 6 . During processing, the laser 4 focuses the laser spot 6 on the material in the area to be processed on the surface of the workpiece 1, and the jet pipe 5 sprays the oxidant to the laser spot. Under the action of the laser, the temperature of the material in the area to be processed will rise rapidly, and then A rapid oxidation reaction occurs with the oxidant to generate the corresponding oxide. By adjusting the parameters of the laser and the oxidant, the rate of the oxidation reaction, the microstructure and characteristics of the oxide are accurately controlled, so that the material in the area to be processed forms a loose an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com