Laser micropore processor of rotating double-optical wedge

A technology of micro-hole processing and double optical wedge, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of insufficient pass precision at the edge of the aperture, improve pass precision and work efficiency, and reduce thermal influence zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention is described in conjunction with accompanying drawing:

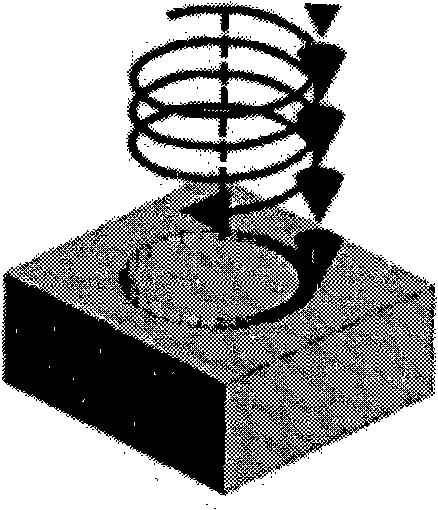

[0040] Depend on Figure 5 As shown, a rotating double optical wedge laser microhole processing device is characterized in that it includes:

[0041] 1. An ultrashort pulse laser output system consisting of a laser, a beam expander and a laser transmission system: the laser is a DPSS solid-state laser that outputs nanosecond-level pulsed parallel light, and a computer is used to control the switch signal of the laser and adjust the laser The output power and repetition frequency are transmitted to the double wedge beam deflection system through the beam expander and the laser transmission system;

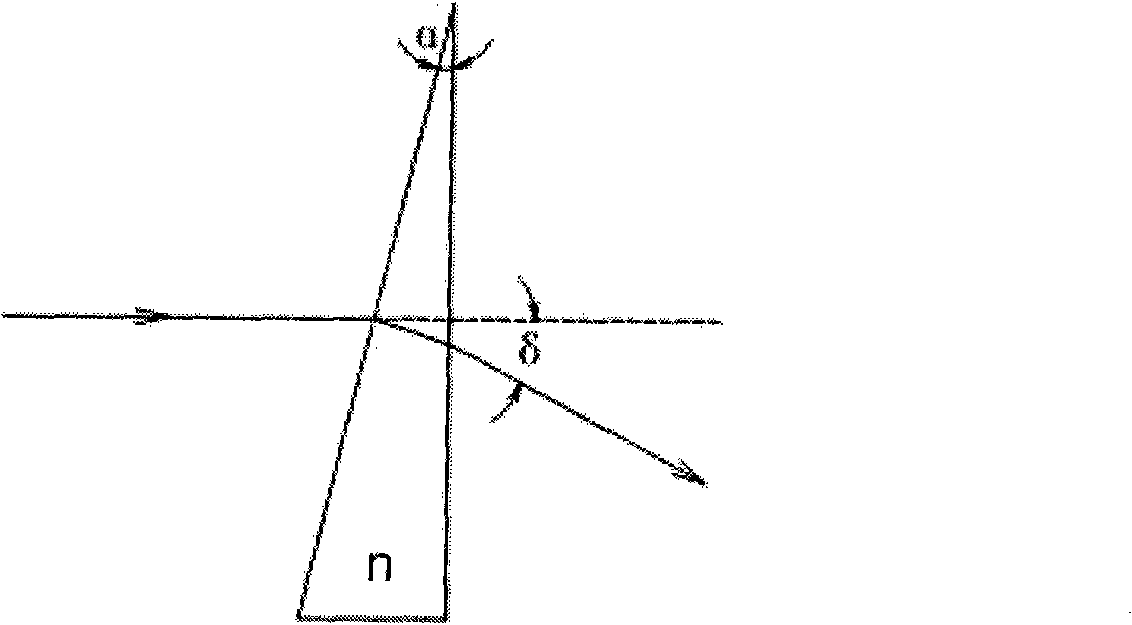

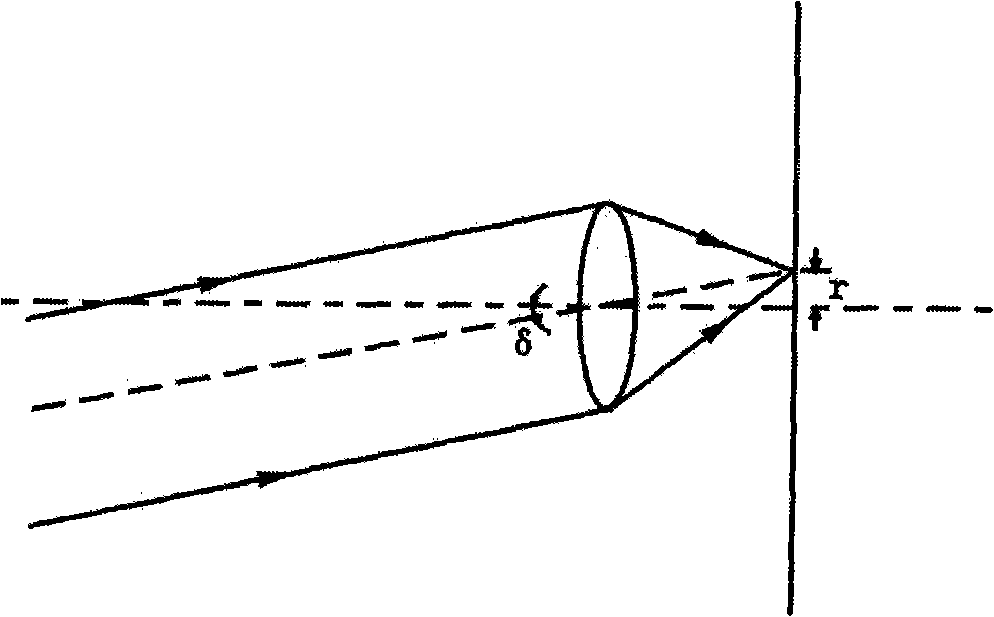

[0042] 2. A double-wedge beam deflection system consisting of two wedges, a double-wedge support rotation mechanism and a control system (such as Figure 4Shown): The two optical wedges are exactly the same, the support and rotation mechanism of the optical wedge makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com