Fill type stirring friction plug repair welding method and welding tool thereof

A friction stir and filling technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as poor mechanical properties and reduced strength of welded joints, achieve small workpiece deformation, ensure one-time forming, and process stability. and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: this embodiment is realized through the following steps: one, the selection of the material of the stirring pin: the material of the stirring pin is the same as the material of the parts to be repaired; Make a positioning hole at the welding seam defect or the keyhole of the welding seam, and use a type drill to expand the positioning hole into a tapered hole according to the repair welding requirements, which is the preset hole for repairing the defect to be repaired; 3. Determine the size of the stirring needle: Stir The outer contour size of the needle should be larger than the inner contour size of the tapered defect repair preset hole to ensure that the stirring needle and the defect repair preset hole have sufficient friction and sufficient filling volume; 4. Positioning: positioning the defect repair preset hole , so that the defect repair preset hole coincides with the axis of the stirring pin; 5. Repair welding: the moving length of the ...

specific Embodiment approach 2

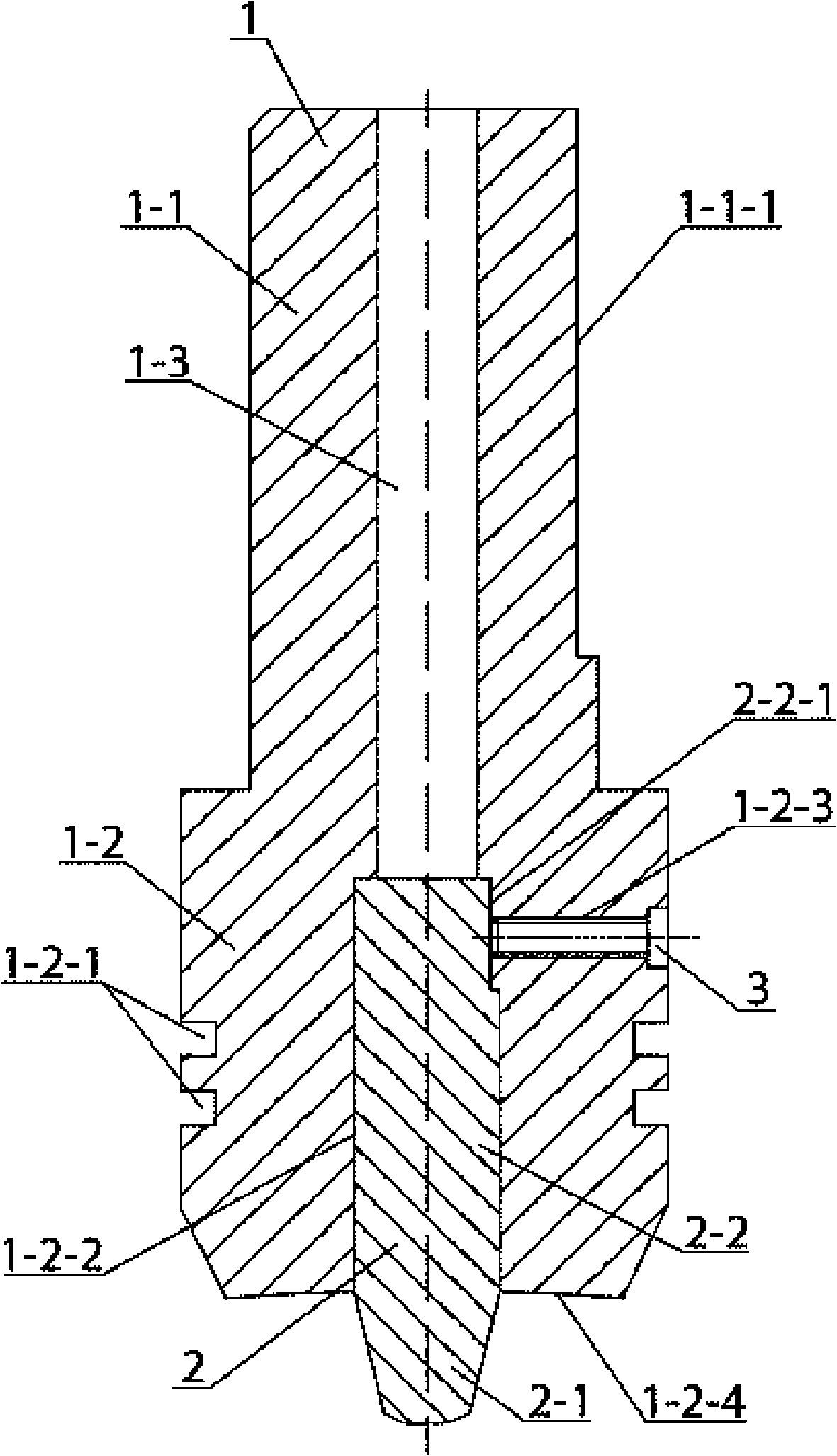

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment includes a welding tool holding body 1 and a stirring body 2, the welding tool holding body 1 is composed of a coaxial upper cylinder 1-1 and a lower cylinder 1-2, the upper cylinder The diameter of 1-1 is smaller than the diameter of the lower cylinder 1-2, the upper cylinder 1-1 and the lower cylinder 1-2 are integrated, and the outer surface of the upper cylinder 1-1 is provided with a welding tool clamping surface 1 -1-1, at least one annular heat insulation groove 1-2-1 is provided on the outer surface of the lower cylinder 1-2, and a clamp for placing the stirring body 2 is provided at the center of the lower end of the lower cylinder 1-2 Holding hole 1-2-2, the side wall of the holding hole 1-2-2 of the lower cylinder 1-2 is provided with a threaded through hole 1-2-3 perpendicular to the axis of the lower cylinder 1-2, the stirring body 2. It consists of a stirring ...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the lower end surface of the lower cylinder 1-2 in this embodiment is a concave shoulder surface 1-2-4 whose outer edge is higher than the center. The concave shoulder surface 1-2-4 effectively prevents the plasticized material from the stirring needle 2-1 from flowing out. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com