Ultrasonic TOFD (Time of Flight Diffraction) detection method for T-shaped welding joint

A technology for welding joints and detection methods, applied in the direction of analysis of solids using sonic/ultrasonic/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below:

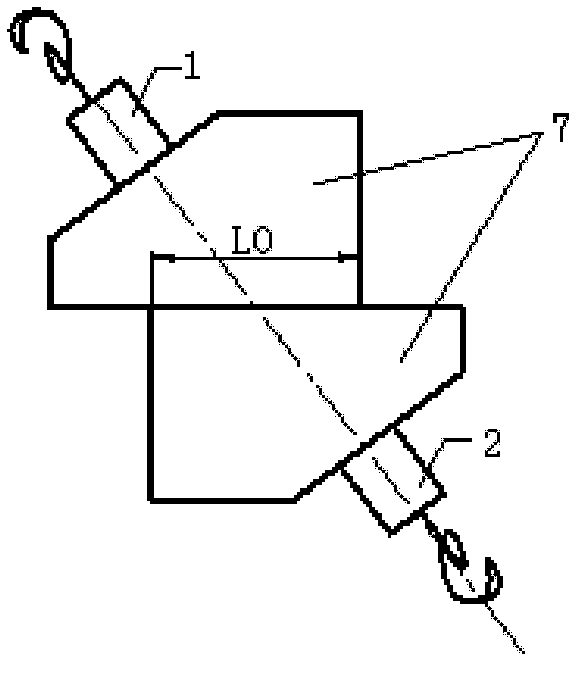

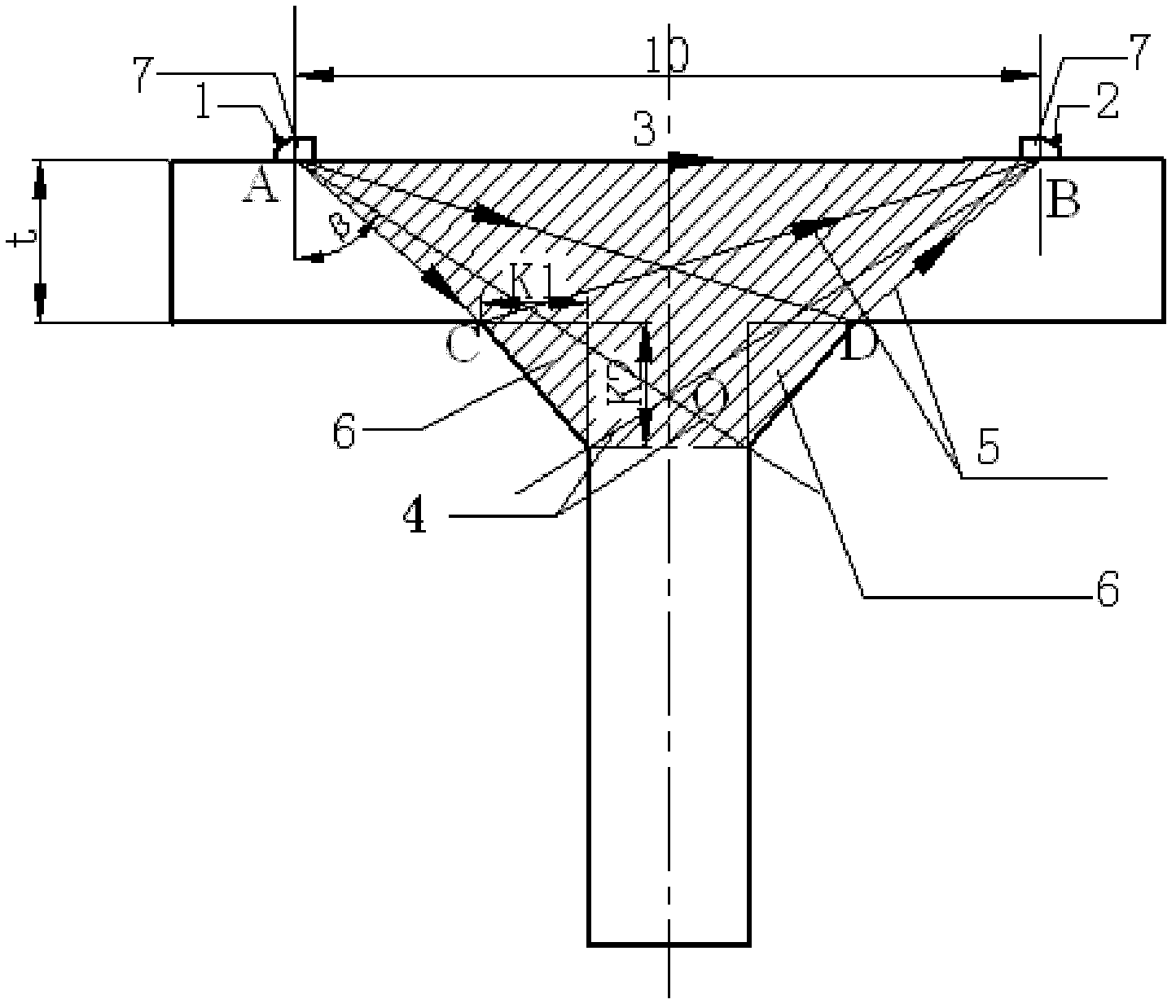

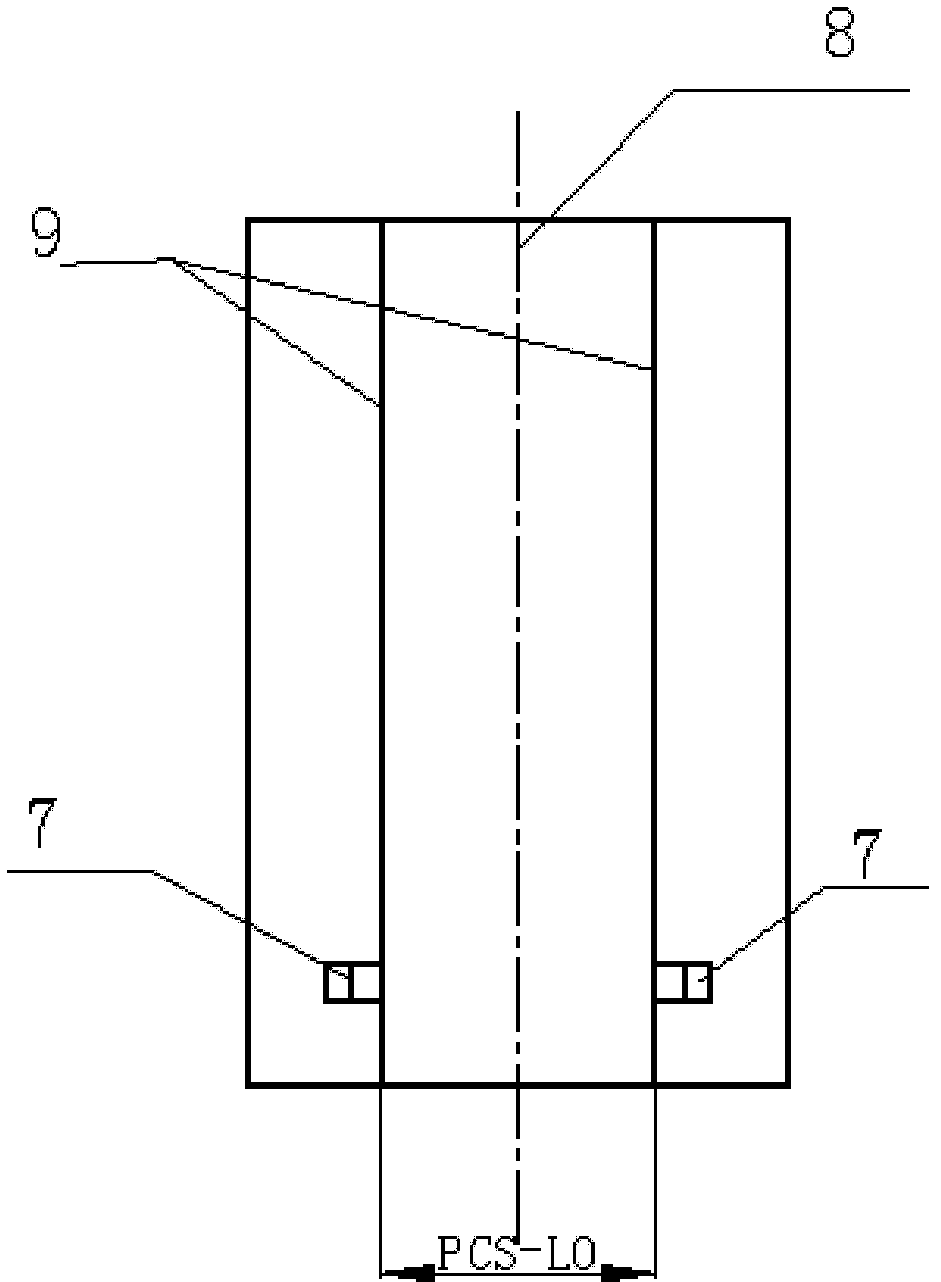

[0024] Determine the distance between the sound incident points of the ultrasonic probe according to the size of the right-angle side of the weld angle of the tested T-welded joint, the thickness of the wing plate, the thickness of the web and the spread angle of the sound beam of the TOFD probe. Make two scanning path lines on the center line of the weld. The distance between them is the difference between the distance between the sound incident point and the sum of the front edges of the two ultrasonic probes. During the inspection, the probe wedge is scanned along the wing plate of the T-welded joint. The path line scan generates a D-scan image, and the internal defect characteristics of the T-shaped welded joint can be obtained by analyzing the image;

[0025] Take the larger value K of the thickness t of the wing plate and the right angle of the weld on one side of the web 2 The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com