Patents

Literature

165results about "Deformable fasteners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

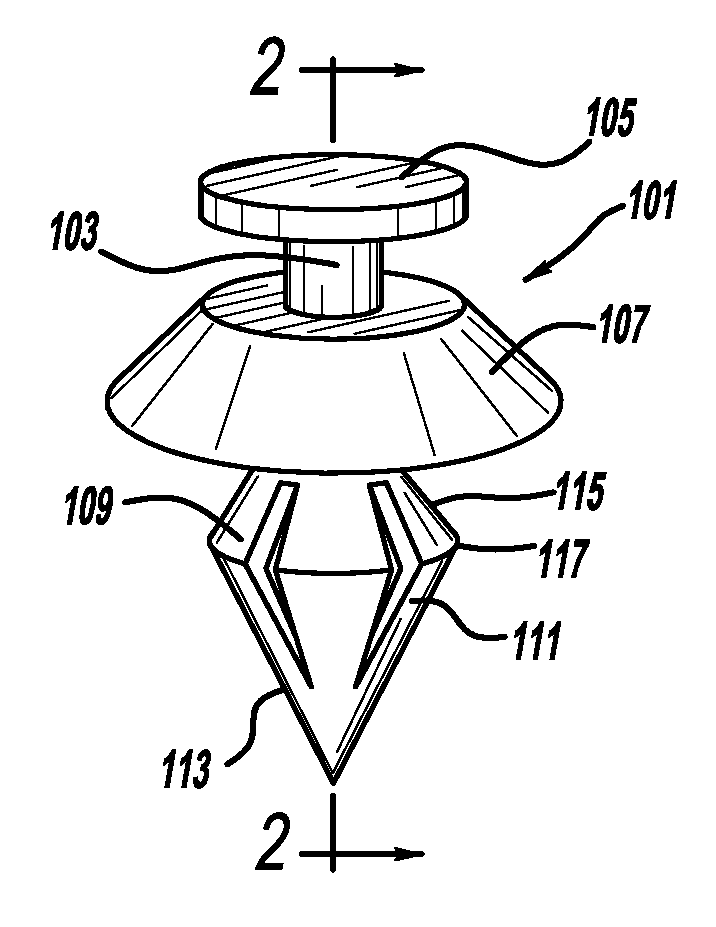

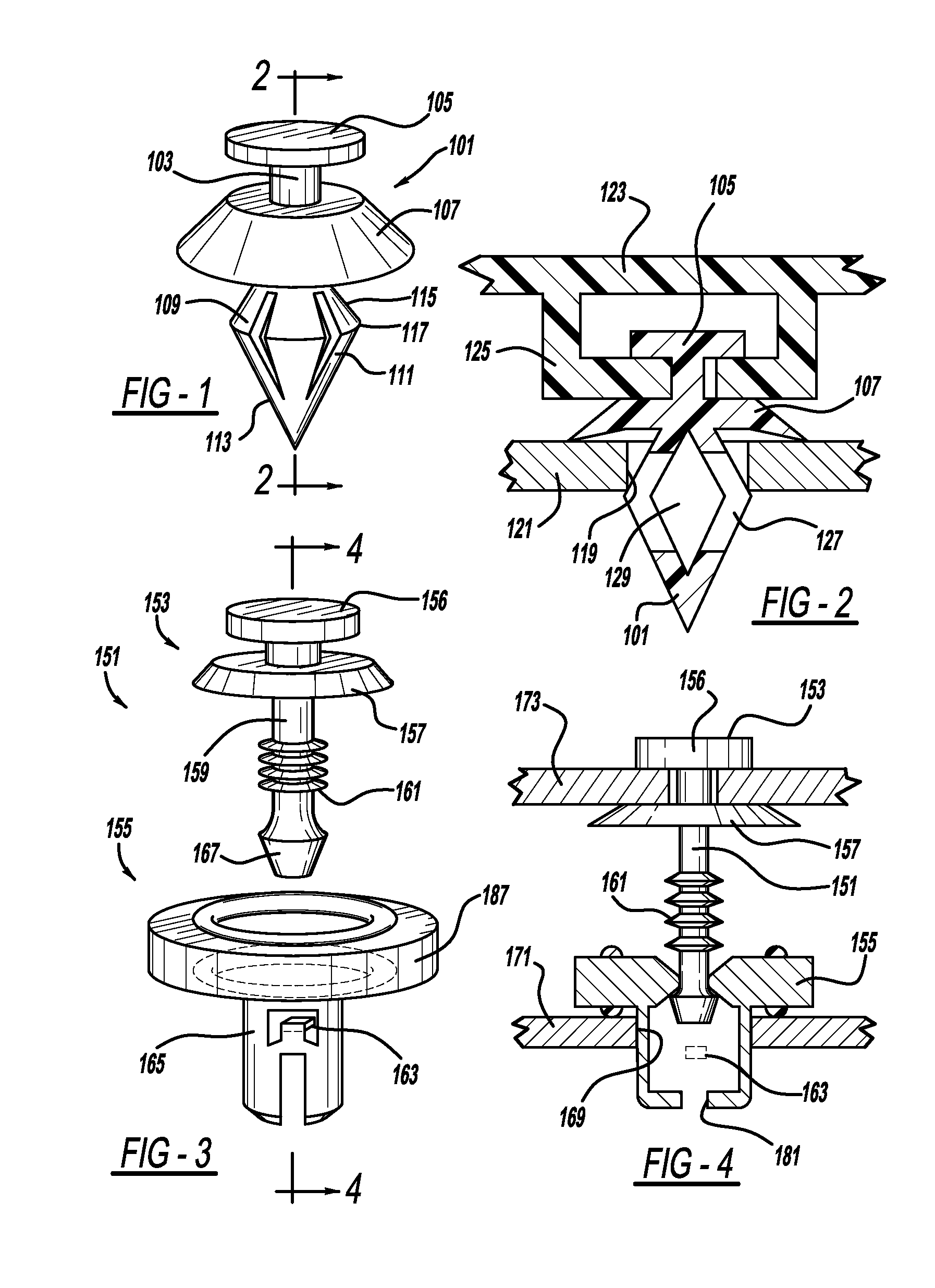

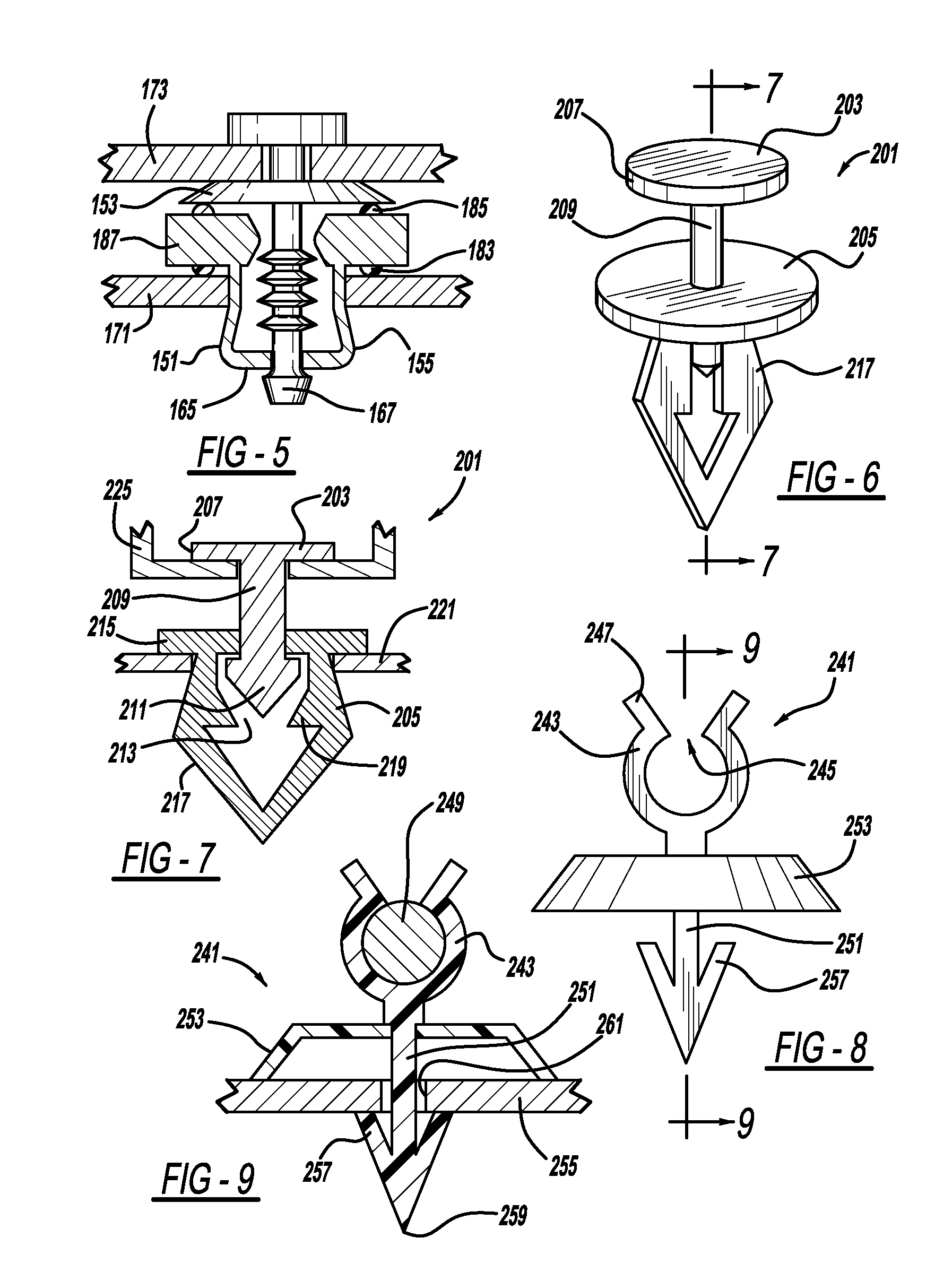

Fasteners manufactured by three-dimensional printing

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

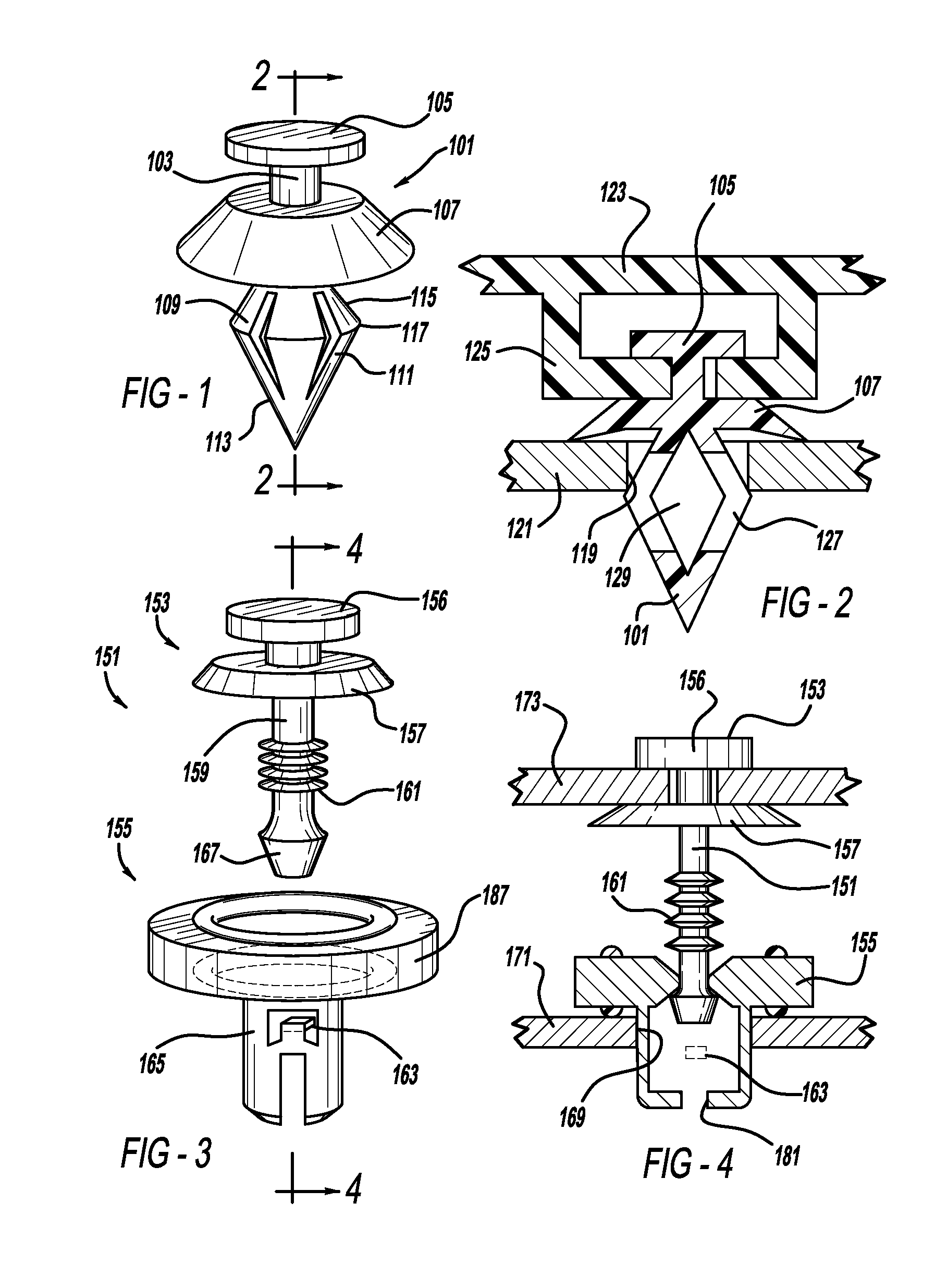

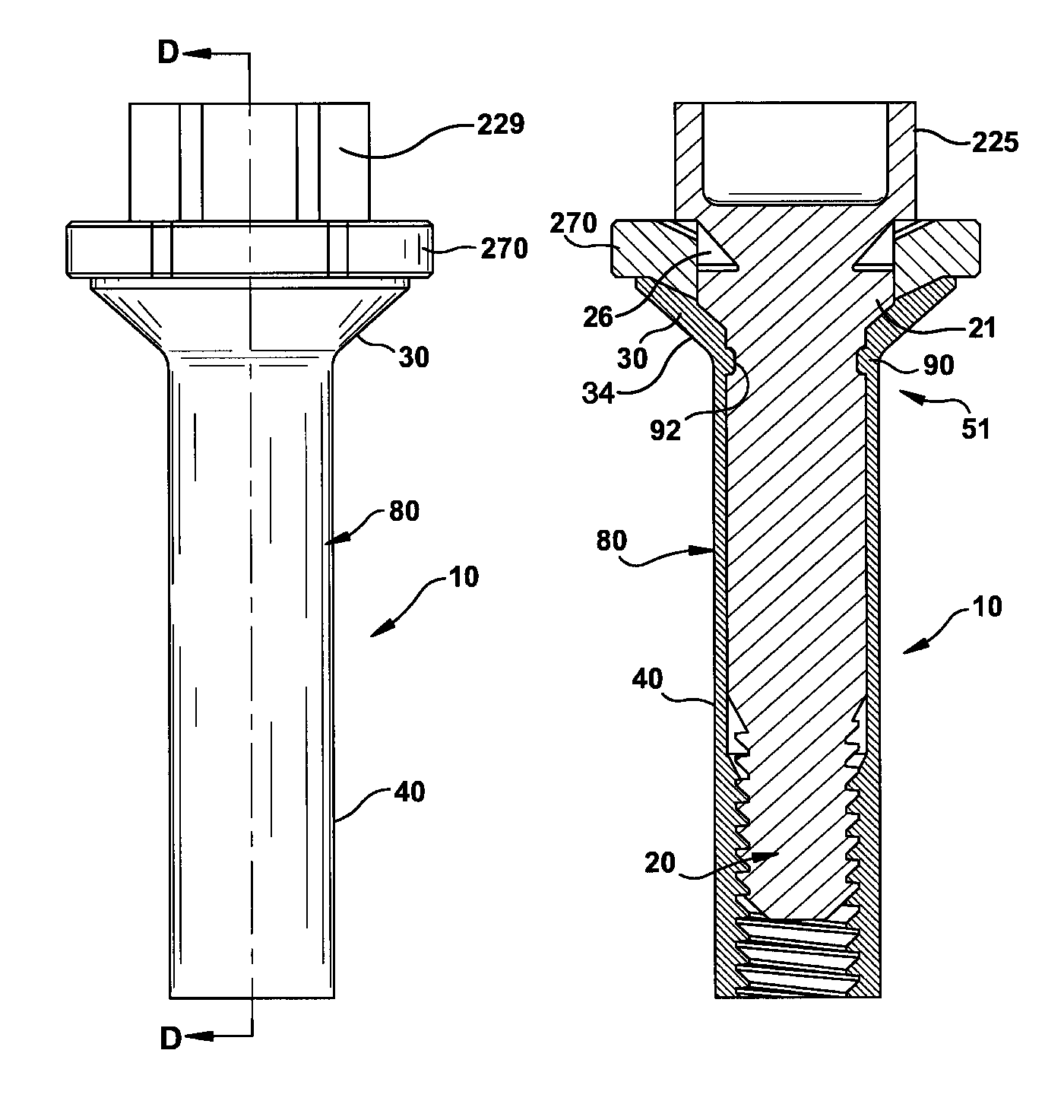

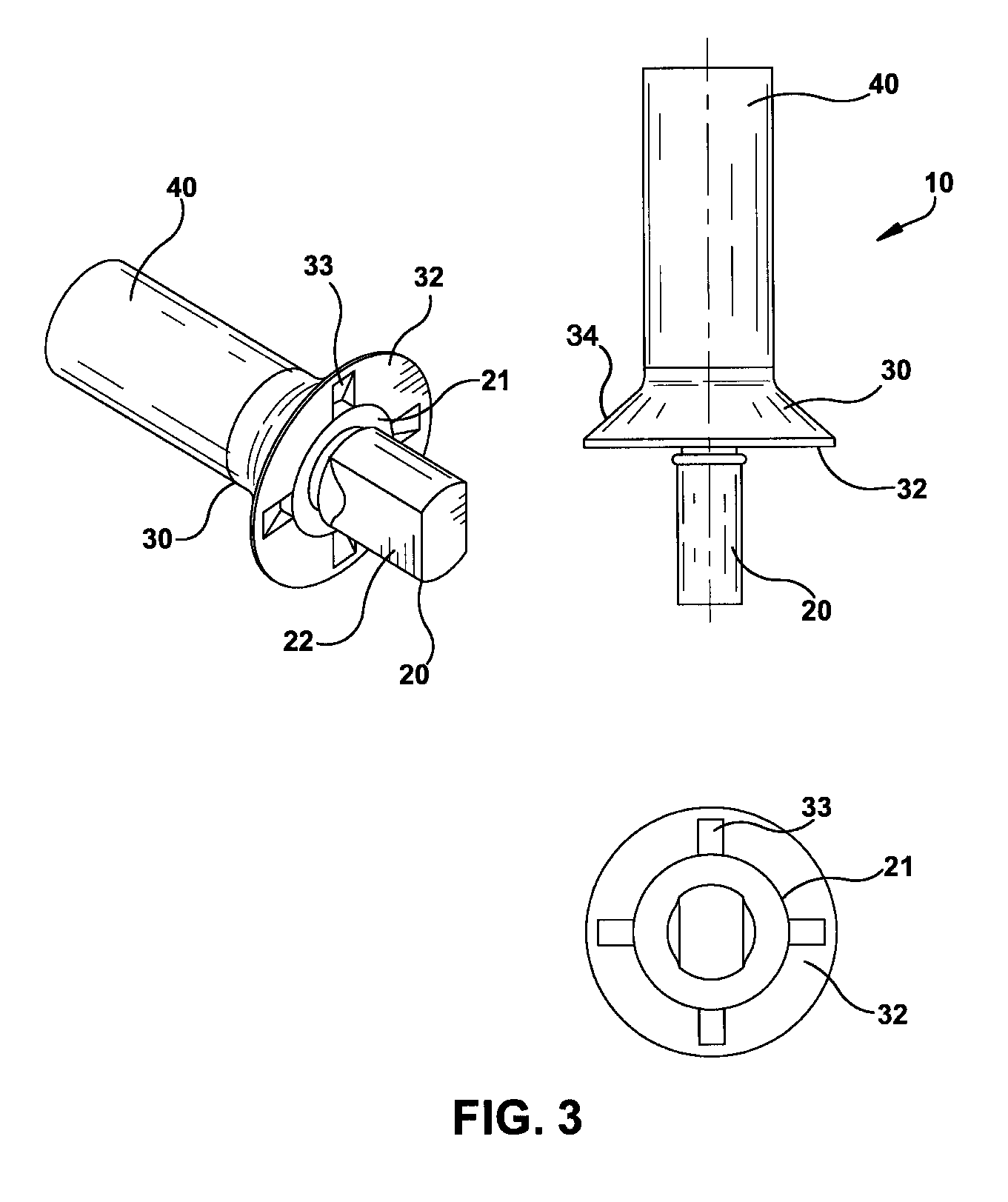

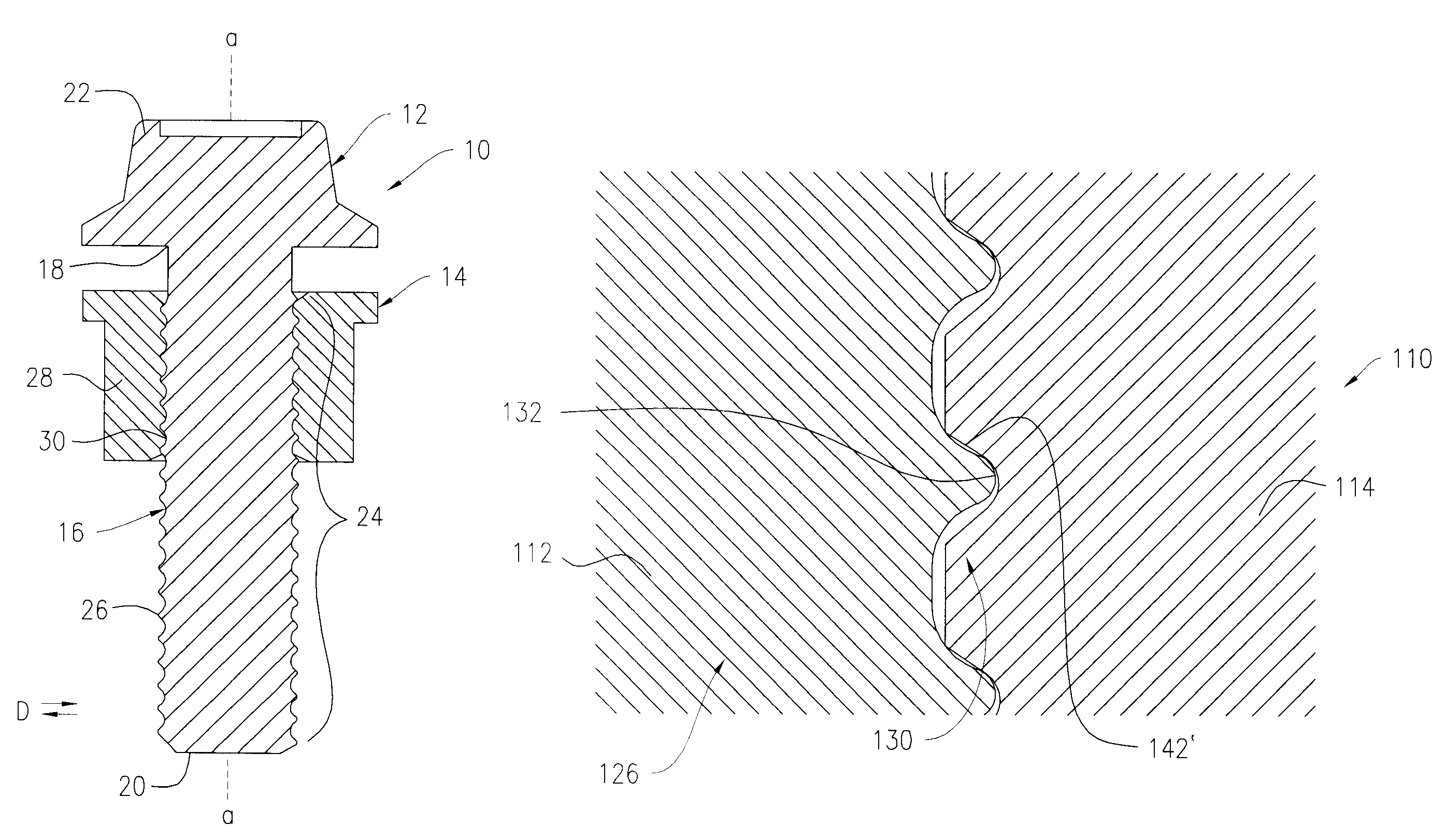

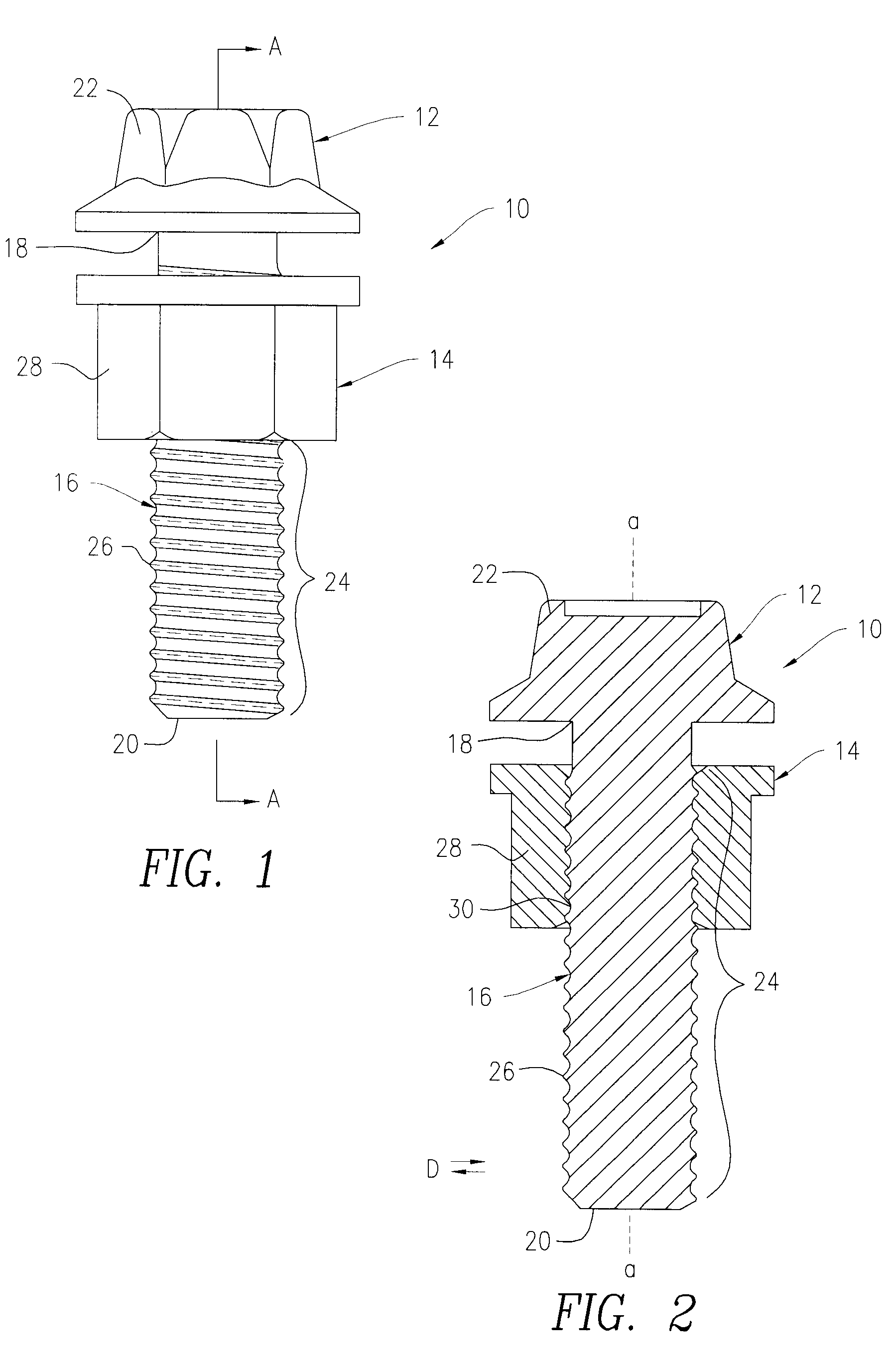

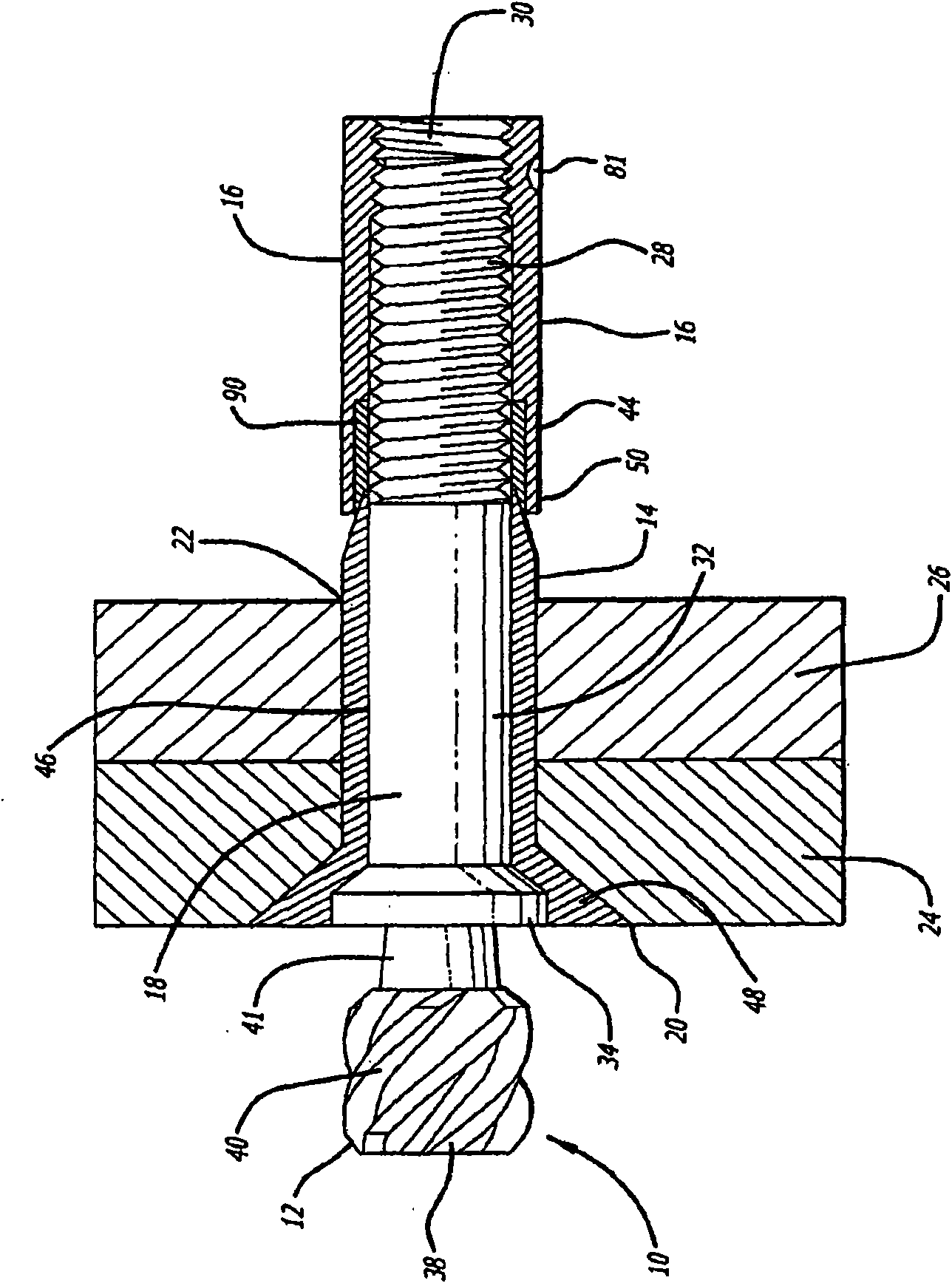

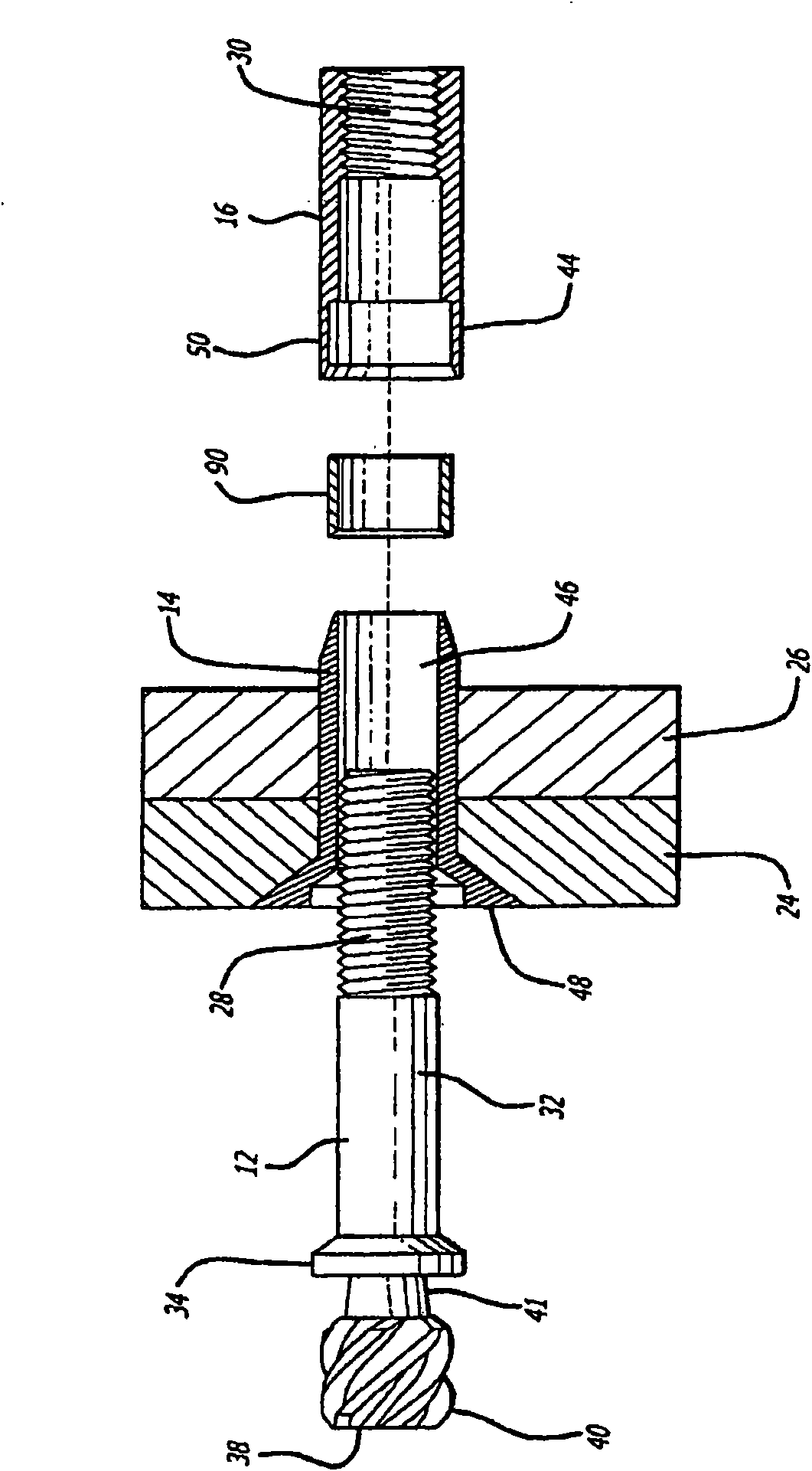

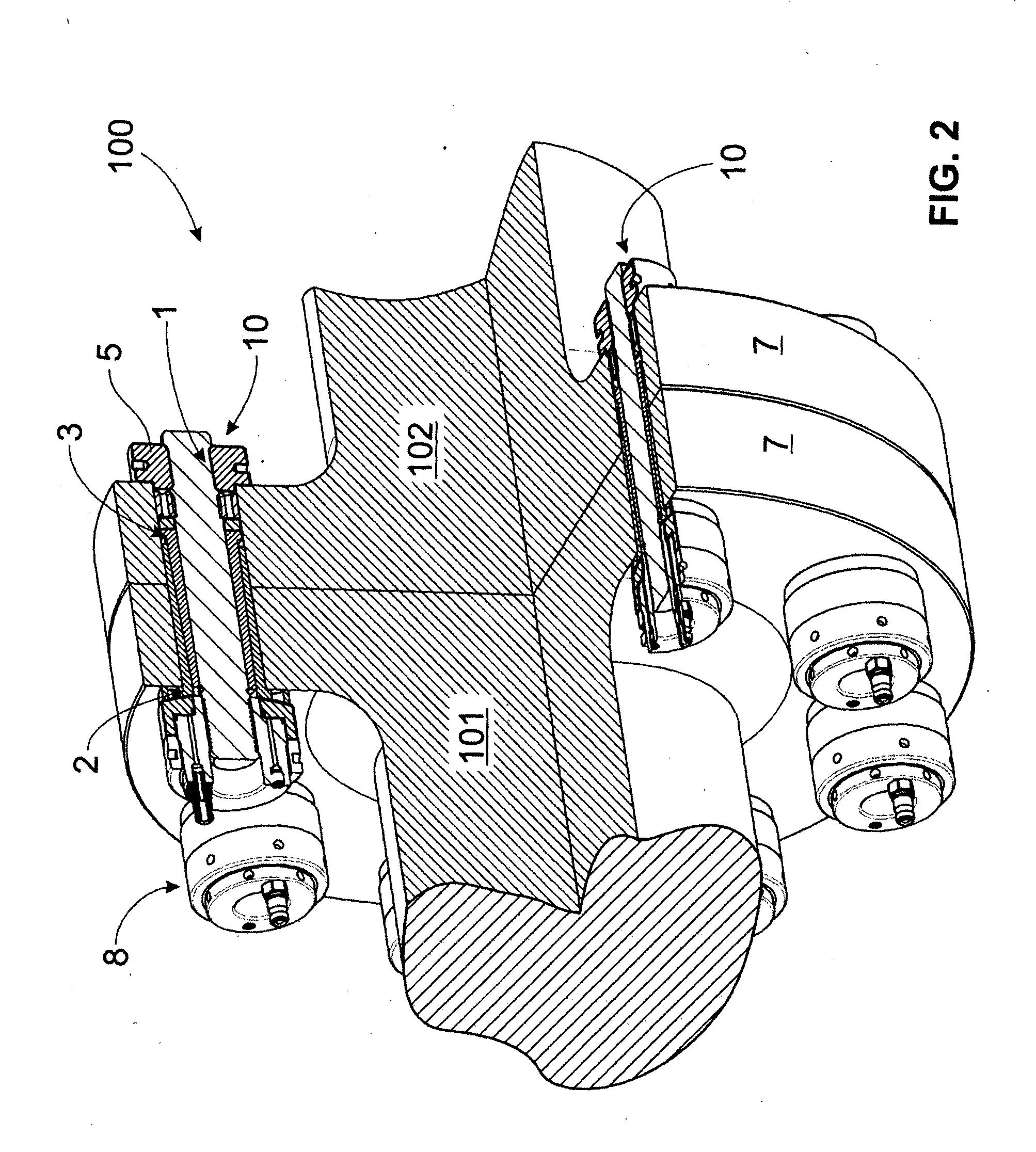

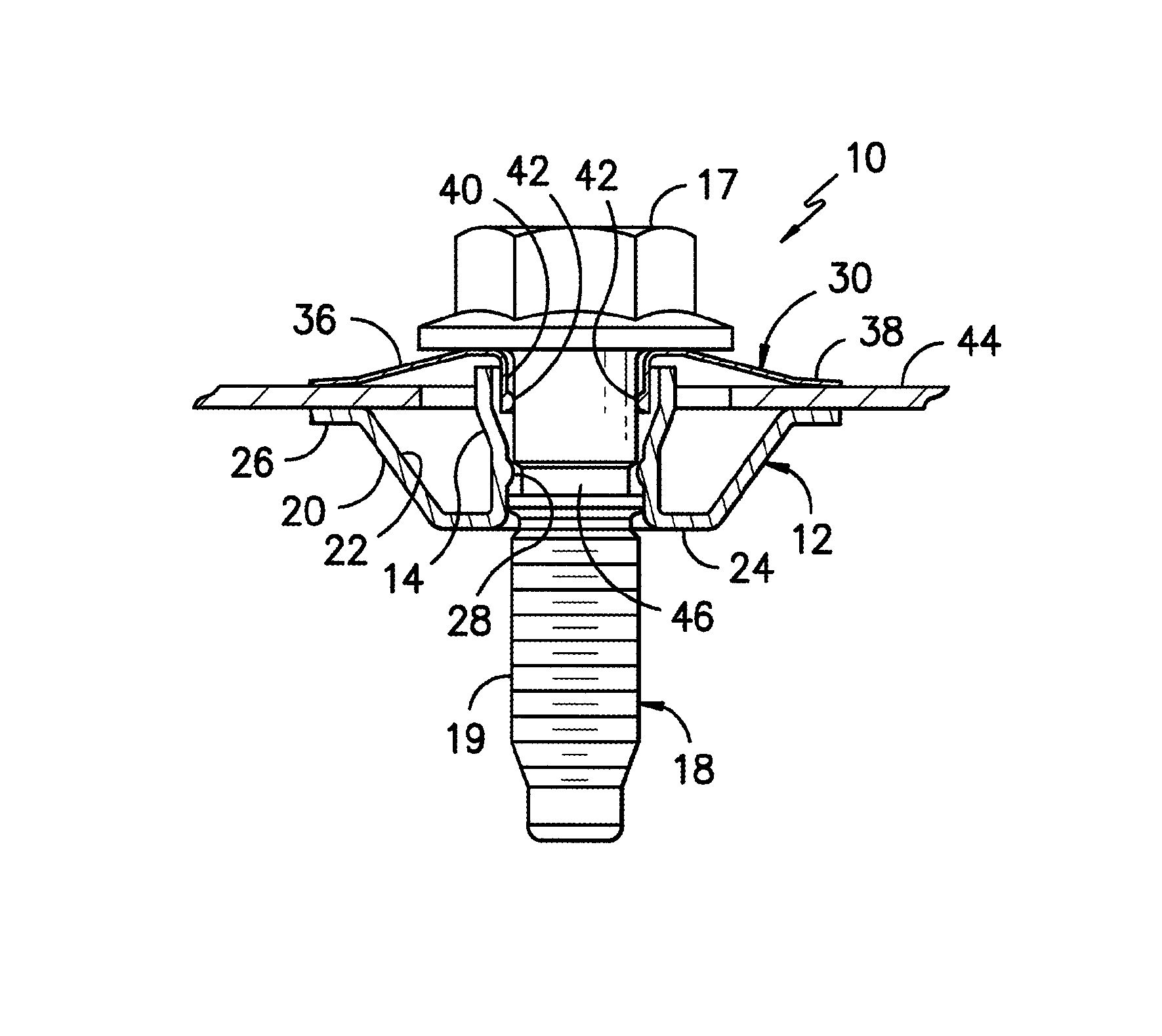

Pivot apparatus including a fastener and bushing assembly

A fastening assembly for use as a pivot joint for a first member and a second member which have alignable openings therethrough. The fastening assembly comprises a fastener having a longitudinal axis and a bushing mounted on the fastener with the bushing having a first end and a second end. The second end of the bushing being formed wherein upon the combined fastener and bushing being mounted within the aligned openings the second bushing end extends only through the opening of the first member whereby upon its engagement with the second member during installation it flares radially outwardly from the longitudinal axis of the fastener and between the first and second members thereby providing automatic retention of the bushing and, resilient spacing between the first and second members.

Owner:SOUTHCO

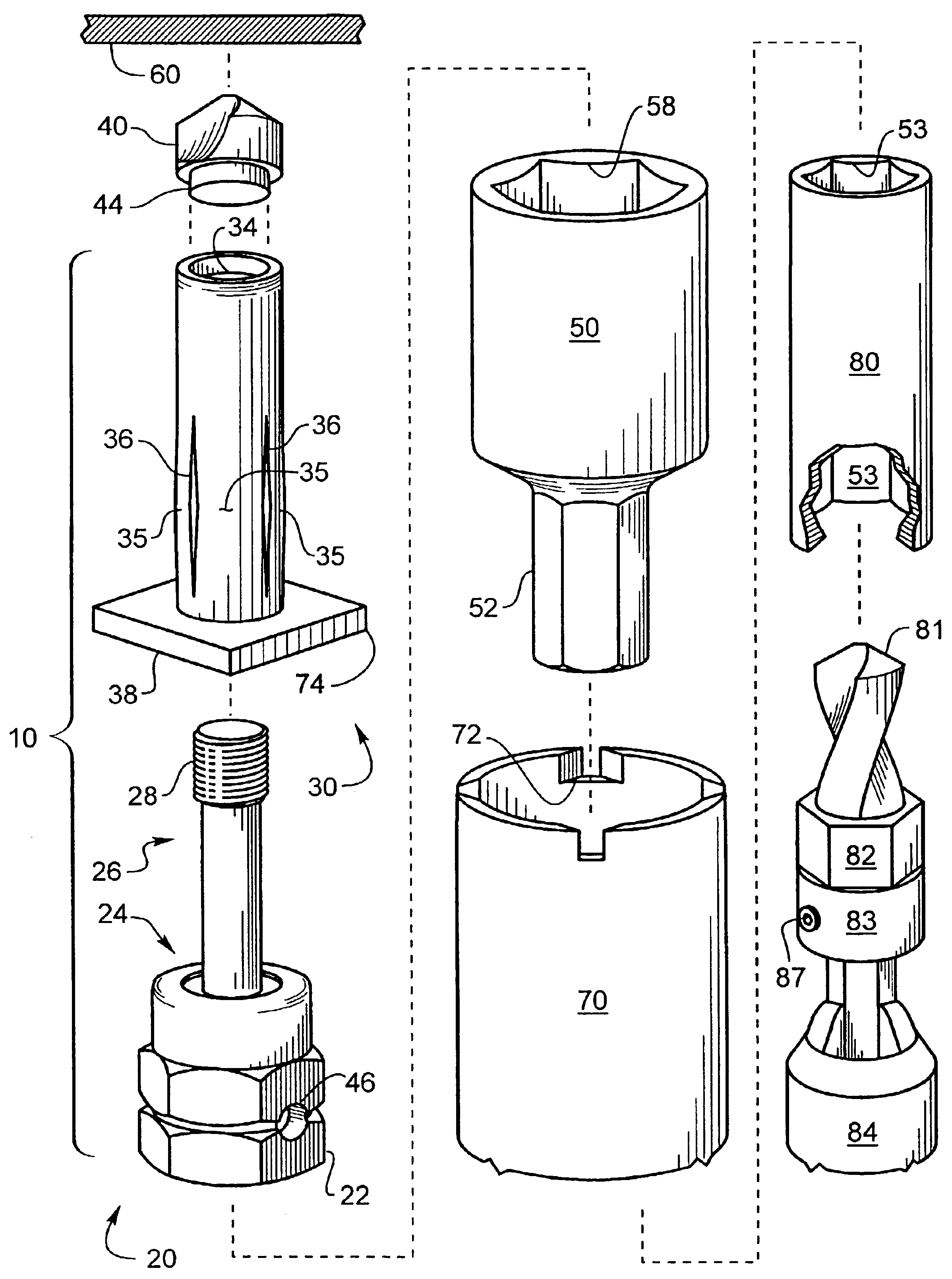

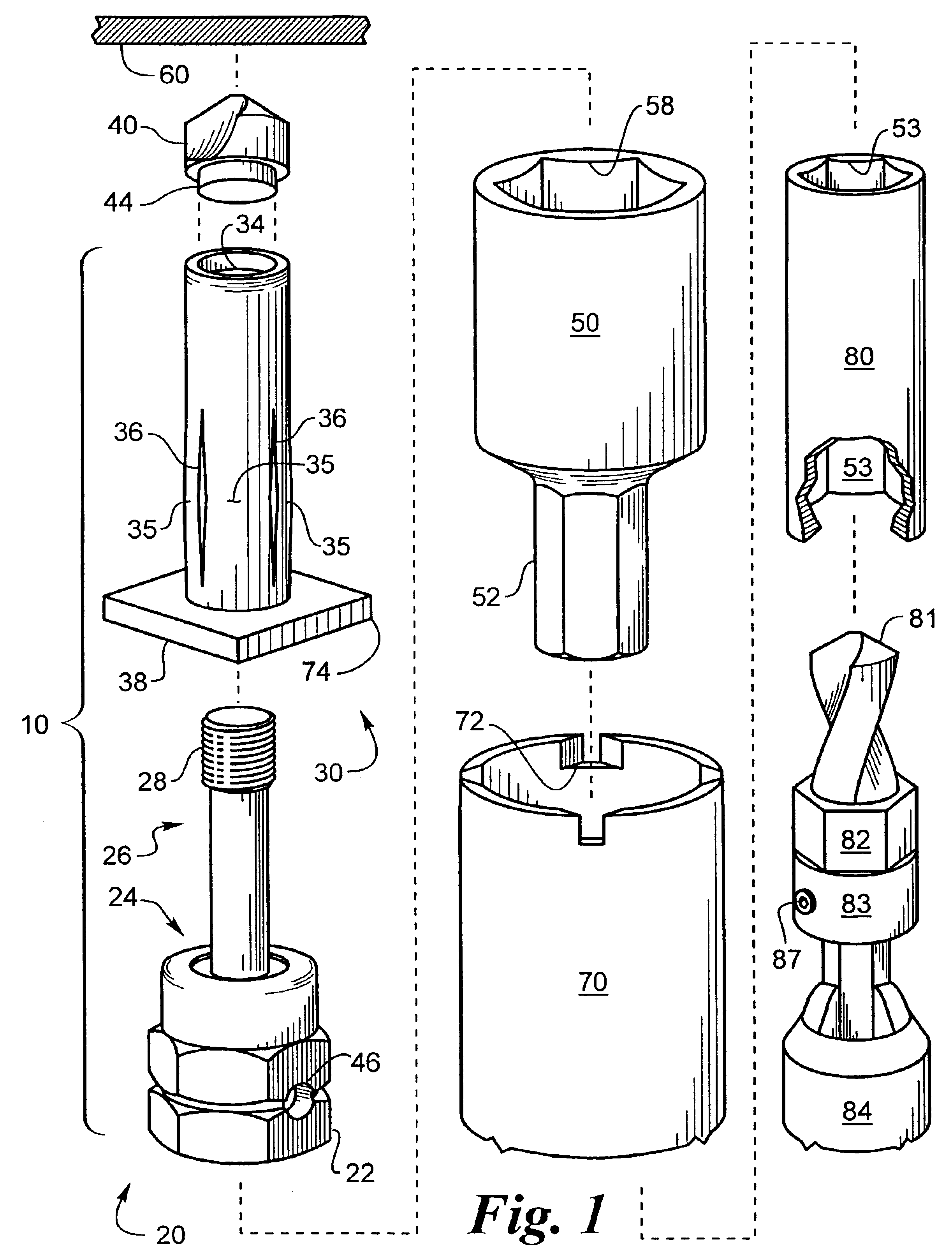

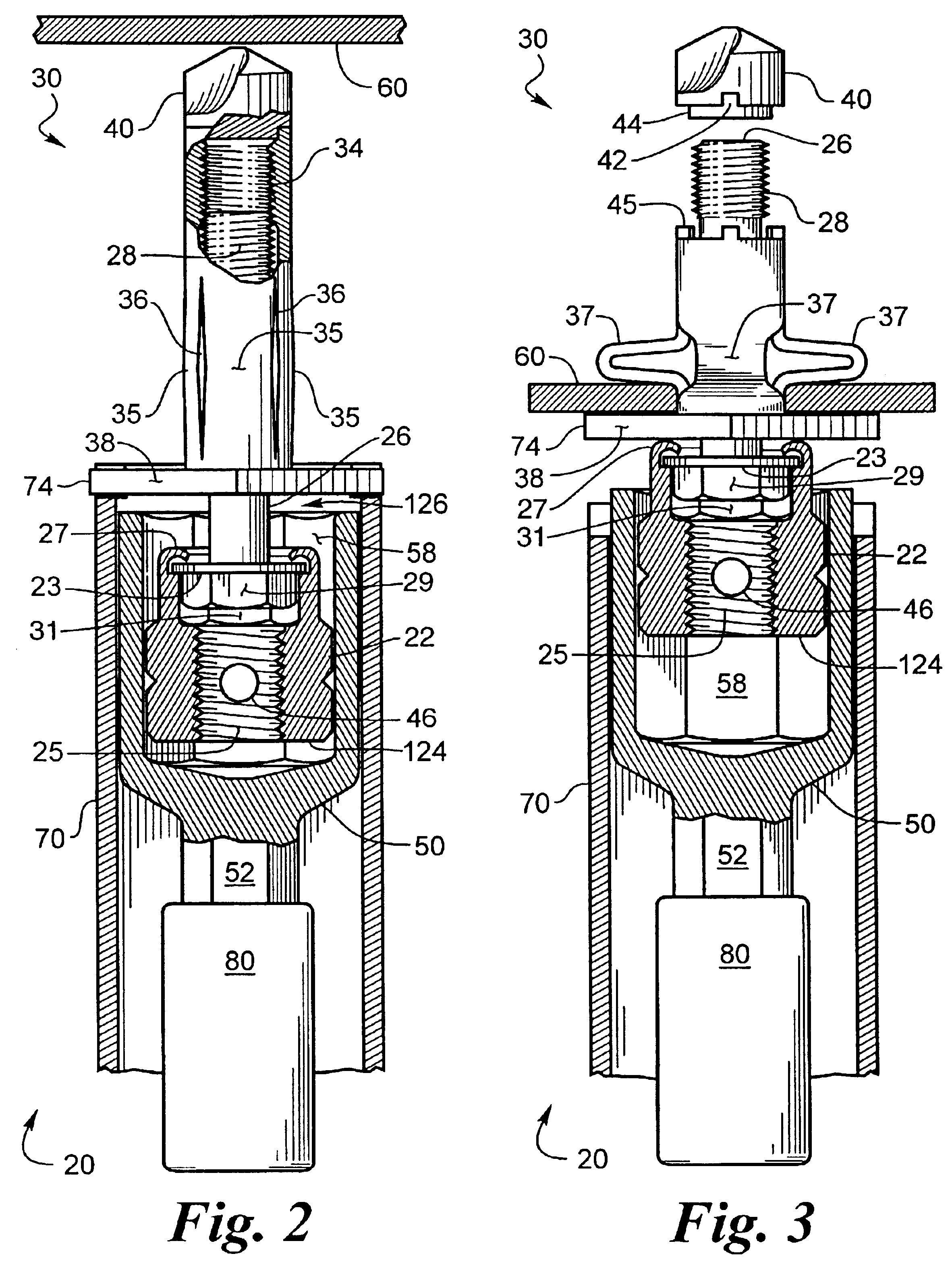

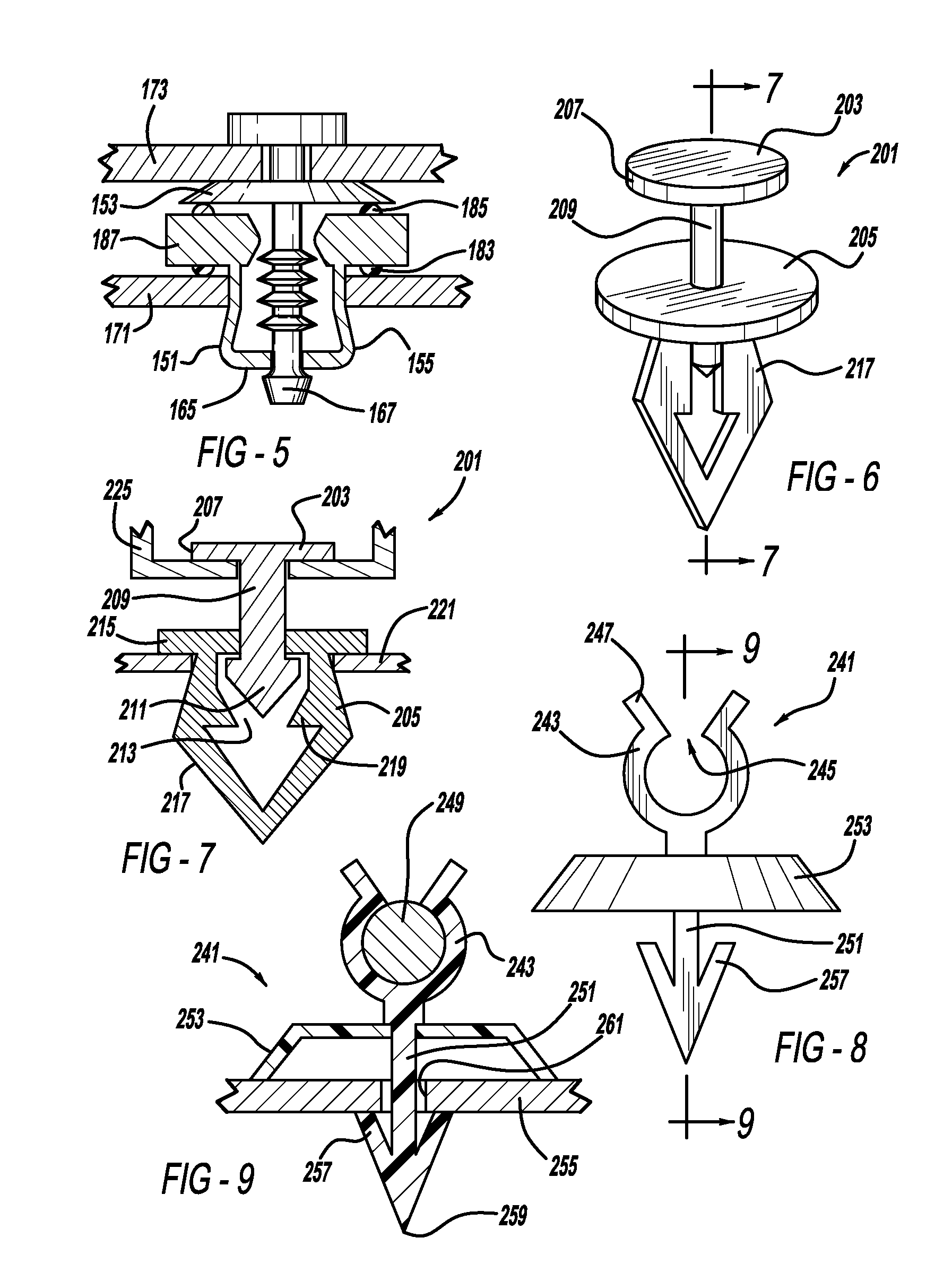

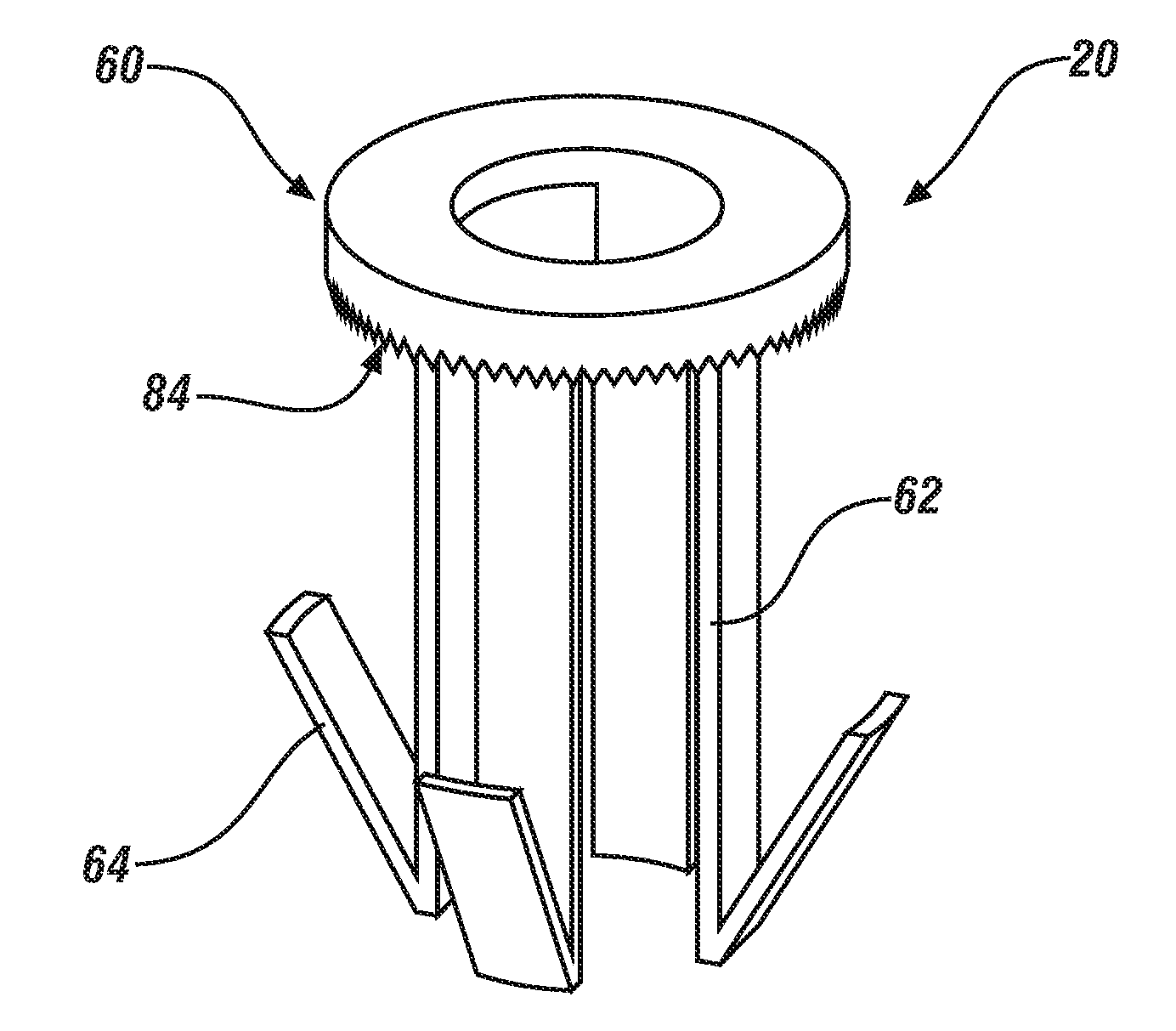

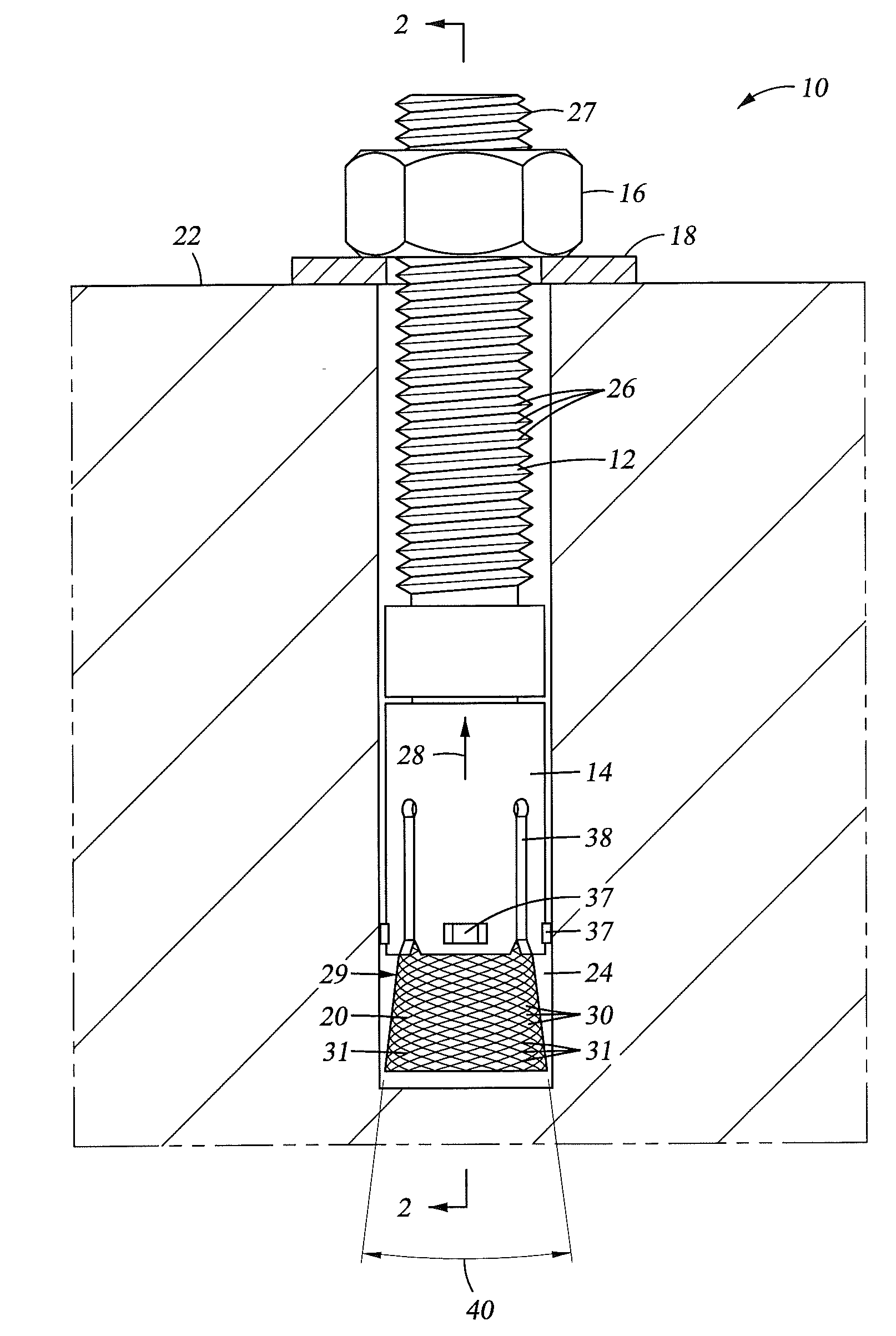

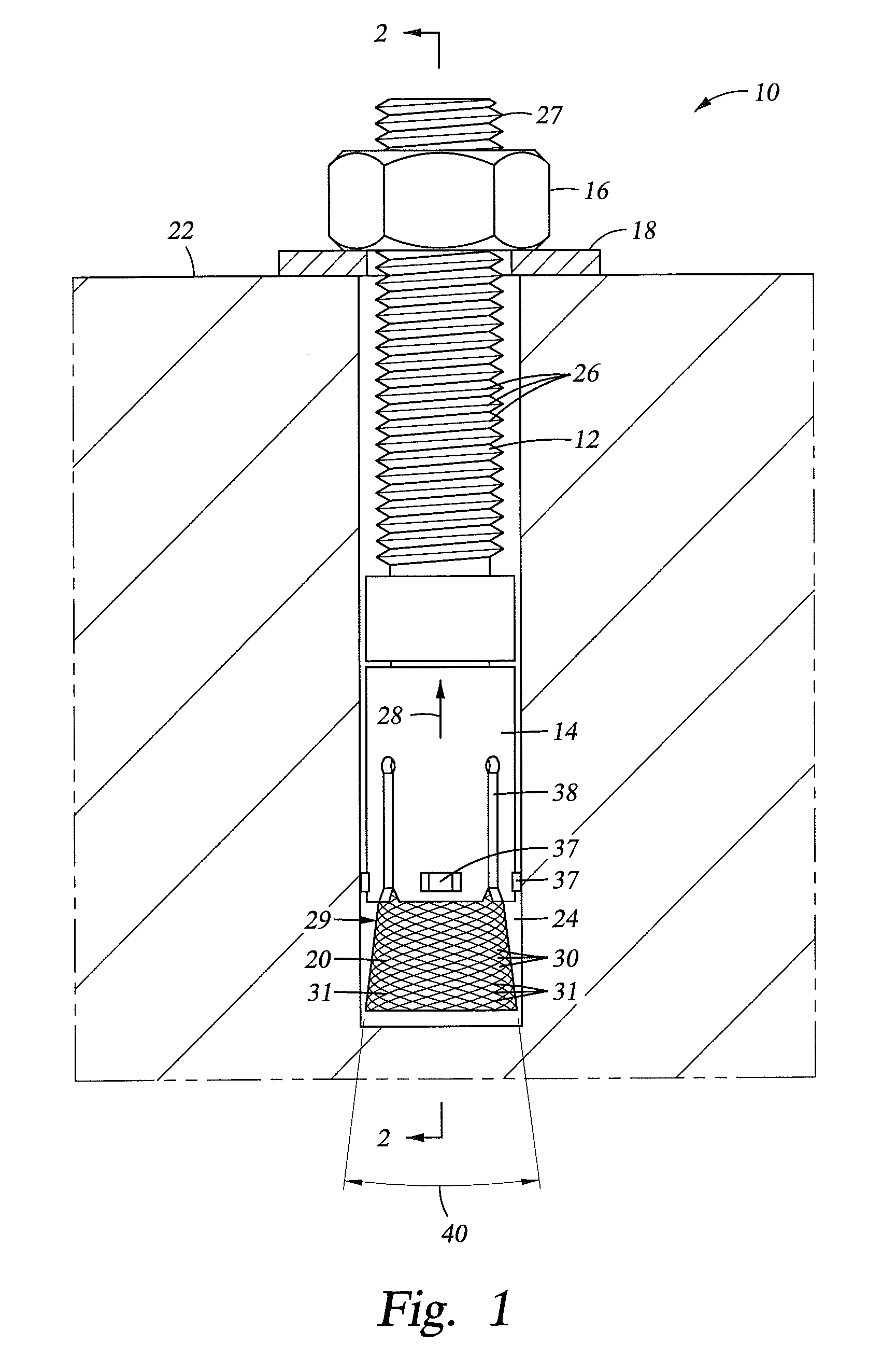

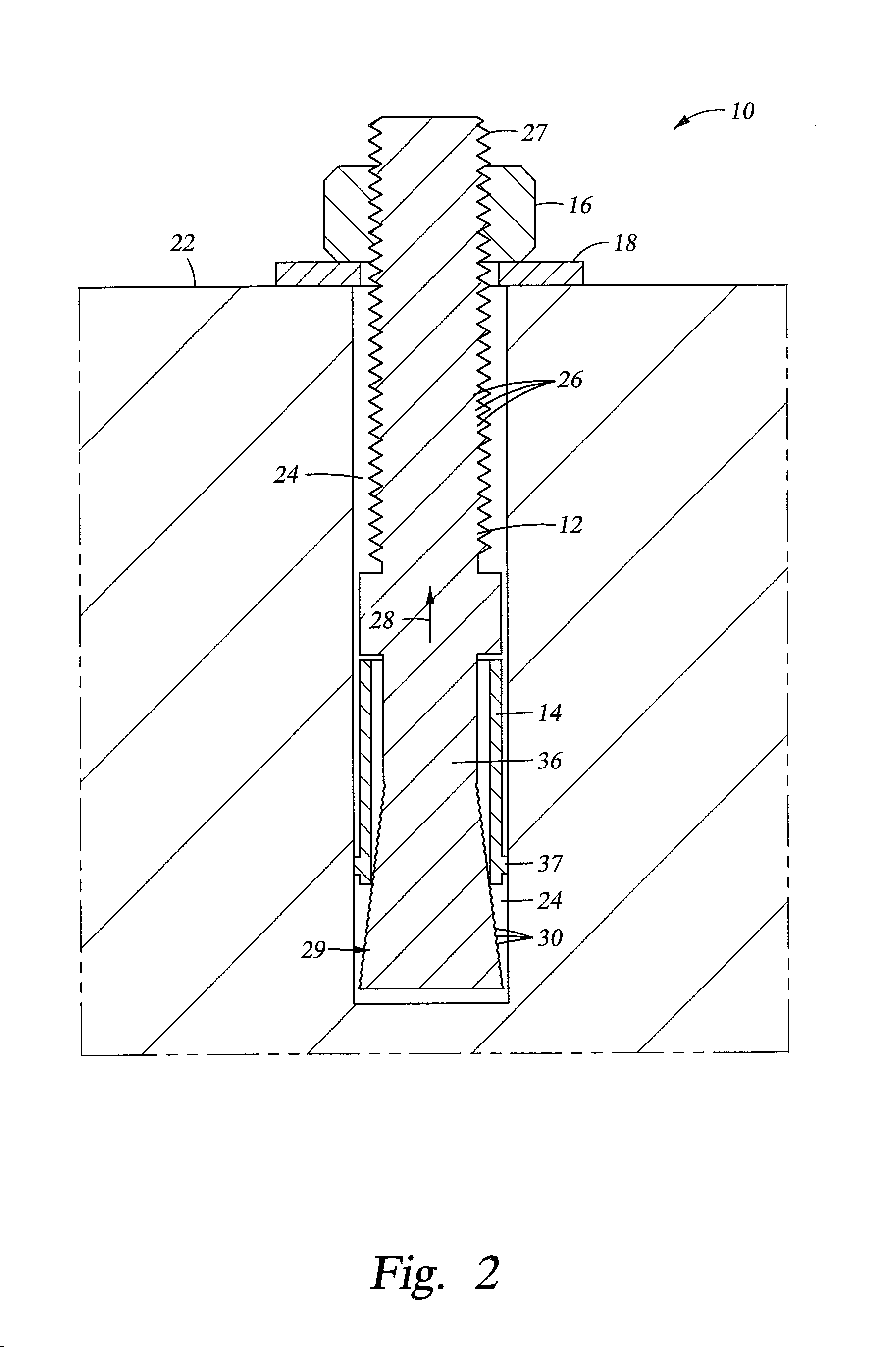

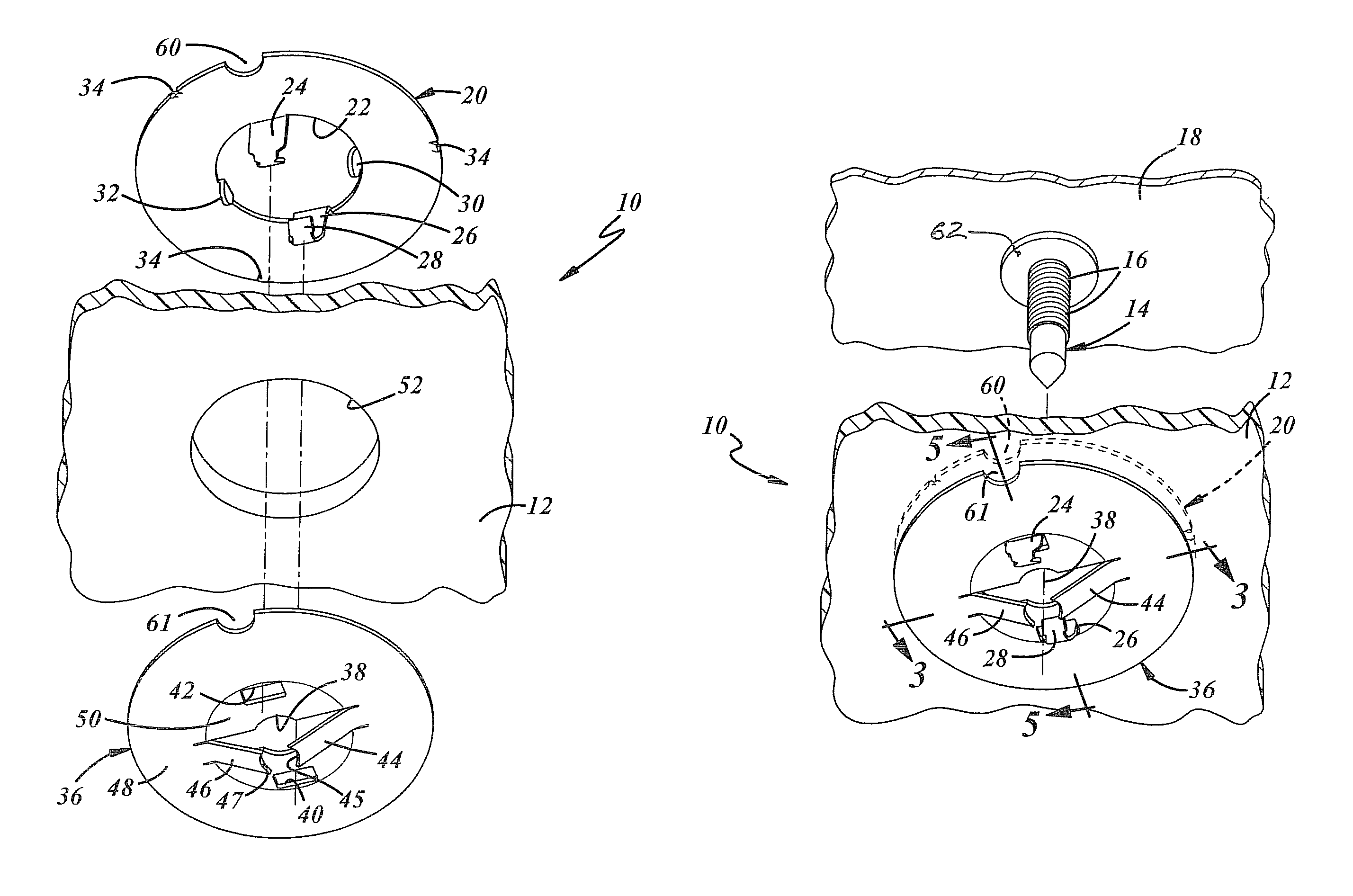

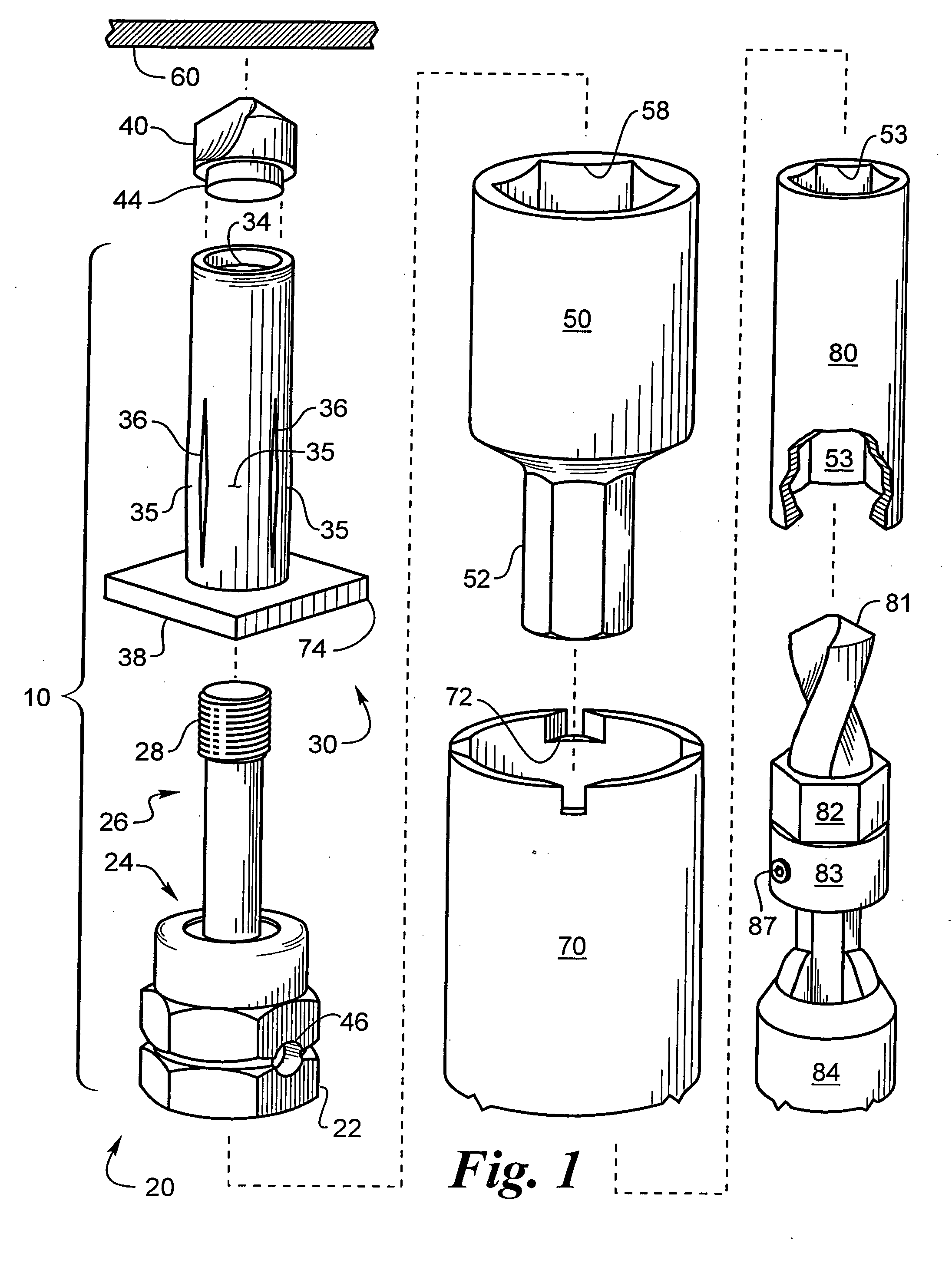

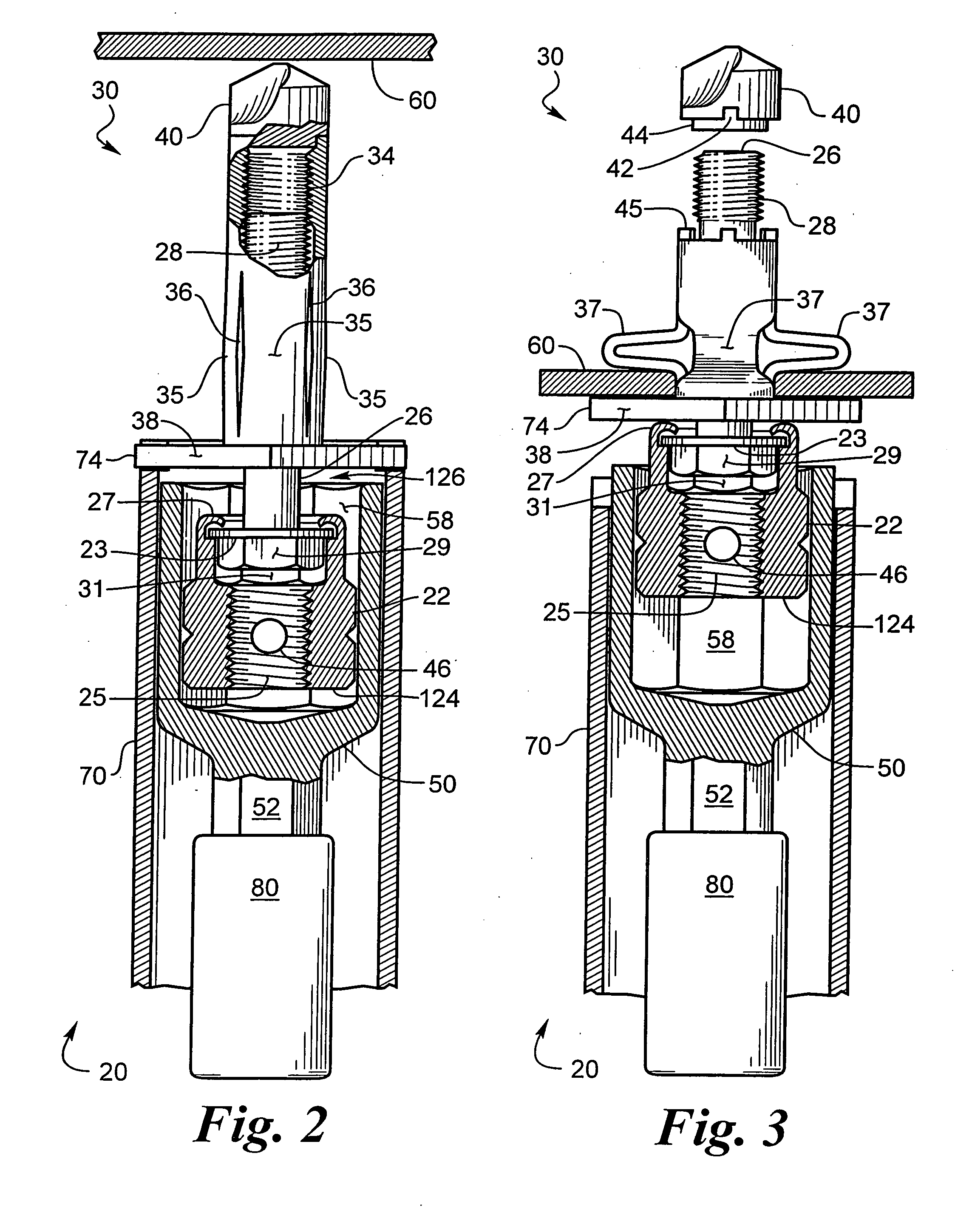

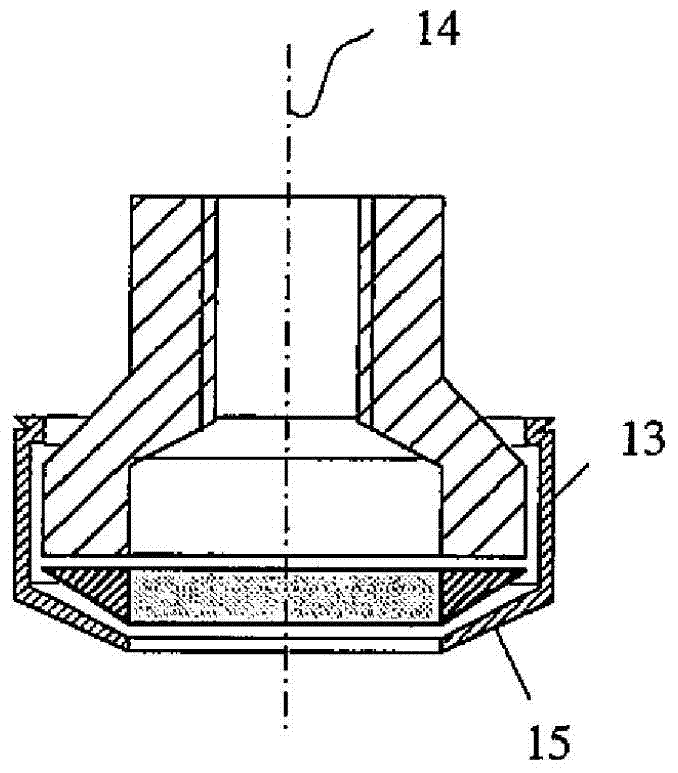

Mushrooming expandable anchor

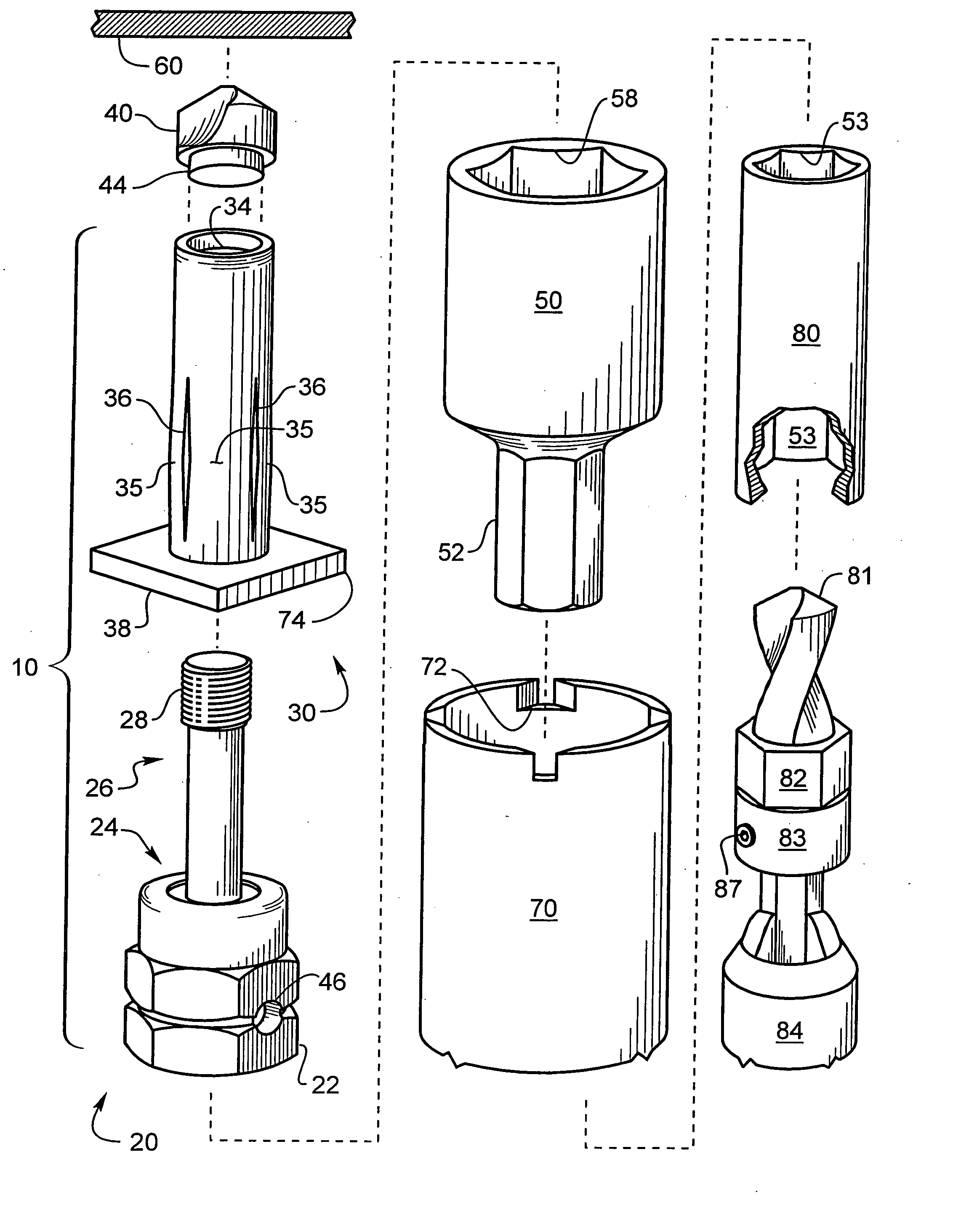

A self-anchoring fastening device for installation in supports for hanging pipes wires or other articles in ceilings is shaped for a socket to drive the device for an easy installation process. The device comprises a collapsible anchoring portion having radially expanding anchoring strips, which will not pull out of a hole drilled in a support. A drill drills a hole in a support and an expandable anchor is inserted through the hole. Threads internal to the expandable anchor cooperate with threads on a screw inserted therein to collapse the expandable anchor, providing anchoring strips over the hole such that the expandable anchor cannot be pulled out of the hole. A threaded portion of the base of the screw is suitable for attaching the article to be hung. The base may be a swivel head type. The drill may be on the expendable anchor assembly.

Owner:ILLINOIS TOOL WORKS INC

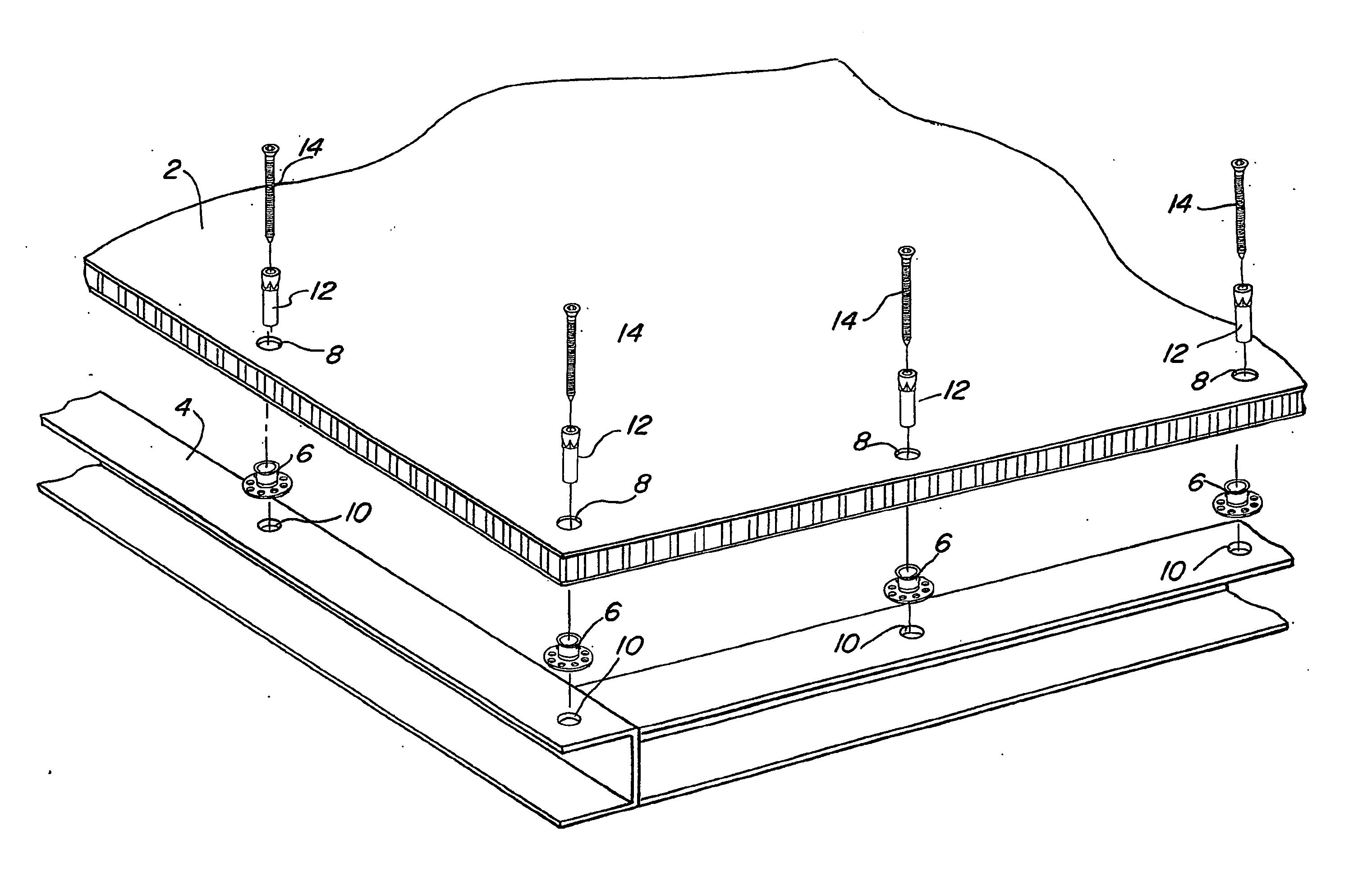

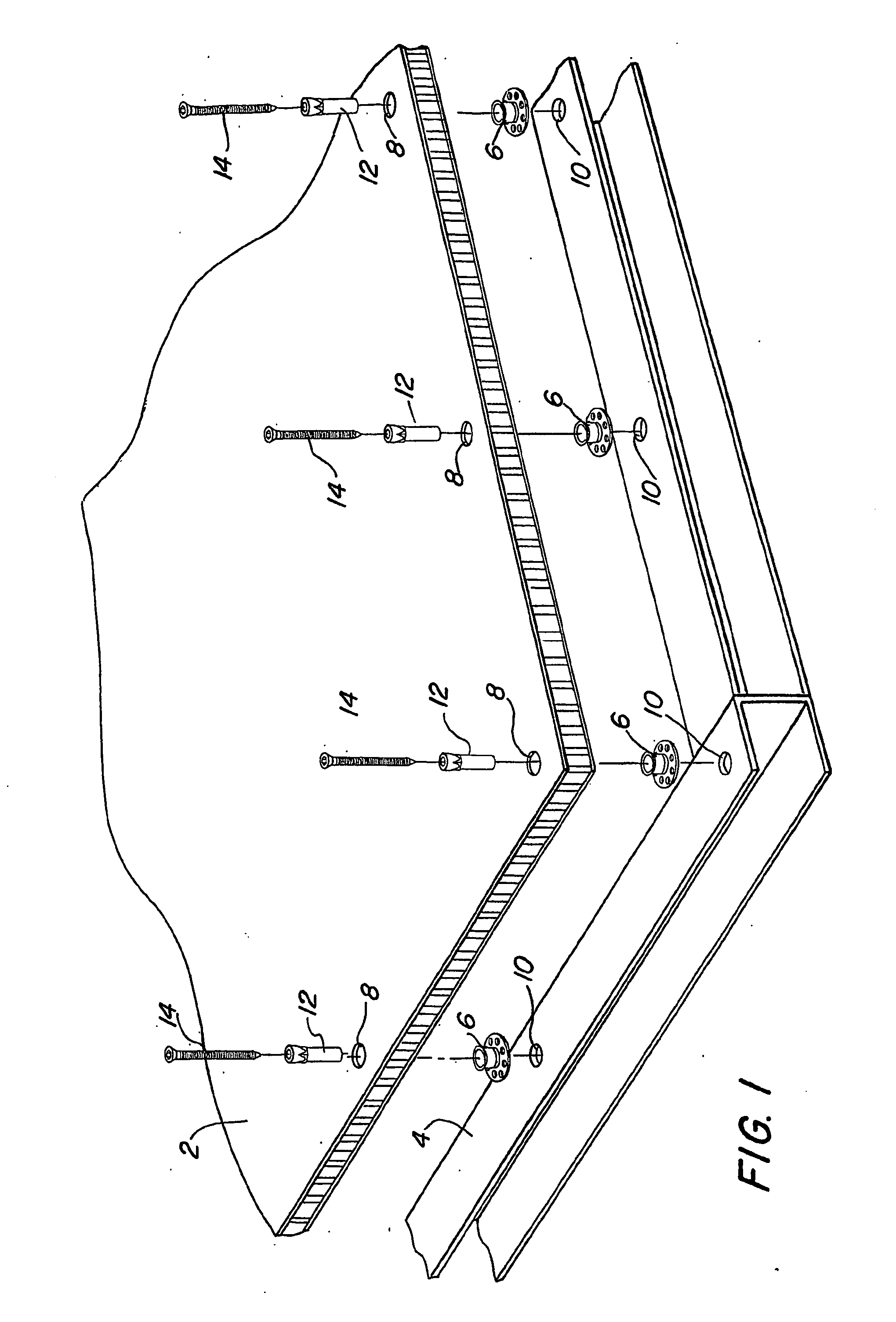

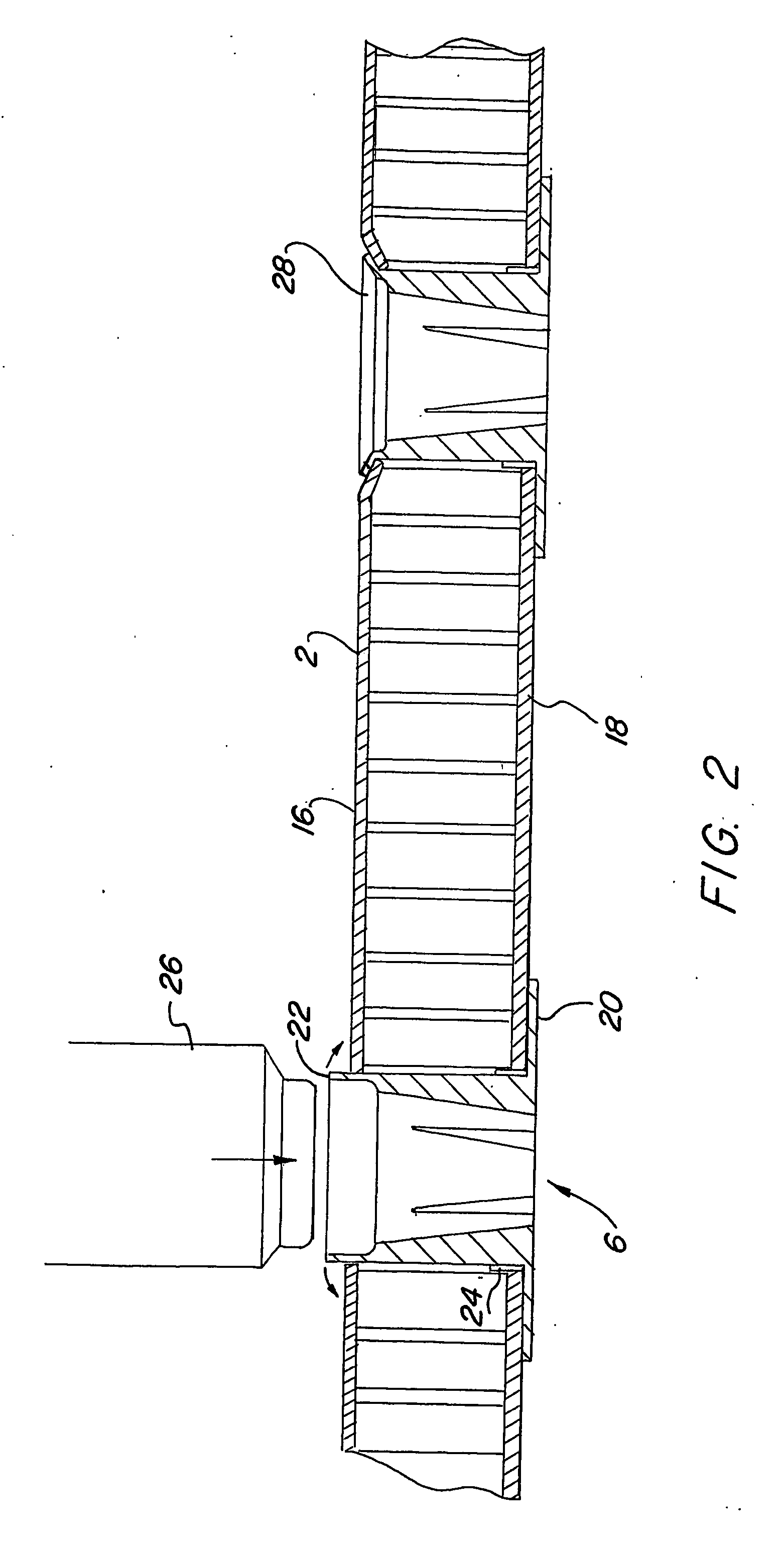

Expanded fastener for a honeycomb structure and method of assembly

InactiveUS20060137294A1Reduce vibrationPrevent exitSheet joiningScrewsEngineeringHoneycomb structure

An expanding panel fastener assembly for affixing a honeycomb panel structure to a support structure is disclosing having an insert member that attaches to a hole drilled within the honeycomb panel. A flexible sleeve and retainer assembly includes a molded flexible sleeve, an expander member and a retainer member. A sleeve spacer can further be attached to the flexible sleeve to assist in retaining it within the insert member. By providing a fastener for engagement with the retainer member, the expander member can further prevent withdrawal of the retainer member and can further assist in expanding the flexible sleeve to provide a sealing configuration with any support structure.

Owner:SPS TECH LLC

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

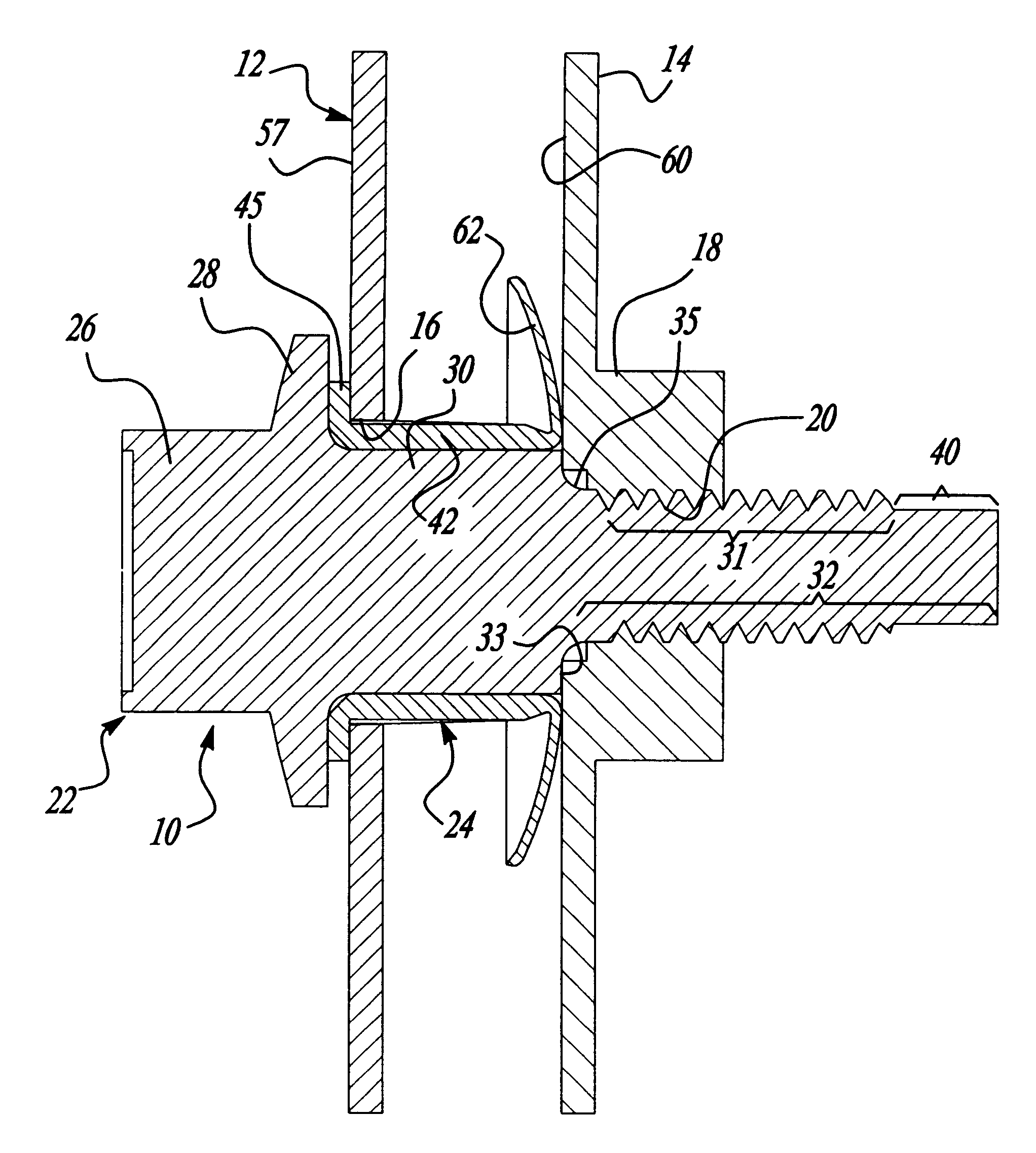

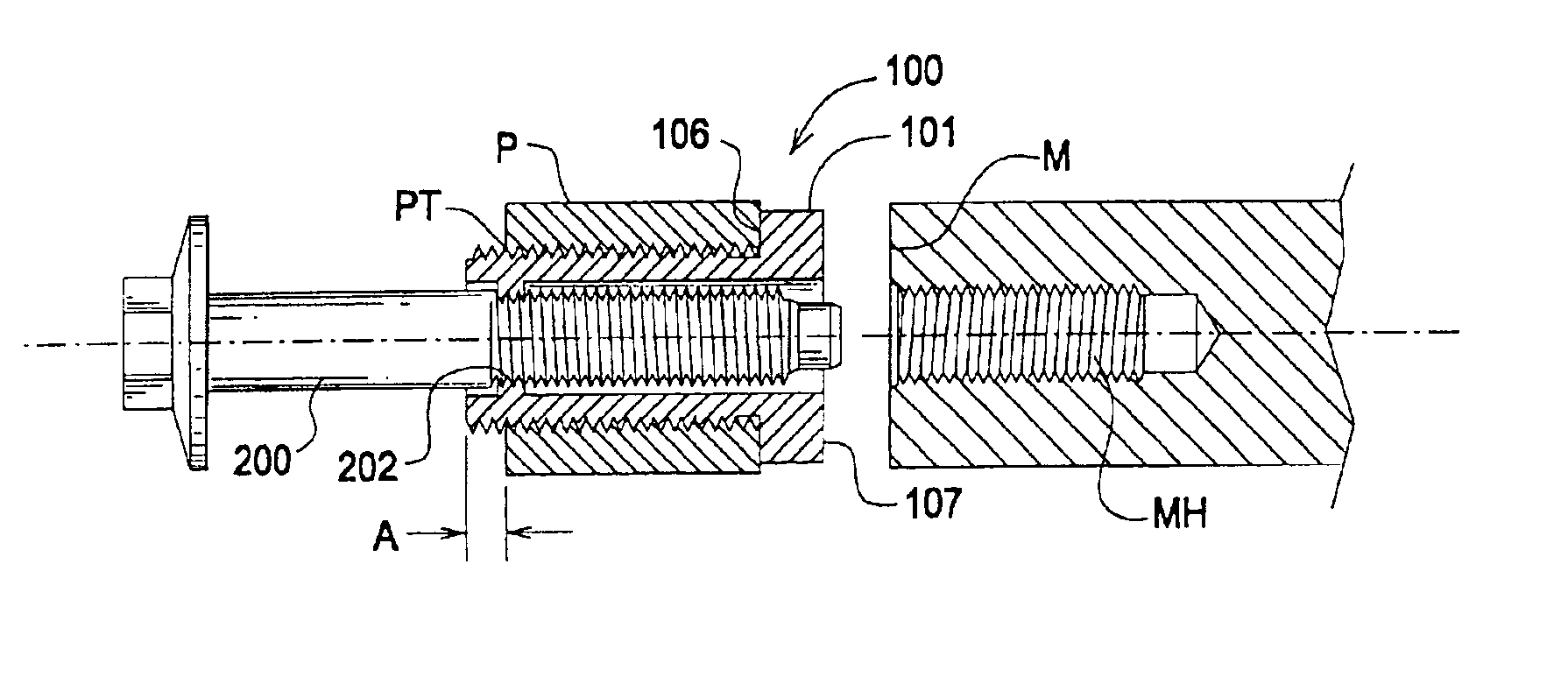

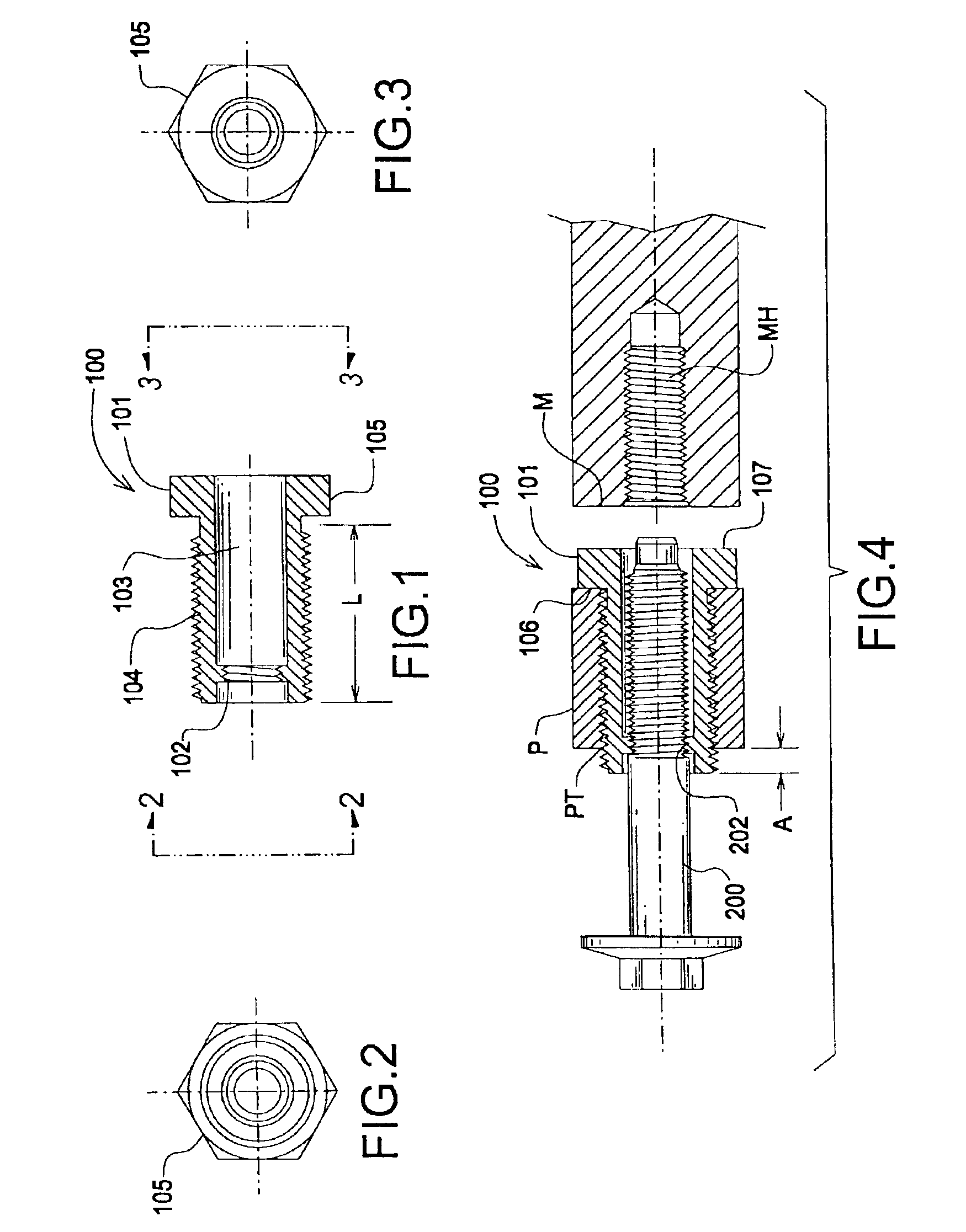

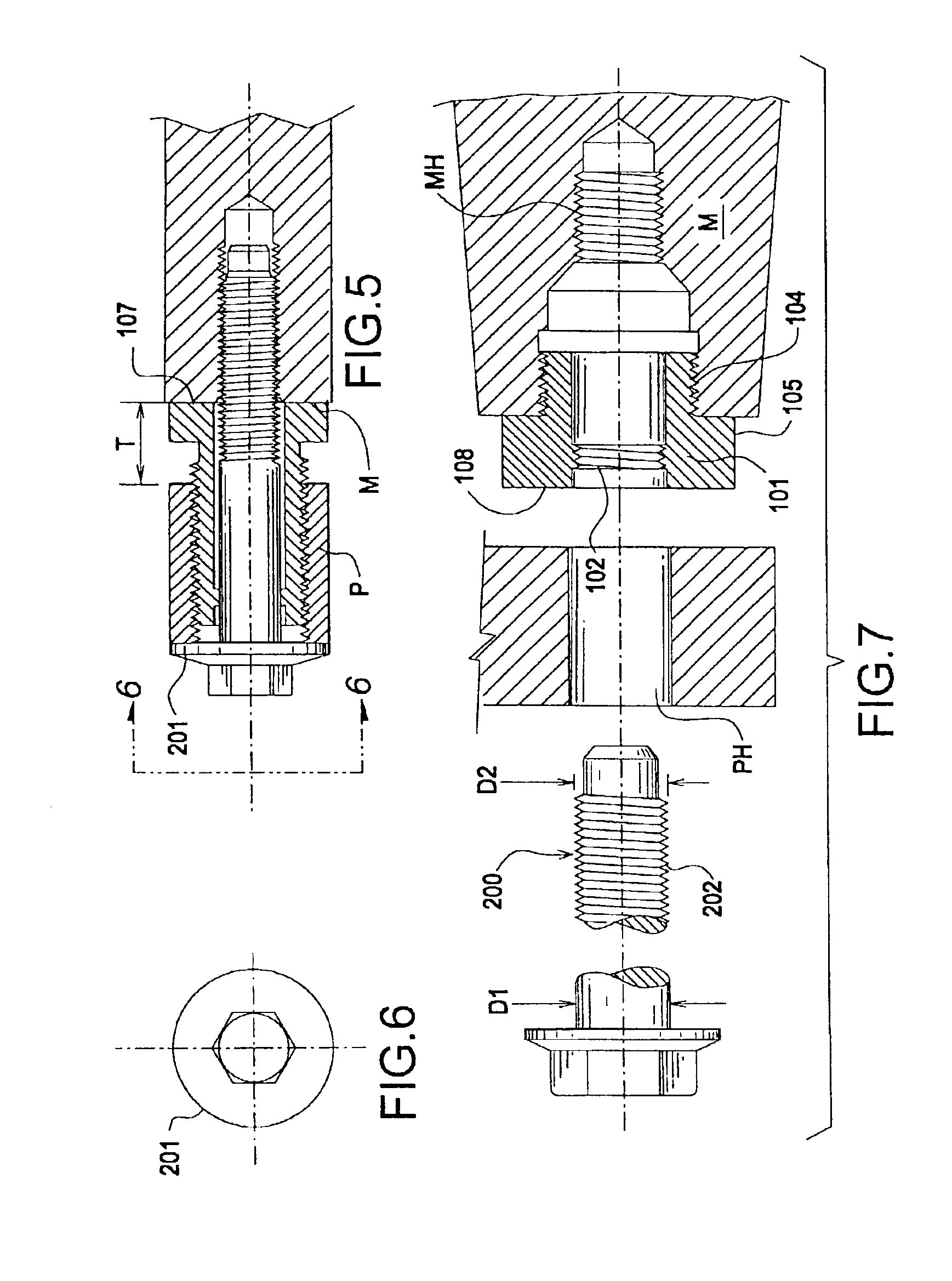

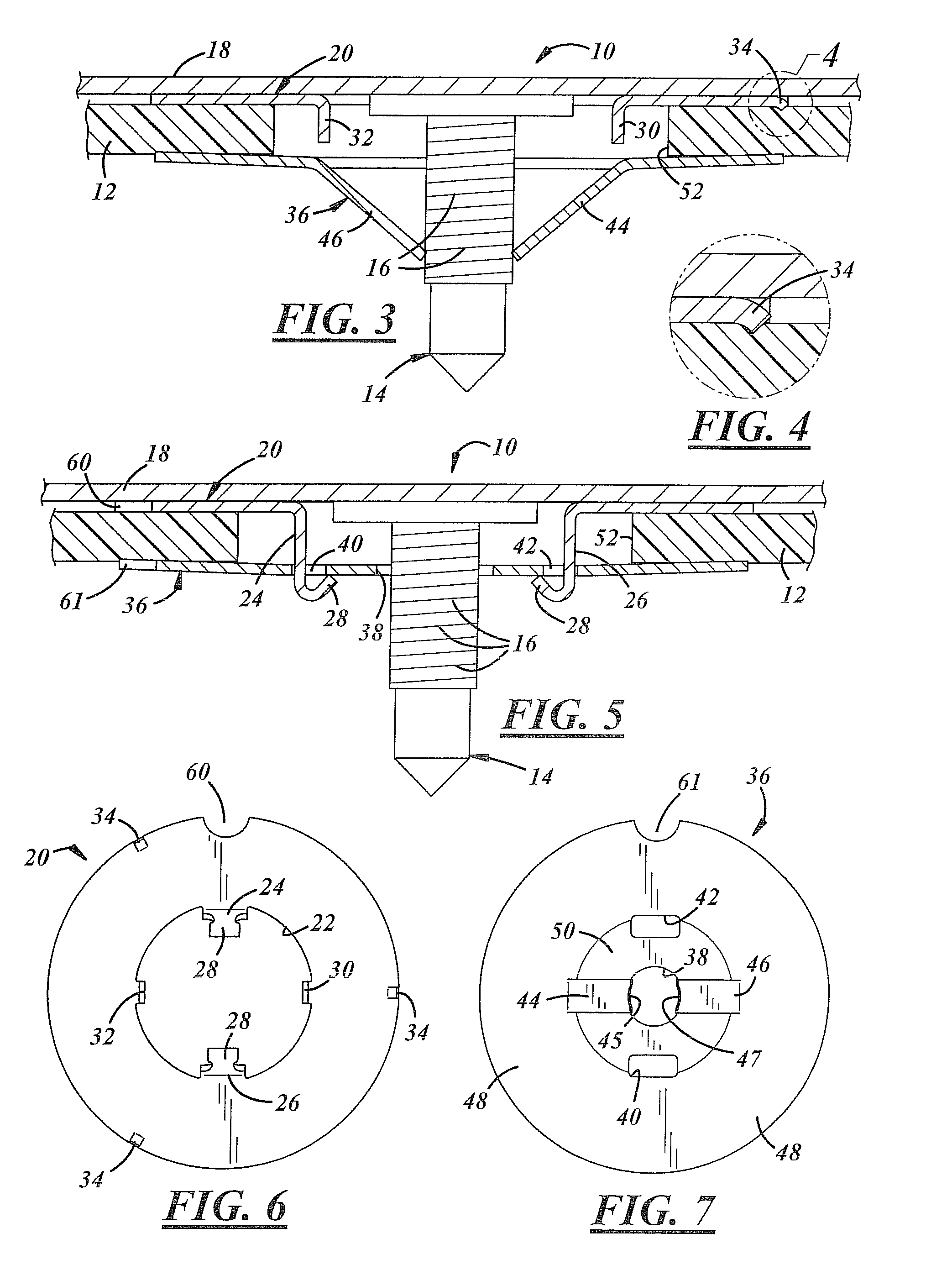

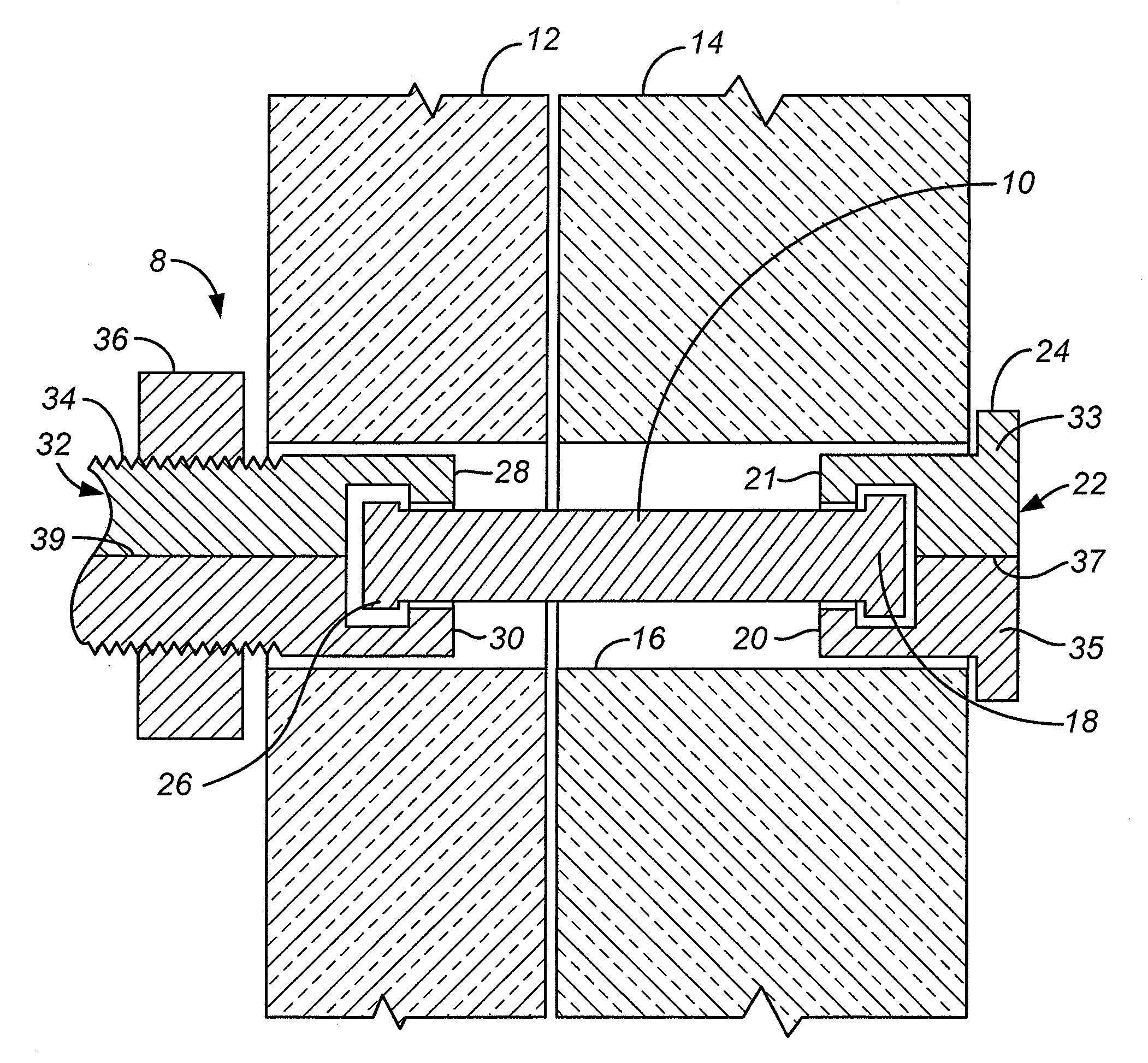

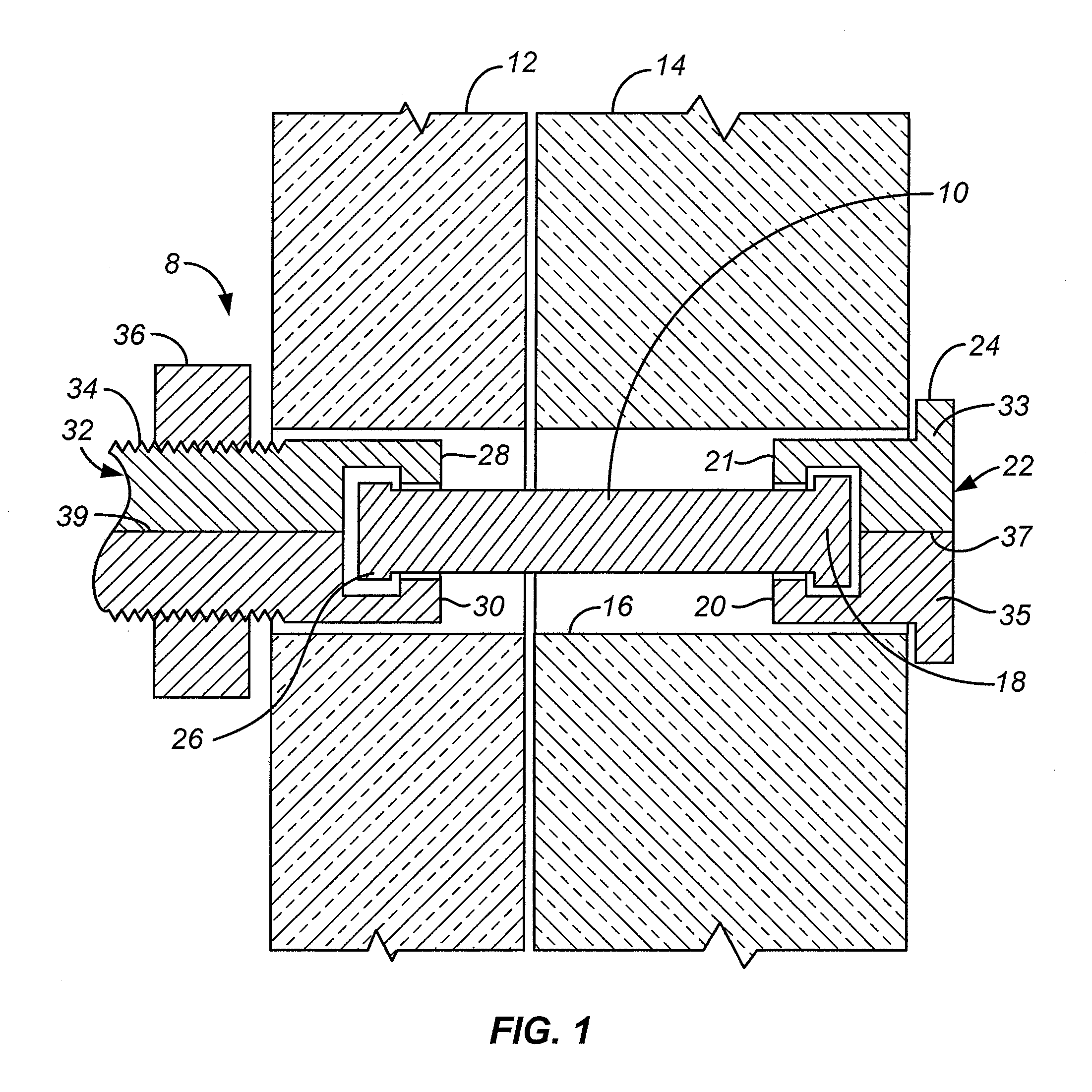

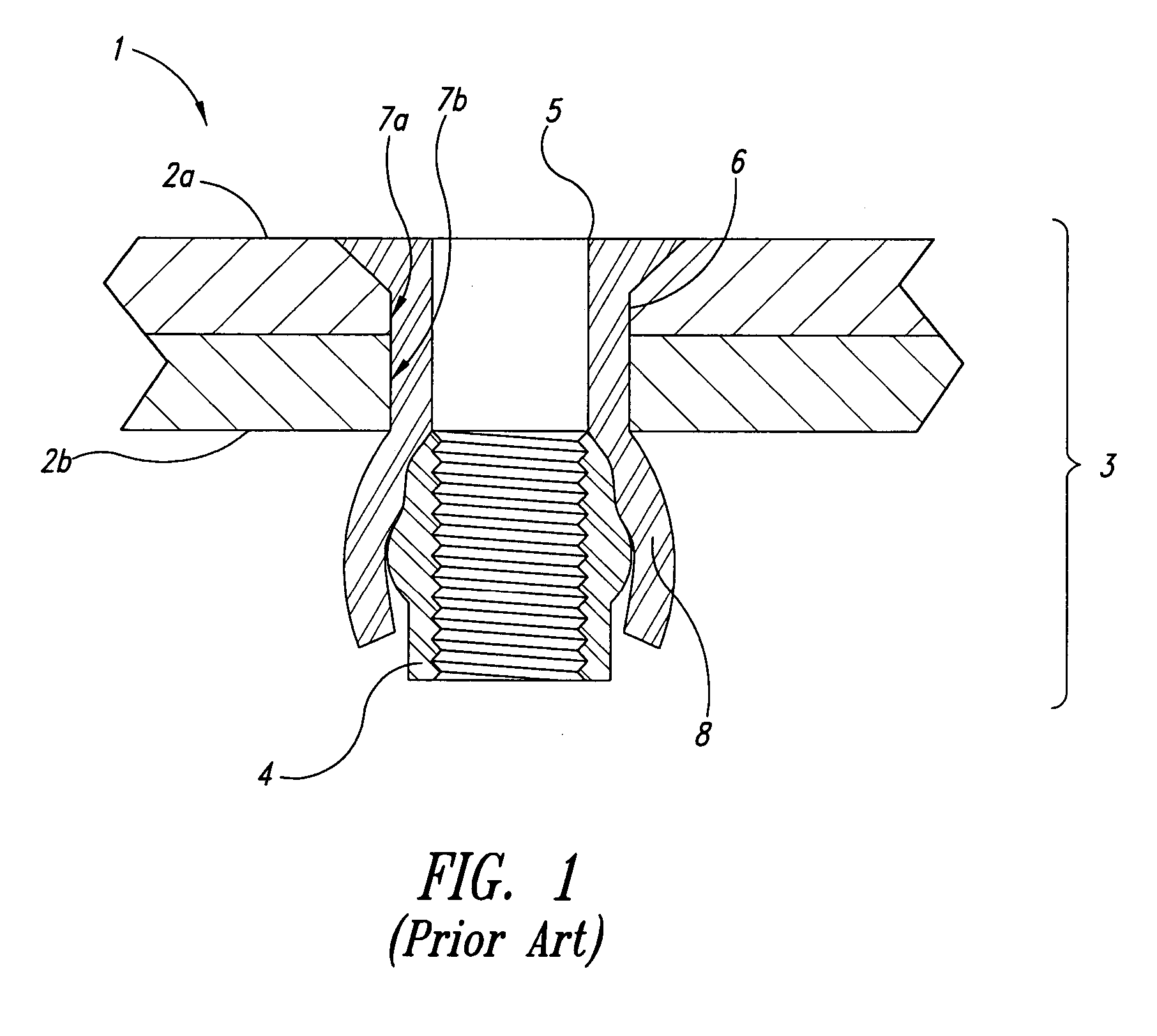

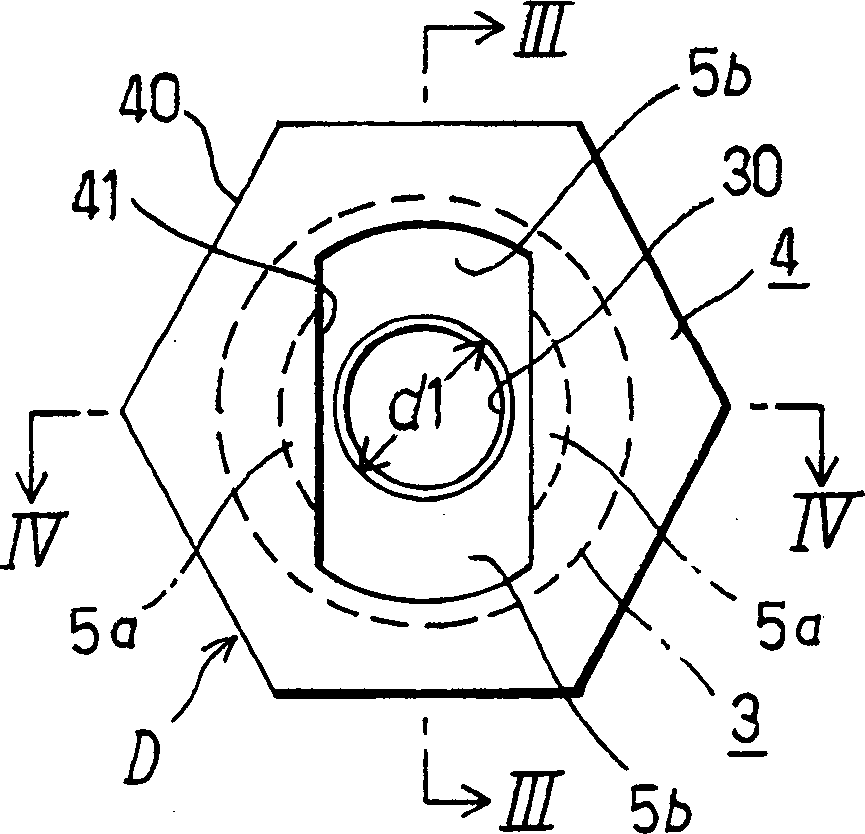

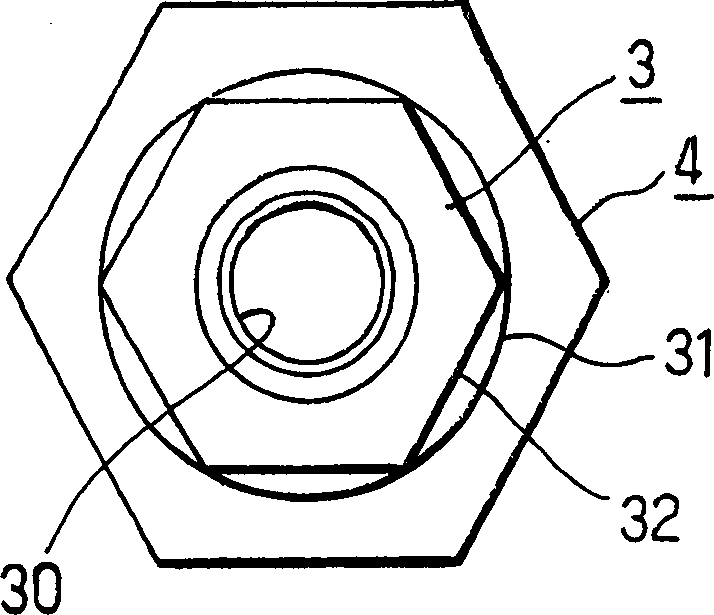

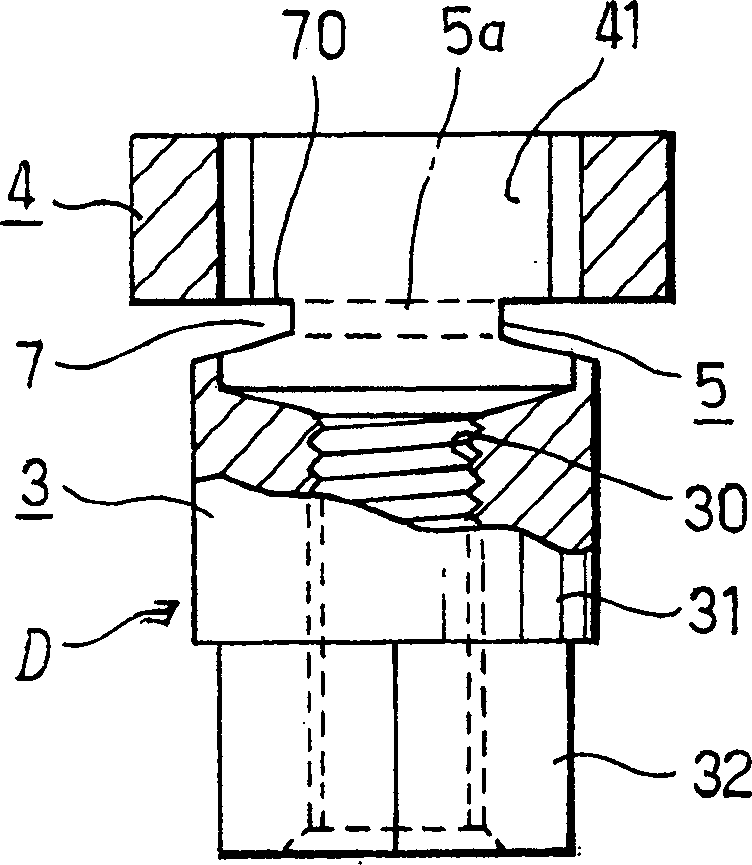

Tolerance compensating mounting device

The invention comprises a tolerance compensating mounting device comprising a bushing having an internal and external thread. The bushing is threaded into a part to be mounted to a surface. A bolt is then threaded into a bushing bore using the internal threads. The internal threads cause an interference fit between the bolt shank and the threads, temporarily preventing further insertion of the bolt. The bolt is then turned further, thereby turning the bushing and causing the bushing to unscrew from the part toward the mounting surface until the bushing seats on the mounting surface, thereby completely compensating for a tolerance gap. As the bolt is turned further, at a relatively low torque the sacrificial internal threads are stripped allowing the bolt to be fully torqued into the mounting surface hole, thereby simultaneously connecting the components with a properly torqued connection while compensating for a tolerance gap.

Owner:THE GATES CORP

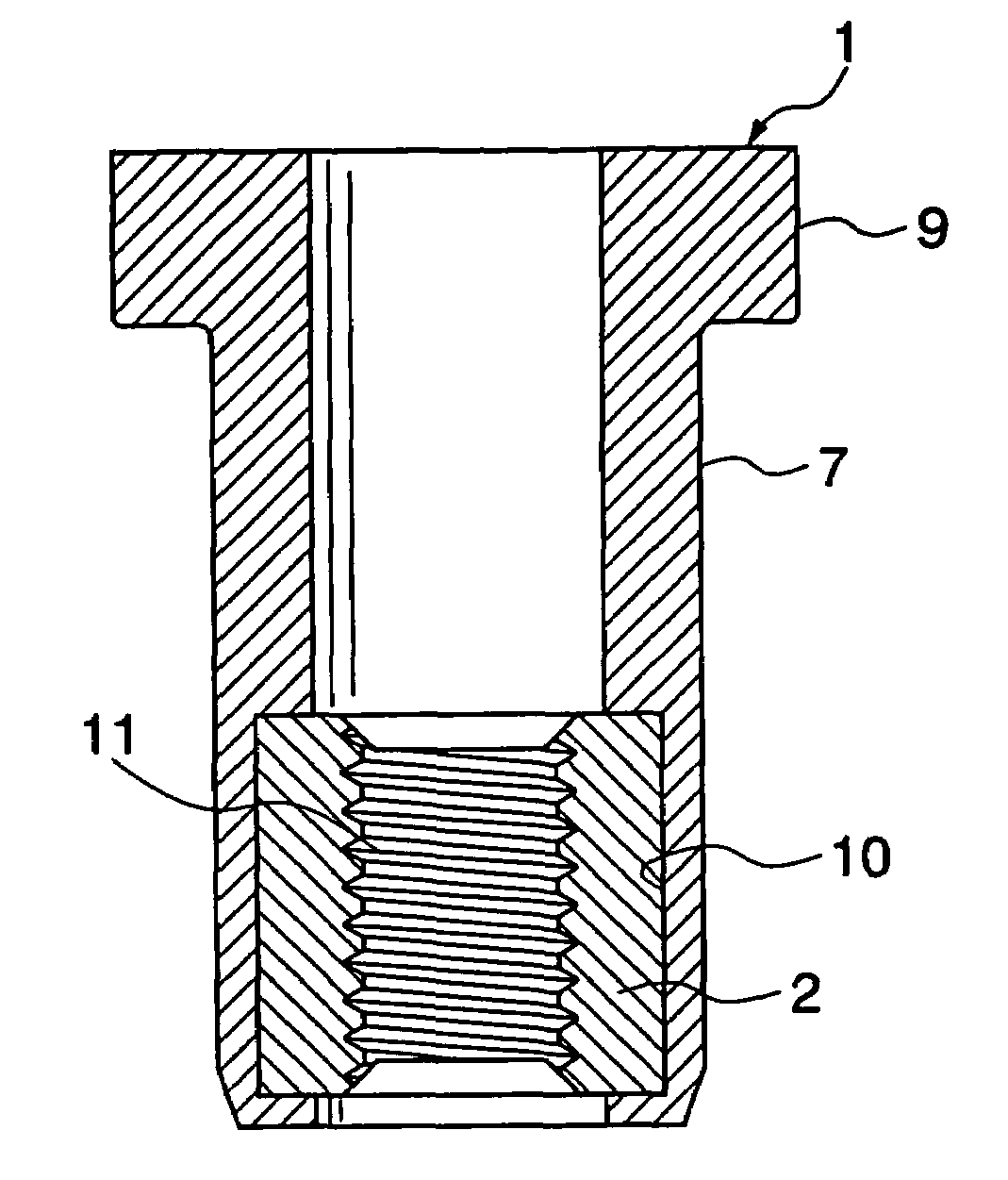

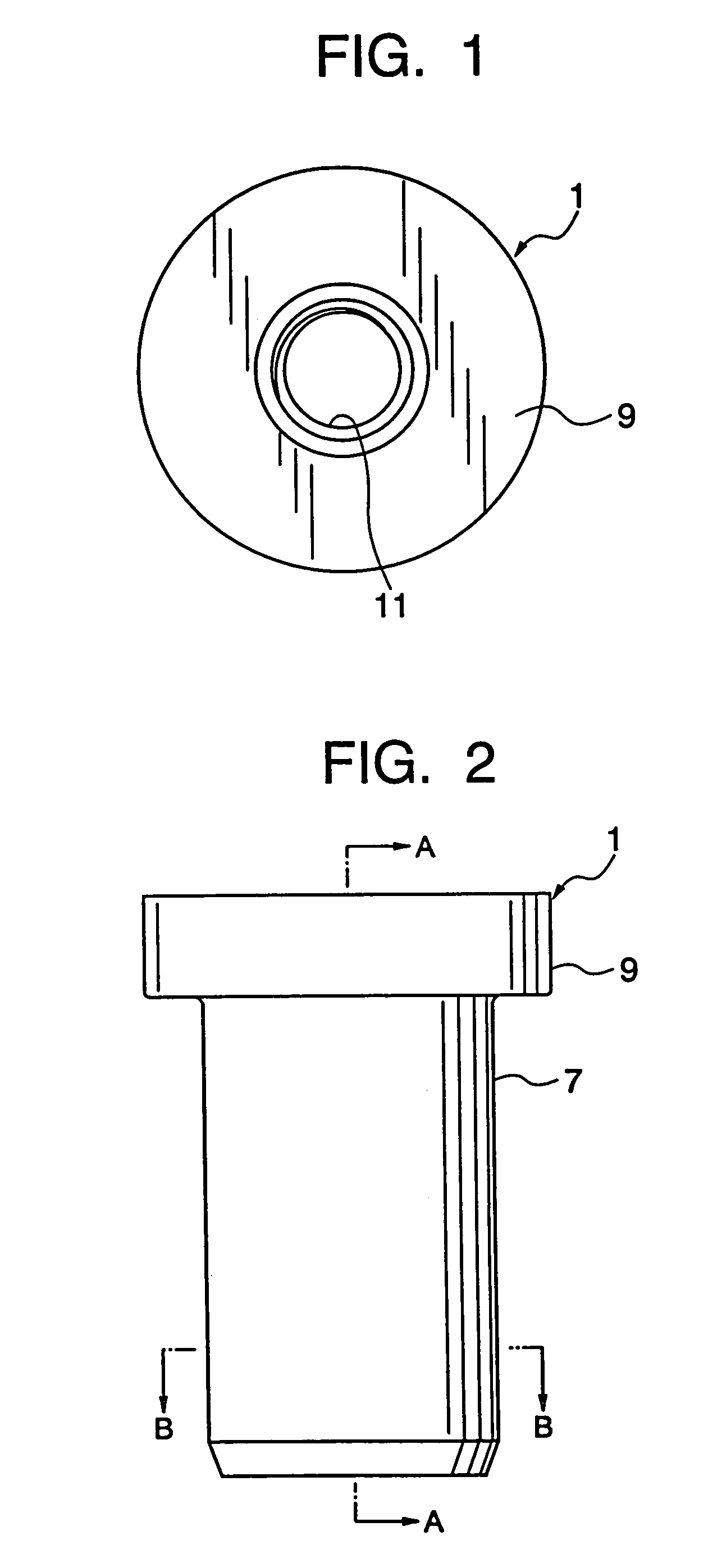

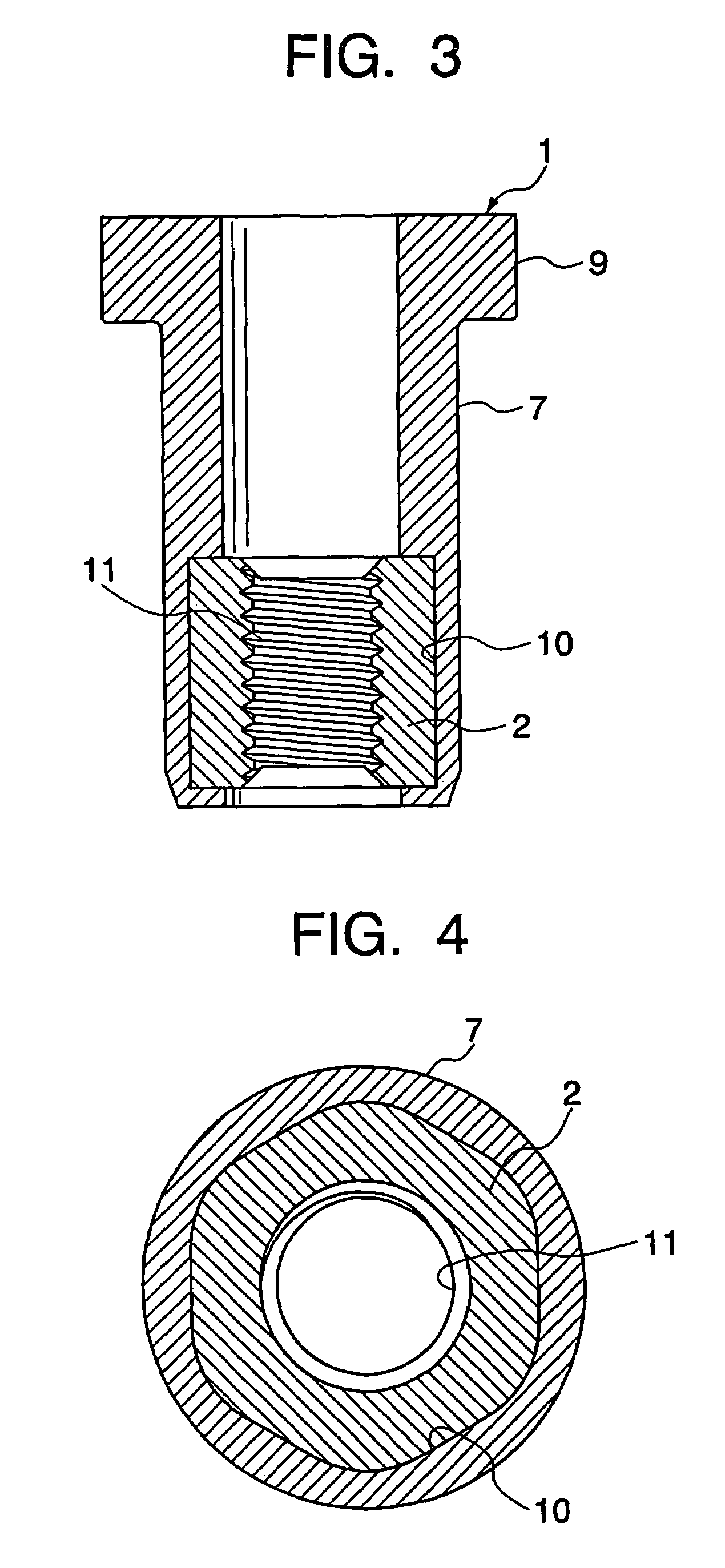

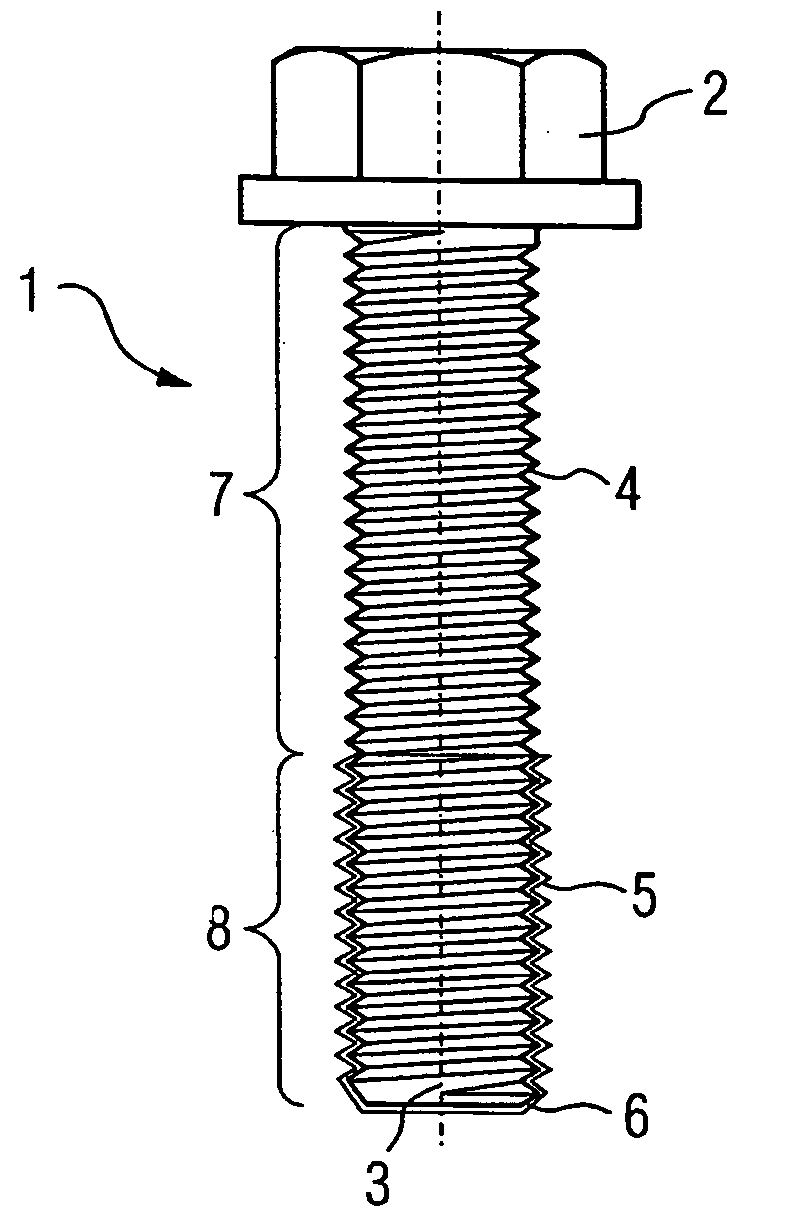

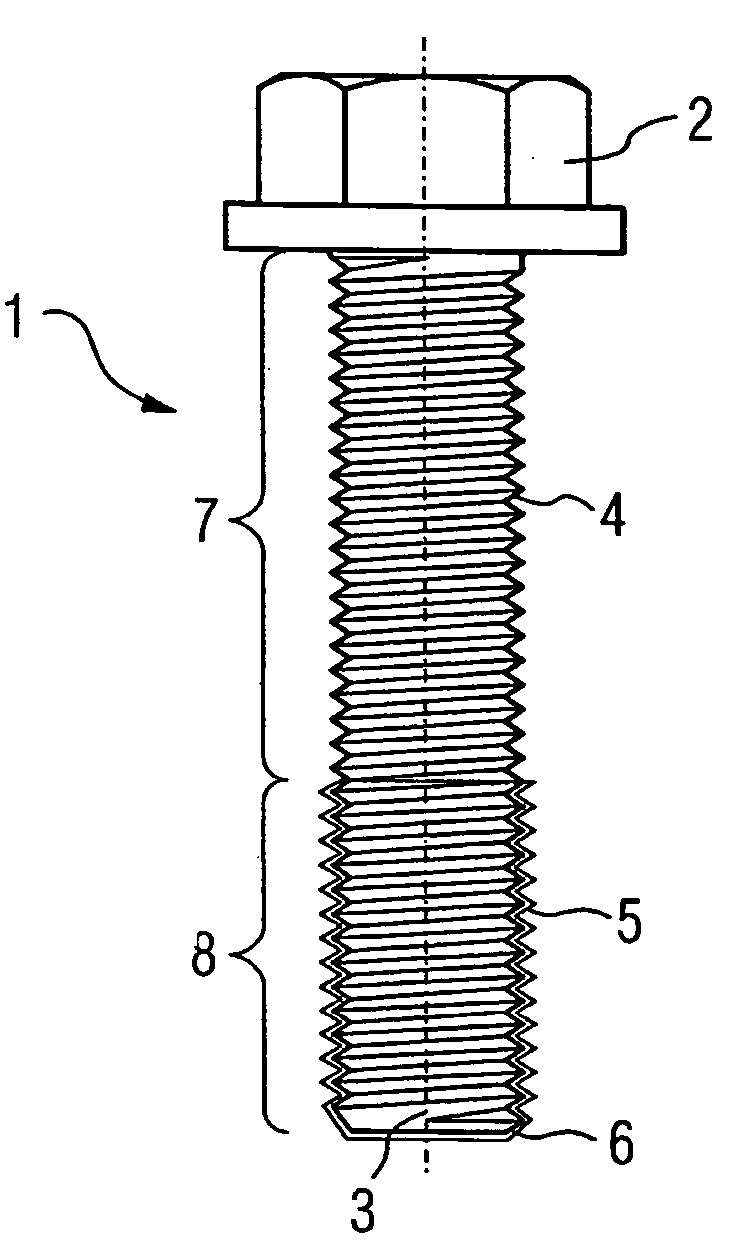

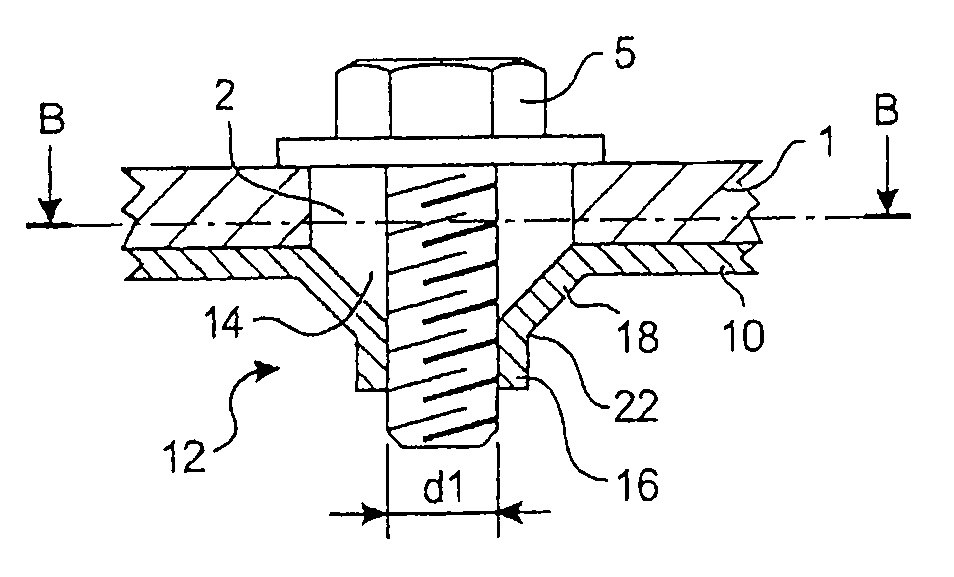

Elastic fastener

An elastic fastener 1 comprises a hollow tubular portion 7, an internally threaded portion 2 provided at one of the ends of the tubular portion 7, and a flange 9 formed at the other end of the tubular portion 7. The tubular portion 7 and the flange 9 are integrally formed of an elastomeric material, such as a styrene-based elastomer, a polyamide-based elastomer and a polyester-based elastomer. The internally threaded portion 2 is formed of a rigid resin material such as a polycarbonate resin. The internally threaded portion 2 is integrally fixed to the tubular portion 7 in a hole of the tubular portion.

Owner:NEWFREY

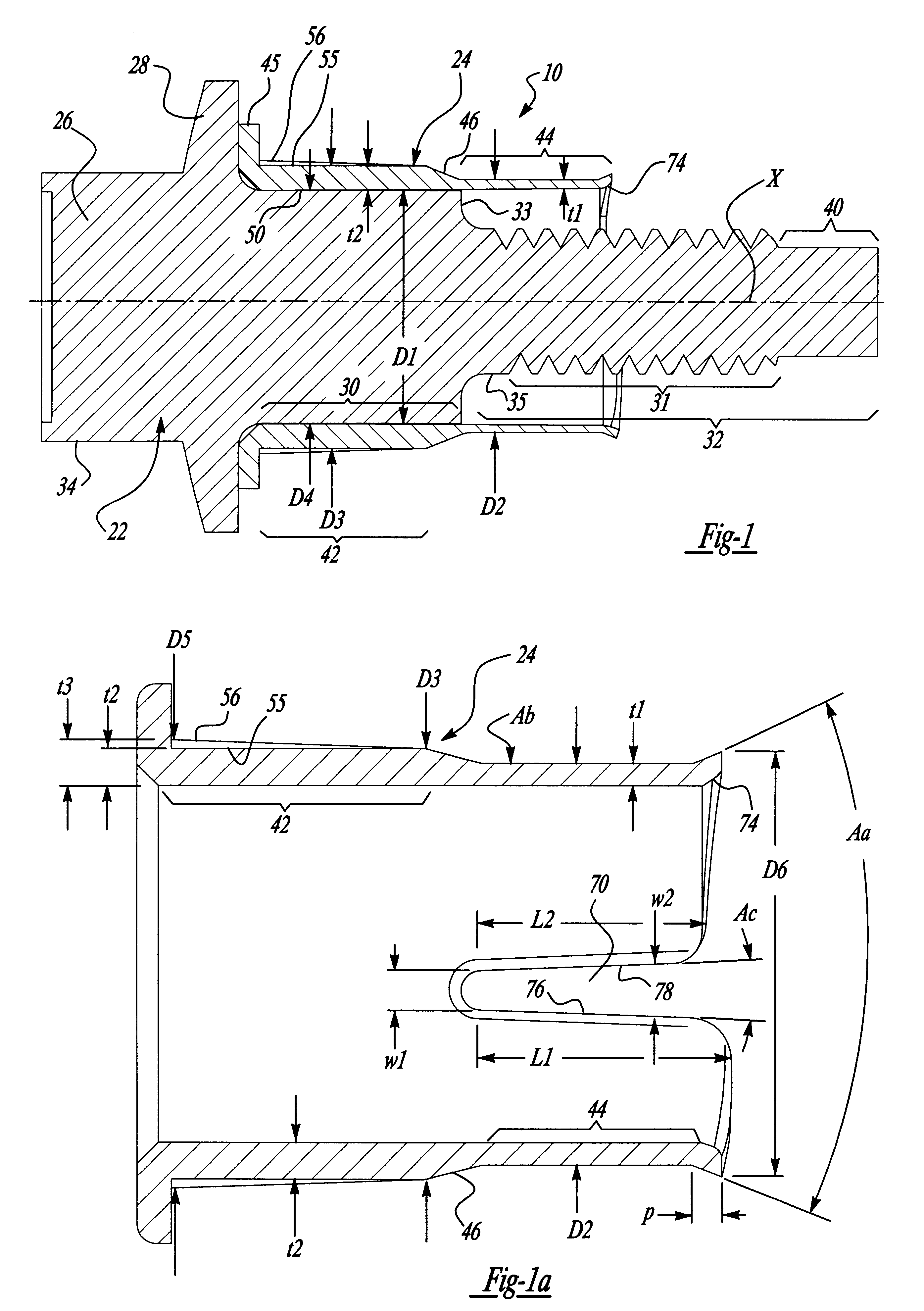

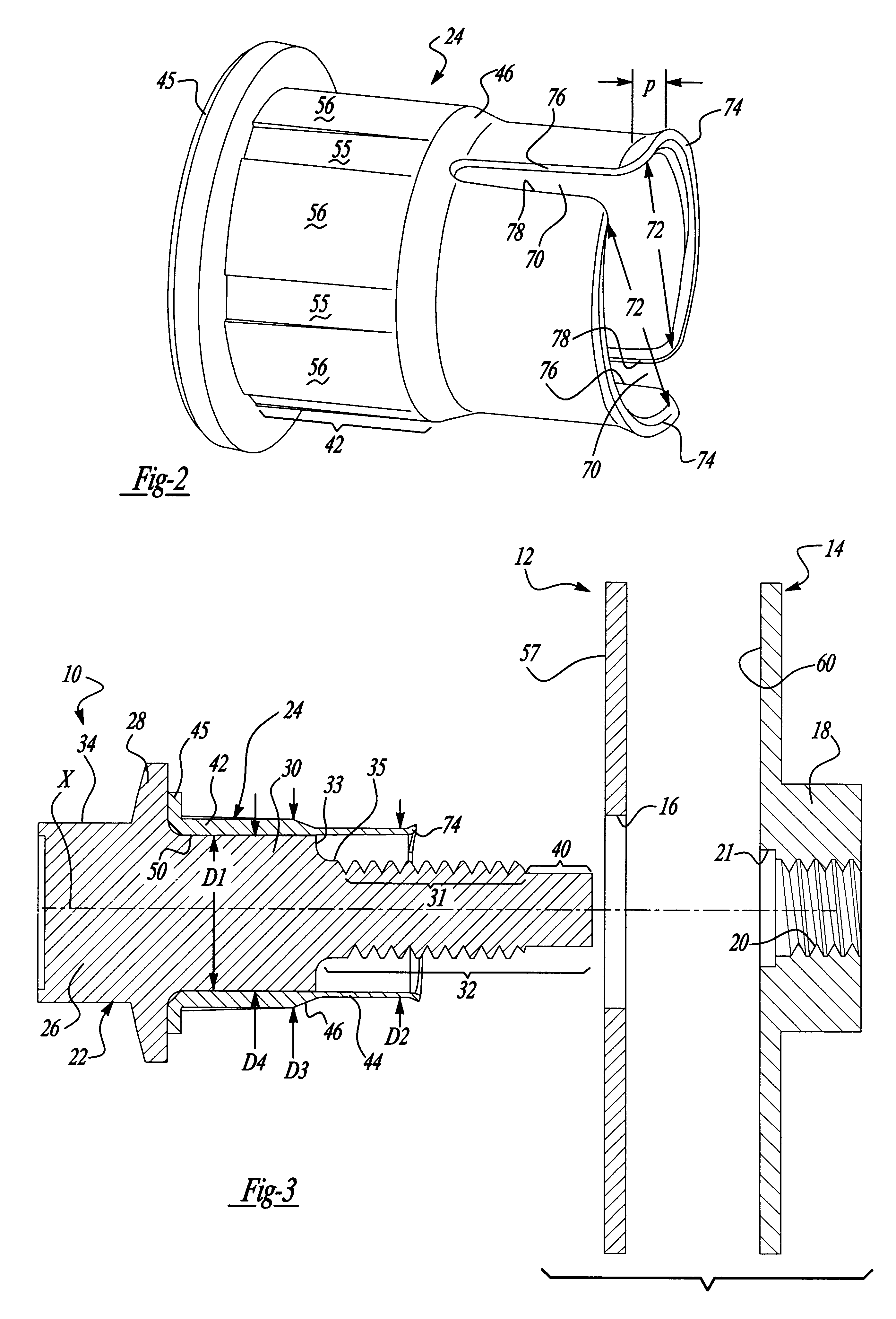

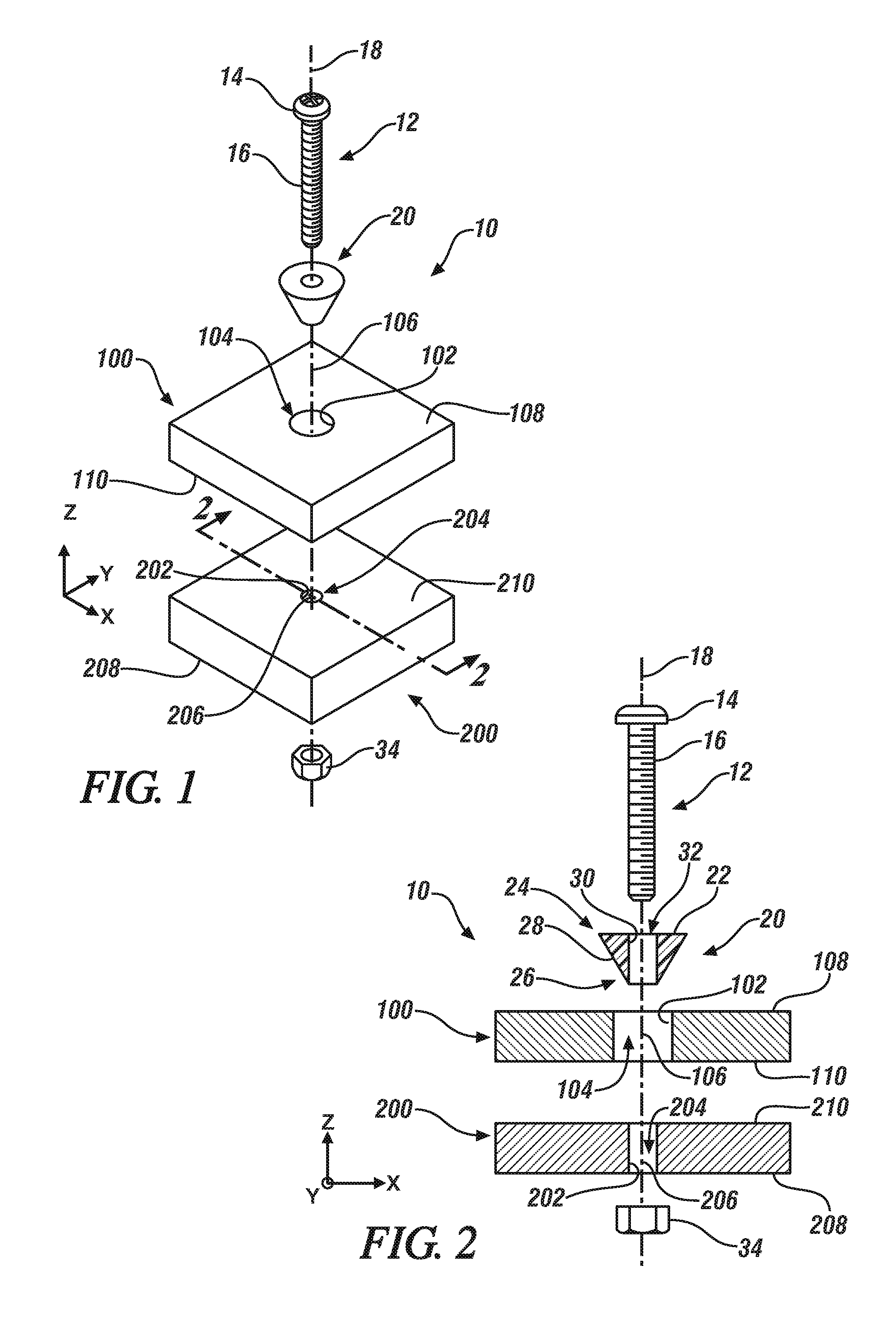

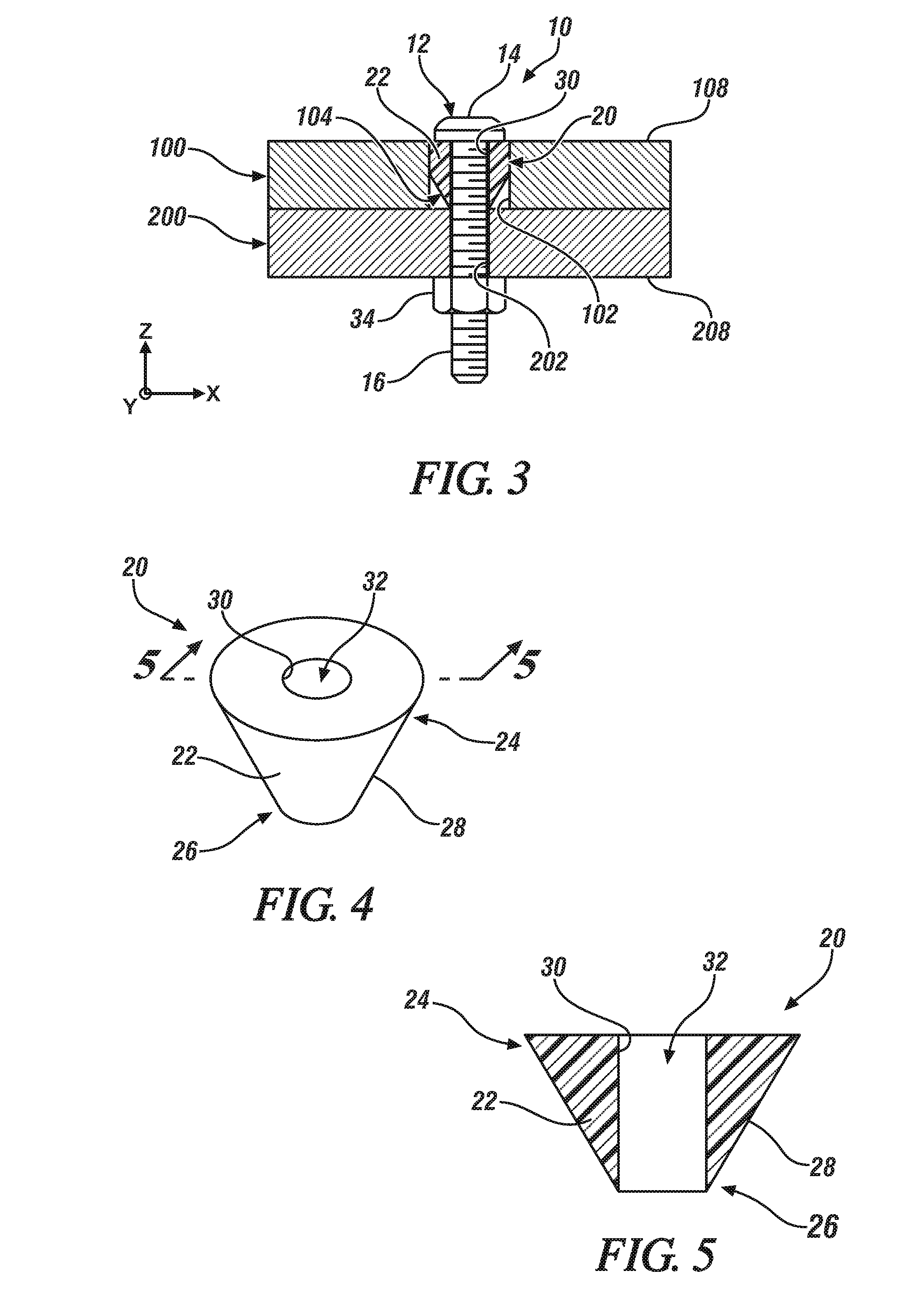

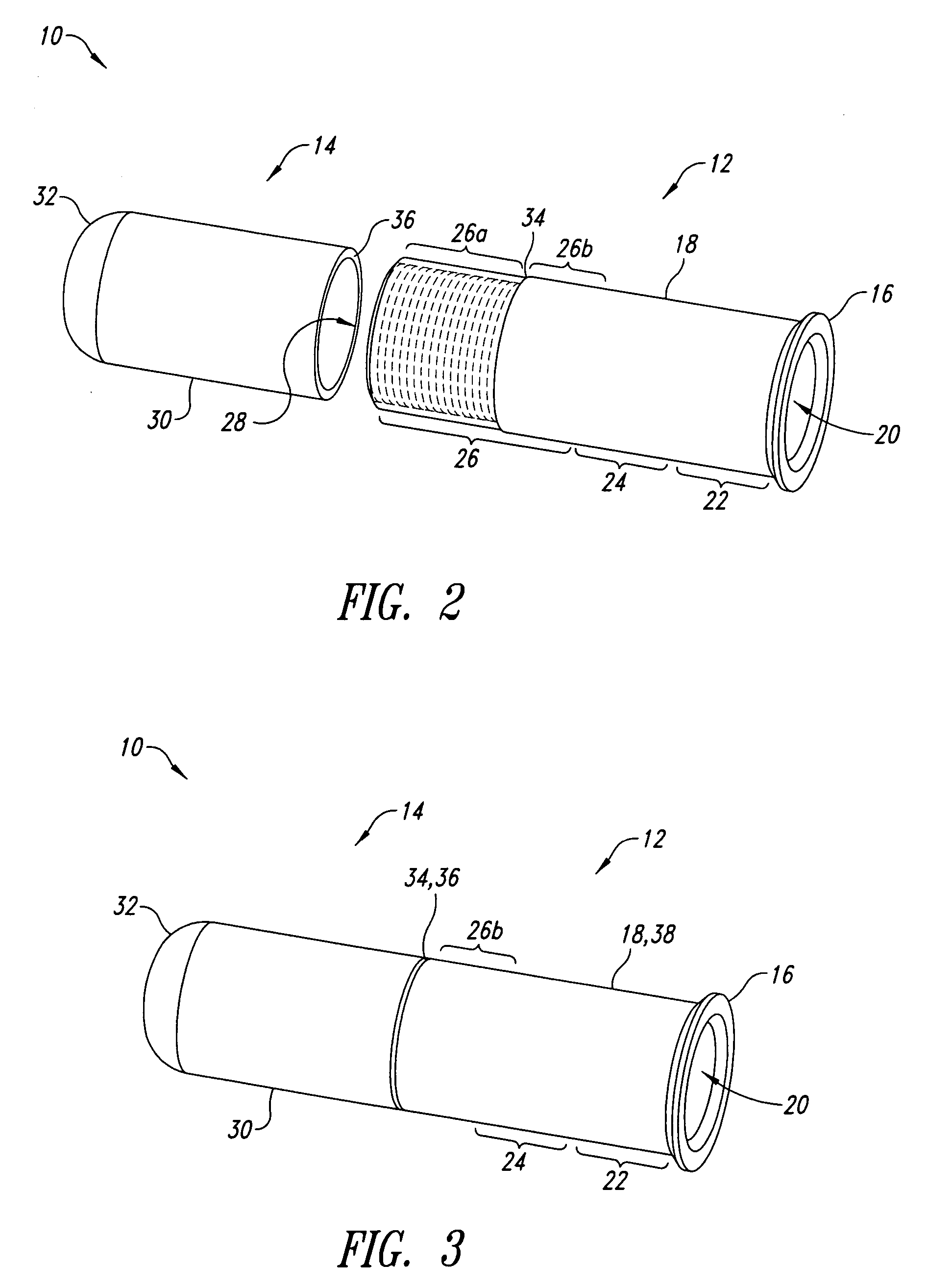

Elastically averaged alignment systems and methods

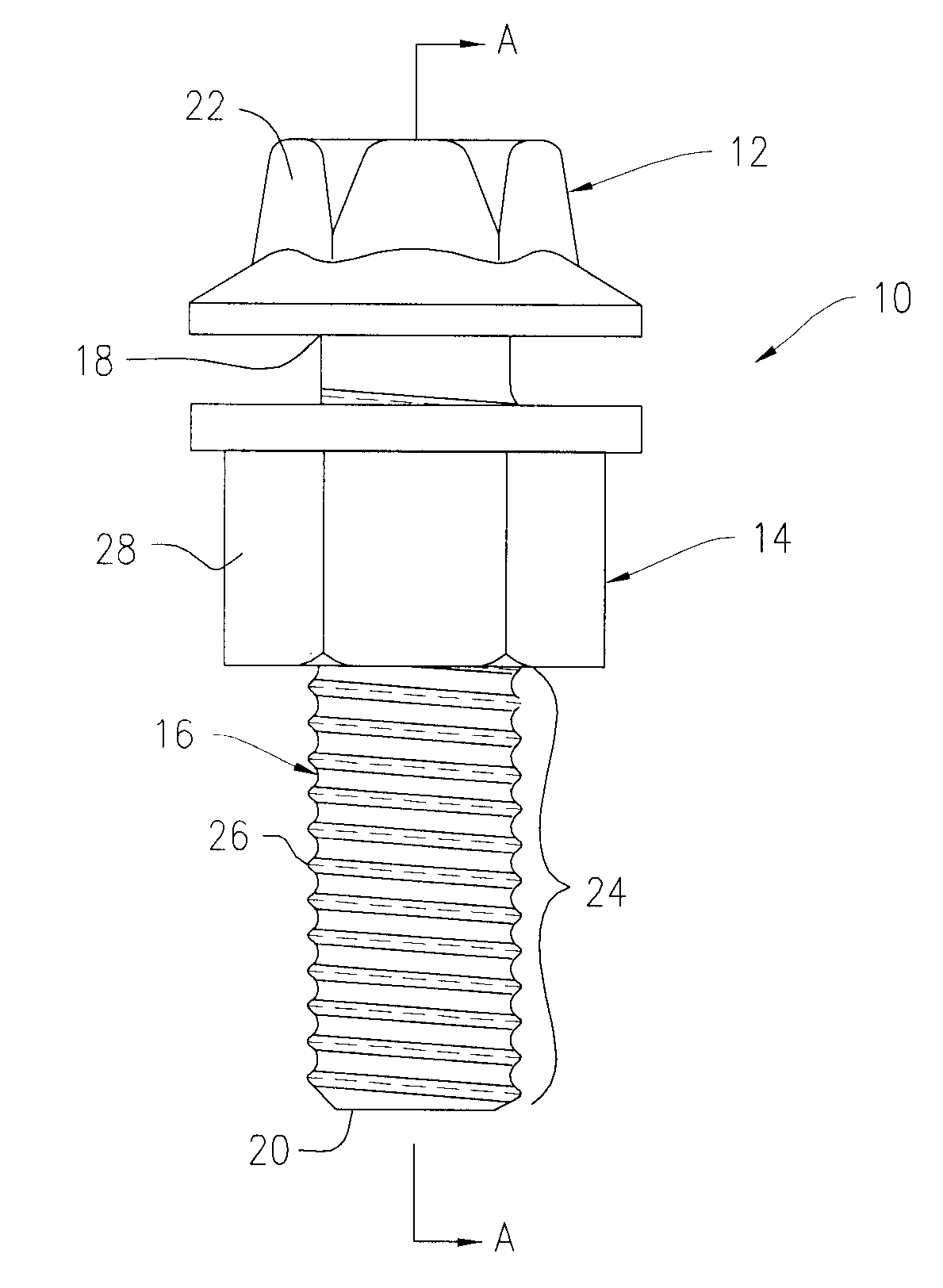

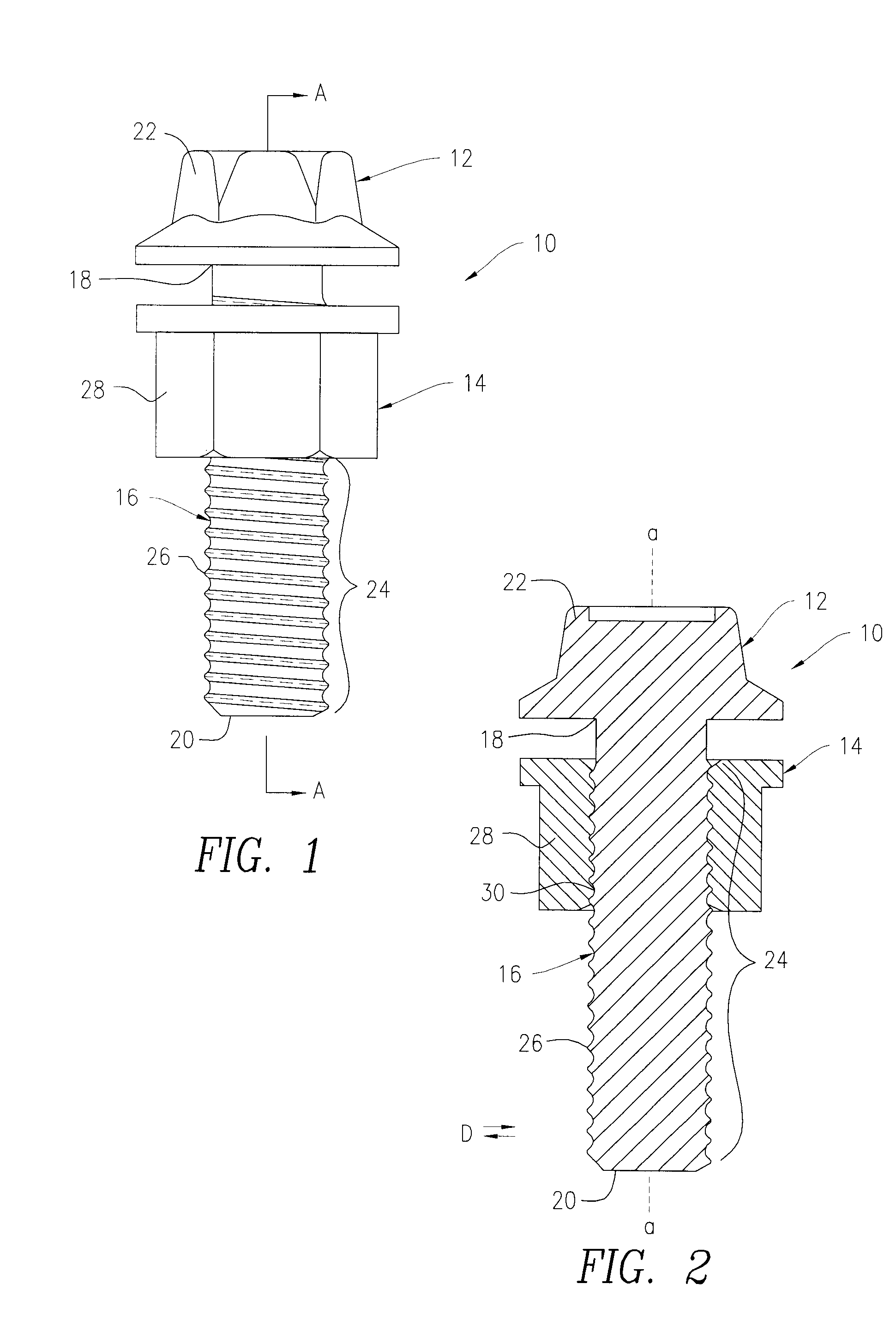

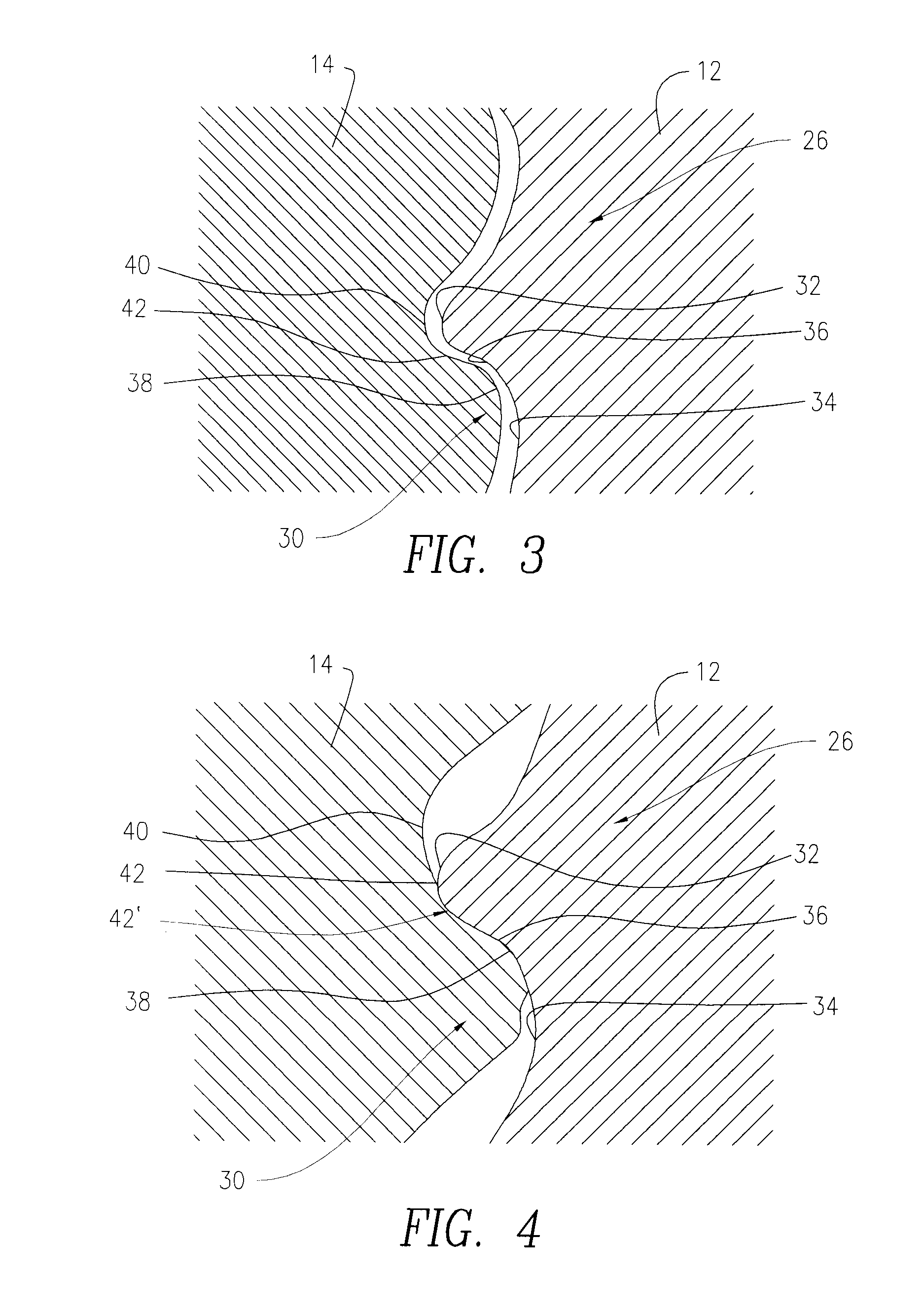

In one aspect an elastically averaged alignment system is provided. The alignment system includes a first component comprising an inner wall defining an alignment aperture, a second component including a receiving aperture, and a fastener configured for insertion into the alignment aperture and the receiving aperture to couple the first and second components. The system further includes an elastically deformable collar inserted onto the fastener. The collar is configured to elastically deform against the inner wall to an elastically averaged final configuration upon insertion into the alignment aperture, thereby coupling the first and second components to facilitate aligning the first component and the second component in a desired orientation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Antigalling anchor bolt and method

InactiveUS20100111639A1Reduce wearReduce contact areaScrewsDeformable fastenersEngineeringAnchor bolt

Disclosed is an anchor bolt including a wedge having a surface with a plurality of protrusions and a sleeve in operable communication with the surface. Furthermore, the sleeve is expandably receptive to the surface.

Owner:BLACK & DECKER INC

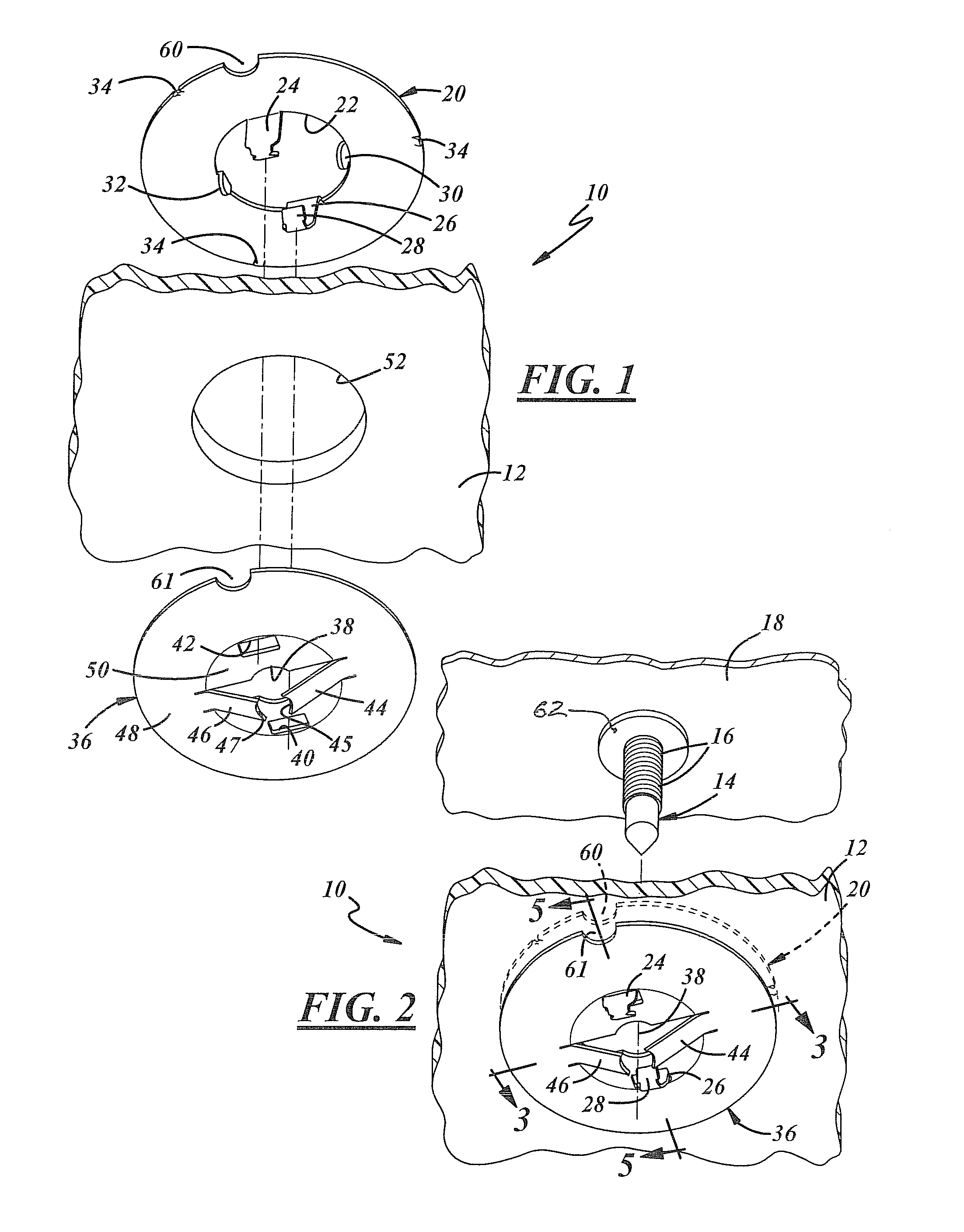

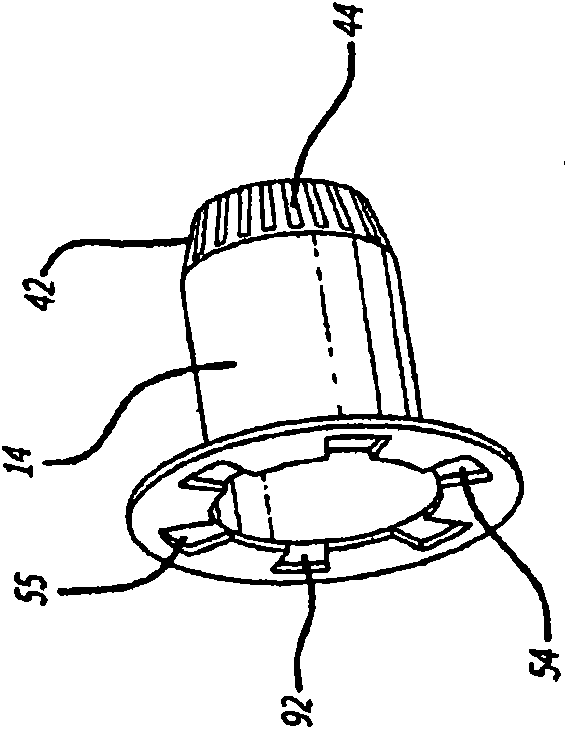

Device for securing a panel to a mounting stud

A device for securing a panel or the like to a mounting stud having external teeth includes an annular first body having an inner periphery and at least one lock finger extending from such inner periphery. An annular second body has a center opening, at least one lock opening spaced from the center opening for receiving the lock finger to lock the first and second bodies together, and at least one leg extending inwardly overlying the center opening for engaging the external teeth on the mounting stud. The second body is adapted for assembly to the first body with a panel or the like between the bodies such that the center opening can be mounted over the mounting stud with the at least one finger engaging the teeth on the mounting stud to prevent removal.

Owner:ALPHA STAMPING

Mechanically locked blind bolt fastener

The present invention provides a blind bolt fastener having a core bolt. The core bolt has a threaded portion and a non-threaded portion engaging a deformable sleeve and a body. A protrusion extends from the sleeve or the body to engage a groove in the core bolt to prevent axial movement of the core bolt with respect to the body and the sleeve. An optional drive nut is positioned between a head of the body and wrenching flats of the core bolt. The drive nut has protrusions engaging mating members in the head of the body.

Owner:PRATT JOHN D

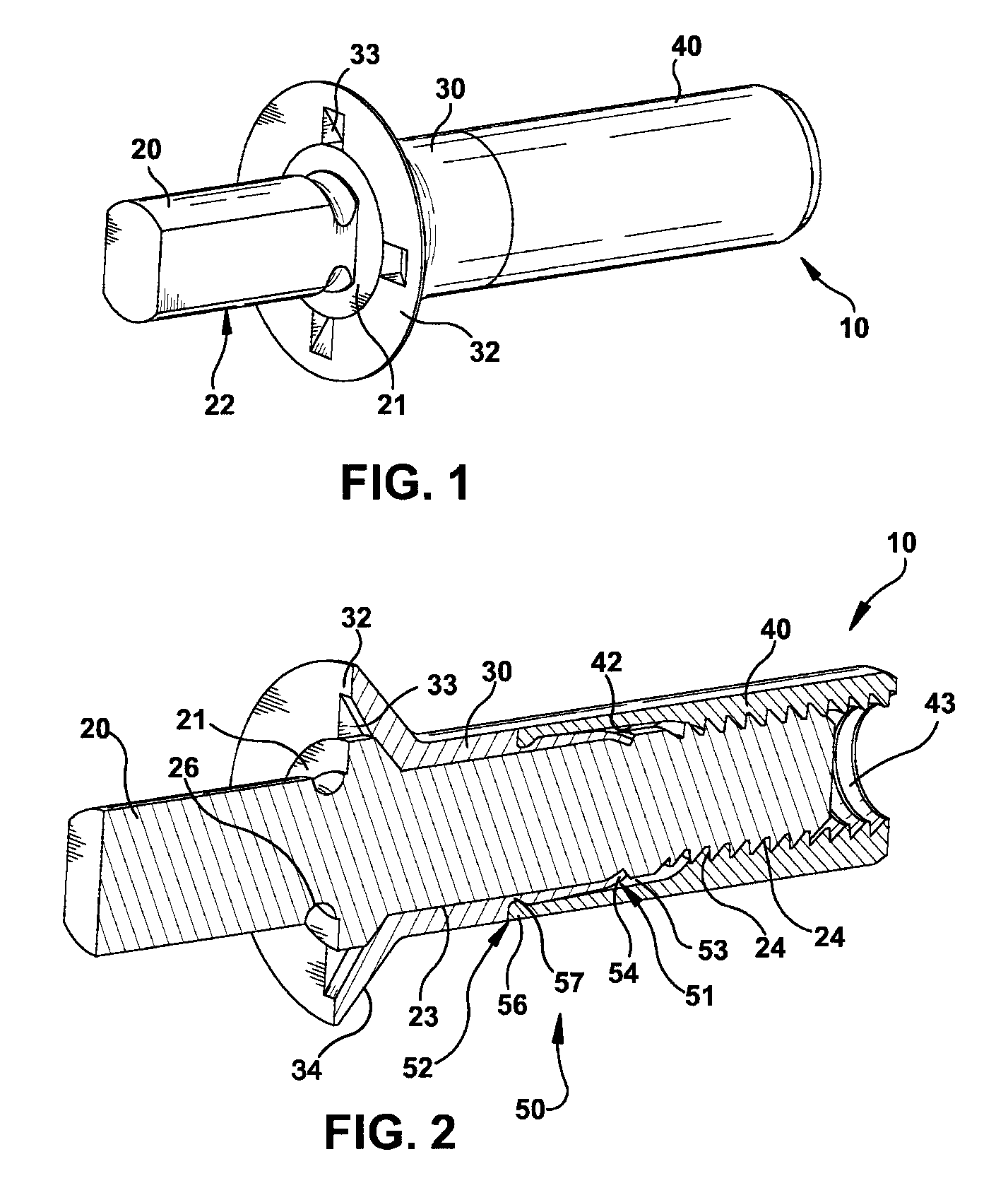

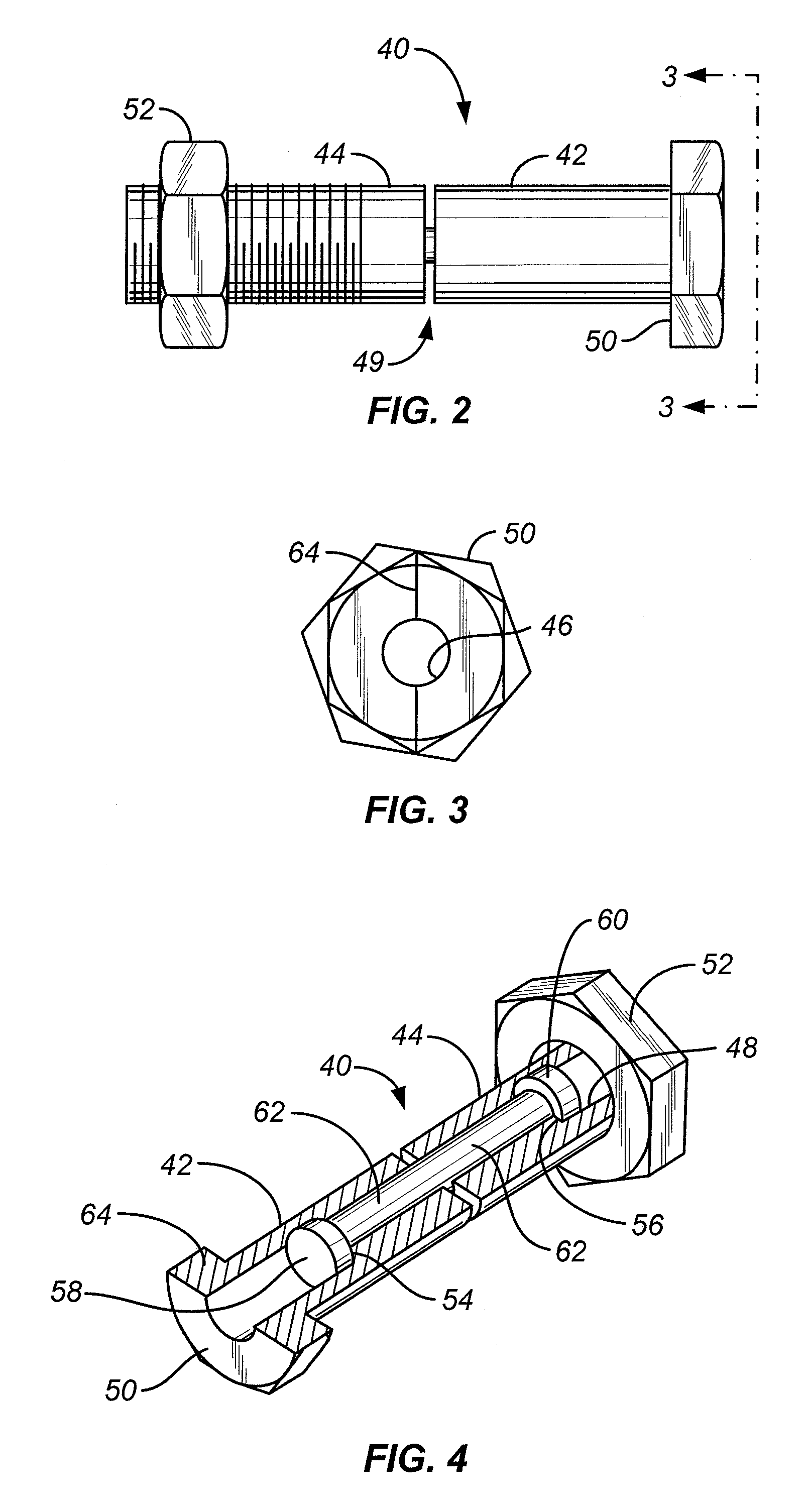

Constant load fastener

Described herein are fasteners and devices for securing together several components so that the load applied to the components is constant or nearly constant. The fasteners described herein include a hyperelastic member having first end to which a first retainer is coupled and a second end to which a second retainer is coupled. The retainers are configured to contact the structures being fastened and transfer the load from the structures to the hyperelastic member. The hyperelastic member may be an elongate shaft (e.g., a rod, cylinder, strut, etc.), and is a shape memory alloy that is typically fabricated as a single crystal.

Owner:TINI ALLOY

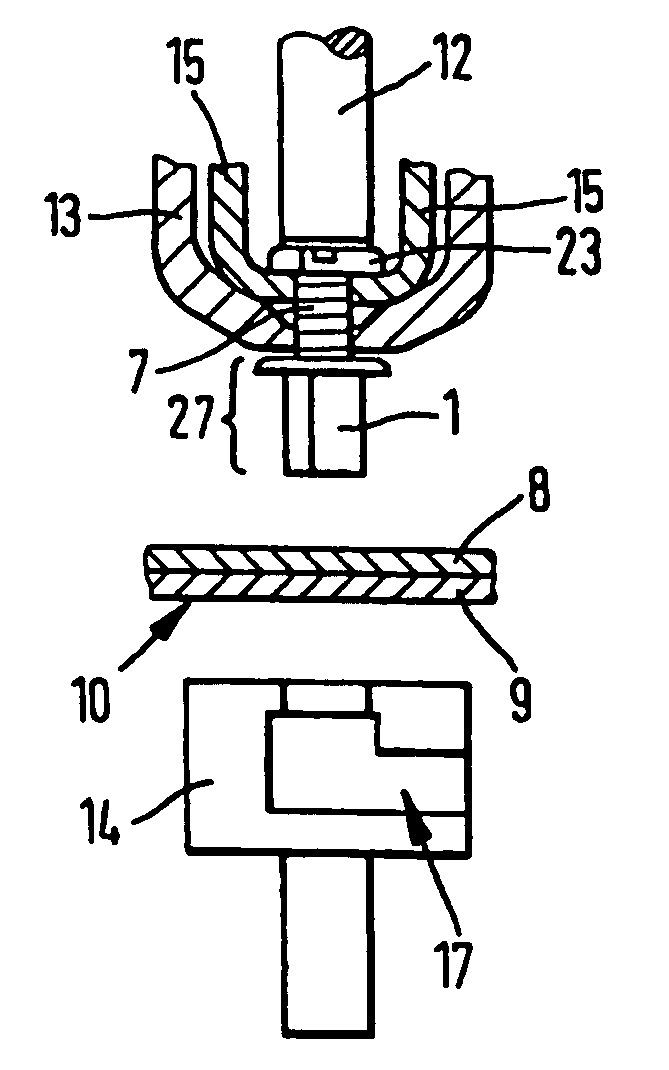

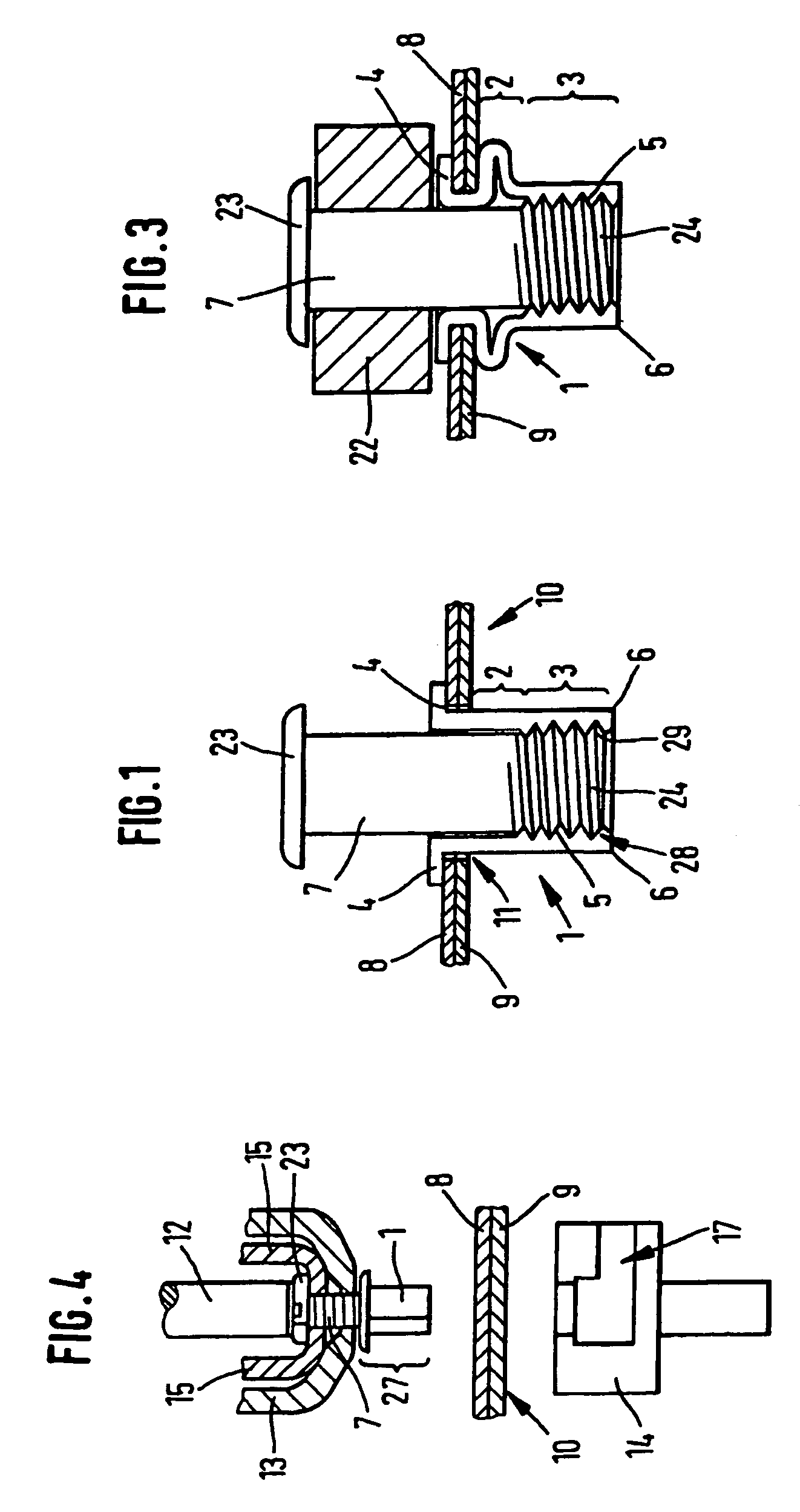

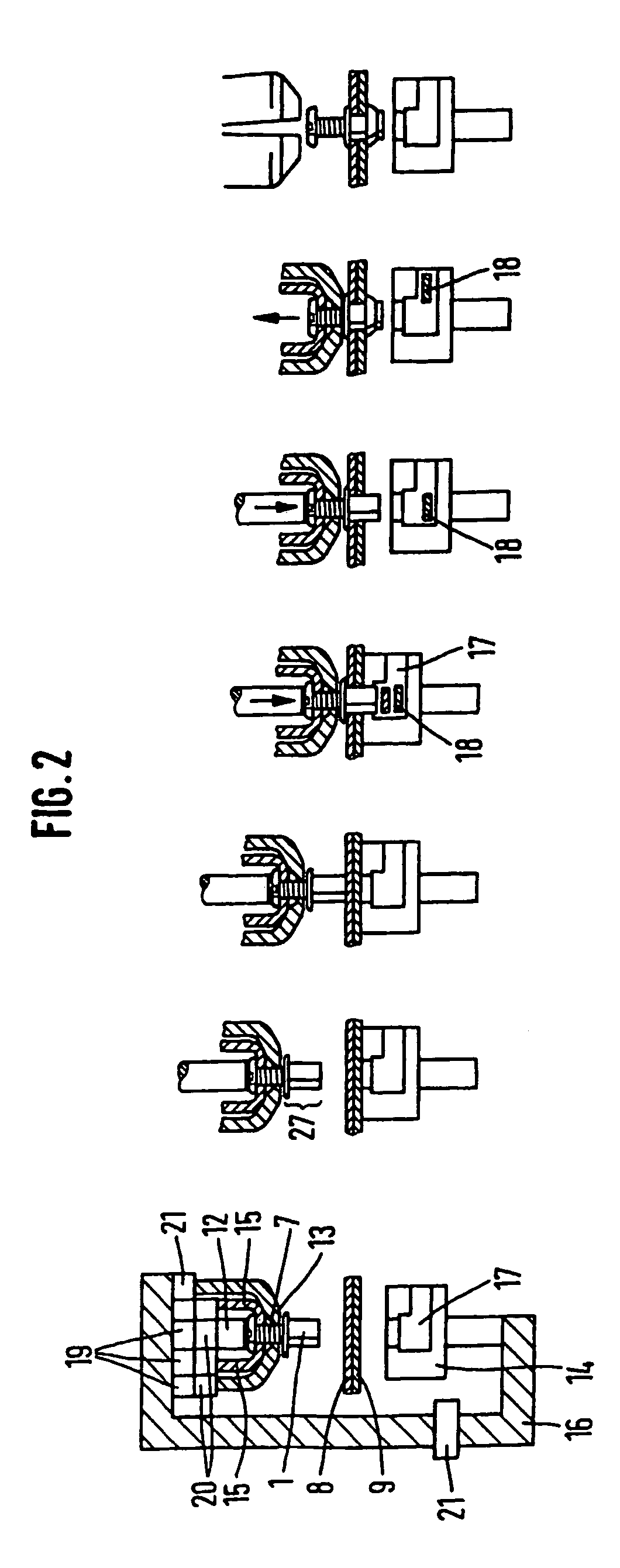

Self-piercing rivet, process and device for setting a rivet element, and employment thereof

InactiveUS7040006B2Easy to openPlace stableThread cutting toolsAutomatic control devicesPunchingRivet

A fastening element (1), in particular for blind riveting, has a setting head (4), a deformation segment (2) and a shank end (3). The deformation segment (2) is arranged between the setting head (4) and the shank end (3). The fastening element (1) is hollow, optionally having a mandrel (7) inside the fastening element (1). The mandrel includes a head (23) and a foot (24) at least tension-resistantly connected to the shank end (3). The shank end (3) includes a punching edge (6) extending substantially along the outermost periphery of the shank end (3). Also identified are a process for setting the fastening element (1), a riveted connection to the fastening element (1), a device for setting the fastening element (1), an employment of the riveted connection obtained, and a die suitable for setting the fastening element (1).

Owner:NEWFREY

Blindly installed, reinforceable nuts for joining structural members

InactiveUS20060078399A1Improve continuityIncreased shear strengthNutsScrewsInterference fitEngineering

A blind nut installed in a structural joint provides an interference fit and a fatigue enhancing benefit to the structural joint. A bolt can be inserted into the nut for additional shear strength and shear continuity. During installation in the structural joint, a first flange of the nut is seated against a first structural member, an installation tool is inserted into a passage in the nut, and the tool is operated to buckle a collapsible portion of the nut to form a second flange on a second structural member. Contemporaneously, an expandable portion of the nut is radially expanded into the structural joint. The installation process induces a high interference fit and may also induce a residual compressive stress in the structural joint.

Owner:FATIGUE TECH

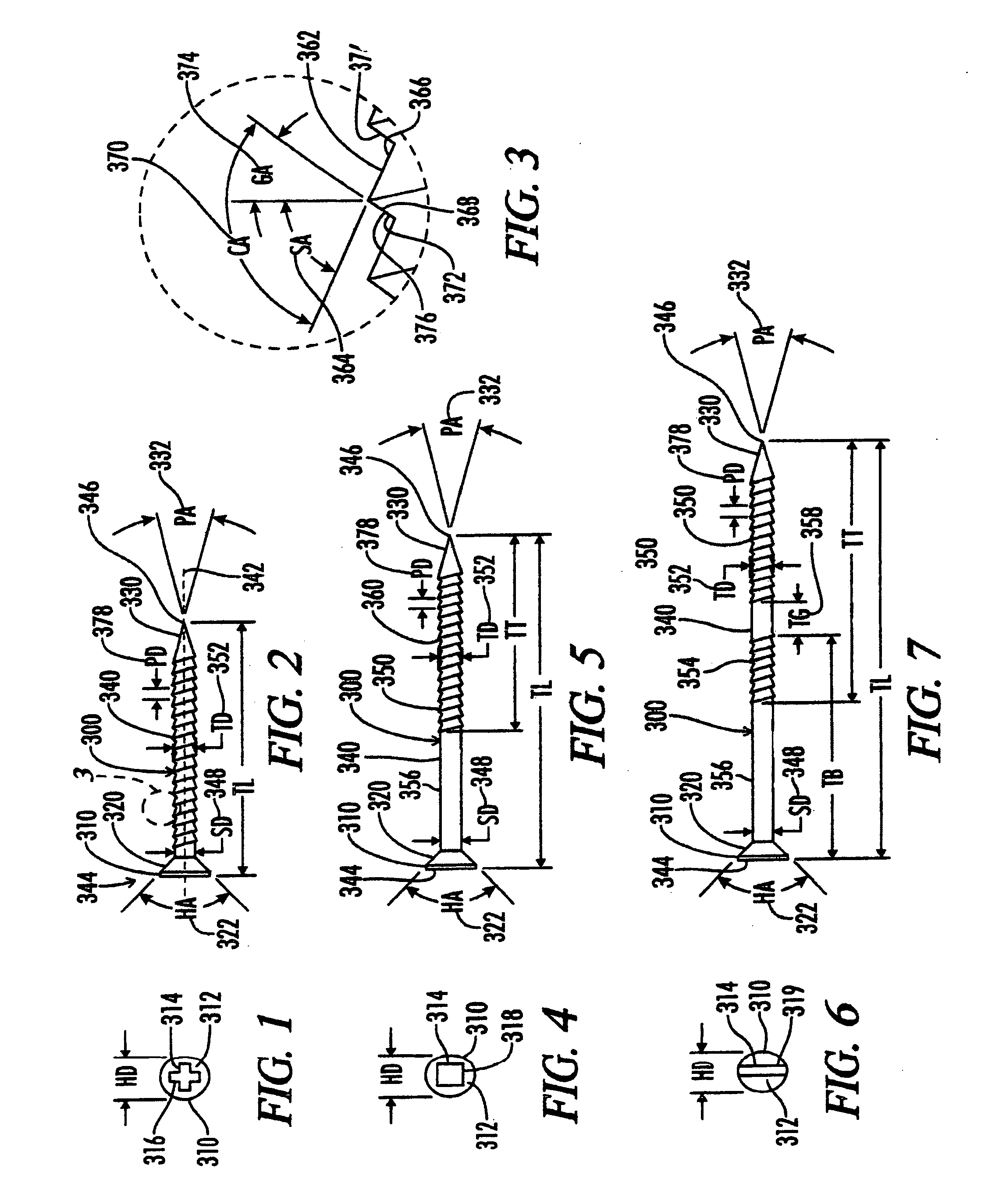

Impact-drivable screw with elastomer seal and tip highlight

An asymmetric thread impact drivable screw and clip for use with a power impact device for penetrating wood fibers while minimizing cut fibers. The screw includes an impact head and a conical shaped tip having a ballistic insertion angle at the ends of a shank. The shank defines asymmetrical threads with an insertion flank having a long side at a slide angle peaking at a crest supported by a catch flank positioned at a grip angle. Varying tool accepting recess are taught for the head along with multiple thread sections. A mushroom compaction thread section is also taught.

Owner:LITZINGER W C

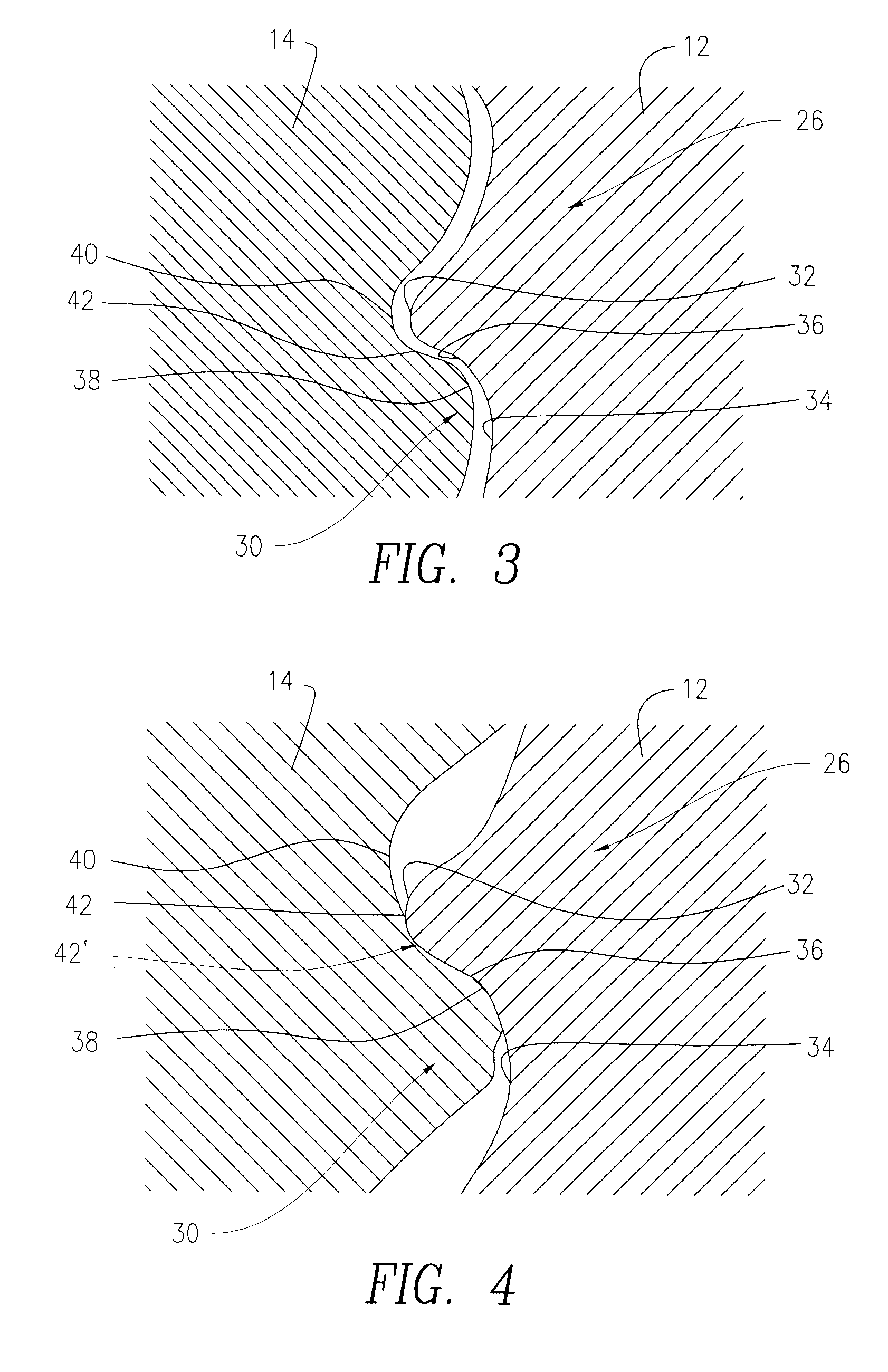

Advanced nut and bolt

A vibration resistant fastening system including a high fatigue strength bolt made from a first material and a nut made from a second material that is softer than the first material of the bolt. The bolt includes bolt threads and the nut includes pre-tapped nut threads that match with the bolt threads. The fastening system utilizes a combination of unique geometry of the nut and bolt threads and a hardness differential between the nut and bolt to provide vibration resistance. When tightened, crests of the bolt threads embed into the soft bearing flanks of the nut threads. Simultaneously with the bolt crest embedment, the softer nut thread crests flow radially inward into the root radius of the bolt threads. This complete contact between the nut and the bolt restricts the nut from moving in a transverse direction relative to a longitudinal axis of the bolt.

Owner:HOWMET AEROSPACE INC

Bolt and process for producing a protective layer on a bolt

The invention relates to a process for producing a protective layer on a bolt, in which an aluminum-containing high-temperature lacquer is first of all applied to the bolt and then cured and stoved at a defined stoving temperature. The screw thread is additionally lubricated prior to installation of the bolt. This process reduces oxidation and ultimately reduces seizing of the screw connection.

Owner:SIEMENS AG

Blind fastener and nose assembly for installation thereof

Owner:ALCOA GLOBAL FASTENERS

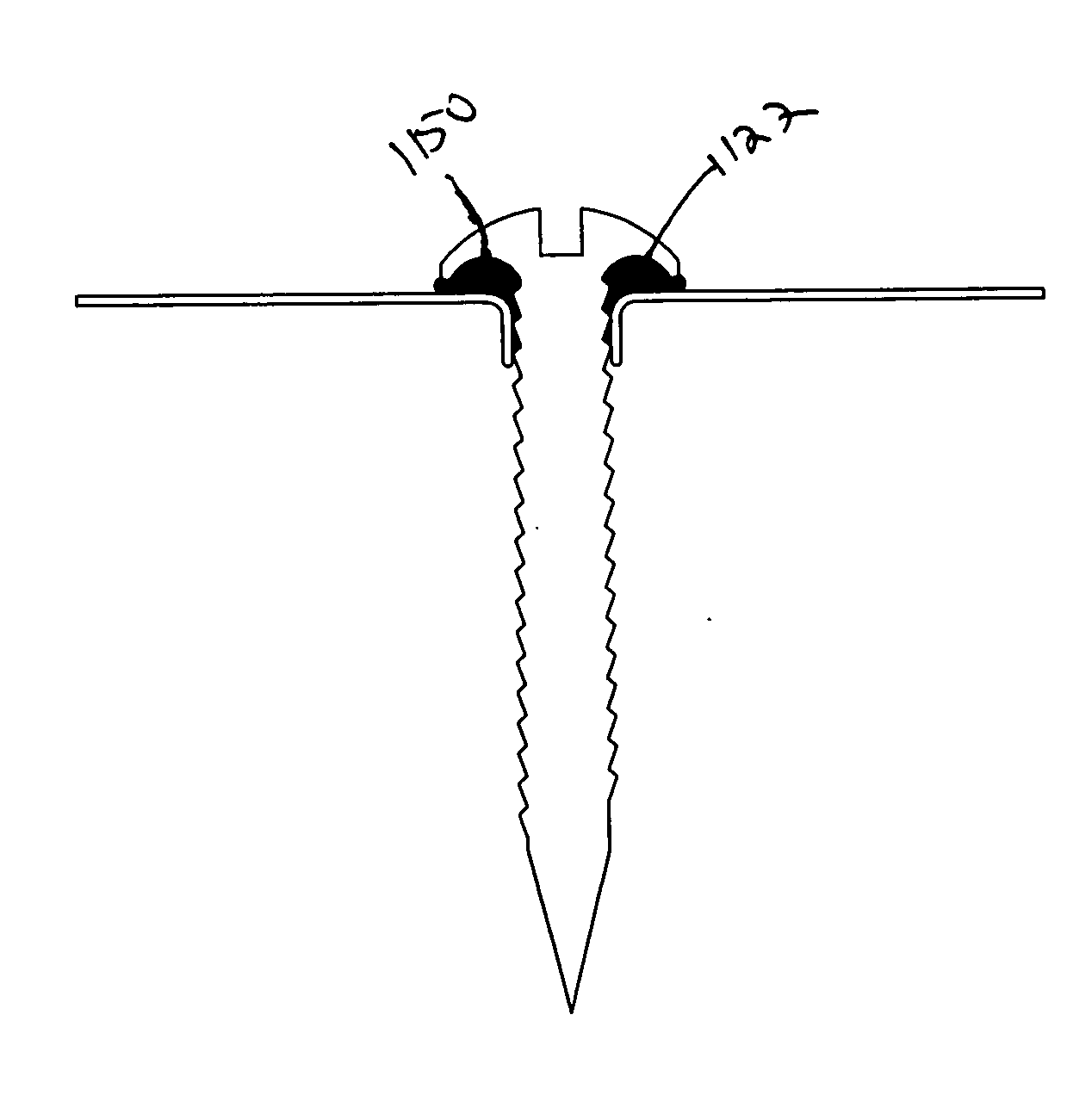

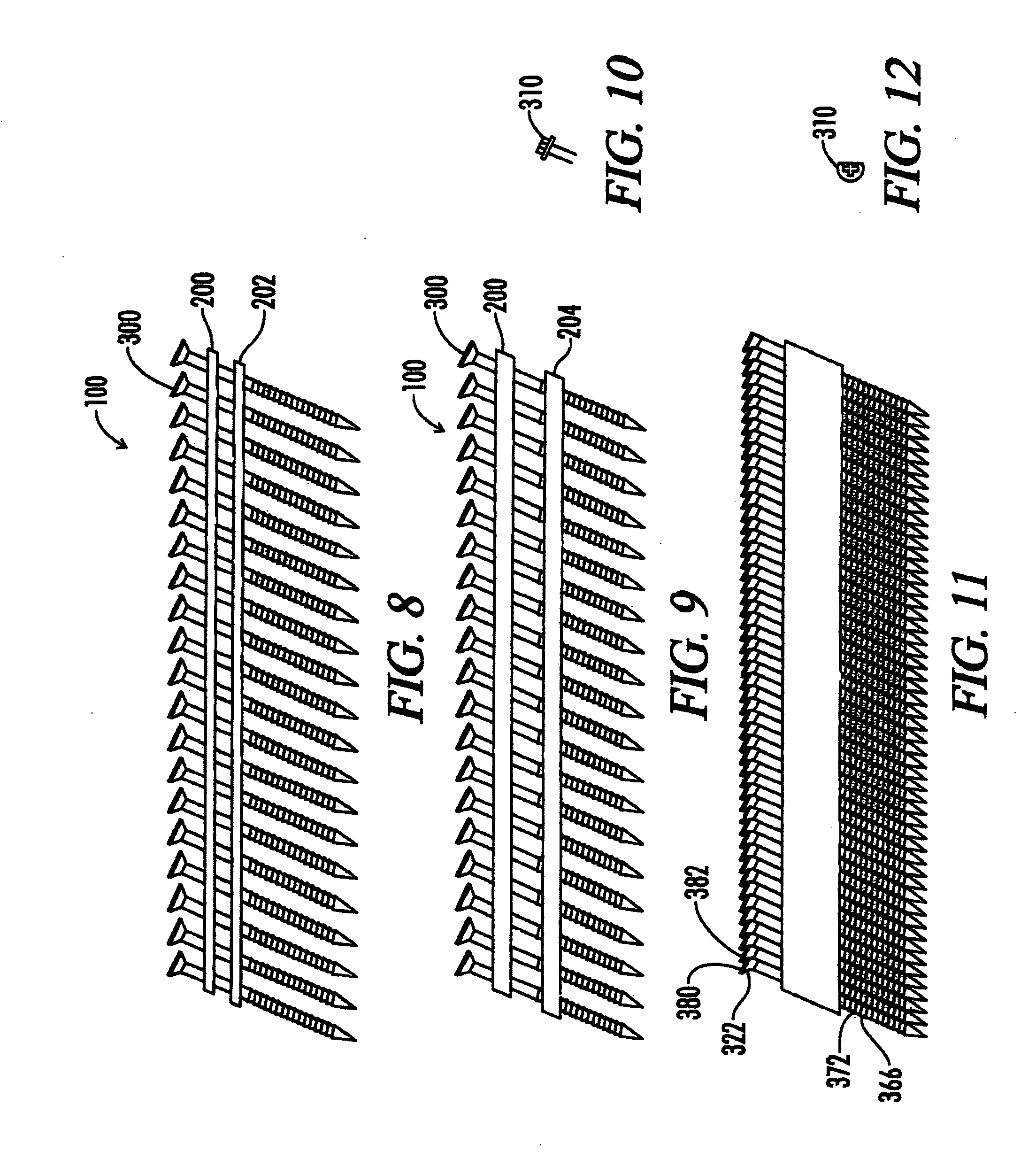

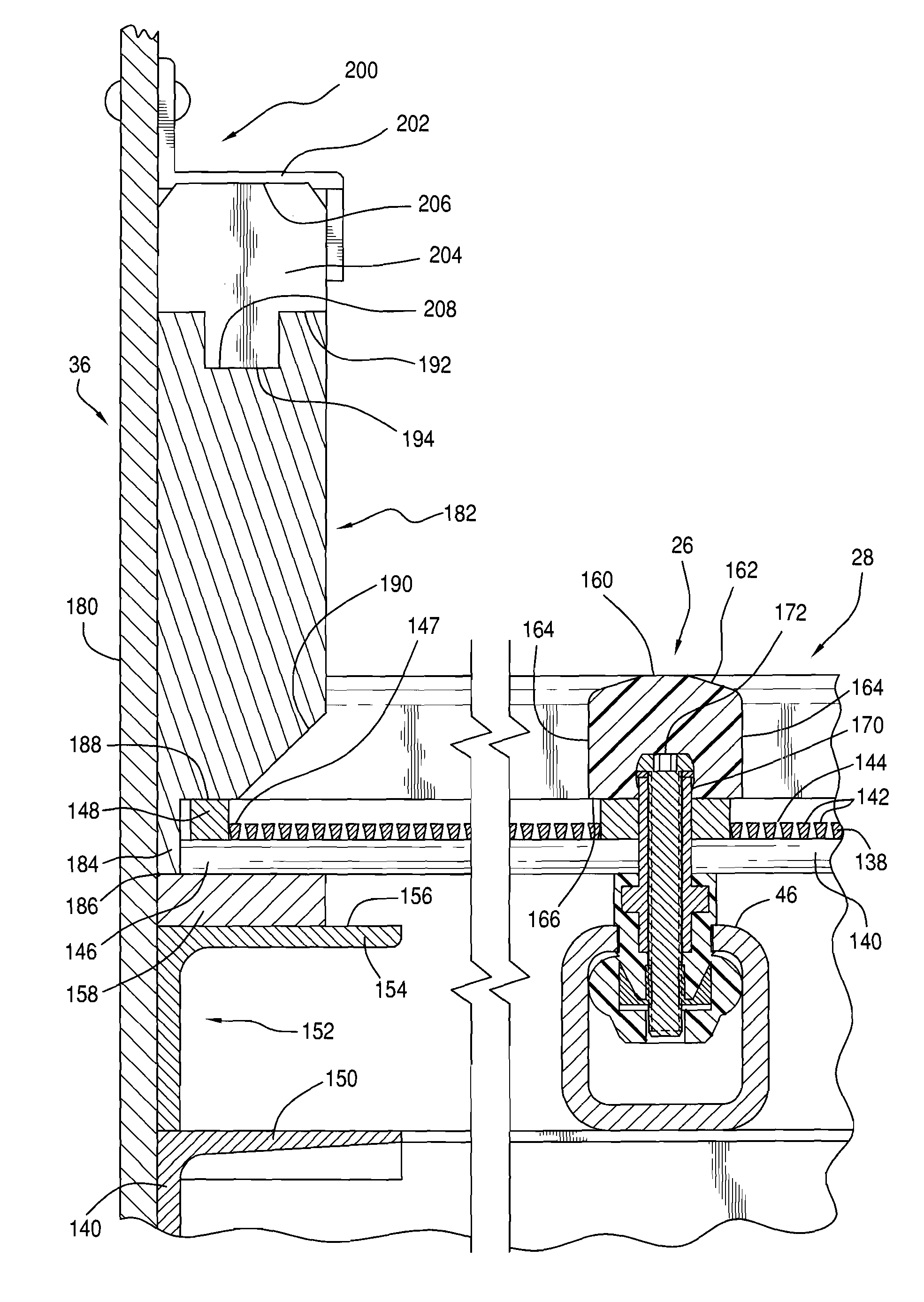

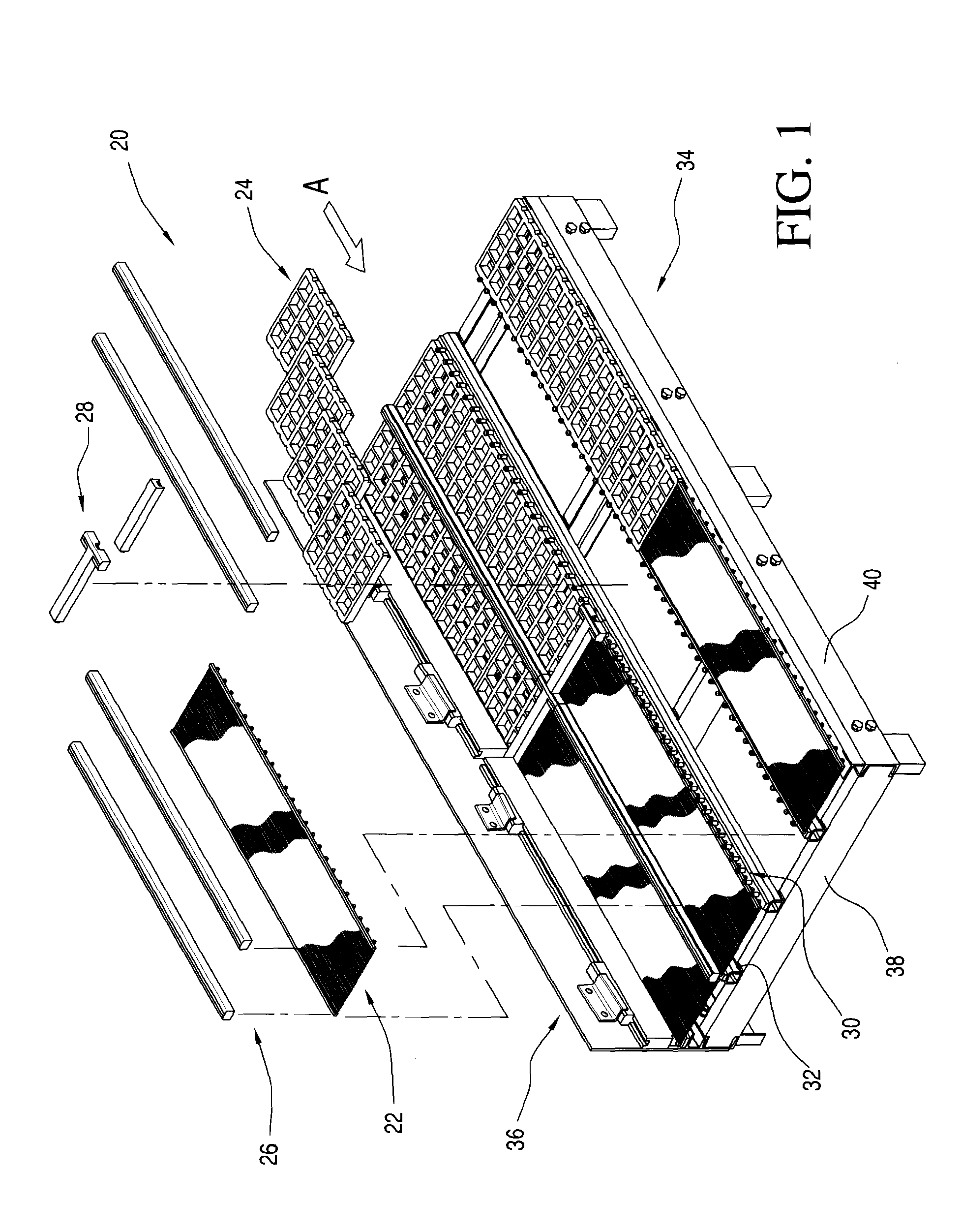

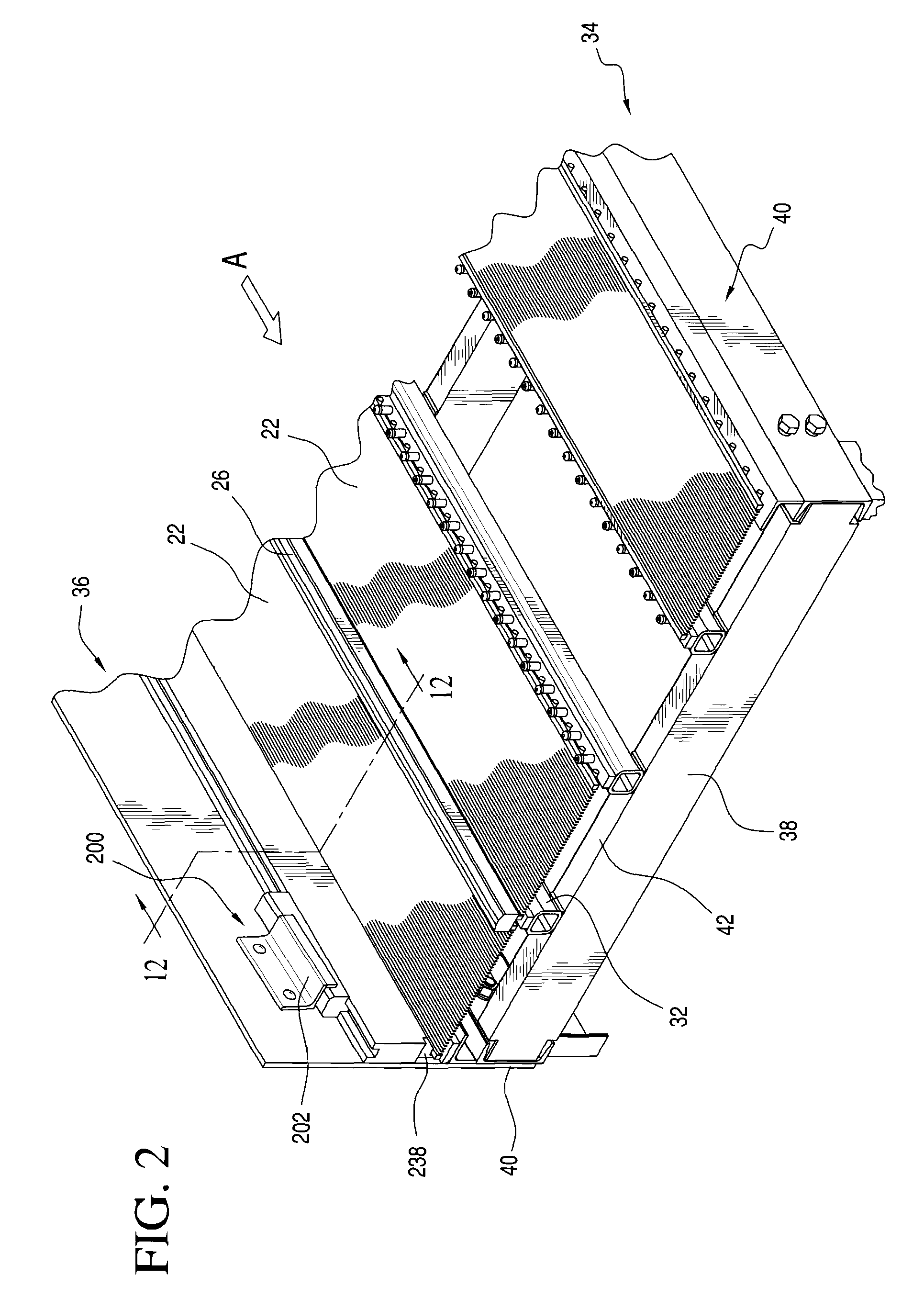

Snap lock separatory panel and retainer system

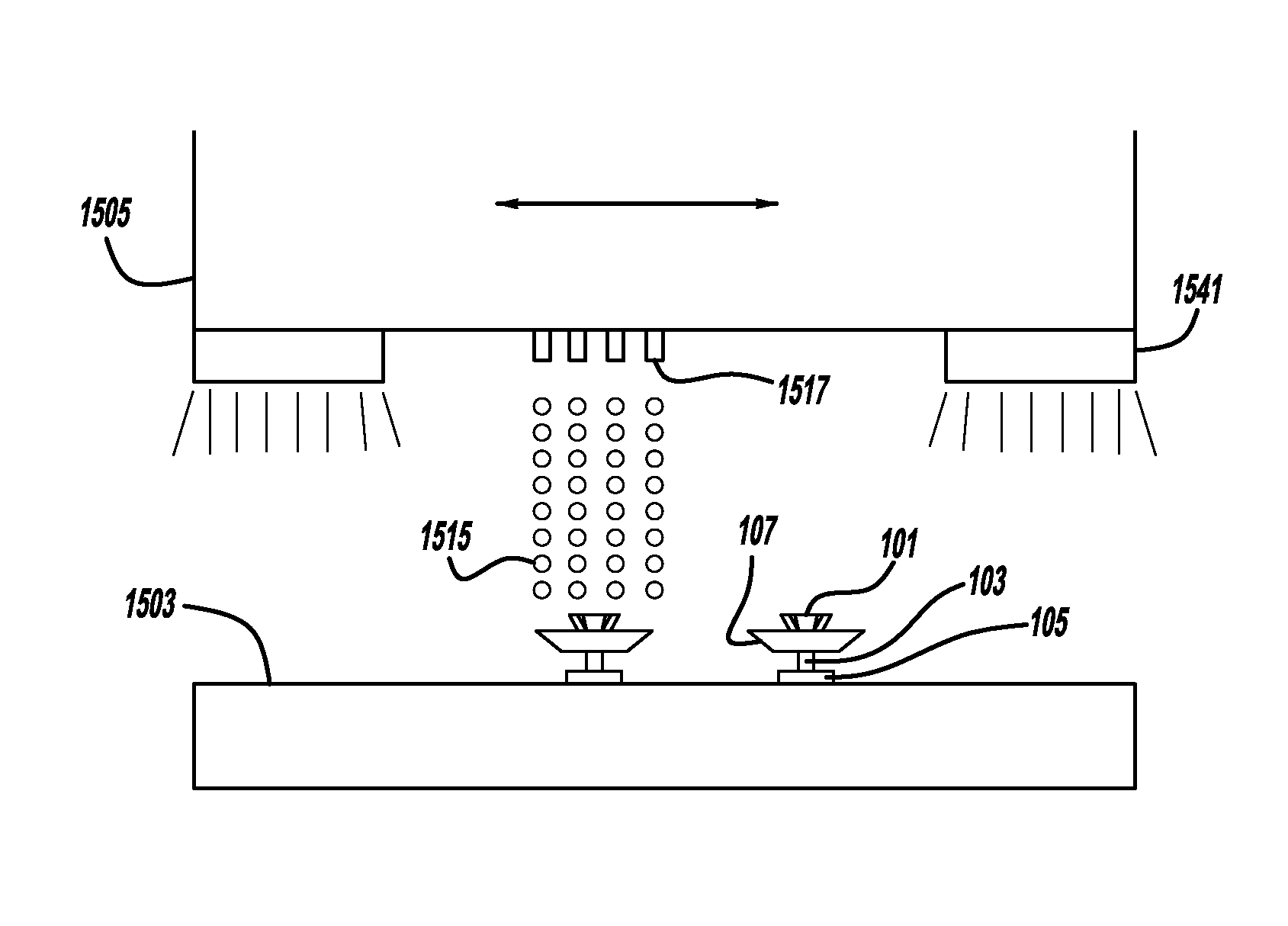

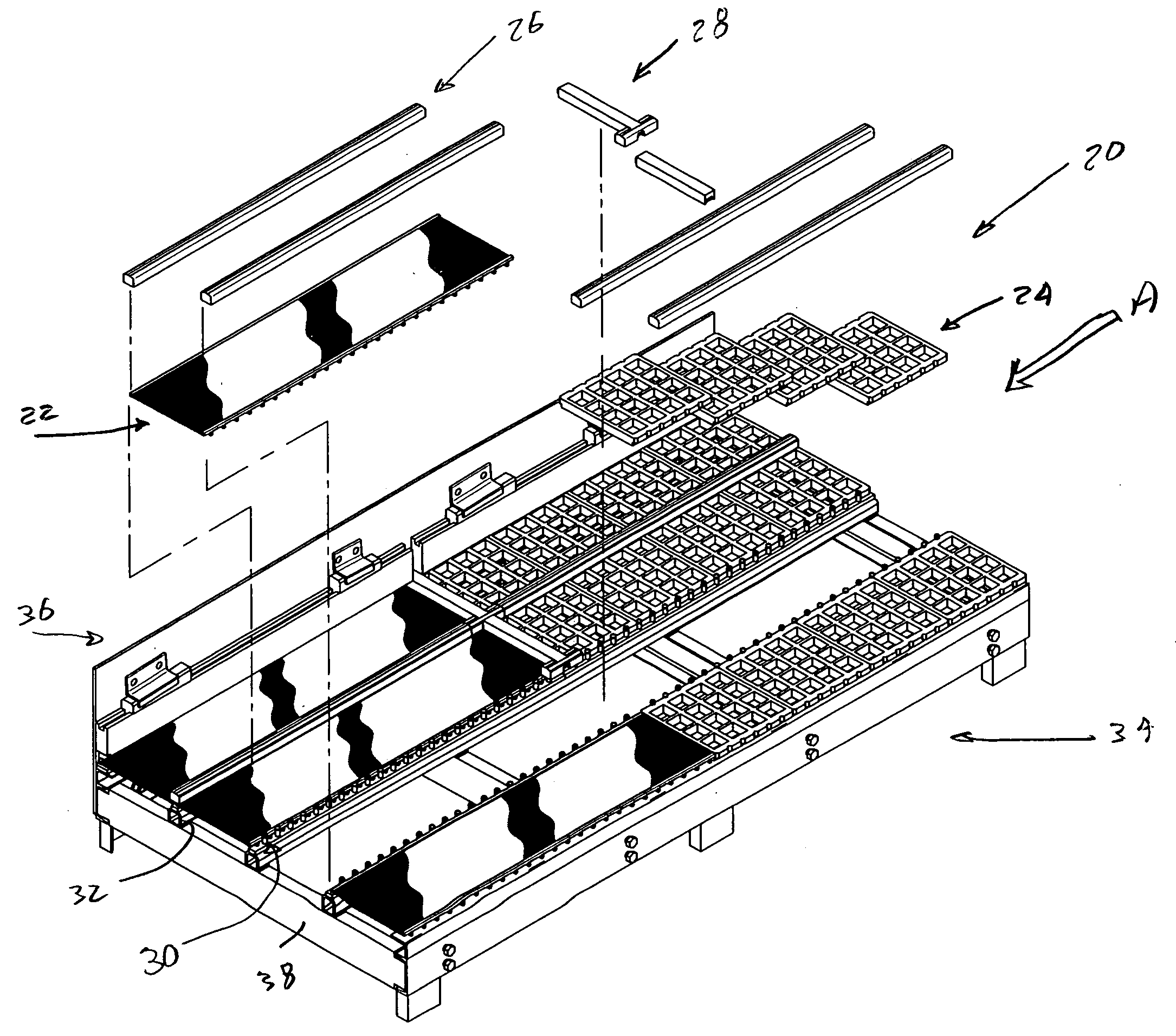

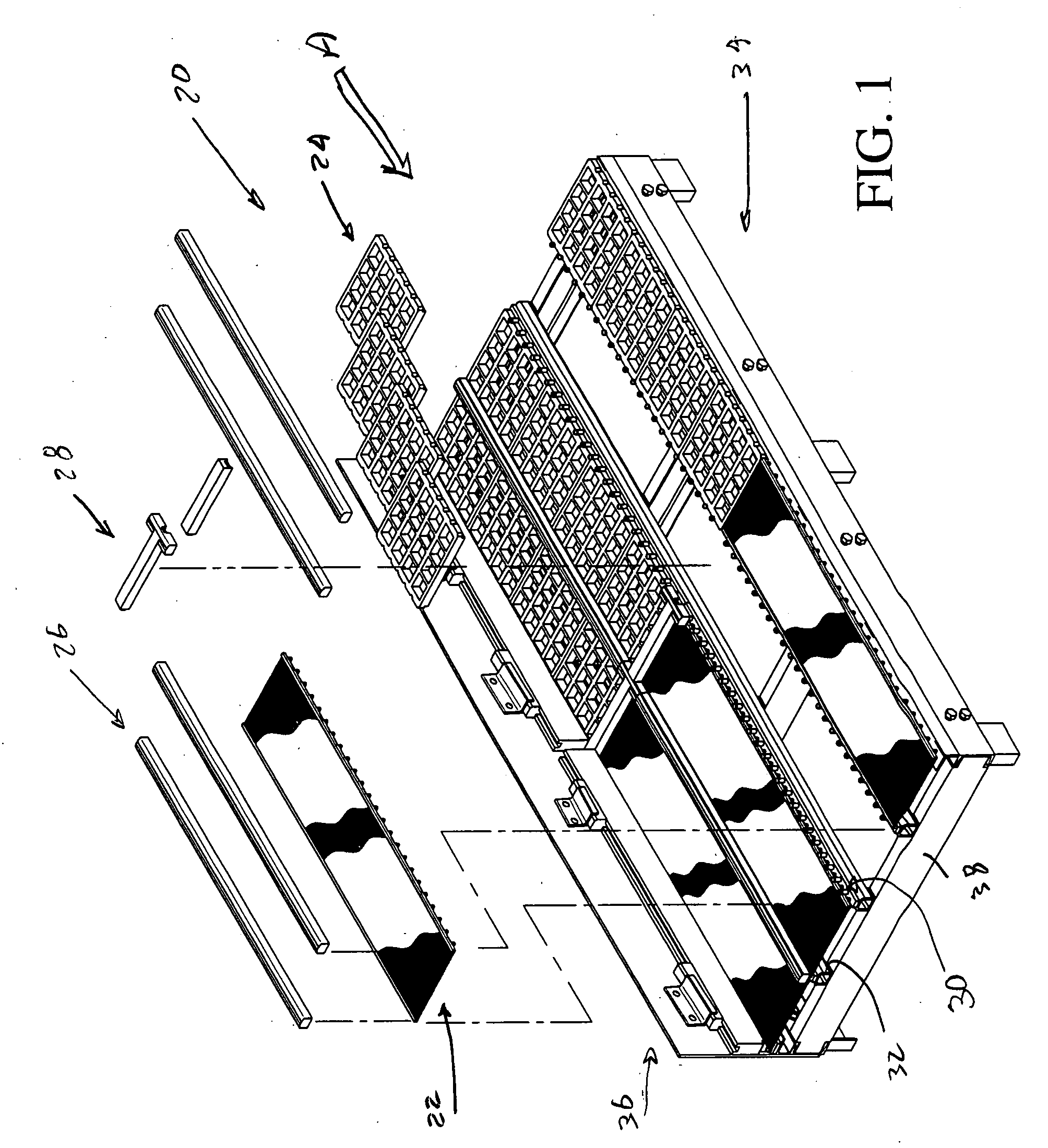

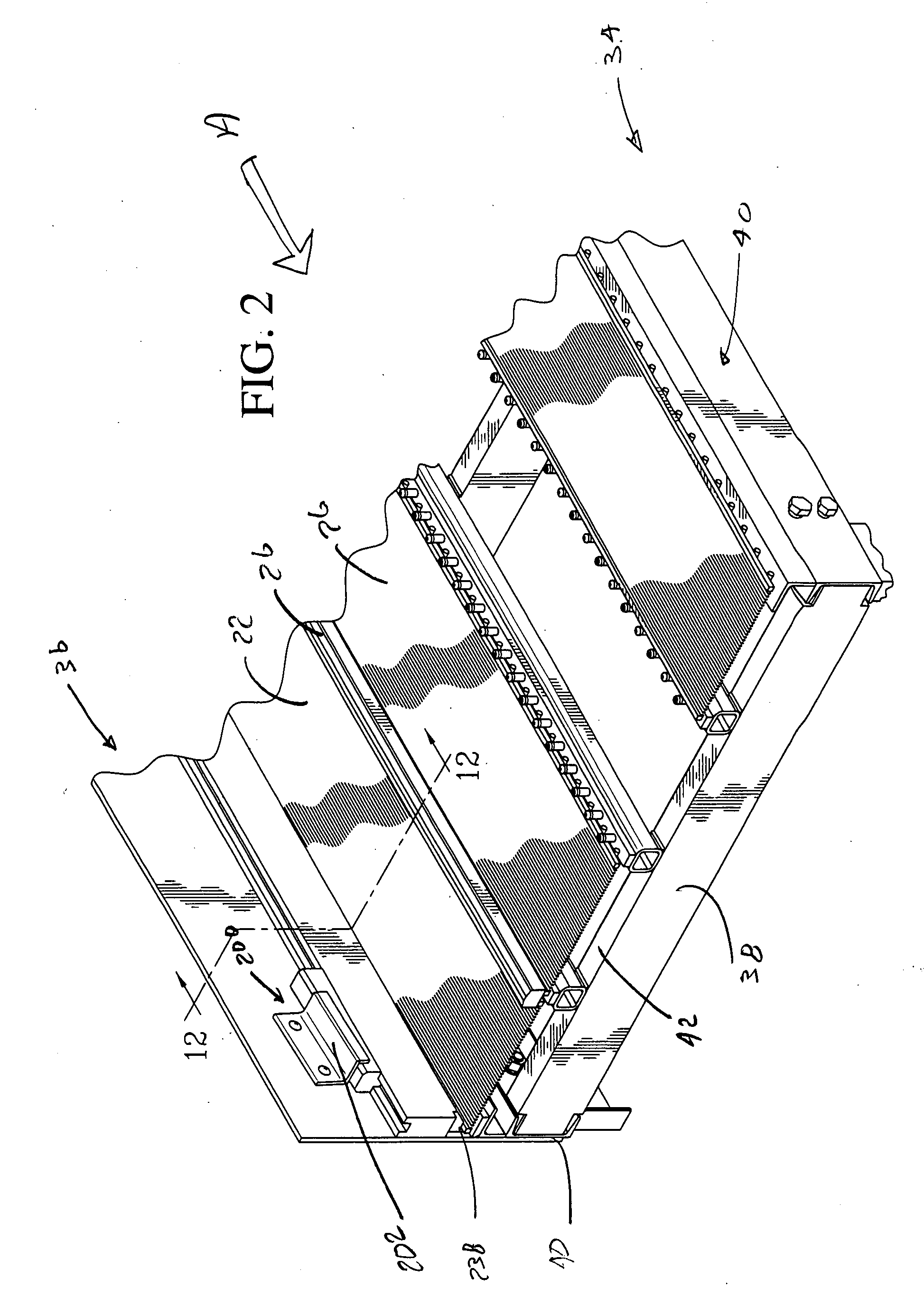

A snap lock separatory panel and retainer system includes either a screen wire panel with laterally spaced, longitudinally extending locking bars defining a locking profile, or a urethane panel with laterally spaced, longitudinally extending lips or flanges which also define a locking profile. A retainer system is provided for use in securing these panels. The retainer system utilized center retainers that are engagable with industry standard holes in screen stringer rails of a vibrating separating machine. Each center retainer is provided with an array of retainer pins which are spaced to interdigitate with either screen wire tie rod ends or with urethane panel wall recesses to support the screen panel locking bars or the urethane panel flanges adjacent the retainer pins. Locking strips are provided with undercurrent bores that terminate in undercut receptacles. These bores and receptacles are sized to receive center retainer pin shanks and heads. The locking strips and center retainers cooperate to positively secure the snap lock screen wire panels and / or urethane panels in place on a vibrating separatory machine.

Owner:CONN WELD IND

Snap lock separatory panel and retainer system

A snap lock separatory panel and retainer system includes either a screen wire panel with laterally spaced, longitudinally extending locking bars defining a locking profile, or a urethane panel with laterally spaced, longitudinally extending lips or flanges which also define a locking profile. A retainer system is provided for use in securing these panels. The retainer system utilized center retainers that are engagable with industry standard holes in screen stringer rails of a vibrating separating machine. Each center retainer is provided with an array of retainer pins which are spaced to interdigitate with either screen wire tie rod ends or with urethane panel wall recesses to support the screen panel locking bars or the urethane panel flanges adjacent the retainer pins. Locking strips are provided with undercurrent bores that terminate in undercut receptacles. These bores and receptacles are sized to receive center retainer pin shanks and heads. The locking strips and center retainers cooperate to positively secure the snap lock screen wire panels and / or urethane panels in place on a vibrating separatory machine.

Owner:CONN WELD IND

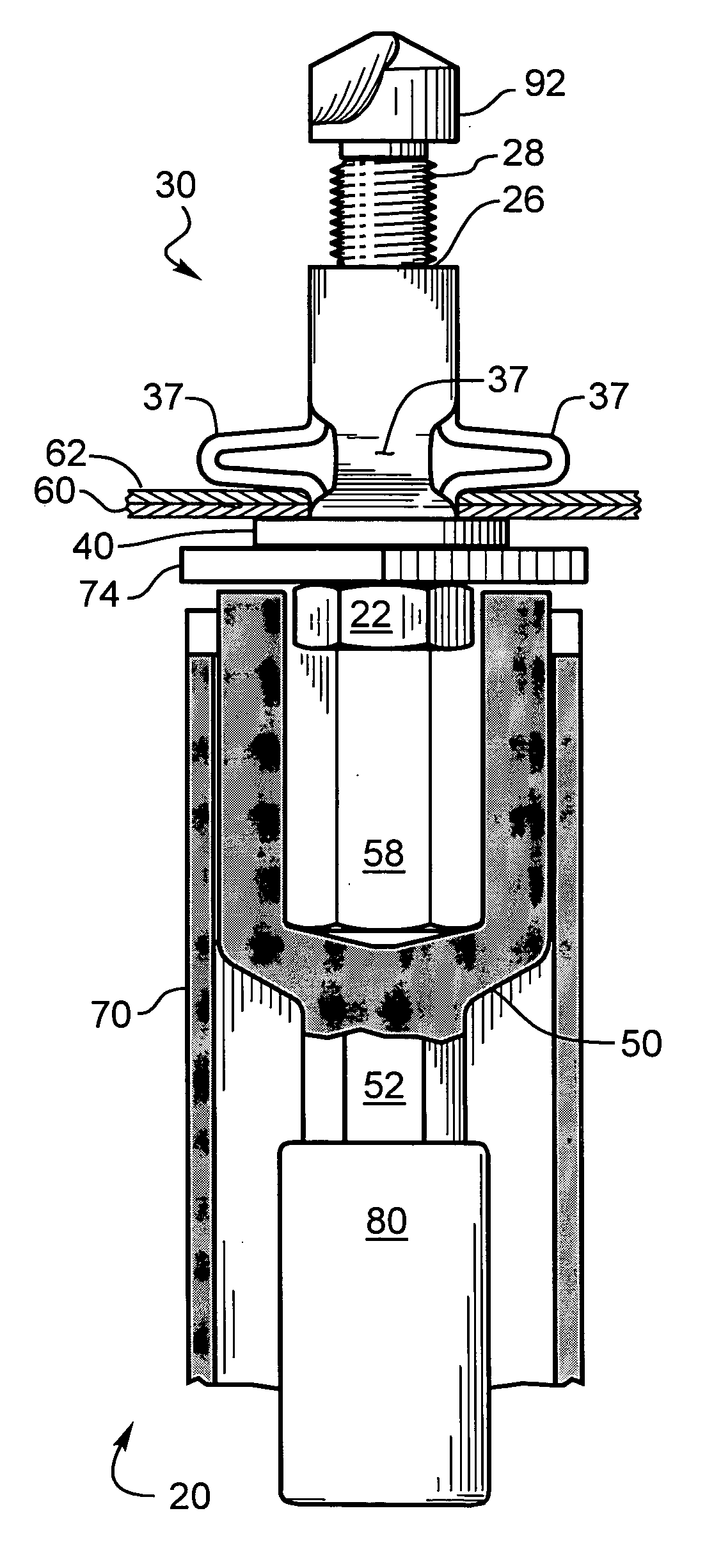

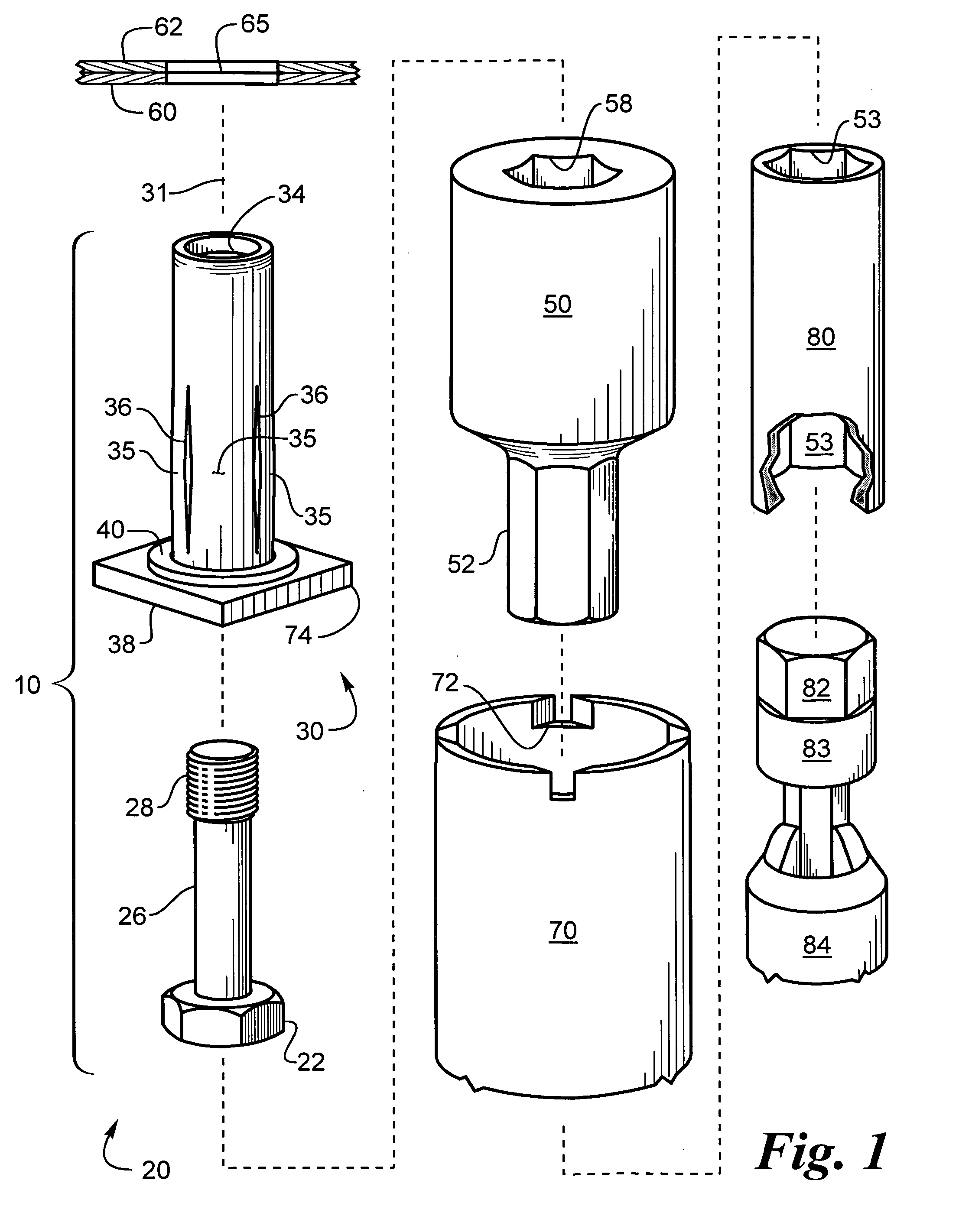

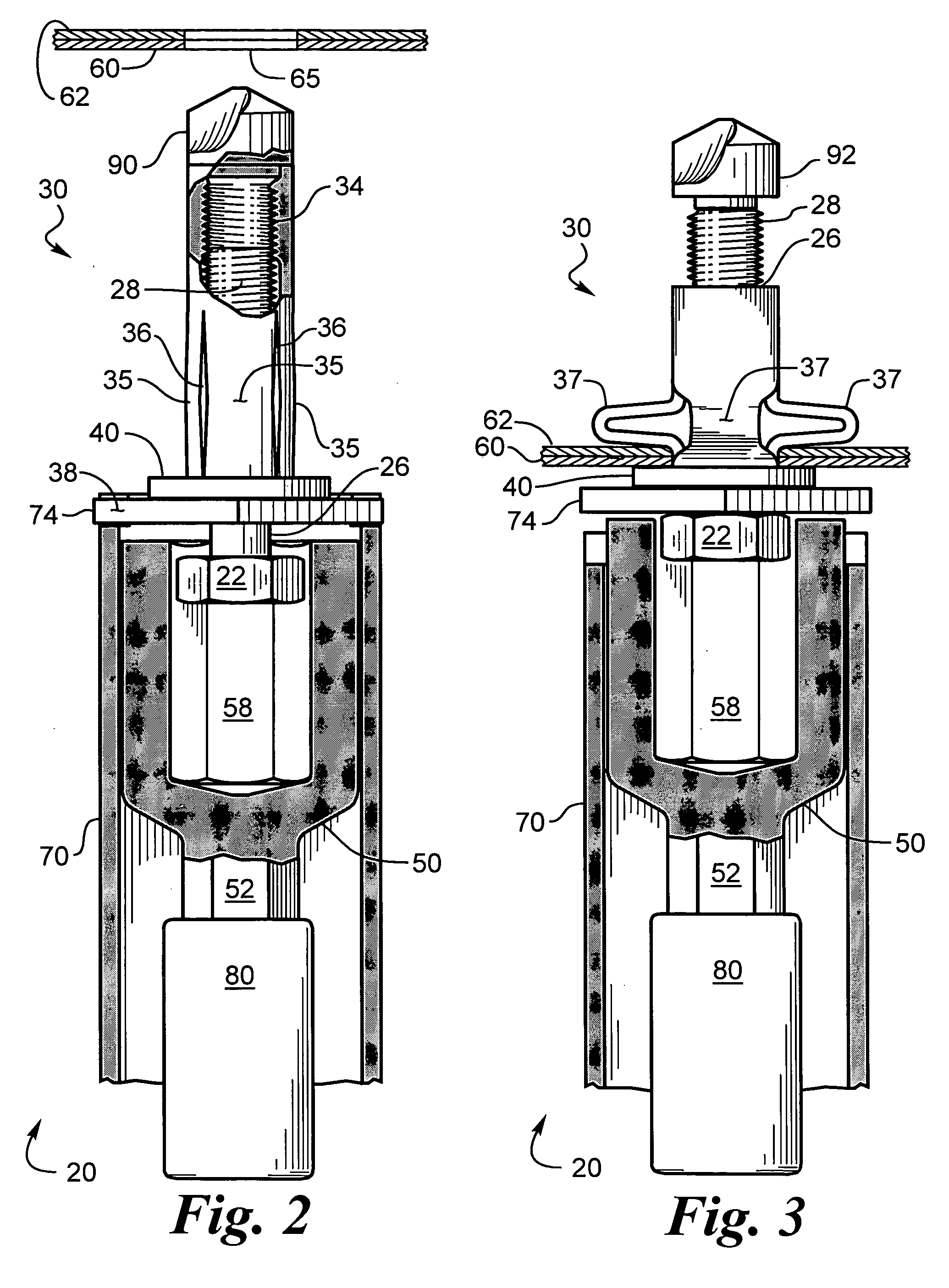

Mushrooming expandable anchor installation tool

The installation tool for a mushrooming expandable anchor has a hollow cylindrical sleeve with an inside diameter, the top having slots for engaging the base of the mushrooming component and a means for engaging and turning a threaded component, which compresses the mushrooming component. The means for turning the threaded component can be a socket, which rotates inside of the sleeve and engages a hex head at the base of the threaded component or alternatively the means for turning the threaded component can be a threaded rod for threading into the base of the threaded component until it reaches the end of the threads in the base. Another means of turning the threaded component is a screwdriver engaging a slot in the treaded component. All of the means for turning the treaded component may be by a powered drill with a connective adapter.

Owner:ILLINOIS TOOL WORKS INC

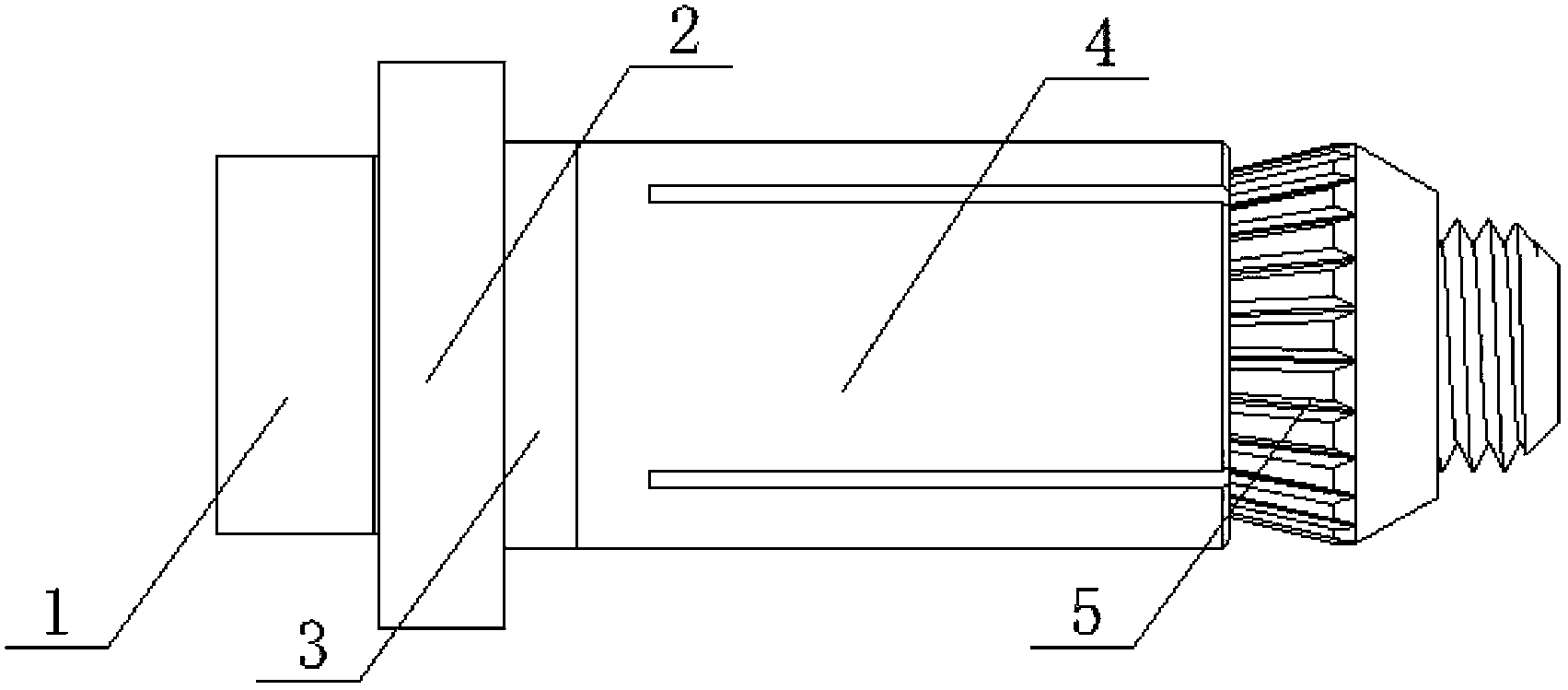

Single-edge fastening bolt

InactiveCN103511420AAdapt to the needs of the connectionIntegrity guaranteedWashersScrewsEngineeringScrew thread

The invention provides a single-edge fastening bolt. The singe-edge fastening bolt comprises a screw and a bolt head at one end of the screw. A gasket, a sleeve and a conical head are sequentially arranged on the screw from the end of the bolt head in a sleeved mode. The conical head is provided with a screwed hole which is in threaded connection with the screw, the gasket is in clearance fit with the screw, the sleeve is also in clearance fit with the screw, the outer diameter of the sleeve is larger than the inner diameter of the gasket, a plurality of axial cracks are formed in the end, close to the conical head, of the sleeve, the smaller end of the conical head is clamped into the sleeve, and the outer diameter of the larger end of the conical head is larger than or equal to the inner diameter of the sleeve. According to the single-edge fastening bolt, on the premise that the installation speed and the node strength are not lowered, the problem that when sealed section part bolt connection is completed through a traditional method, an opening of a connected section is weakened, and the single-edge fastening bolt has the advantages that installation is convenient and quick, the requirements for sealed section part connection are met, and the integrity of the connected section is guaranteed.

Owner:TONGJI UNIV

Advanced nut and bolt

A vibration resistant fastening system including a high fatigue strength bolt made from a first material and a nut made from a second material that is softer than the first material of the bolt. The bolt includes bolt threads and the nut includes pre-tapped nut threads that match with the bolt threads. The fastening system utilizes a combination of unique geometry of the nut and bolt threads and a hardness differential between the nut and bolt to provide vibration resistance. When tightened, crests of the bolt threads embed into the soft bearing flanks of the nut threads. Simultaneously with the bolt crest embedment, the softer nut thread crests flow radially inward into the root radius of the bolt threads. This complete contact between the nut and the bolt restricts the nut from moving in a transverse direction relative to a longitudinal axis of the bolt.

Owner:HOWMET AEROSPACE INC

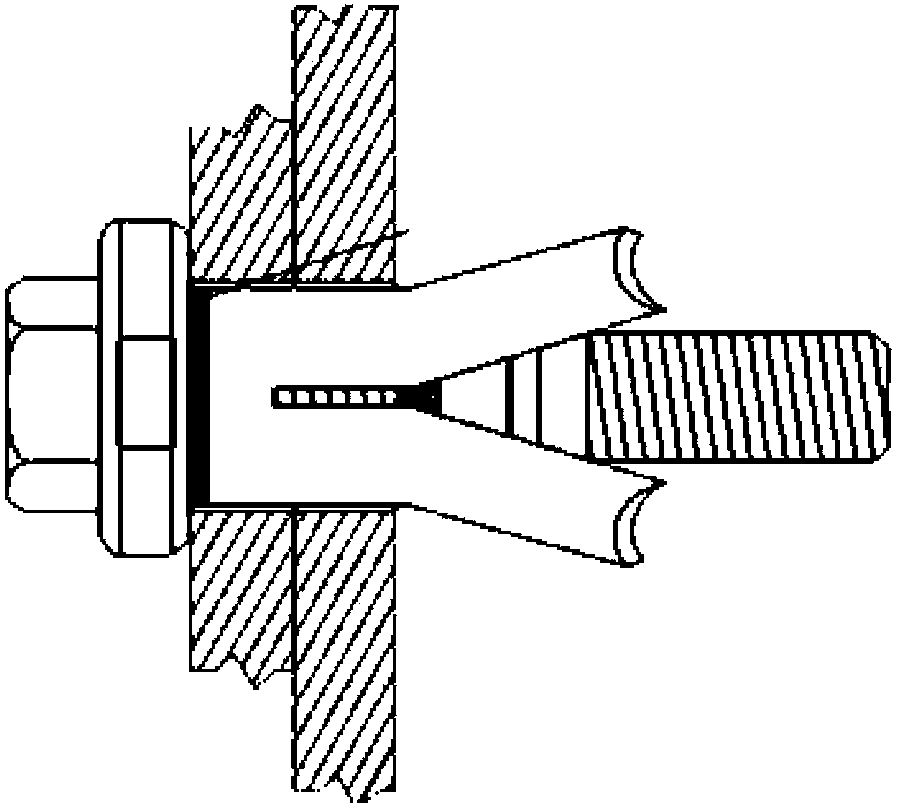

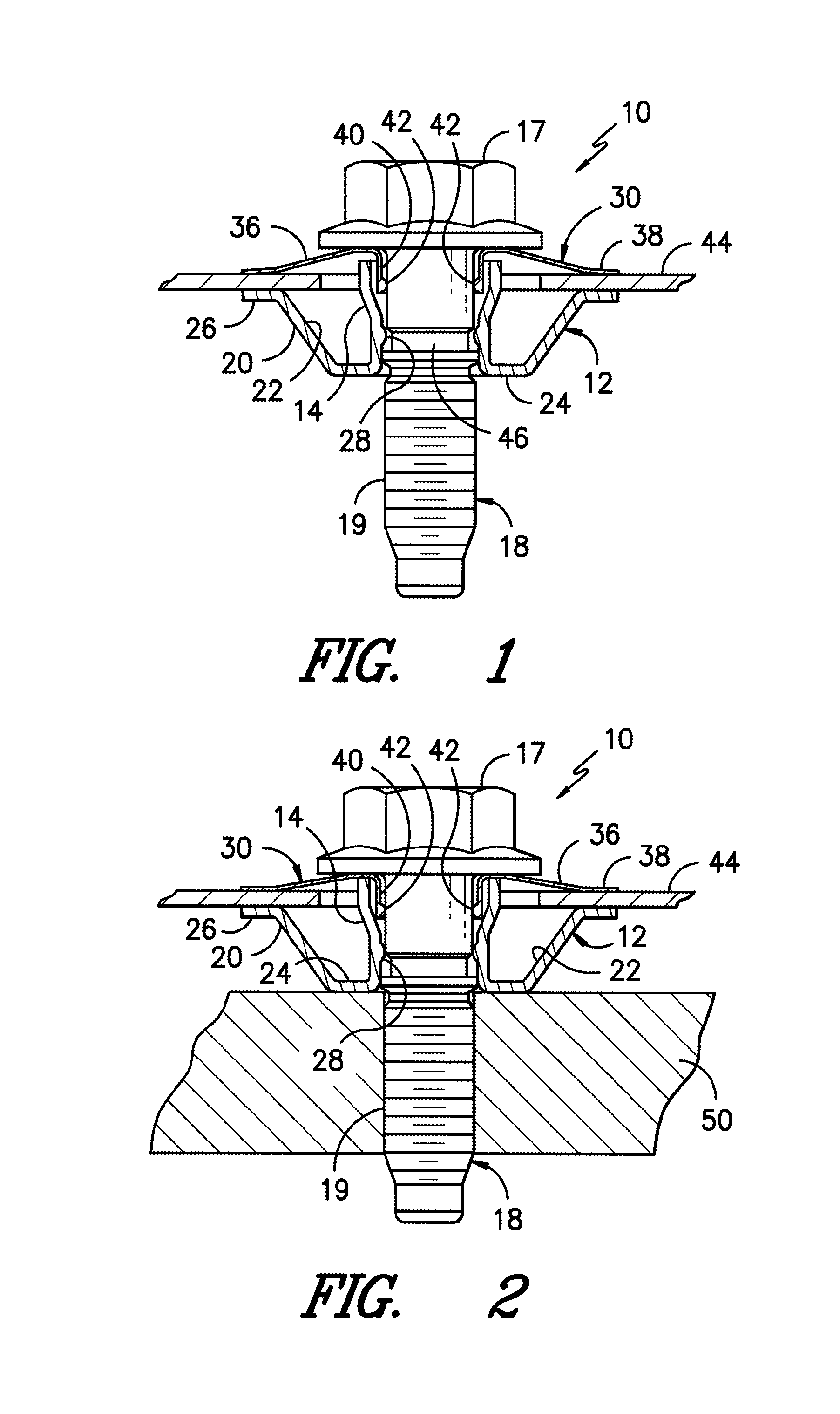

Panel fastening and waterproofing anchor

A self-anchoring fastening device for laminating sheets of material such as sheets of metal used in constructing metal buildings. The anchor comprises a collapsible anchoring portion having radially expanding anchoring strips, which will not pull out of a hole drilled in the sheets. Threads internal to the expandable anchor cooperate with threads on a bolt inserted therein to collapse the expandable anchor, providing anchoring strips over one sheet such that the expandable anchor cannot be pulled out of the hole. A washer between the base of the collapsible anchoring portion and one sheet provides for a waterproof fastener such that the building will be watertight. The anchor is easy to install by placing the anchoring device though aligned apertures in two sheets and then turning the bolt relative to the collapsible anchoring portion to extend the radially expanding strips thus securing one sheet to the other.

Owner:ILLINOIS TOOL WORKS INC

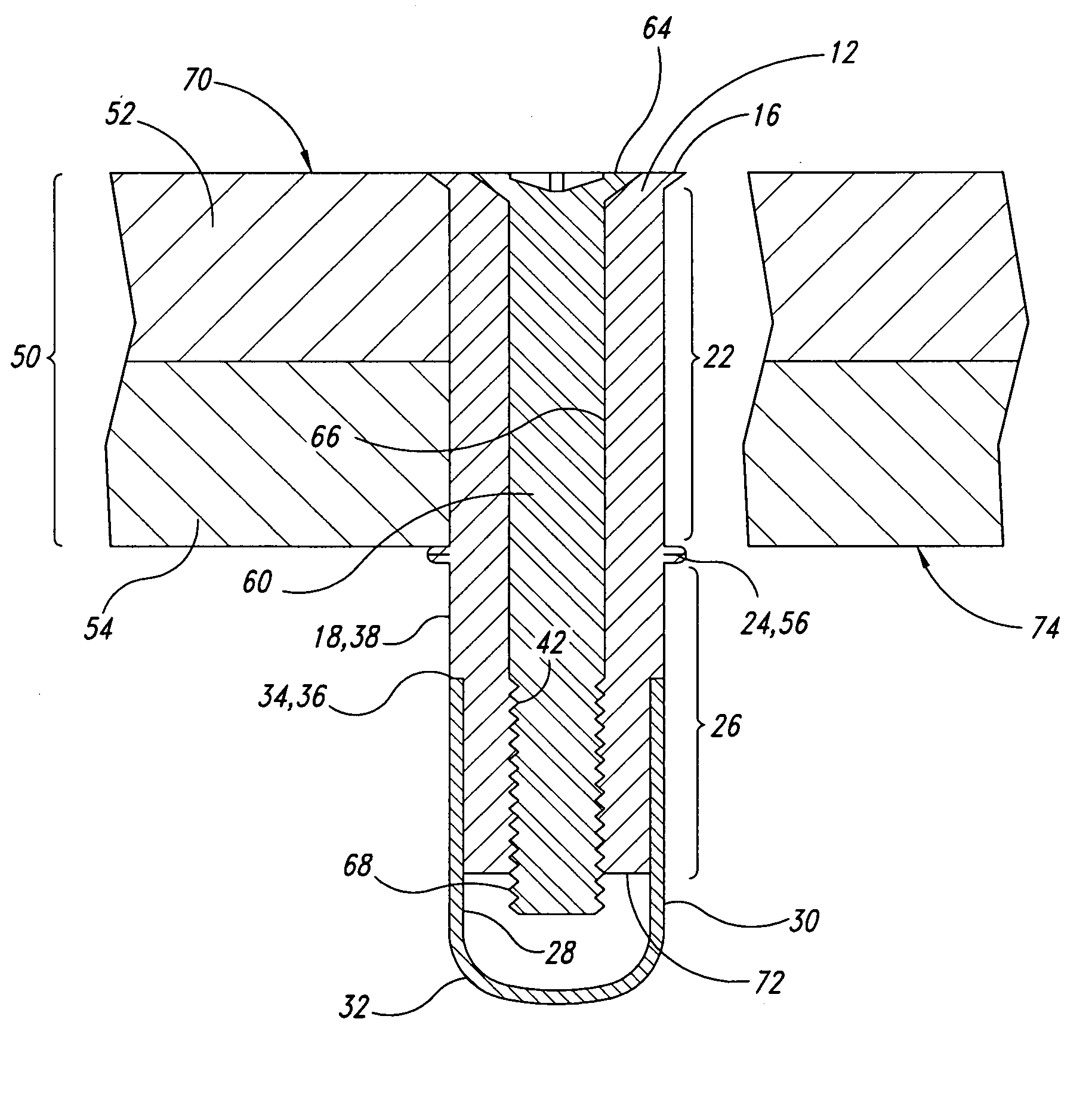

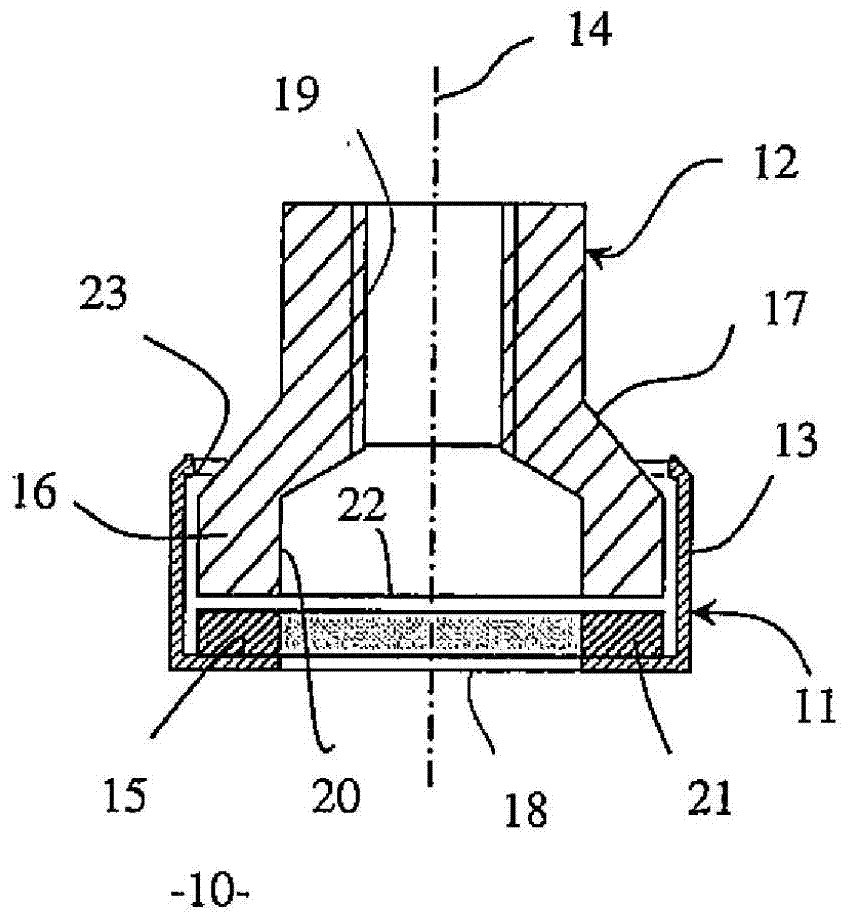

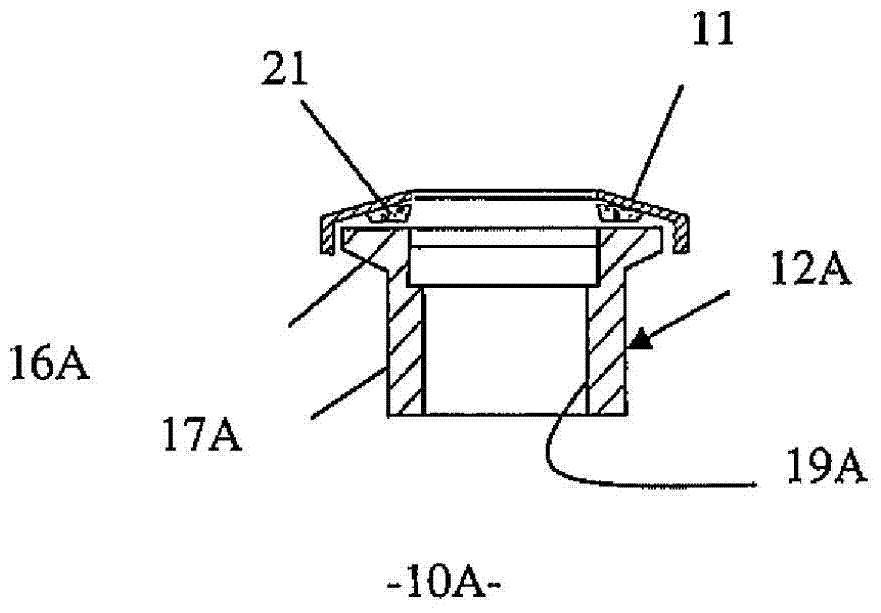

Leak-proof fastening device and assembly method thereof

The invention provides a leak-proof fastening device and an assembly method thereof. The leak-proof fastening device comprises an annular base (15) and a washer (11) of a substantially cylindrical skirt (13) at the outer periphery of the annular base. The annular base comprising a central orifice (18) coaxial with the axis (14) of the skirt, characterized in that the annular base is at least partially covered with a layer (21) of a viscous composition capable of forming a liquid-tight coating through polymerization. When installing a nut having such a washer onto a male fastener such as a pin (33), the spreading of the viscous layer makes it possible to fill in the gaps (36) of the assembly, the polymerization of the composition ensuring its leak-tightness afterwards.

Owner:LISI AEROSPACE

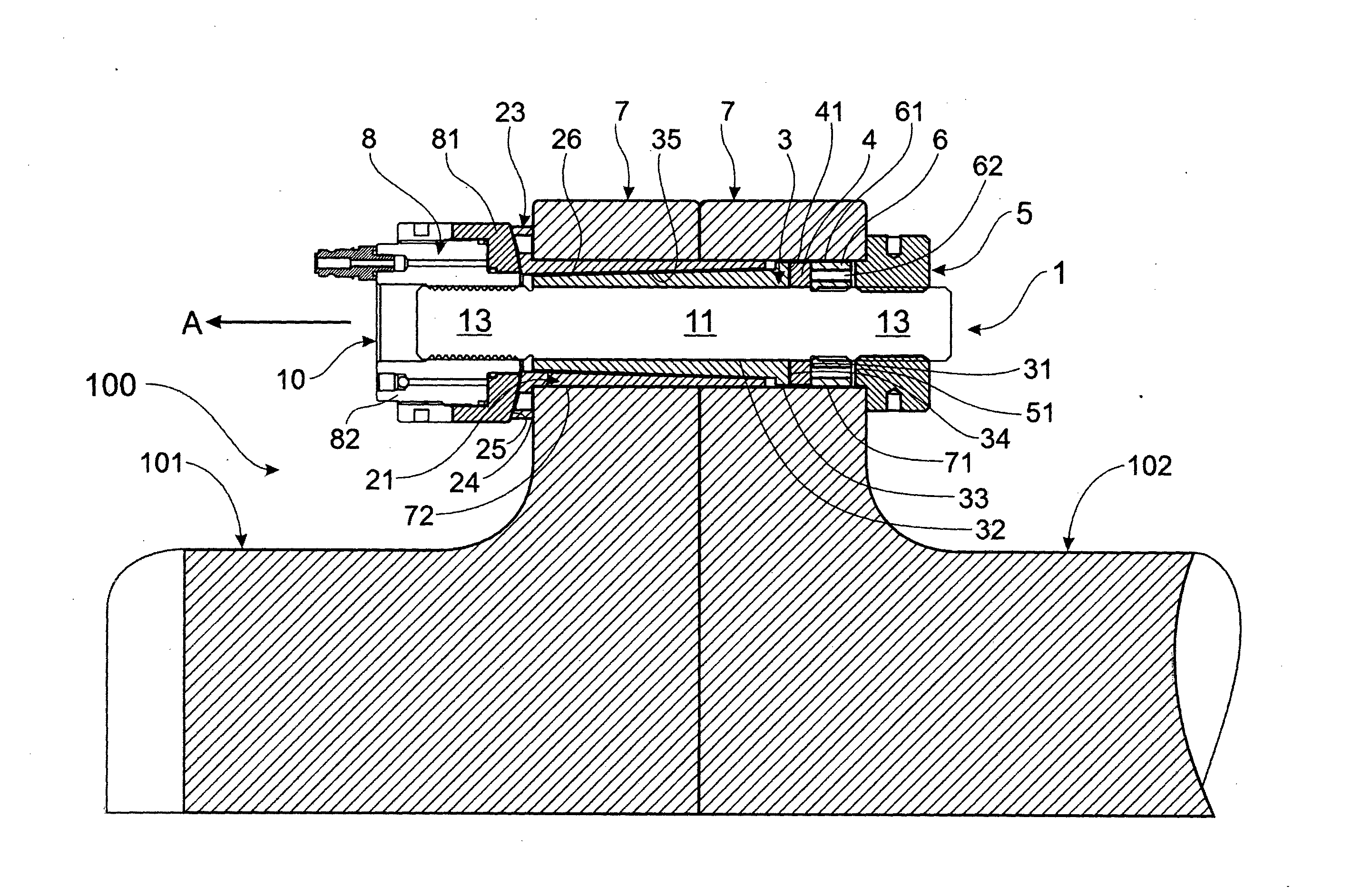

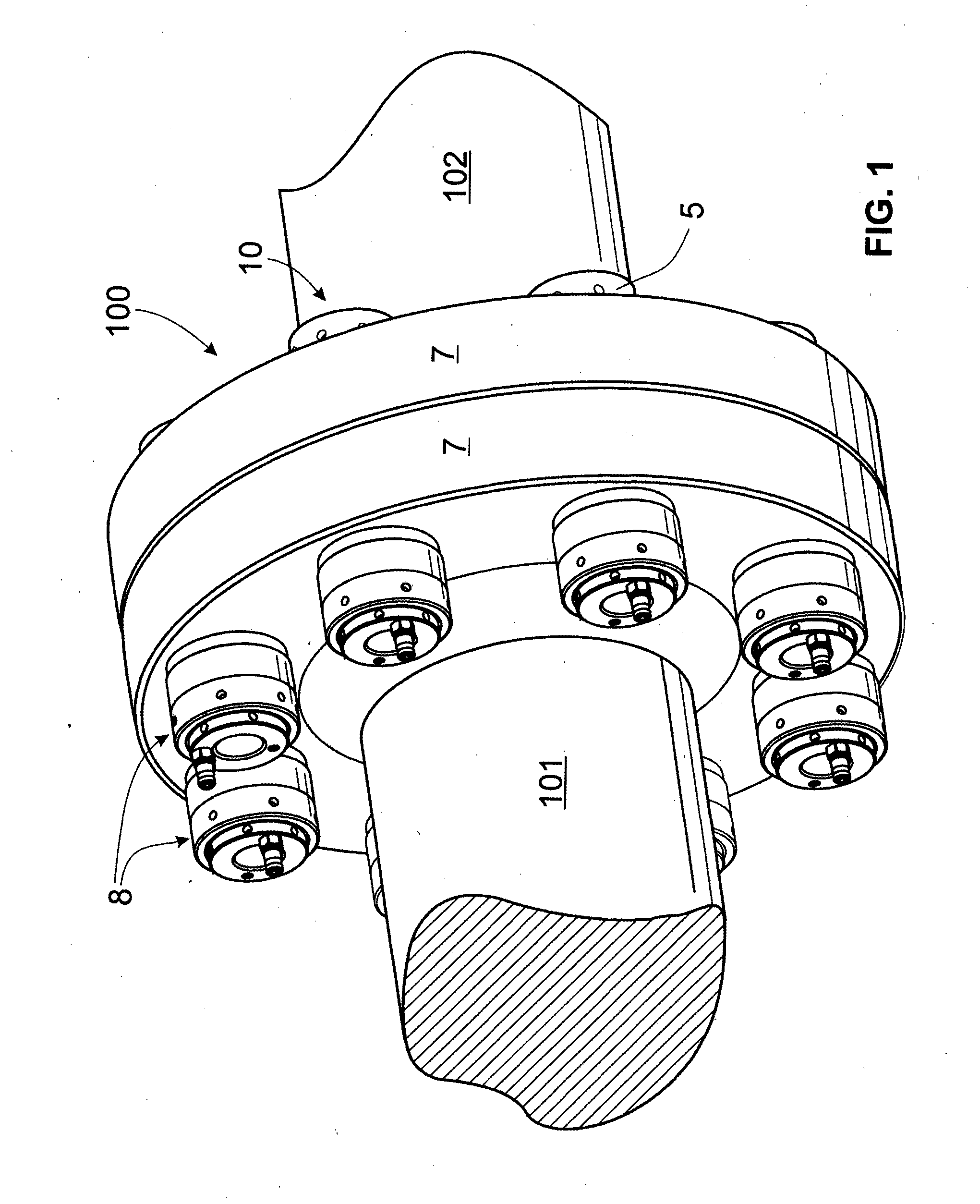

High-capacity radial fit coupling bolts

A high capacity radial-fit coupling bolt (or “expanding sleeve bolt”) has a pair of tapered sleeves about a shank of a bolt to which can be applied a tensioning load. An extrudable ring, or a compression ring, is interposed between a head nut or head flange at one end of the shank, and one end of an inner sleeve. A tensioning load is applied to the shank, the inner sleeve causing the outer sleeve to expand diametrically. At a preset load limit, the extrudable ring is extruded through at least one bore in a drive piston between the head nut and the extrudable ring, to allow shank to move relative to the inner sleeve until the tensioning load is fully applied. Alternatively, a drive member is provided between the head nut or head flange and the compression ring, and at a preset limit, the compression ring allows the shank to move relative to inner sleeve until the tensioning load is fully applied. The preset limit will typically correspond to the force required to fully expand the outer sleeve.

Owner:TECHNOFAST IND

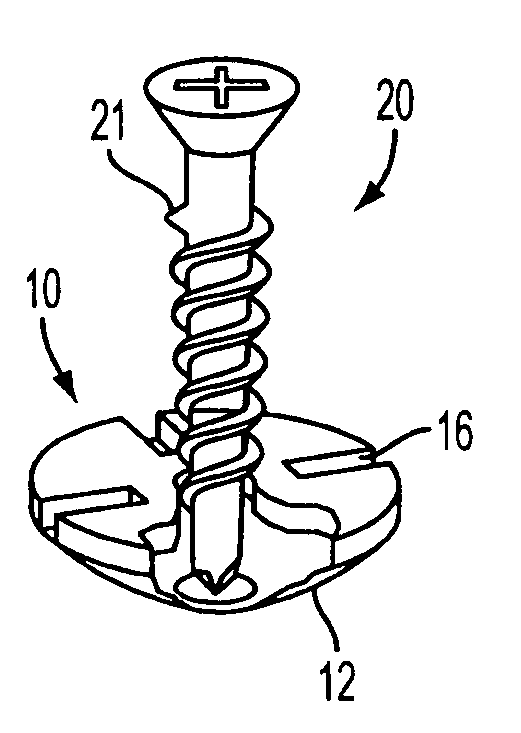

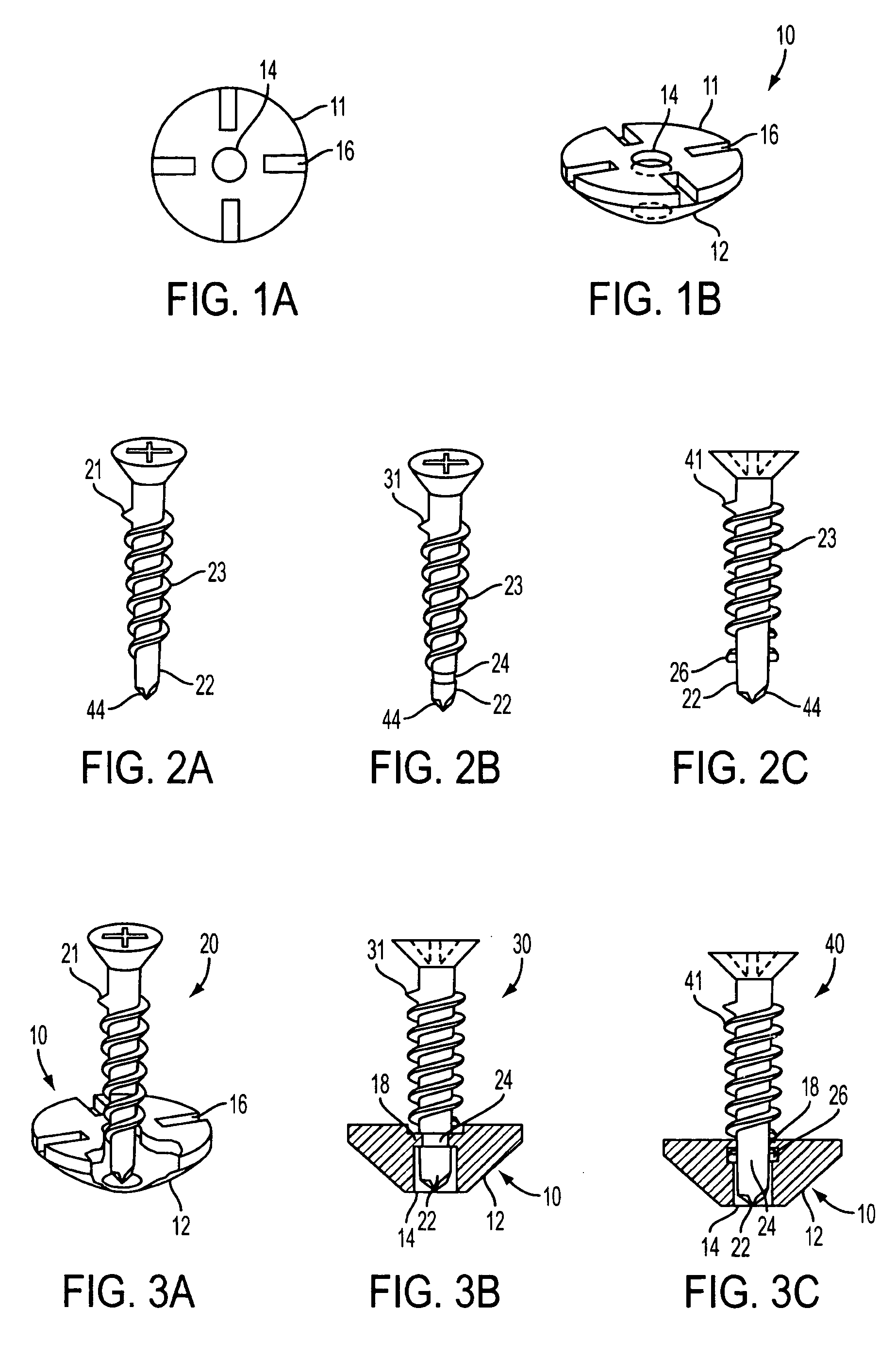

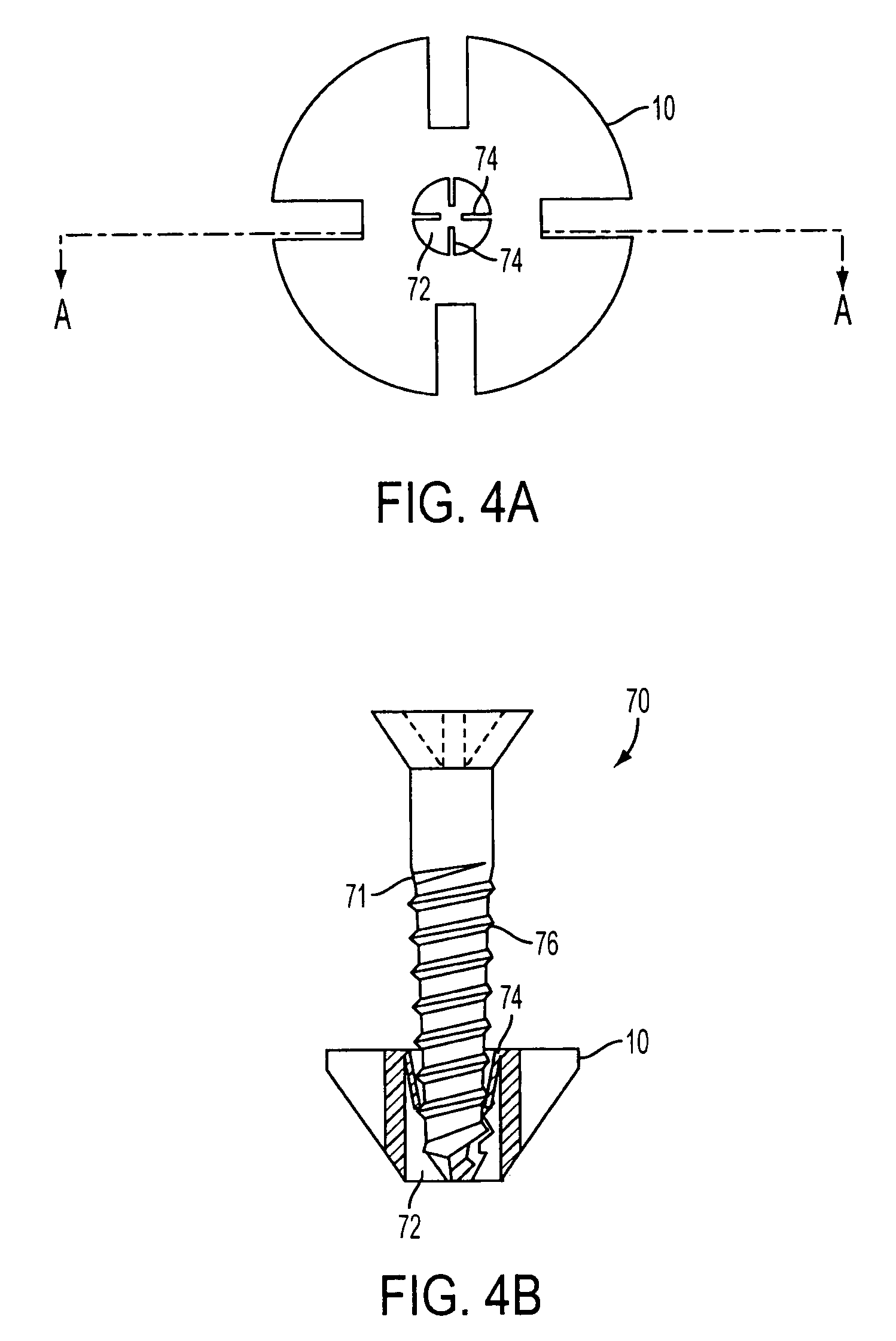

Screw and plastic part unit

A screw-plastic part unit in which the plastic part can be a guide having a tapered bottom end for fitting into a countersink to center the tip end of the screw in the countersink and also can have at least one cut-out portion at its top end to facilitate fracturing of the guide as the screw is threaded into a base member. In one embodiment the screw has a thread between its head and tip end which extends to near the tip end leaving a clear area between the thread end tip end and the part of plastic material molded around the screw clear area in which there can be a circumferential groove or rib into or over which the plastic part is molded to better hold the part to the screw. In another embodiment fins extend into the part hole to hold the screw by an interference type fit.

Owner:WEINSTEIN BURTON +1

Assigned torsion nut

A specified torque nut, which is suitable for tightening fittings, etc., can only be tightened to the specified tightening torque, and can be checked at a glance whether the tightening is complete or not. The torque operation part with the tool locking surface on the outside is integrally formed with the nut body with the female thread hole, and the torque operation part has a non-circular hole concentric with the female thread hole and larger in diameter than the female thread hole from the end surface to the nut body , At the junction between the nut main body and the torque operating part, there is a torque limiting part that surrounds the non-circular hole and includes at least two weak parts.

Owner:太西正胜 +1

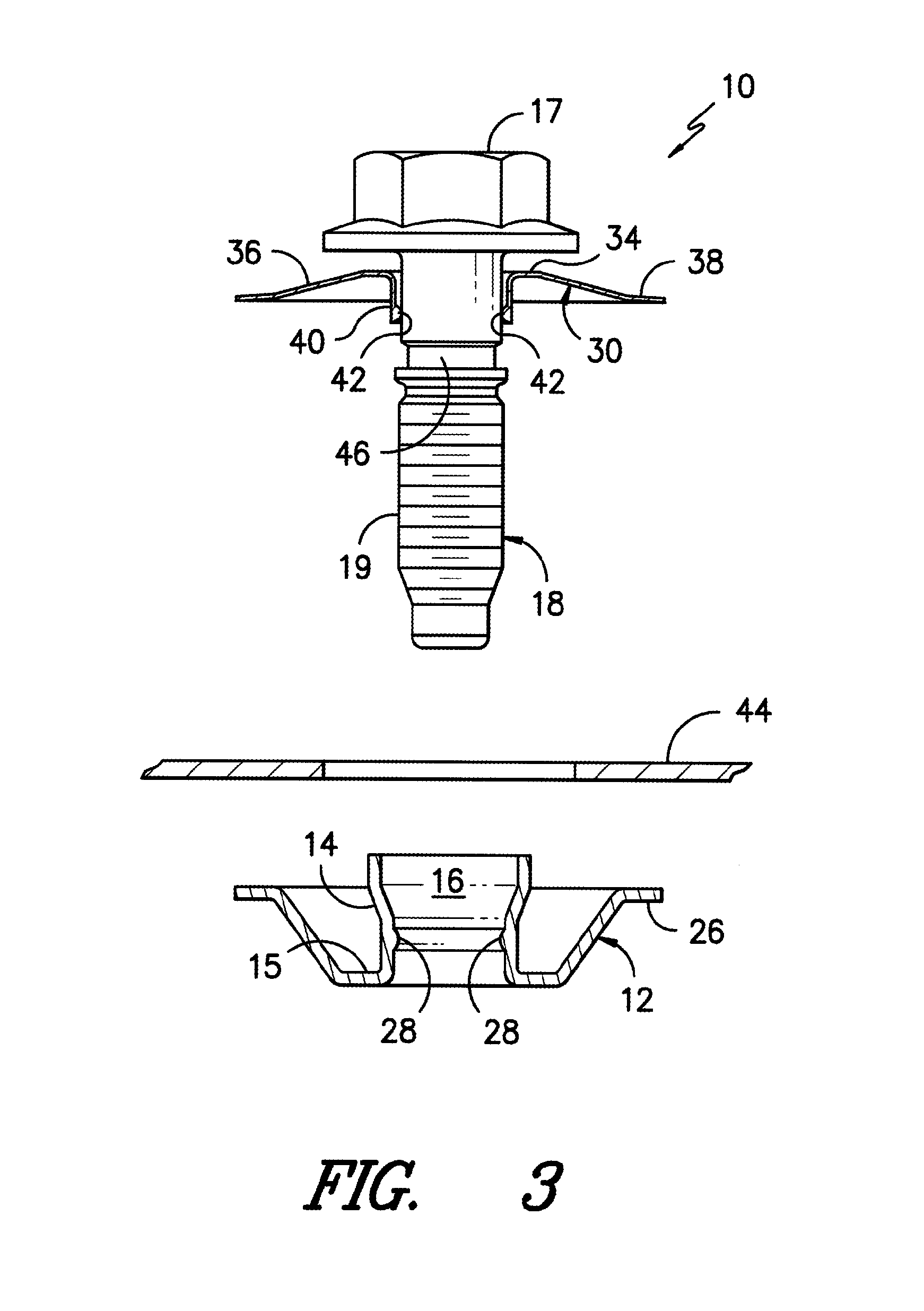

Light load compression limiting fastening system

A compression limiting fastening system incorporating a spring element and cooperating compression limiting sleeve adapted for substantially coaxial receipt of a fastening element through a fastened component so as to apply a relatively light load to an outer surface of the fastened component during the fastening operation. Once fastened down, the compression limiting sleeve supports the fastening load while the spring element applies a relatively light opposing load to the fastened component.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com