Ultraviolet laser drilling device

A technology of ultraviolet laser and laser, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that are difficult to realize, achieve high efficiency, good edge processing effect, and reduce the effect of heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

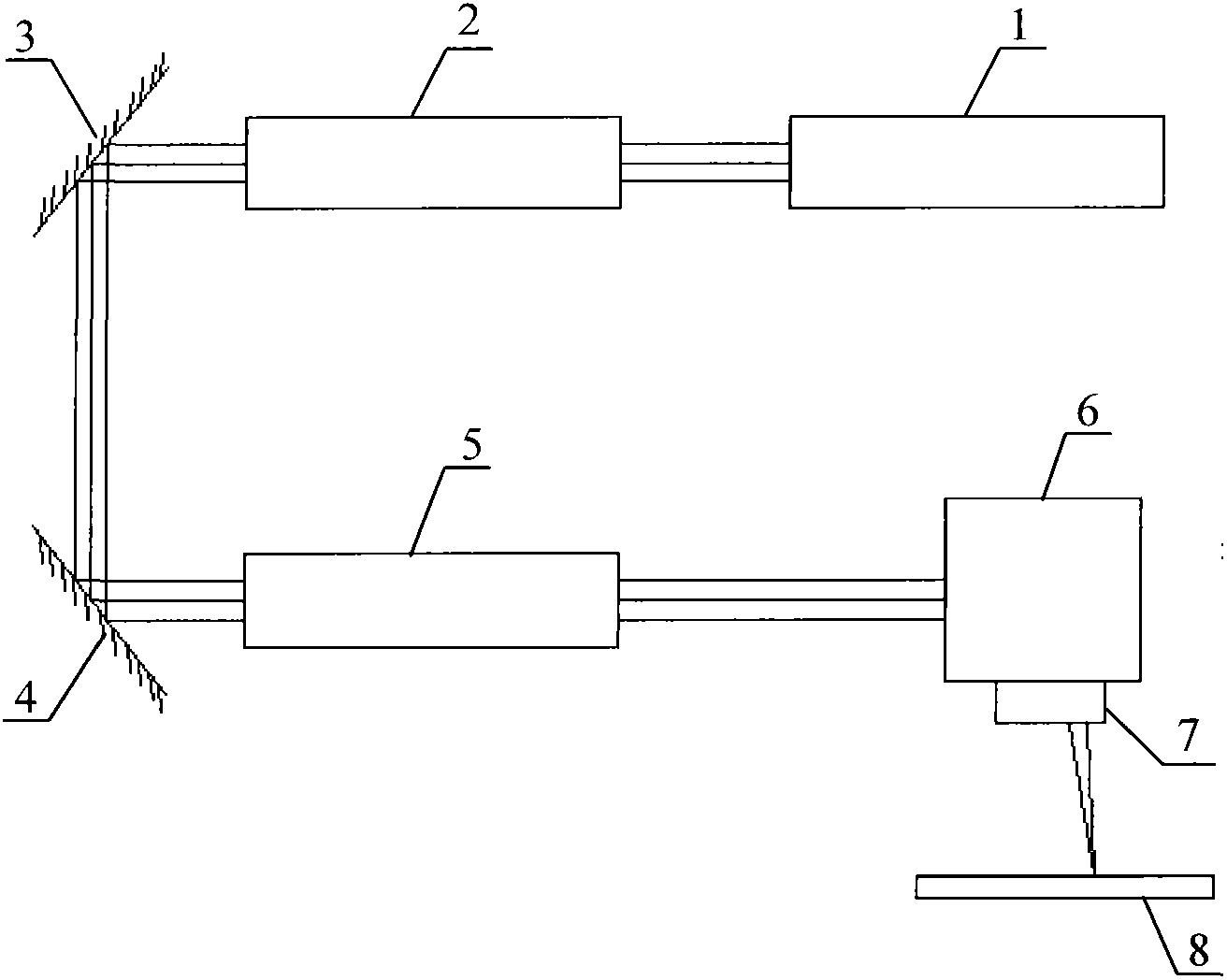

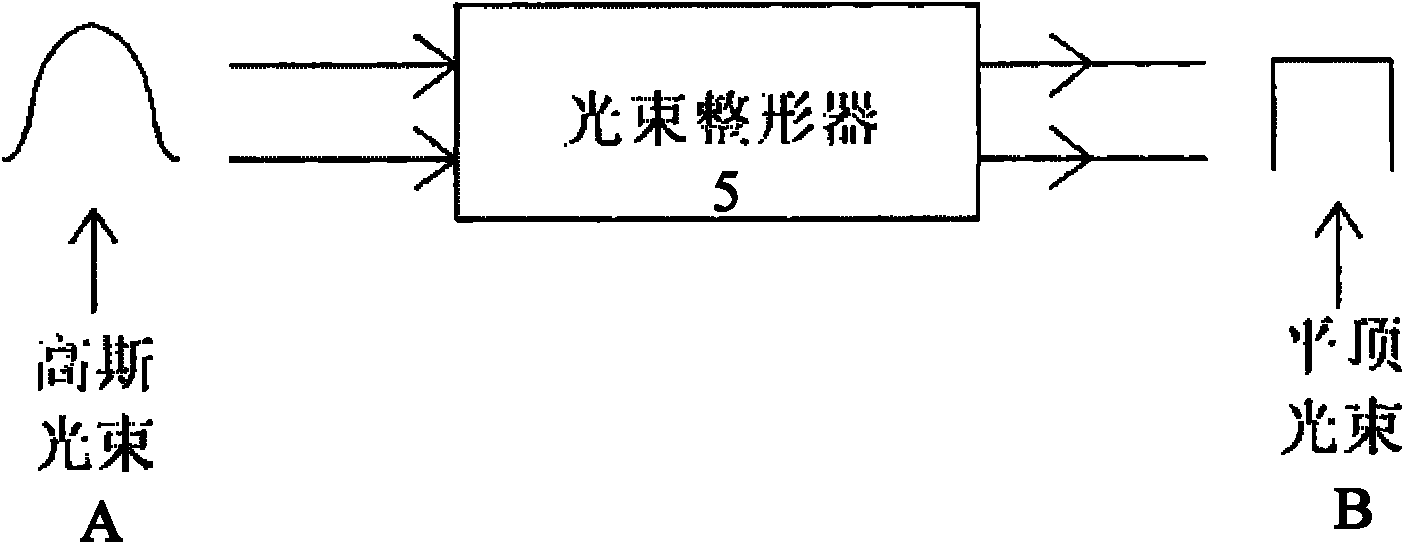

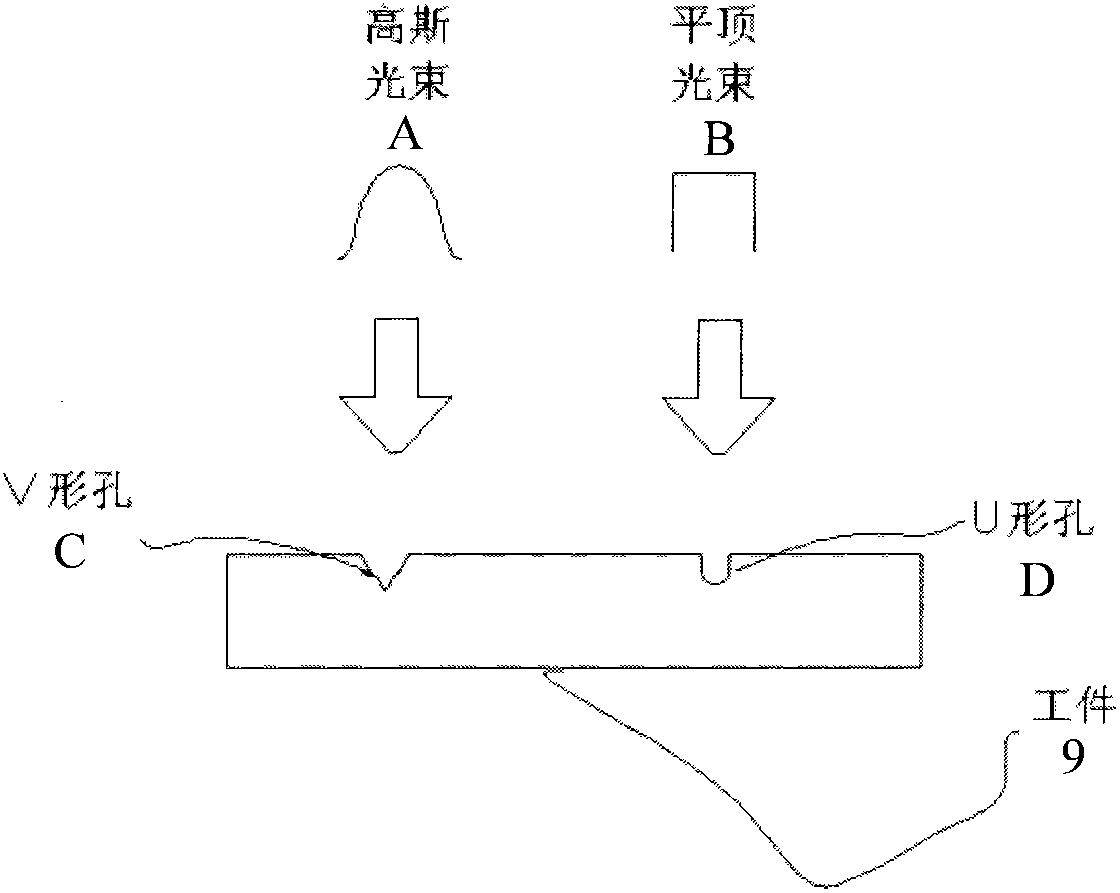

[0016] Such as figure 1 As shown, the UV laser drilling device, the UV Q-switched solid-state laser 1 is an UV Q-switched solid-state laser with an output wavelength of 355nm, and the pulse width is on the order of nanoseconds; the output end of the UV Q-switched solid-state laser 1 is provided with a beam expander 2 , the output end of the beam expander 2 is arranged with a first reflector 3, the first reflector 3 connects with the second reflector 4, the output end of the second reflector 4 is arranged with a beam shaper 5, and the output end of the beam shaper 5 A scanning galvanometer 6 is arranged, the output end of the scanning galvanometer 6 is connected to a focusing mirror 7, and a three-dimensional mobile platform 8 is arranged below the focusing mirror 7, and a suction device and a high-resolution auxiliary positioning imaging system are installed on the three-dimensional mobile platform 8 , The suction device is used to suck away the dust generated in the process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com