Limited welding seam manufacturing method for oblique Y-shaped groove crack welding test

A technology of groove welding and crack testing, which is applied in the direction of welding/welding/cutting articles, manufacturing tools, welding equipment, etc., can solve the problems of difficult removal, lower work efficiency, and manpower consumption, so as to save heavy work and reduce labor Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

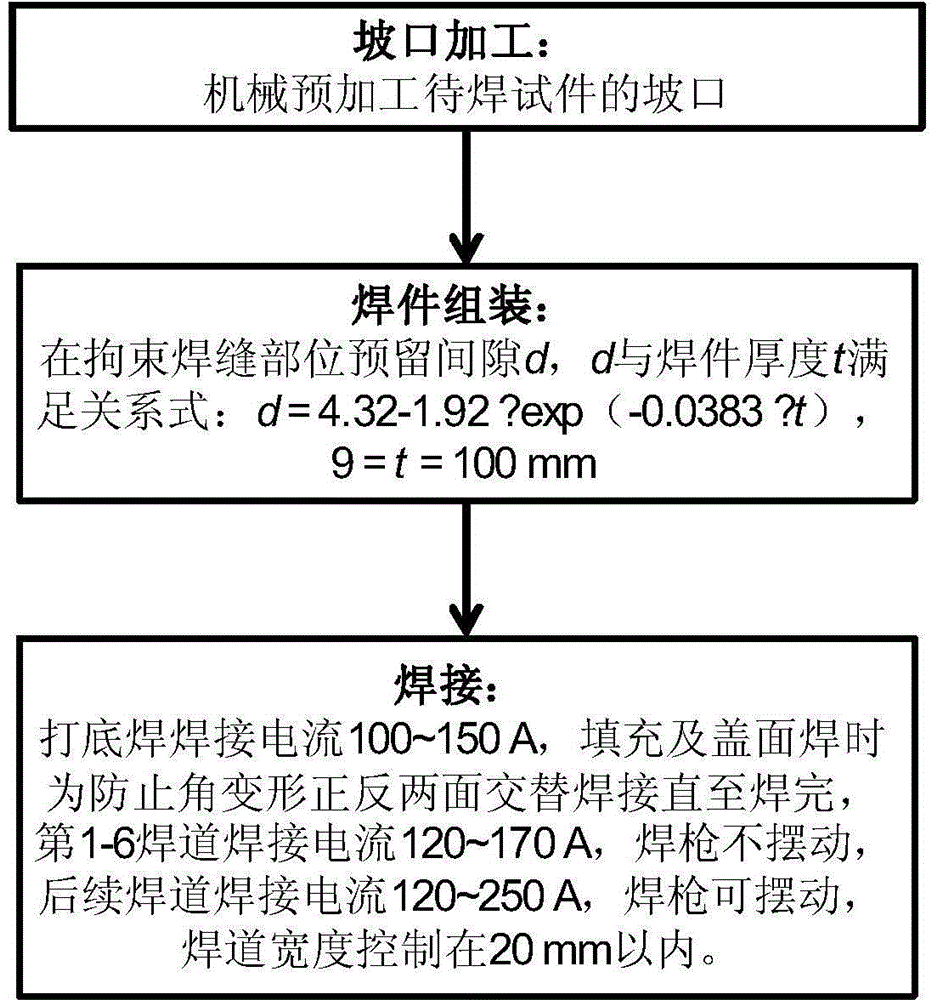

Method used

Image

Examples

Embodiment 1

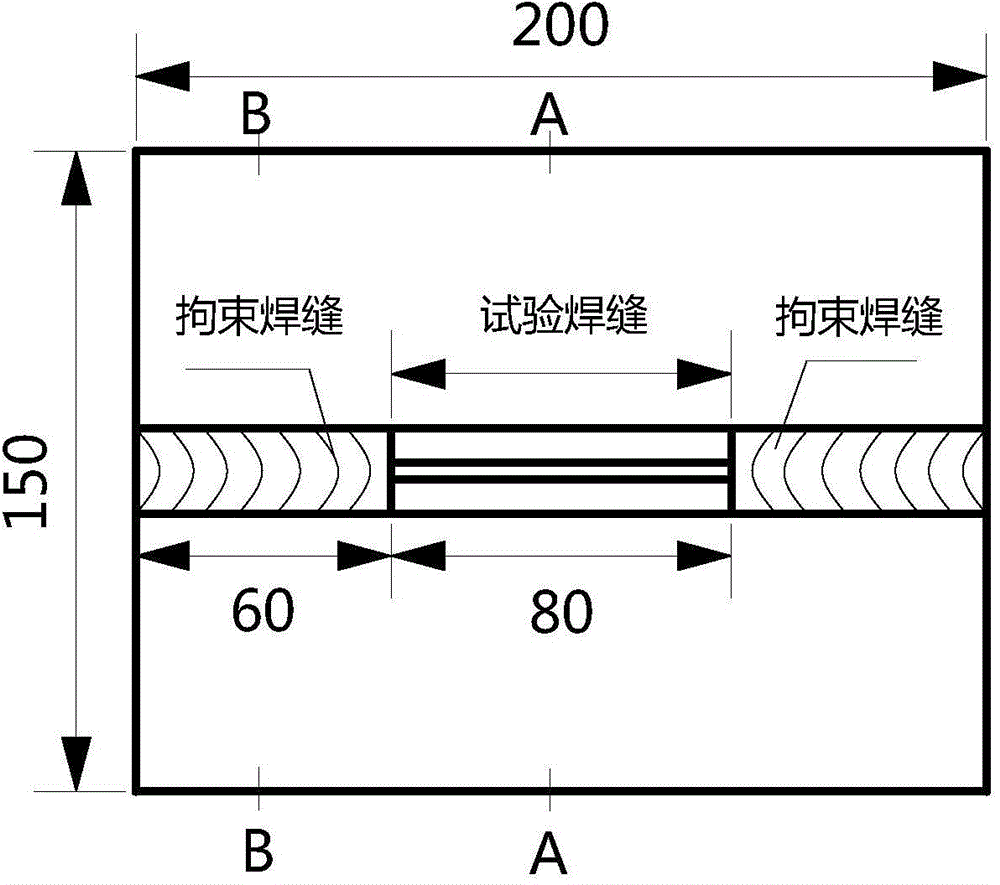

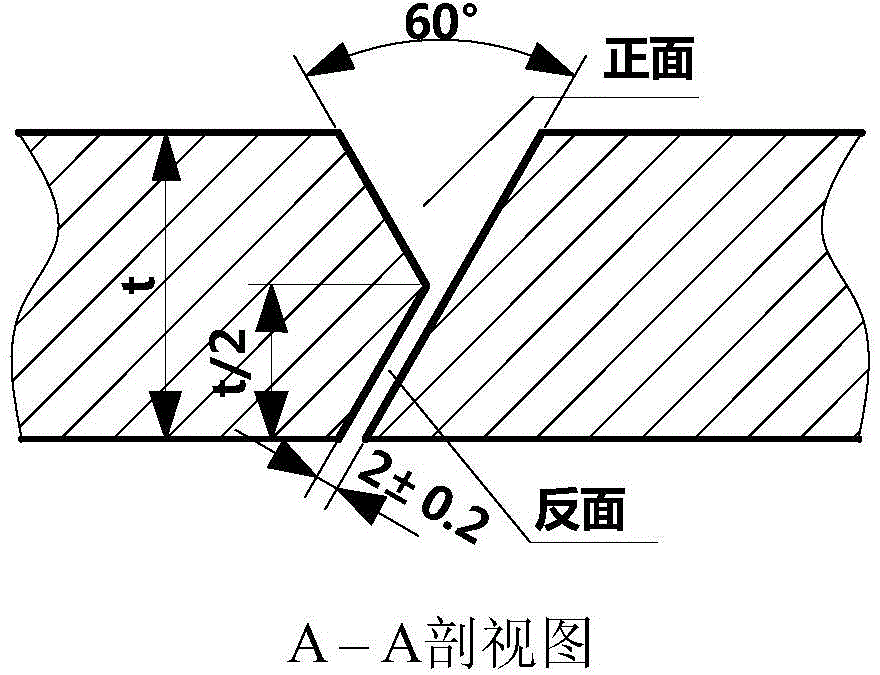

[0022] The base material of the weldment is 80mm thick ship plate and marine steel EH47, which is cut and blanked by a sawing machine, and the groove is processed by a planer and a milling machine according to the standard requirements. figure 1 to assemble.

[0023] Reserve 4.2mm gap between restrained welds, use Lincoln PowerWave 455M / STT multifunctional gas shielded welding machine for single-side welding and double-side forming STT mode for bottom welding, welding current 100-130A, welding heat input 5-8kJ / cm.

[0024] Filler welding is performed directly on the opposite side of the weld bead after rooting welding. The filling and cover welding adopt pulse MAG welding, the front and back sides are welded alternately, the welding current of the 1st-6th welding pass is 150~170A, the welding heat input is 15~20kJ / cm, the welding torch does not swing; the welding current of the subsequent welding pass is 200~230A, The welding heat input is 18-22kJ / cm, the welding torch swings...

Embodiment 2

[0027] The base material of the weldment is Q345R steel for pressure vessels with a thickness of 16 mm, and the groove processing and assembly of the weldment are the same as in the first embodiment.

[0028] Reserve 3.3mm for restraint weld seam gap, adopt 100% CO 2 Gas shielded welding is performed on the reverse side of the weldment, the welding current is 120-150A, and the welding heat input is 7-10kJ / cm.

[0029] After rooting welding, the reverse side of the weld bead is polished by a grinding wheel, and then fill welding is performed. 100% CO is used for filling and cover welding 2 Gas-shielded welding, alternating welding of front and back sides, welding current of all welds is 150-170A, welding heat input is 10-15kJ / cm, welding torch does not swing.

[0030] After the restraint weld is welded and the weldment is completely cooled, the gap between the test weld and the test weld is 2.1mm.

Embodiment 3

[0032] The base material of the weldment is 07MnNiDR steel for low-temperature pressure vessels with a thickness of 38mm, and the groove processing and assembly of the weldment are the same as in the first embodiment.

[0033] Reserve 3.9mm for restraint weld seam gap, adopt 100% CO 2 Gas shielded welding is performed on the reverse side of the weldment, the welding current is 110-140A, and the welding heat input is 6-9kJ / cm.

[0034] After rooting welding, the reverse side of the weld bead is polished by a grinding wheel, and then fill welding is performed. Electrode arc welding is used for filling and covering welding, the diameter of the electrode is 4.0mm, the front and back sides are alternately welded, the welding current of the 1st to 6th welds is 150-170A, the welding heat input is 14-17kJ / cm, and the welding torch does not swing; the subsequent welds are welded The current is 150-170A, the welding heat input is 20-25kJ / cm, the welding torch swings, and the width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com