Lift cap feeding and arranging AIO (All-In-One) machine

An all-in-one, lifting technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of low production speed, high processing cost, inconvenient adjustment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

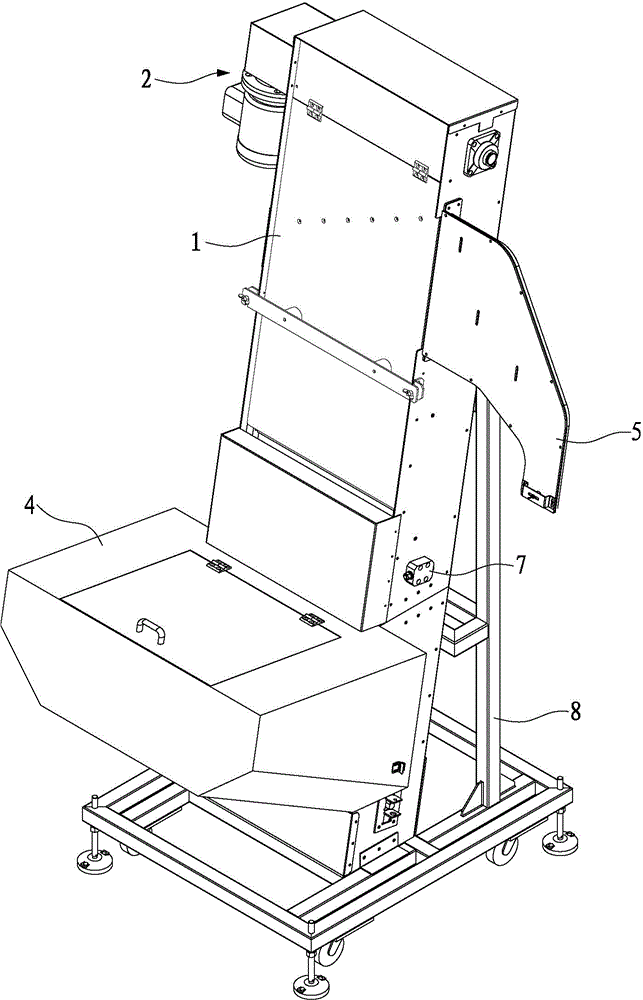

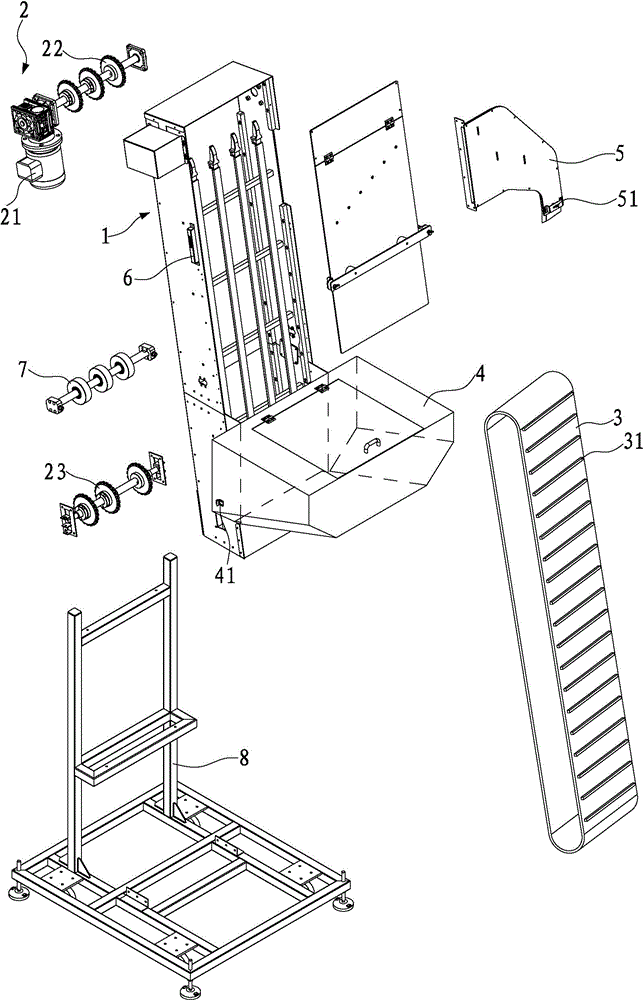

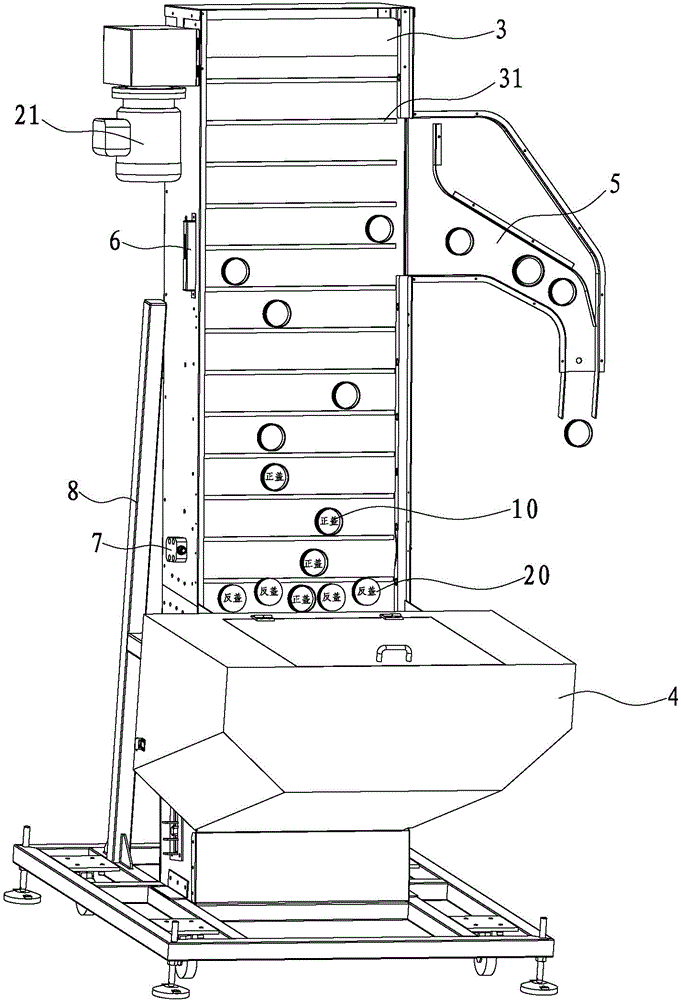

[0056] refer to Figure 1 to Figure 14 As shown, a lift-type cover delivery integrated machine disclosed by the present invention includes a frame 1, a power mechanism 2, a conveyor belt 3, a storage hopper 4, a conveyor track 5, an air blowing mechanism 6 and a rejecting wheel assembly 7.

[0057] The power mechanism 2 and the conveyer belt 3 are installed on the frame 1, the power mechanism 2 drives the conveyer belt 3 to rotate, and the transverse retaining strips 31 are arranged at intervals on the conveyer belt 3, and the frame 1 is arranged obliquely, such as figure 1 As shown, the frame 1 is installed obliquely on the support frame 8 .

[0058] In this embodiment, the power mechanism 2 is composed of a motor 21, a driving wheel assembly 22 and a driven wheel assembly 23, the motor 21 and the driving wheel assembly 22 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com