Constant-speed scanning positioning type post-welding seam tracking and residual stress removal system

A technology of scanning positioning and residual stress, which is applied in the field of sensing and measurement and control, can solve the problems of not having the automatic tracking function of long welds and curved welds, and achieve the effects of simple structure, high tracking accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

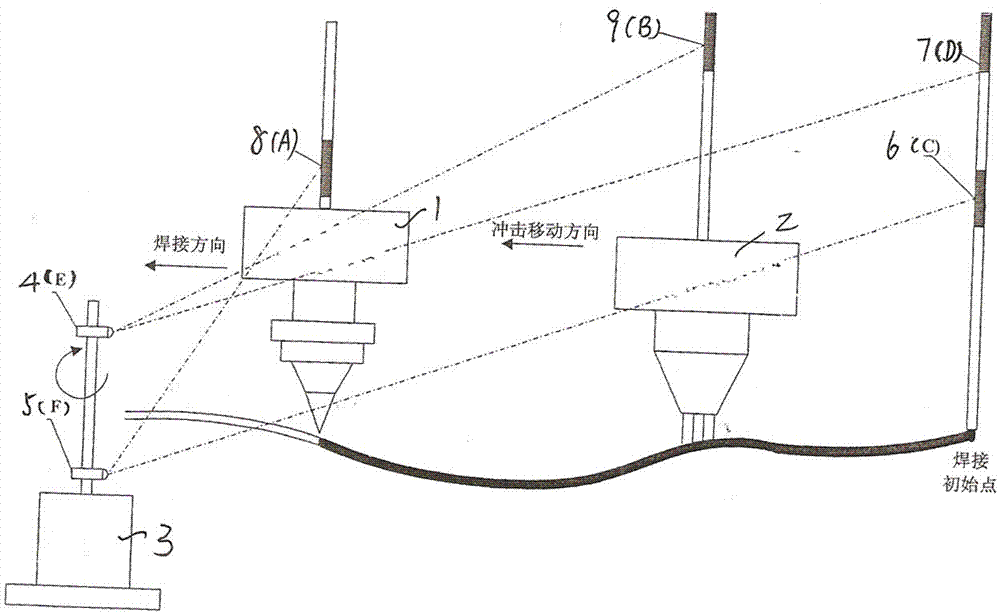

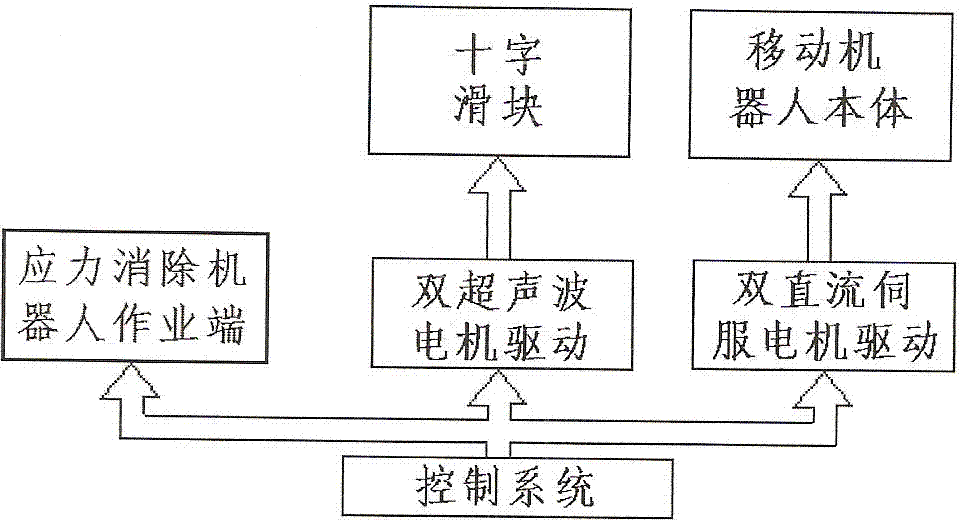

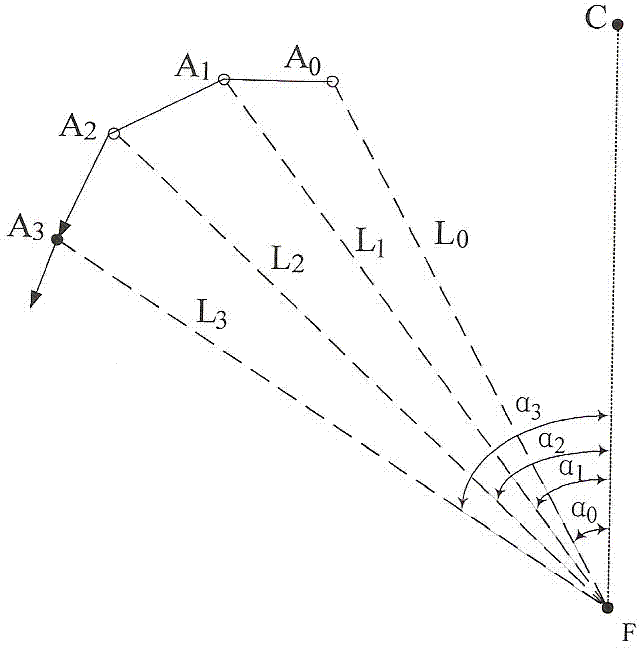

[0018] A constant-speed scanning and positioning post-weld seam tracking and residual stress relief system, including mobile welding equipment 1 for welding seams, a welding stress relief mobile robot 2 for eliminating welding stress, and a synchronous motor 3 fixedly placed on the Outside the weld seam, take the shaft center of the synchronous motor as the reference point; two reflective ranging sensors 4 and 5 are fixed on the motor shaft and rotate coaxially with the motor, and there is a distance between the two sensors; at the initial welding point, moving There are reflective sheets 6 (reflective sheet C), 7 (reflective sheet D), 8 (reflective sheet A), 9 (reflective sheet B ), with the distance measuring sensor mentioned above, one of the distance measuring sensors respectively detects the distance between the reference point and the welding initial point, the reference point and the welding nozzle, and the other distance measuring sensor respectively detects the referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com