Shunting automatic protection system and automatic shunting method

An automatic protection and shunting technology, applied in railway signaling and safety, can solve the problems of difficult and effective protection, inaccurate information, misoperation, etc., and achieve the effect of perfecting closed-loop self-checking, satisfying portability, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

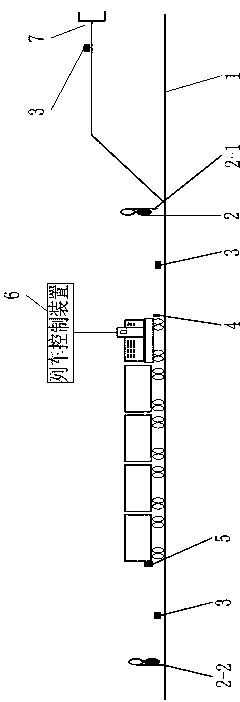

[0039] Such as figure 1 As shown, the shunting automatic protection system among the present invention, it is provided with two ground equipment 3 between two shunting signal machines 2 before and after each lane 1, promptly at the rear of front shunting signal machine 2-1 8-12 meters, 8-12 meters ahead of the rear shunting signal 2-2 to set the ground equipment 3; in addition, also set the ground equipment 3 8-12 meters ahead of the head block 7 of the track; the above-mentioned ground equipment 3 Collect the shunting status signal and locomotive running status signal of the shunting signal machine 2, and transmit the collected signals to the locomotive device 4, and send the above signals to the train control device 6 after being processed by the locomotive device 4. And the information sending method in the present invention refers to the uplink communication method of the A port of the transponder "Technical Specifications for Transponder Equipment".

[0040] Generally, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com