Pressure vessel weld defect identification method and device based on neural network

A technology for pressure vessel and defect recognition, which is applied in the field of image processing and defect recognition of radiographic inspection welds, can solve problems such as blurred defect edges, complex defect shapes, and high image noise, and achieves the goals of wide application, improved efficiency, and reduced detection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

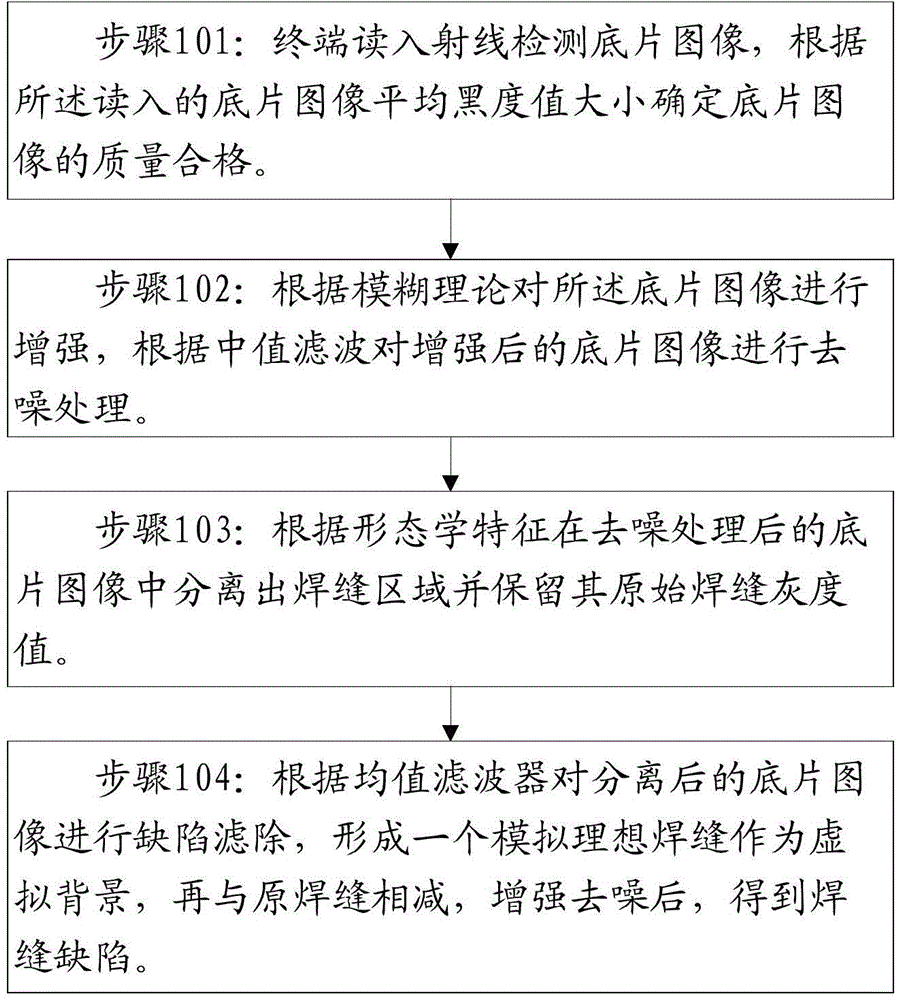

[0033] An embodiment of the present invention provides a neural network-based method for identifying weld defects in pressure vessels, such as figure 1 As shown, the method is implemented through the following steps:

[0034] Step 101: The computer reads in the radiographic negative film image, and determines whether the quality of the negative film image is qualified according to the average blackness value of the read in negative film image.

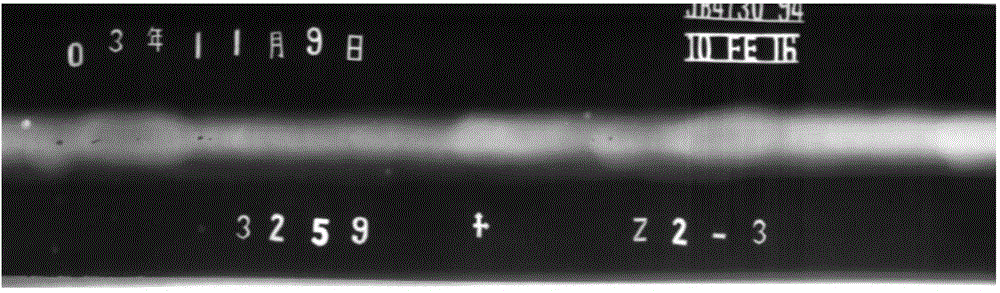

[0035] Specifically, the computer first needs to judge the qualification of the film quality for the read-in film image, and the read-in film image is as follows: figure 2 As shown, the average blackness value of the film image is calculated by dividing the sum of the blackness values of each pixel by the number of image pixels. By calculating a large number of qualified film images, exit the appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com