Cap sorter

A technology of cap arranging machines and capping bins, applied in the field of cap arranging machines, can solve the problems of low efficiency of manual cap arranging and inability to arrange special-shaped bottle caps, etc., and achieve the effect of improving the efficiency of cap arranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

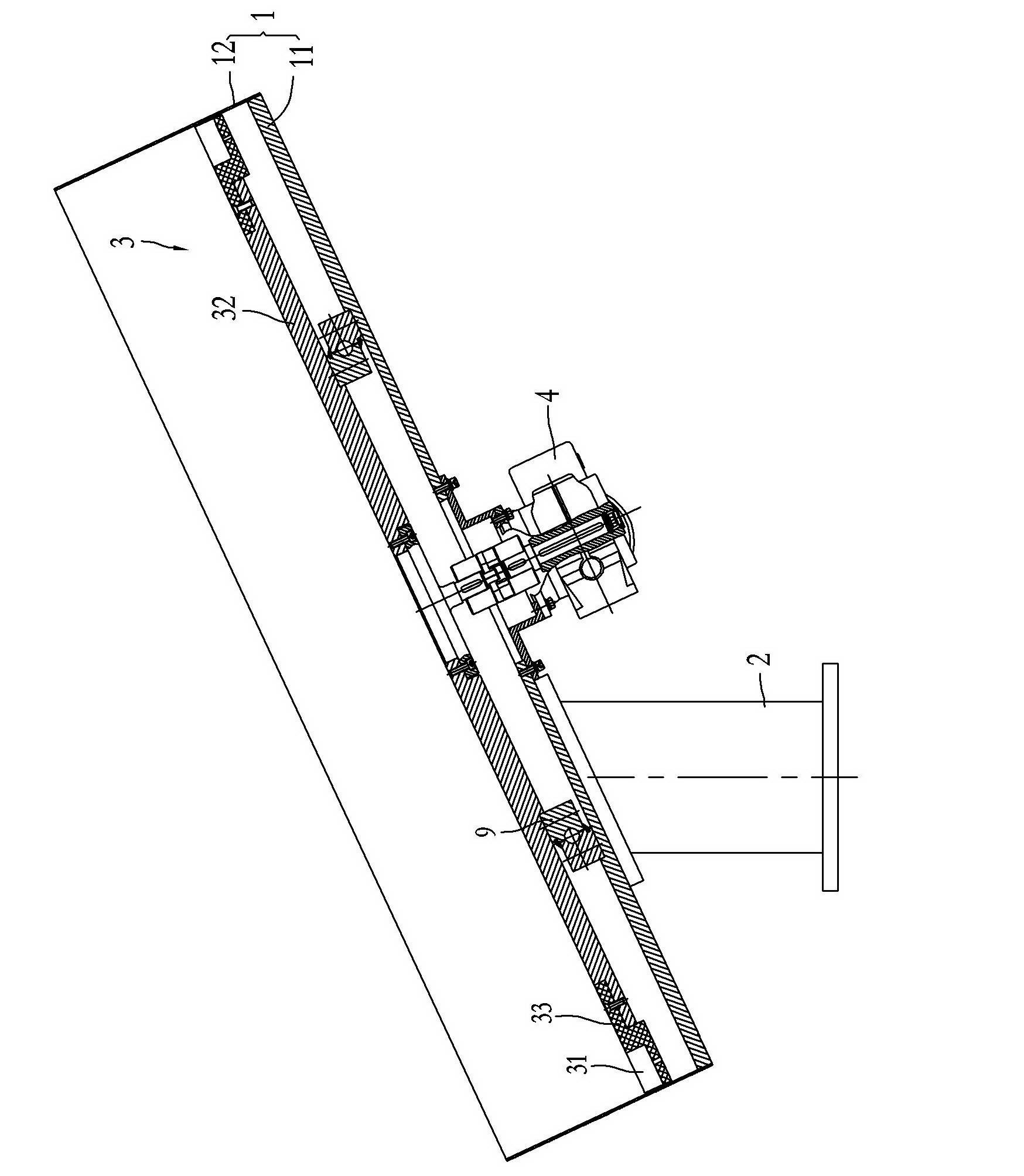

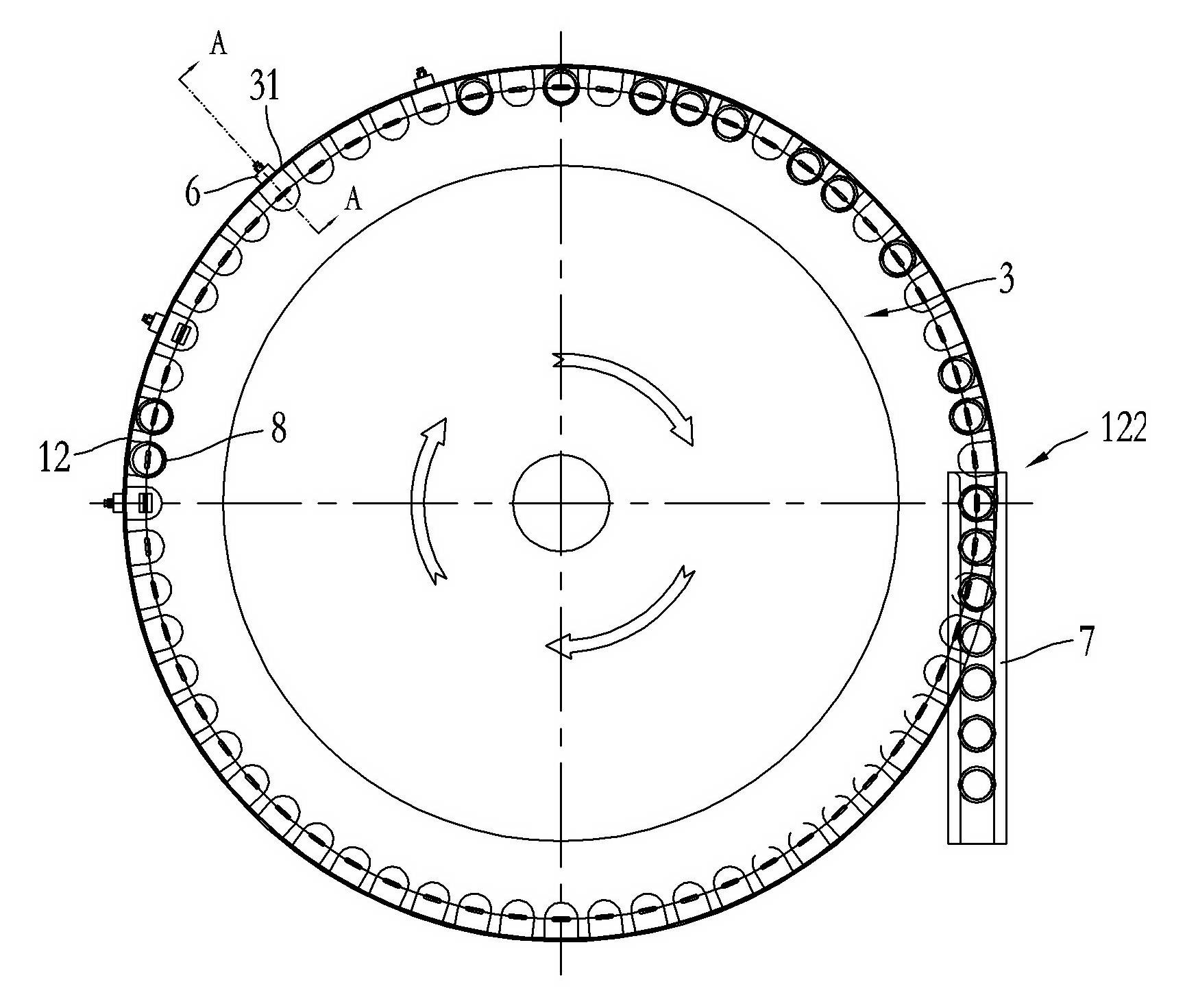

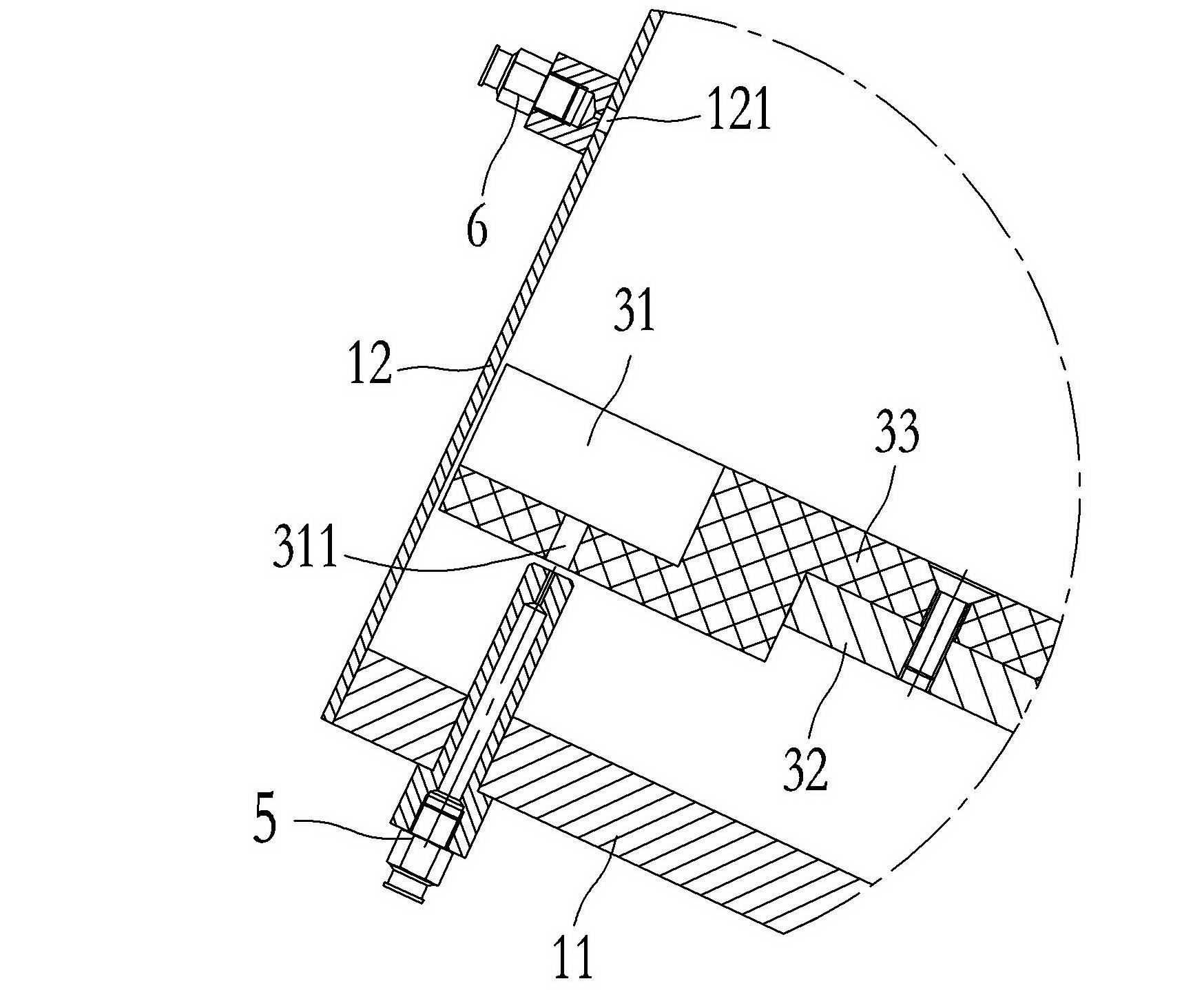

[0012] Such as Figures 1 to 6 As shown, a cover sorting machine according to the present invention includes a cover bin 1 obliquely installed on the support 2. The cover bin 1 includes a bottom plate 11 and a coaming plate 12 fixed on the outer edge of the bottom plate 11. The inside of the cover bin 1 corresponds to There is an inclined turntable 3 above the bottom plate 11, and a transmission device 4 for driving the inclined turntable 3 to rotate is installed on the bottom plate 11. A plurality of accommodating grooves 31 are distributed on the edge of the inclined turntable 3, and the accommodating grooves The width and length of 31 are slightly larger than the outer diameter of bottle cap 8, and the accommodating groove 31 is evenly distributed along the edge of the inclined turntable. The position is fixed with a bottom blowing nozzle 5, and the bottom blowing nozzle 5 is connected to an external air compression device (not shown in the figure). The distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com