Weld seam and weld seam defect detection method based on deep learning

A defect detection and deep learning technology, which is applied in the direction of optical test defects/defects, can solve the problem that the type and position of weld defects cannot be effectively detected, and achieve the effect of increasing accuracy and classifying accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0043] A method for detecting welds and weld defects based on deep learning, using YOLO V3 network to achieve weld and / or weld defect detection; (YOLO V3 network includes input layer, interconnected convolutional layer, activation function layer, dropout Layer, residual layer, fully connected layer, softmax logic output layer; between two adjacent layers, the output value of the previous level is used as the input value of the next level.)

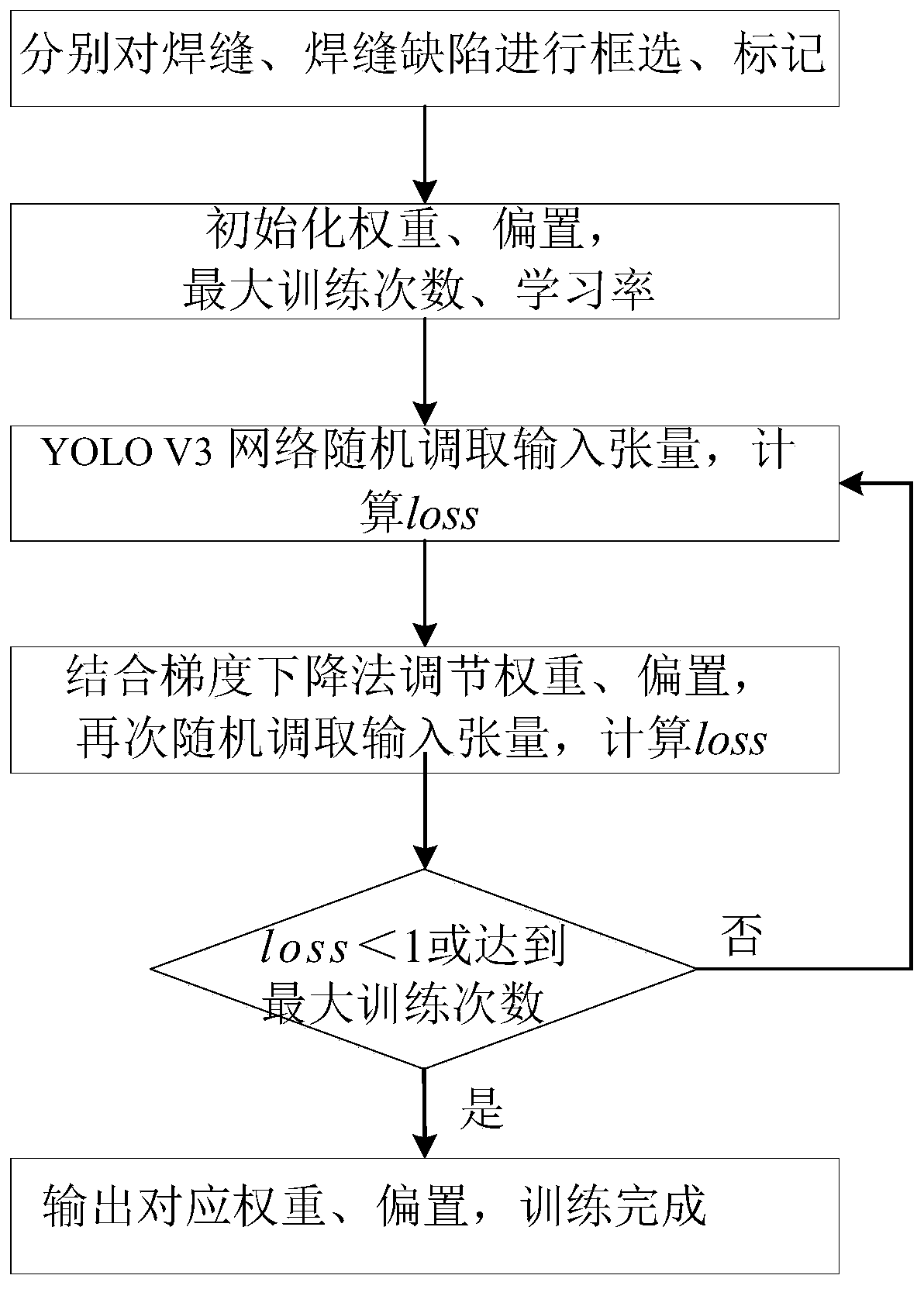

[0044] The YOLO V3 network for weld and / or weld defect detection is trained through the following steps:

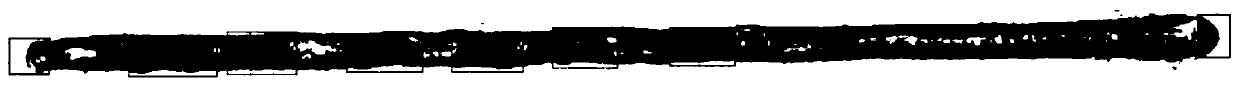

[0045] 1) Use the rectangular positioning frame to select and mark the welds of the workpiece images containing the welds, and use 5000 such images as the training data set;

[0046] As an embodiment of the present invention, a single workpiece image contains 2-15 weld seam areas;

[0047] The weld image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com