Method for diagnosing galvanized steel laser powder addition welding defects on line based on characteristic spectrum

A welding defect and characteristic spectrum technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as lack of research, achieve the effect of ensuring quality, solving welding defect problems, and avoiding pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

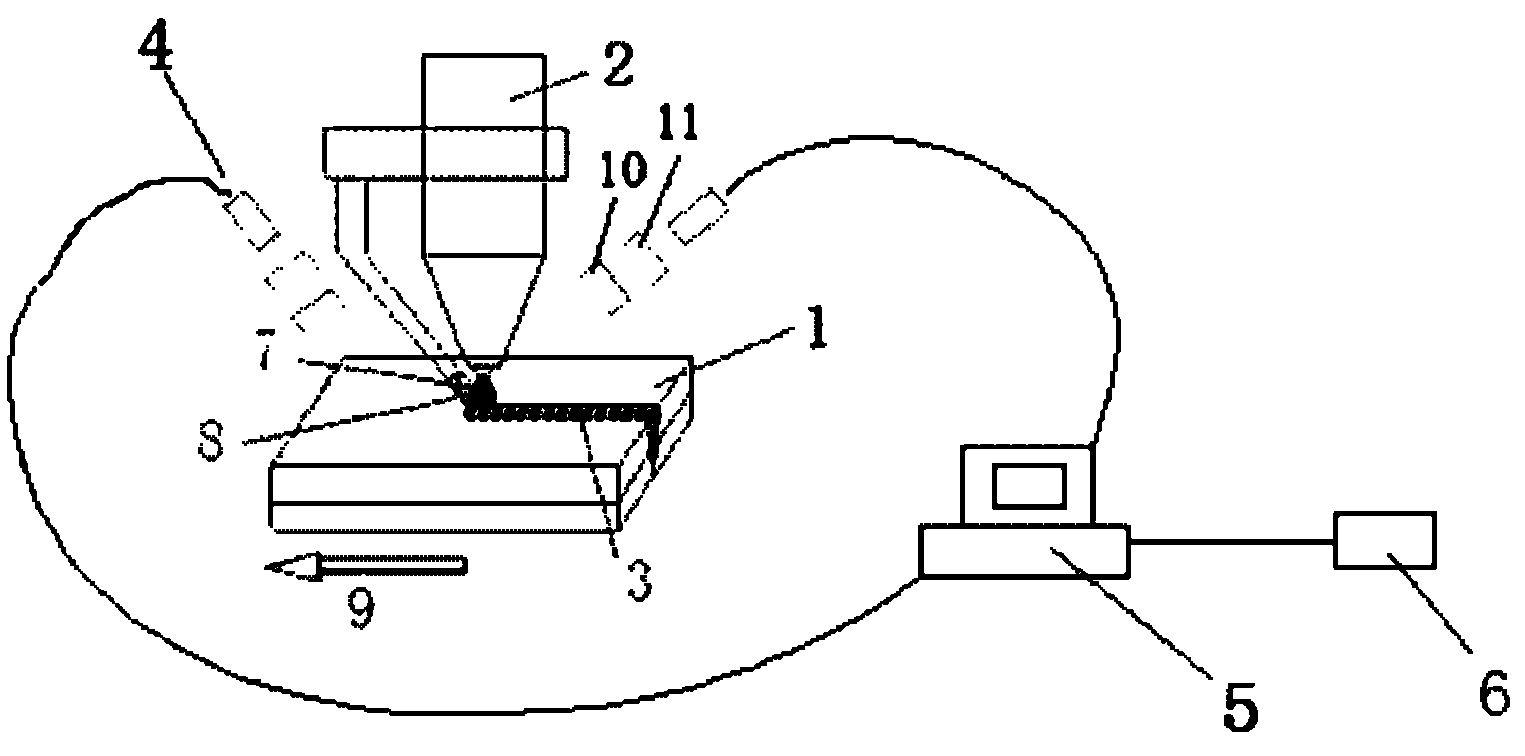

[0021] Such as figure 1 As shown, the on-line diagnosis device for welding defects according to an embodiment of the present invention includes a workbench and a galvanized steel 1 fixed on the workbench. Focusing mirror, welding head 2 is fixed with galvanized steel laser powder feeder 7 (model: wi77544, IGS-3, IGS-3X, etc.), and galvanized steel 1 is equipped with laser beam imaging Lens 10, a single-wavelength photodetector assembly composed of a filter 11 (center wavelength 324.8nm) and a photodetector 4 (silicon photodiode), the single-wavelength photodetector is connected to a plasma for storing and displaying collection through an optical fiber The computer 5 of the volume light signal is connected, and the computer 5 is connected with the laser 6 (DC025 type slat type CO2 laser).

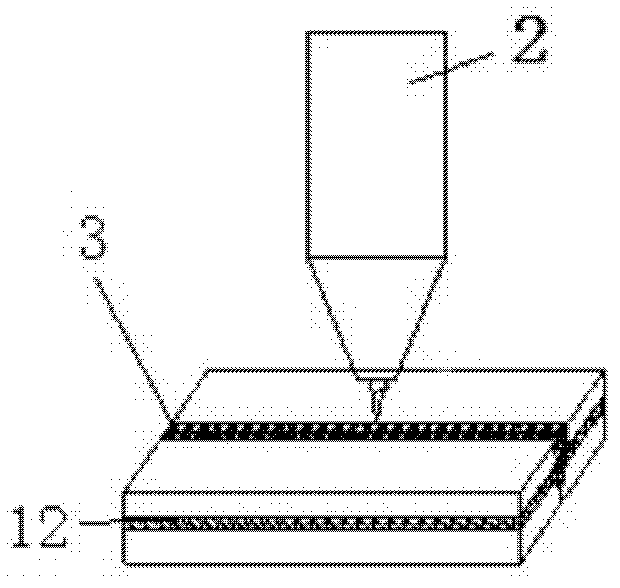

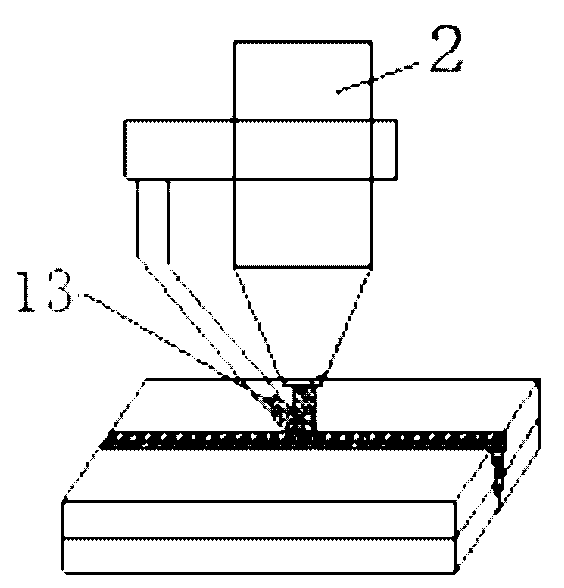

[0022] Such as figure 1 and 2 As shown, the way of adding powder is to add powder in advance or to feed powder synchronously. figure 2 In the shown synchronous powder feeding mode, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com