Fully mechanized mining face coal-seam thickness self-adaption cutting control method and electronic equipment

A fully-mechanized mining face, coal seam thickness technology, applied in fully-mechanized mining face coal seam thickness adaptive cutting method and electronic equipment field, can solve the problem of automatic control accuracy of shearer cutting height, difficult shearer cutting height Problems such as real-time adjustment, cutting pose information, coordinate information disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

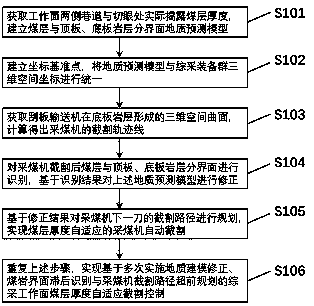

[0039] like figure 1 Shown is a work flow diagram of a fully mechanized mining face coal seam thickness self-adaptive cutting control method of the present invention, including:

[0040] Step S101, performing statistical analysis on the actual exposed thickness of the coal seam during the process of roadway excavation and hole opening on both sides of the working face, and establishing a geological prediction model for the interface between the coal seam, the roof rock layer, and the floor rock layer;

[0041]Step S102, establishing a coordinate reference point on the working face, unifying the three-dimensional space coordinates of the geological prediction model with the three-dimensional space coordinates of the fully mechanized mining equipment group;

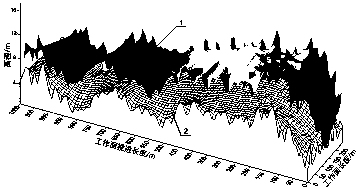

[0042] Step S103, obtaining the three-dimensional curved surface formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com