Online diagnosis method for welding defects in laser powder-adding welding process of galvanized steel based on characteristic element plasma optical signal

A technology of plasma and characteristic elements, applied in laser welding equipment, welding equipment, thermal excitation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

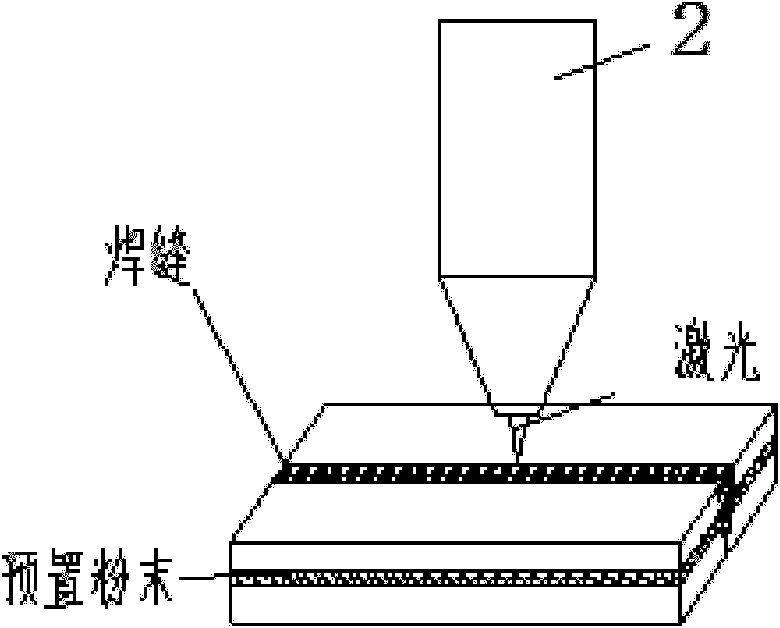

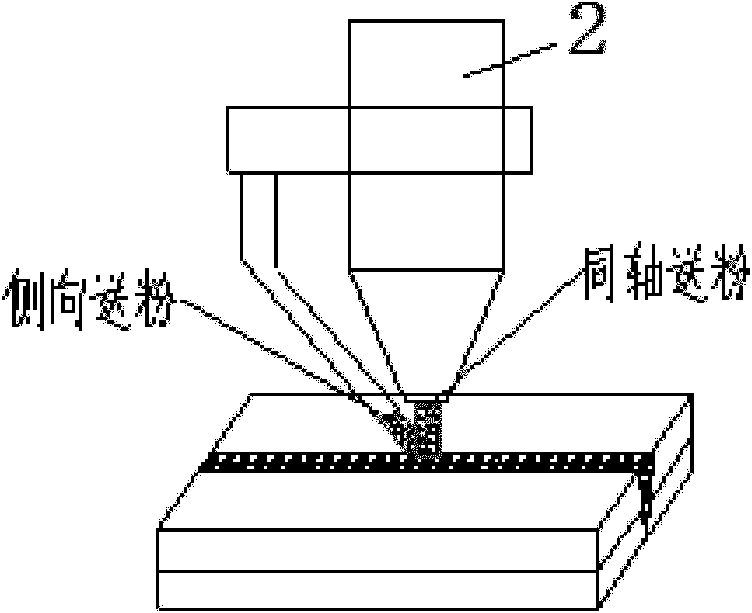

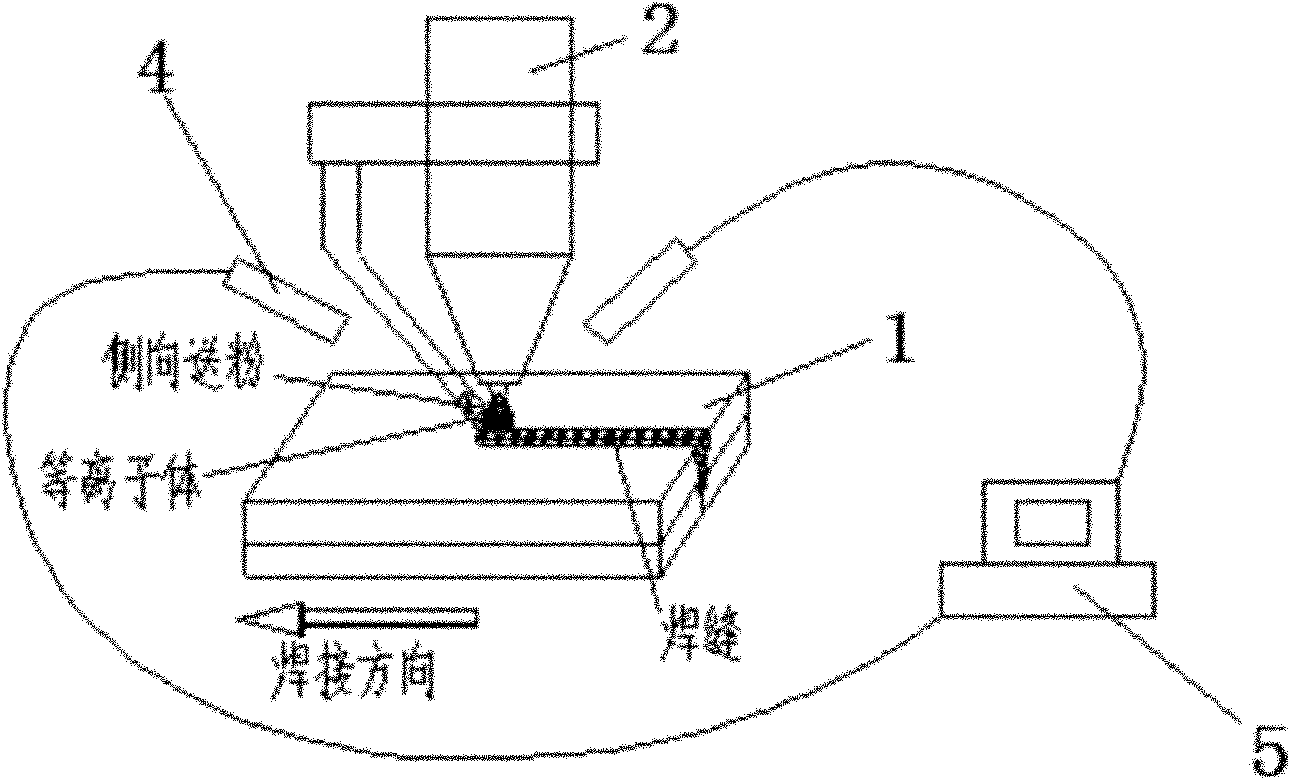

[0033] This embodiment adopts as image 3 The shown test device includes a workbench, a galvanized steel 1 fixed on the workbench; a welding head 2 is arranged directly above the welding part of the galvanized steel 1, and a focusing lens is arranged in the welding head 2. A reflector at an angle to the horizontal direction is arranged above the welding head 2, and a plurality of photosensitive sensors 4 are arranged on the side of the welding part of the galvanized steel 1, and the photosensitive sensors 4 are connected with an optical fiber for storage and display collection. The computer 5 of the plasma light signal is connected. The laser beam is focused and irradiated vertically on the surface of the workpiece by the output of the corresponding laser, and the focus position is on the surface of the material. The workbench is controlled by the corresponding CNC machine tool. Laser welding of galvanized steel is a welding arrangement in the form of lap joints, the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com