Umbilical cable floating body

An umbilical cable and floating body technology, applied in the field of umbilical cable floating body, can solve the problems of poor balance, low reliability, difficult operation, etc., and achieve the effects of low density, improved stability and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The body uses a density of 0.42g / cm 3 The main body of the umbilical cable buoyant body is prepared with lightweight pressure-resistant buoyancy material, and the material properties are shown in Table 1

[0030] Table I

[0031] project unit performance density g / cm 3 0.42 Uniaxial compressive strength MPa 15 bulk modulus MPa 1050 hydrostatic pressure MPa 6 Water absorption (6 MPa 24 hours) % 0.8

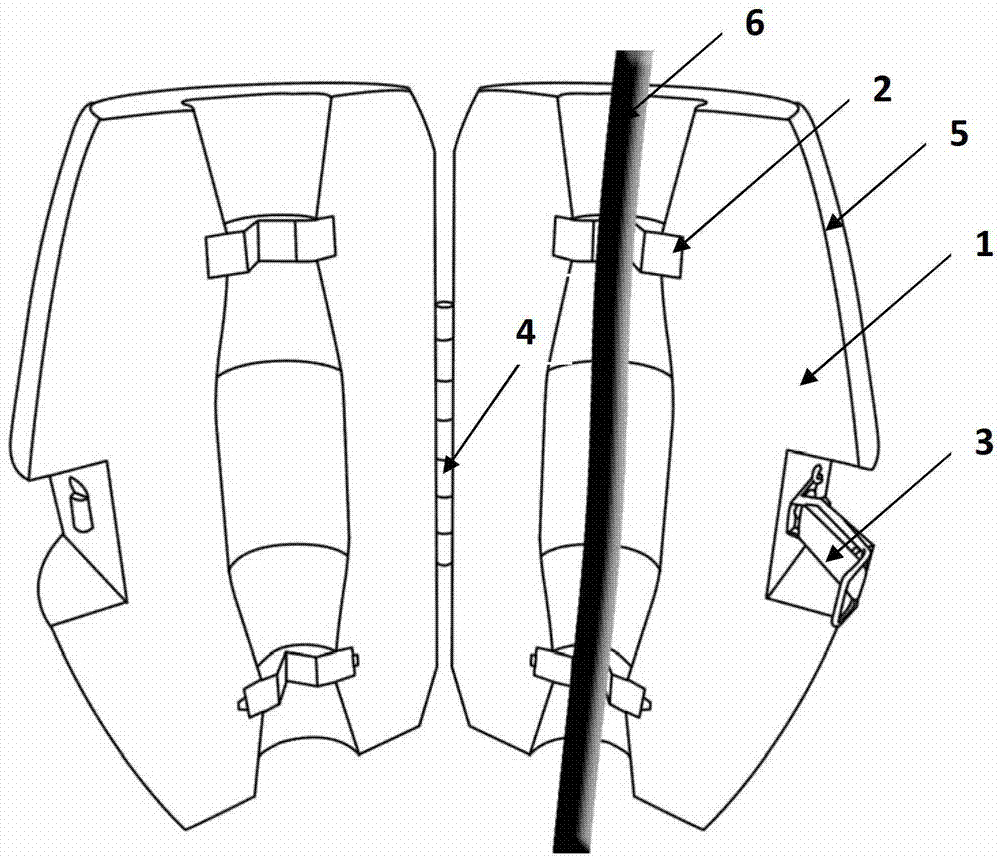

[0032] refer to figure 1 , the body of the floating body is machined into an ellipsoid, the long axis of the ellipsoid is 600mm, the short axis is 340mm, the external chamfer of the floating body is R8, the internal chamfer is R3, and the internal groove adopts a straight hole in the middle and steps at both ends. The structure of the hole, the umbilical cable with a diameter of 9-13mm can pass through it, and the V-shaped rubber body is fixed at both ends of the groove according to the size of the umbilical cable. ...

Embodiment 2

[0034] The body uses a density of 0.54g / cm 3 The main body of the umbilical cable buoyant body is prepared with light-weight pressure-resistant buoyancy material, and the material properties are shown in Table 2

[0035] Table II

[0036] project unit performance density g / cm 3 0.54 Uniaxial compressive strength MPa 45 bulk modulus MPa 1800 hydrostatic pressure MPa 45 Water absorption (45 MPa 24 hours) % 0.6

[0037] refer to figure 1 , the body of the floating body is machined into an ellipsoid, the long axis of the ellipsoid is 600mm, the short axis is 340mm, the external chamfer of the floating body is R8, the internal chamfer is R3, and the internal groove adopts a straight hole in the middle and steps at both ends. The structure of the hole, the umbilical cable with a diameter of 9-13mm can pass through it, and the V-shaped rubber body is fixed at both ends of the groove according to the size of the umbilical cab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com