Patents

Literature

30results about "Cold pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hermetically sealing using a cold welded tongue and groove structure

ActiveUS8191756B2Provide goodReduce oxidationSemiconductor/solid-state device detailsSolid-state devicesHermetic sealEngineering

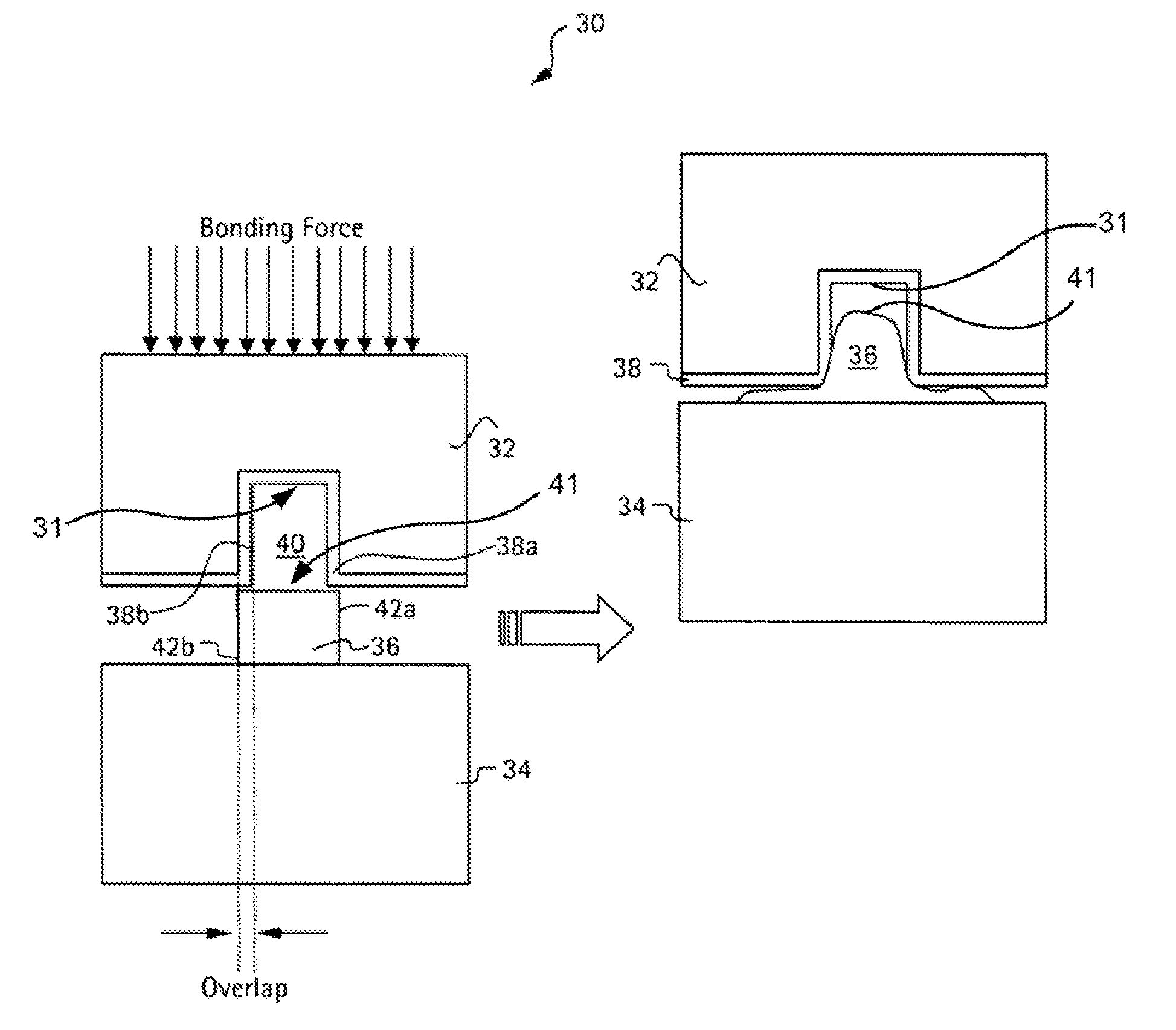

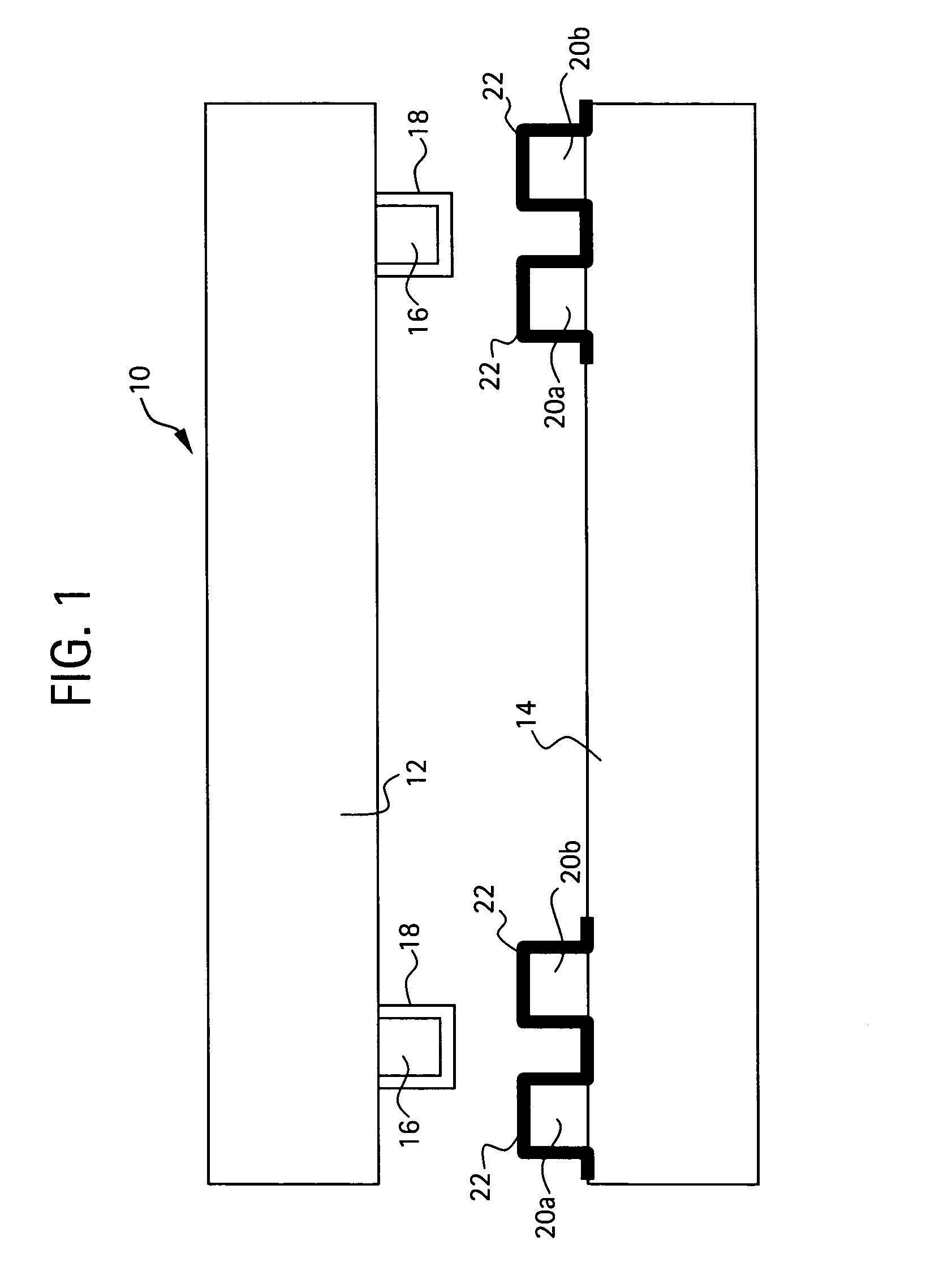

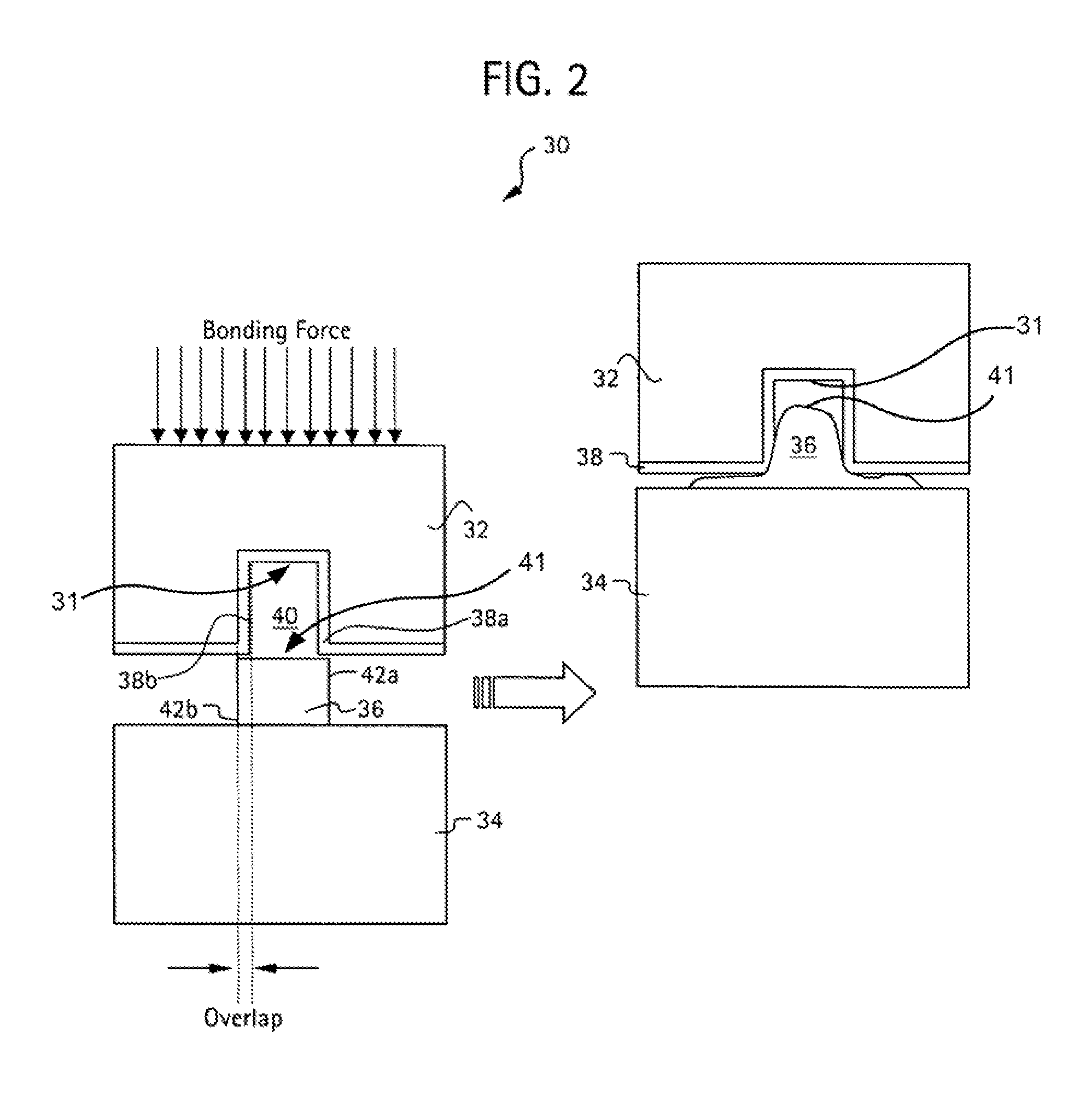

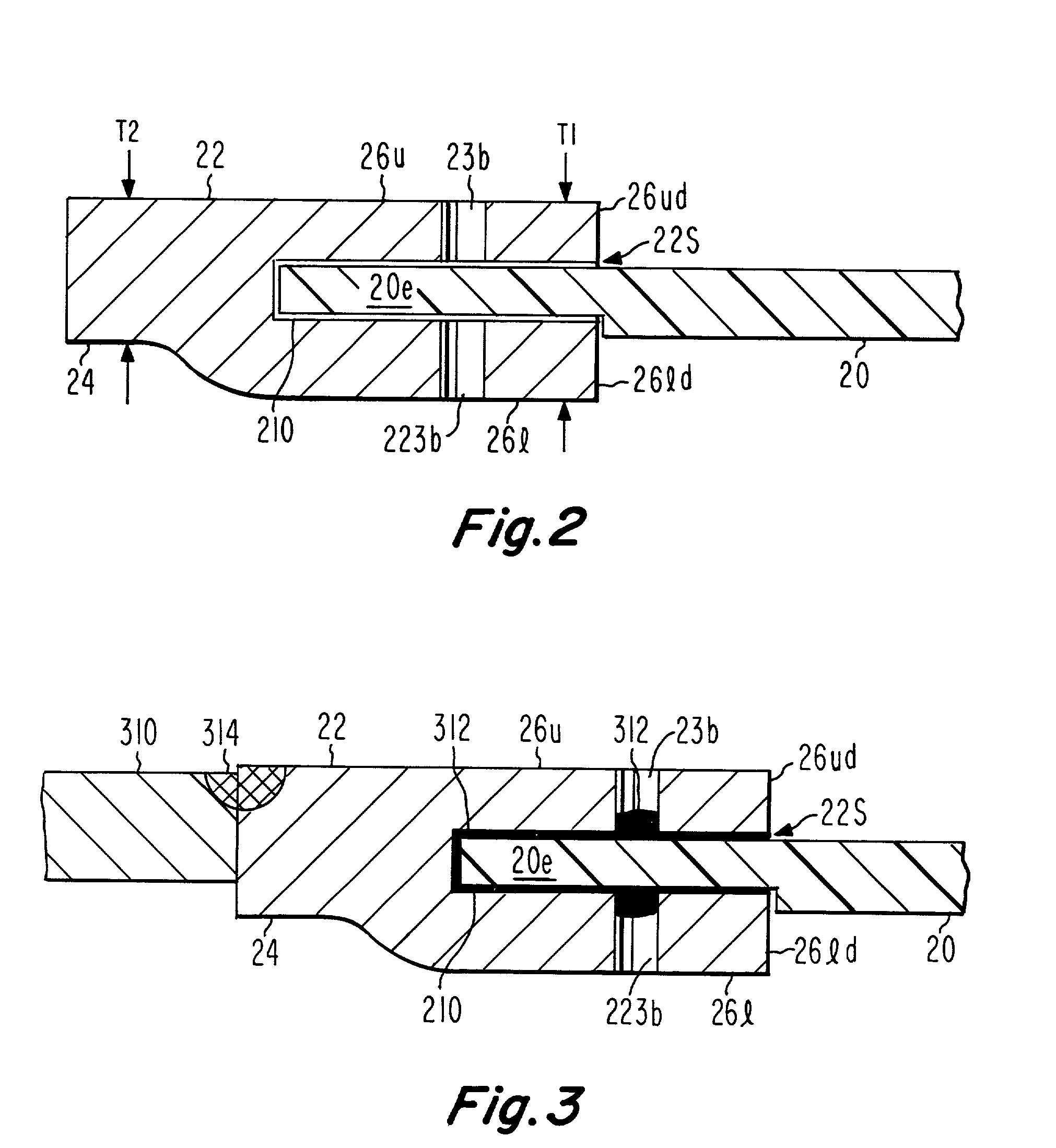

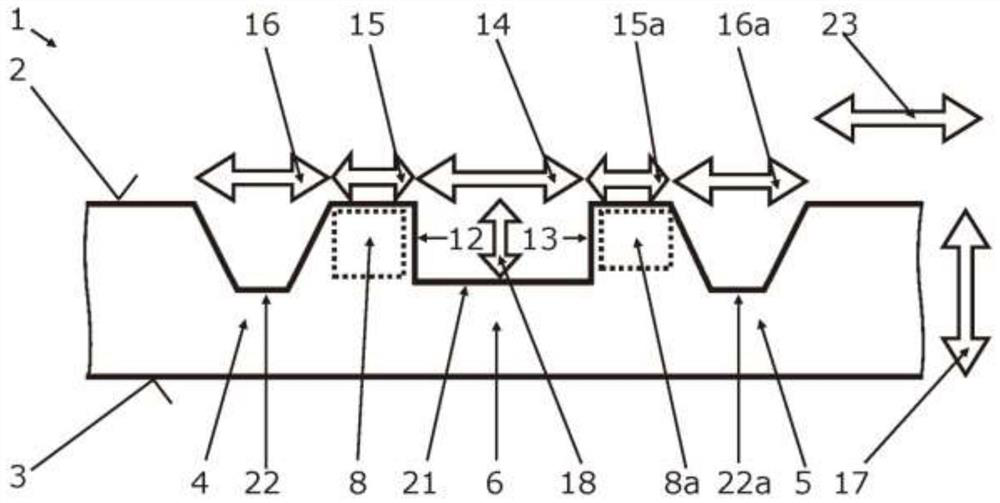

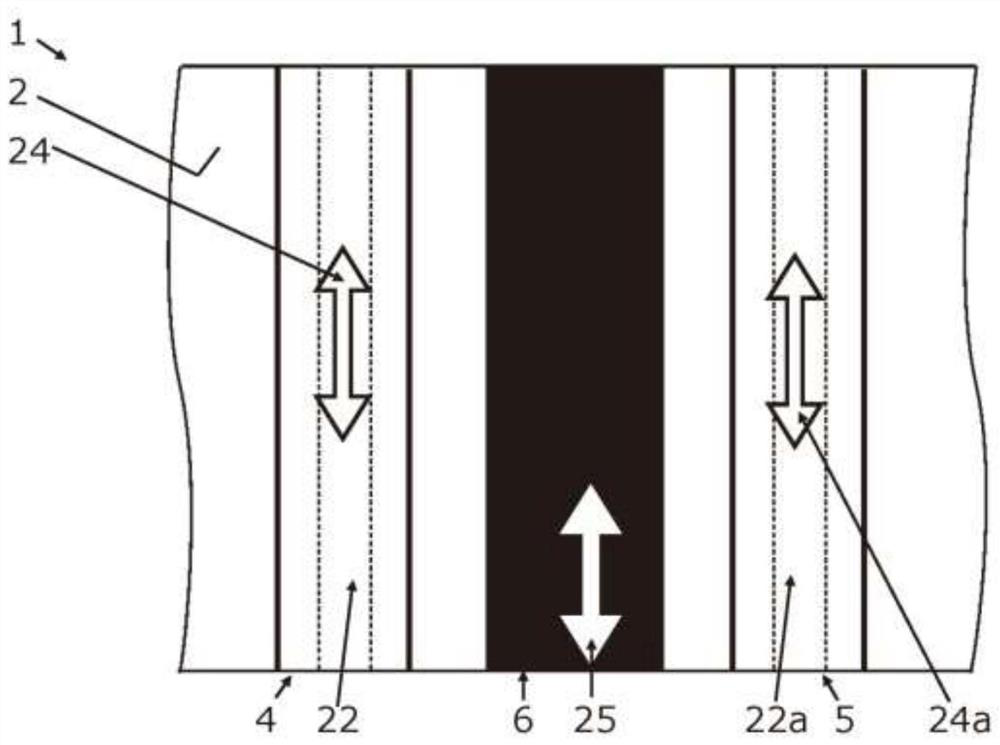

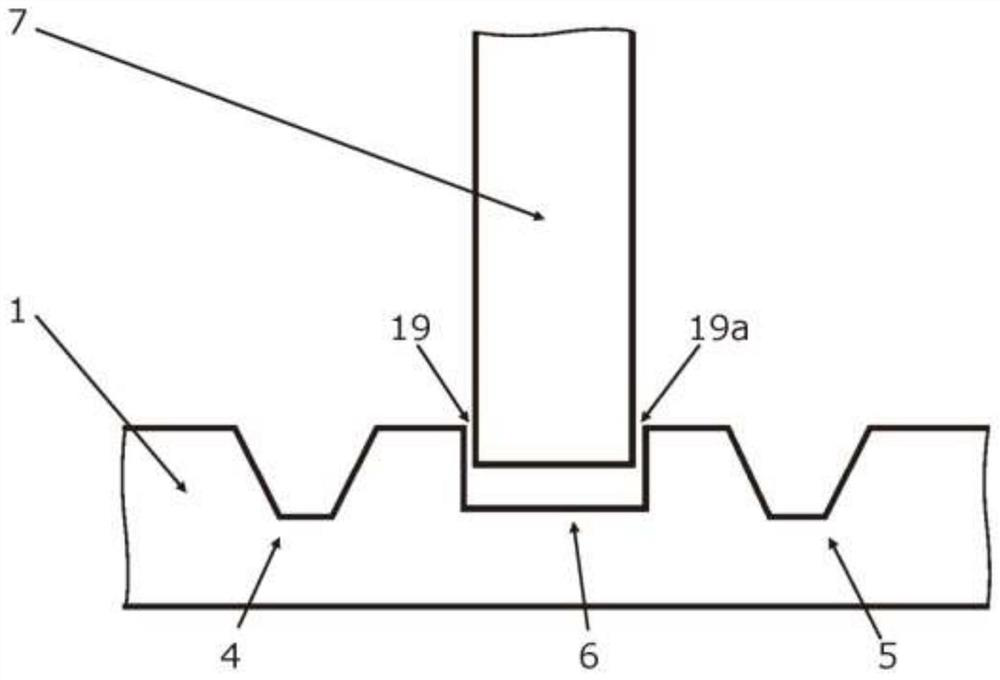

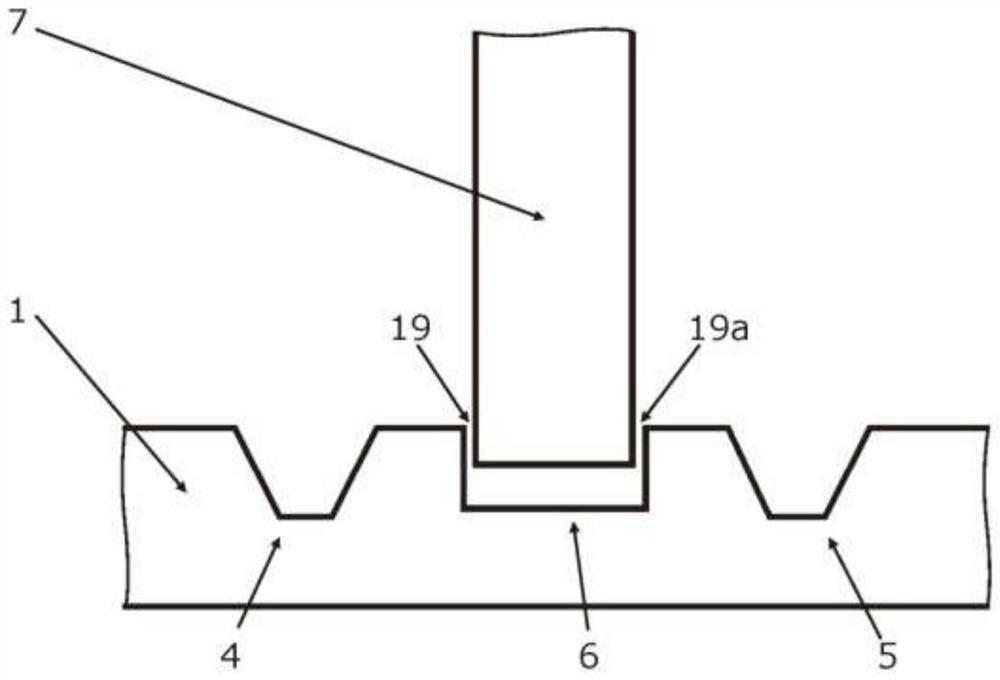

Compression cold welding methods, joint structures, and hermetically sealed containment devices are provided. The method includes providing a first substrate having at least one first joint structure which comprises a first joining surface, which surface comprises a first metal; providing a second substrate having at least one second joint structure which comprises a second joining surface, which surface comprises a second metal; and compressing together the at least one first joint structure and the at least one second joint structure to locally deform and shear the joining surfaces at one or more interfaces in an amount effective to form a metal-to-metal bond between the first metal and second metal of the joining surfaces. Overlaps at the joining surfaces are effective to displace surface contaminants and facilitate intimate contact between the joining surfaces without heat input. Hermetically sealed devices can contain drug formulations, biosensors, or MEMS devices.

Owner:DARE MB INC

Leak-proof fastening device and assembly method thereof

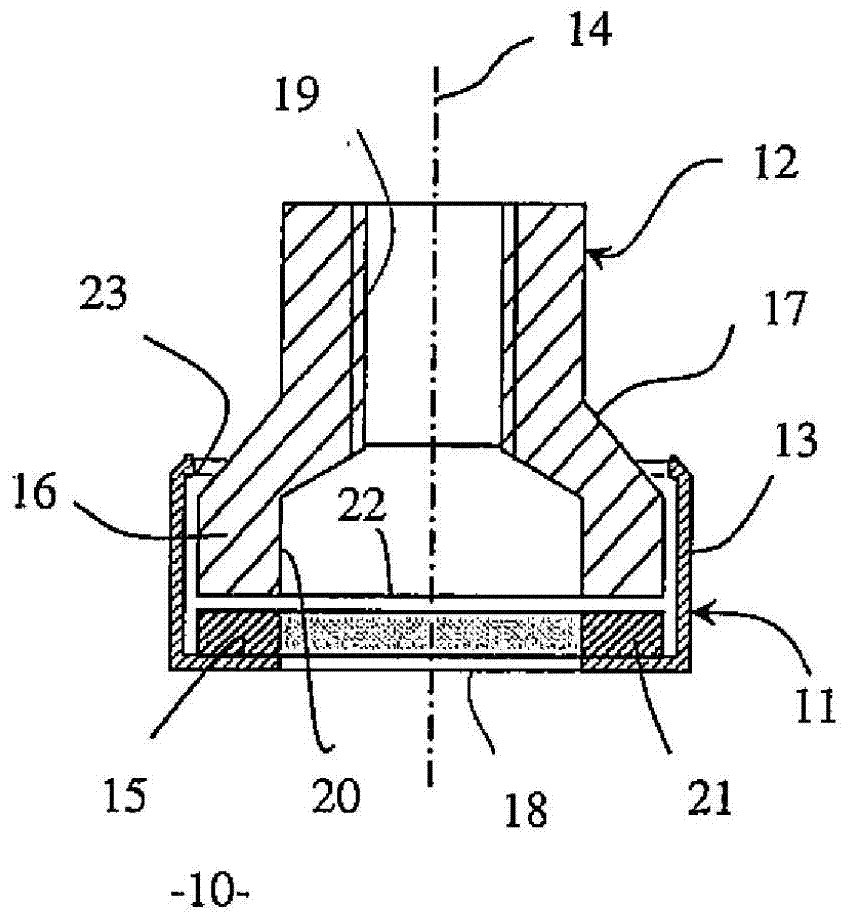

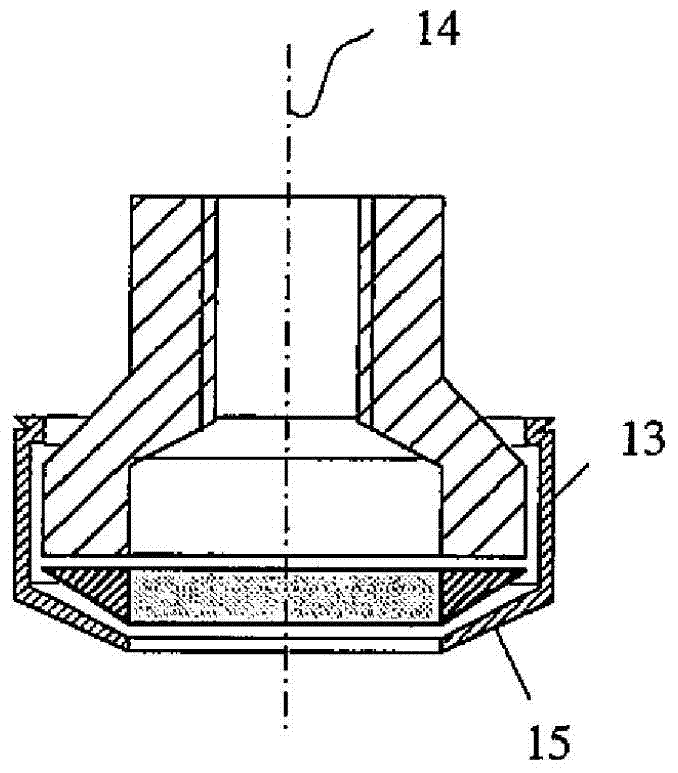

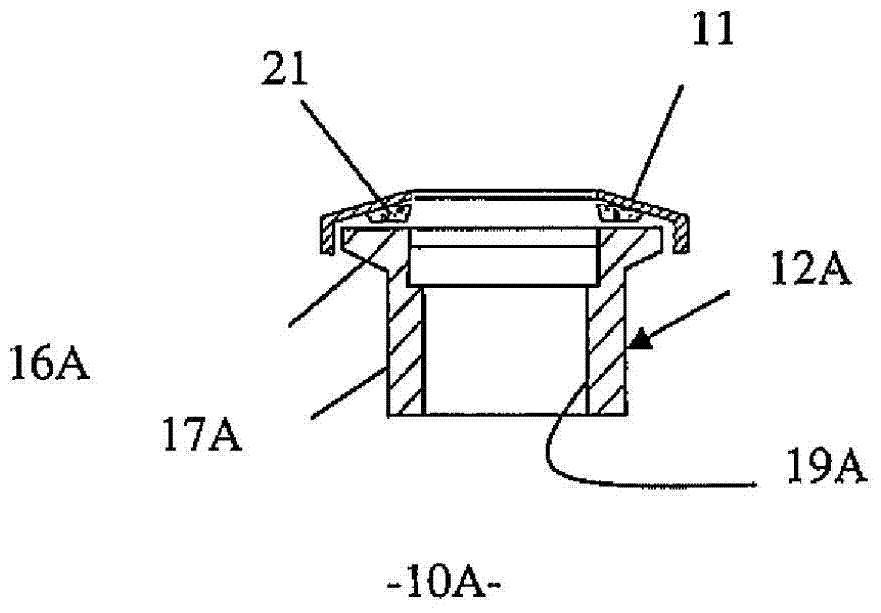

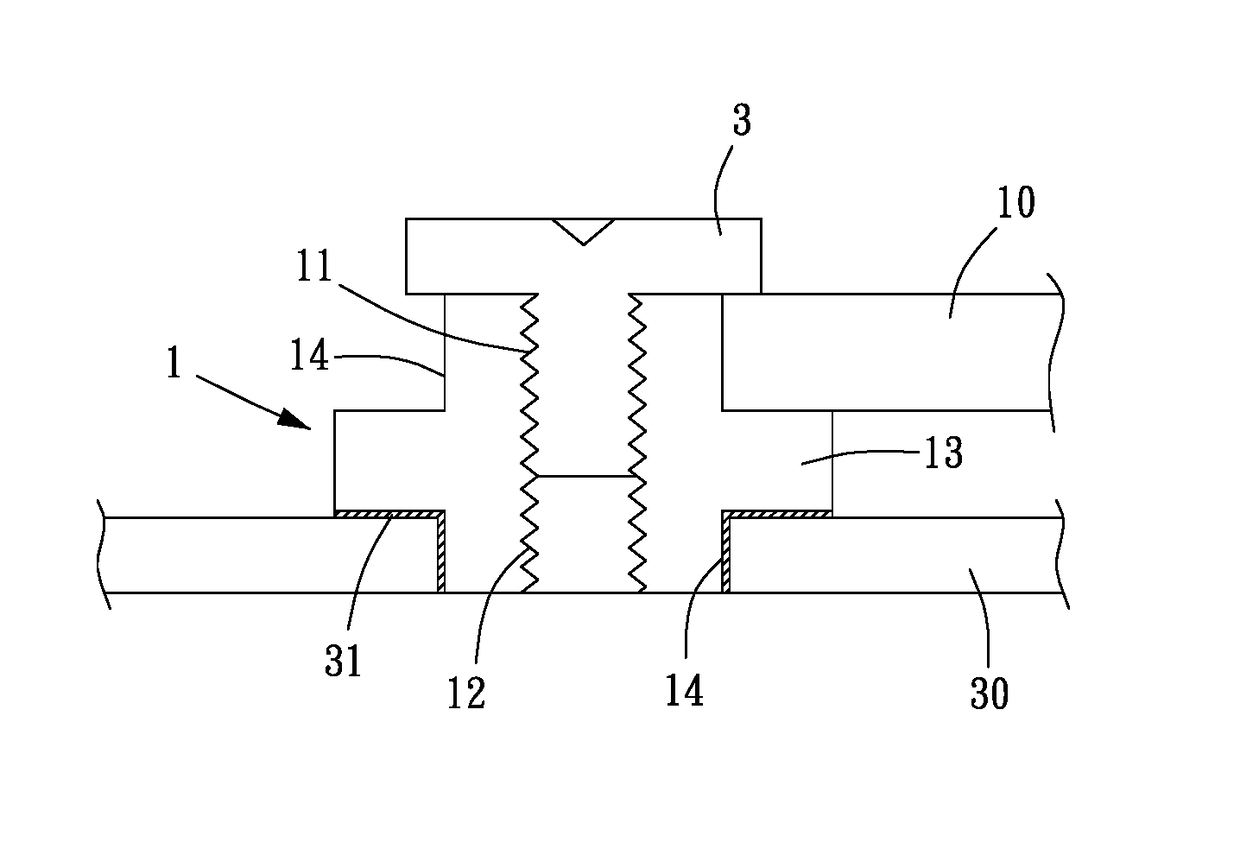

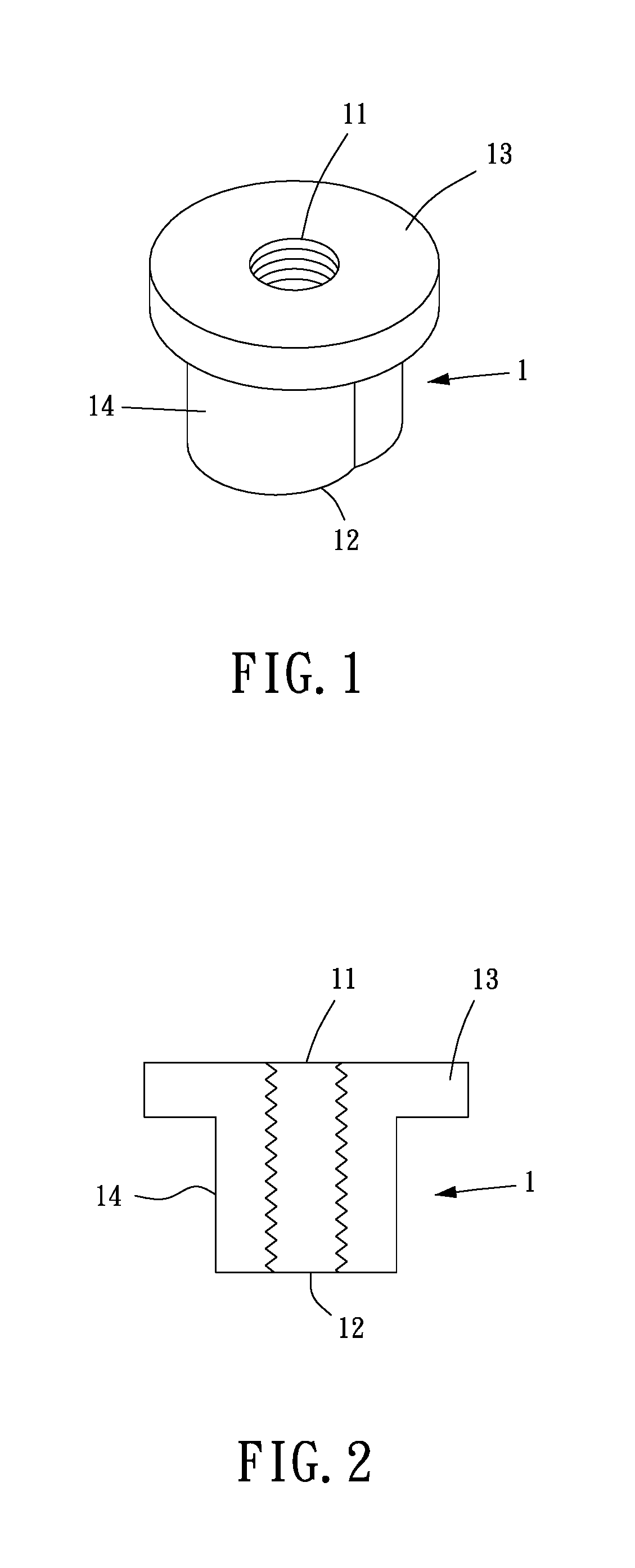

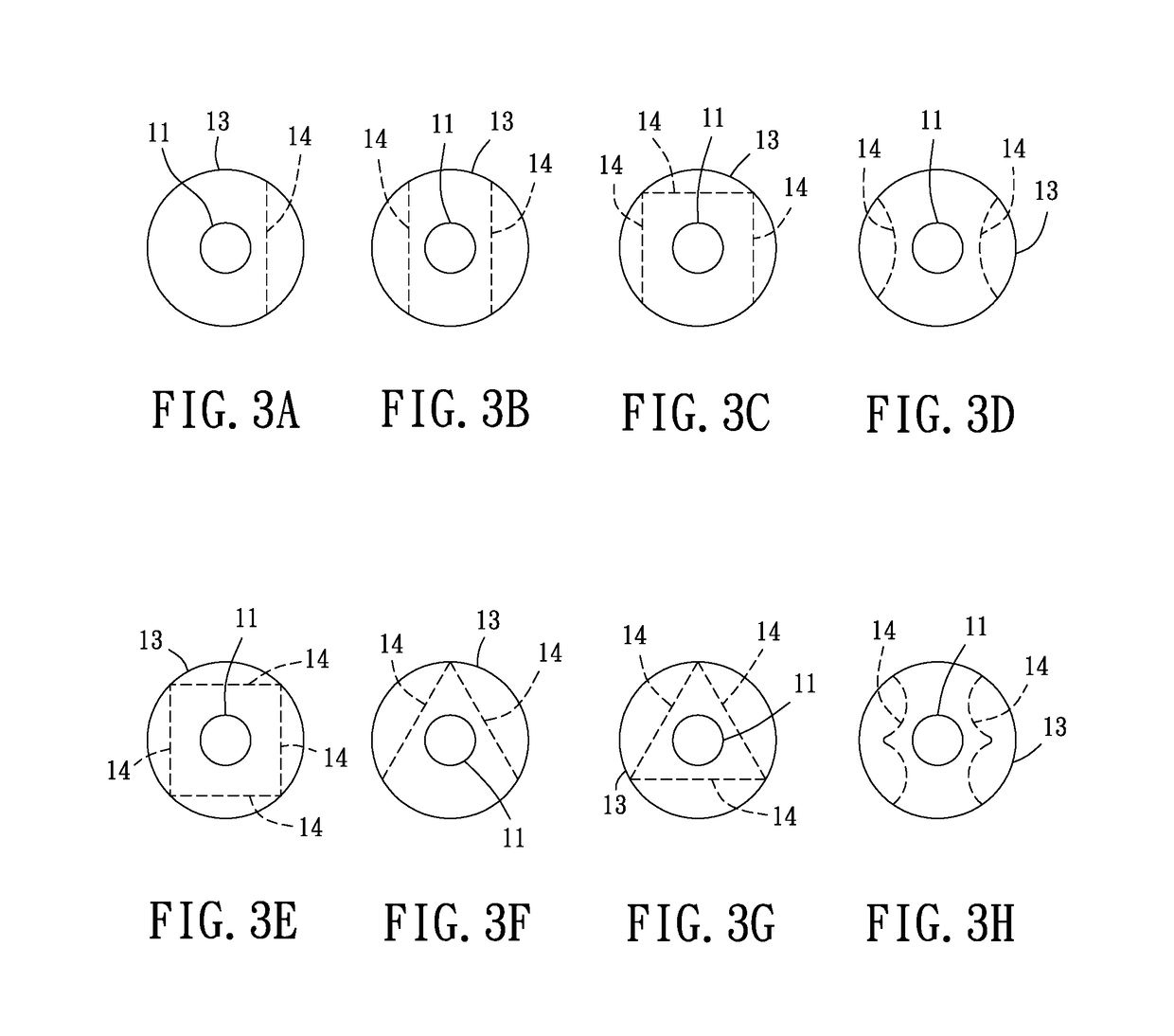

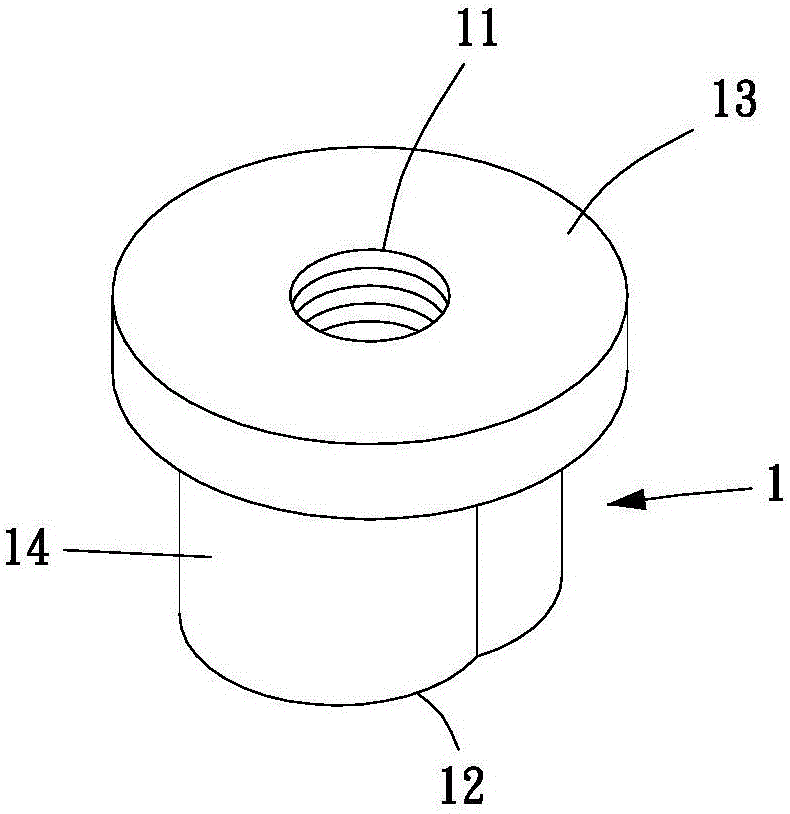

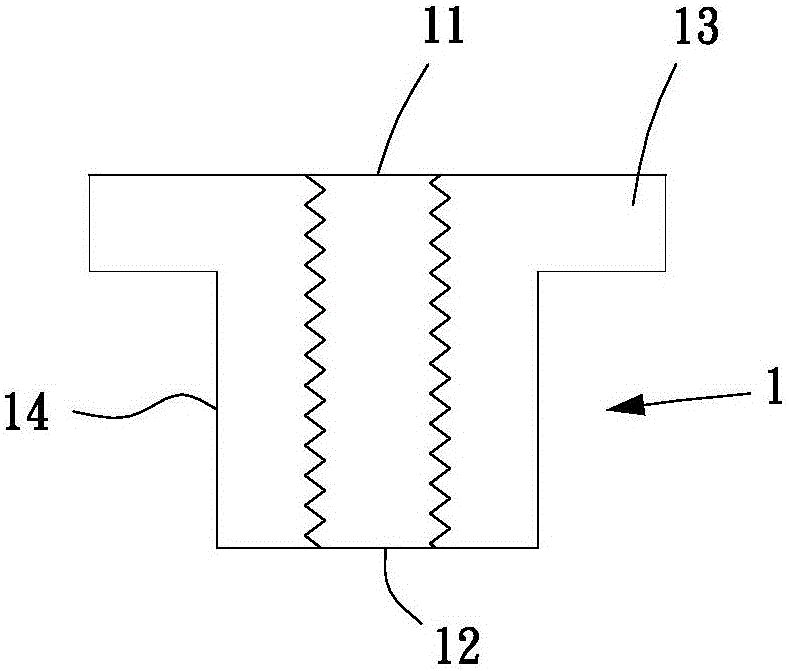

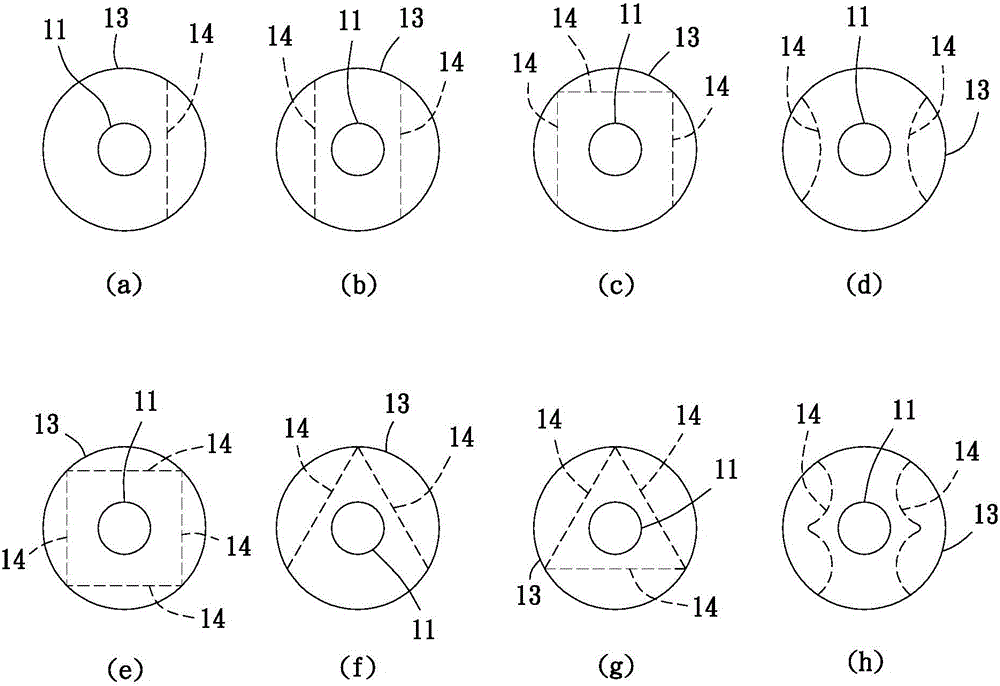

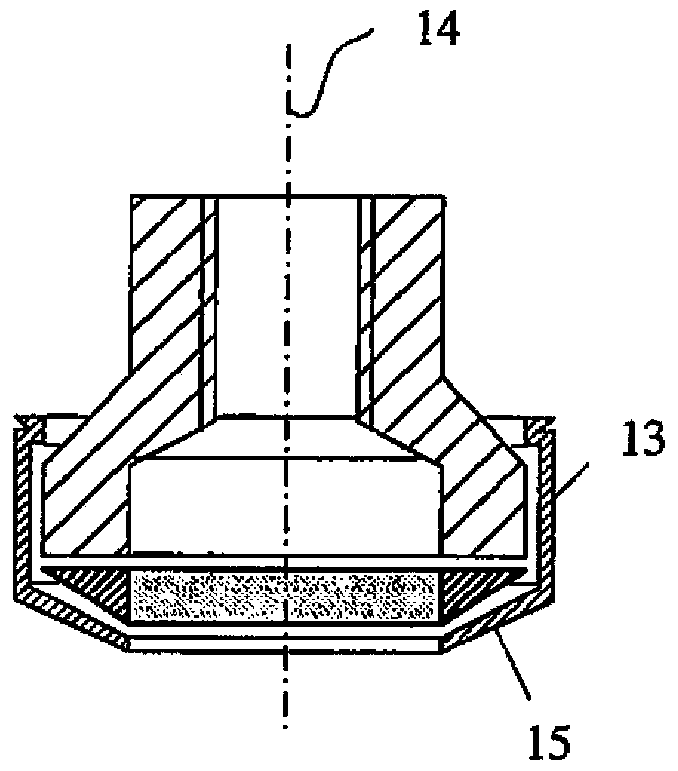

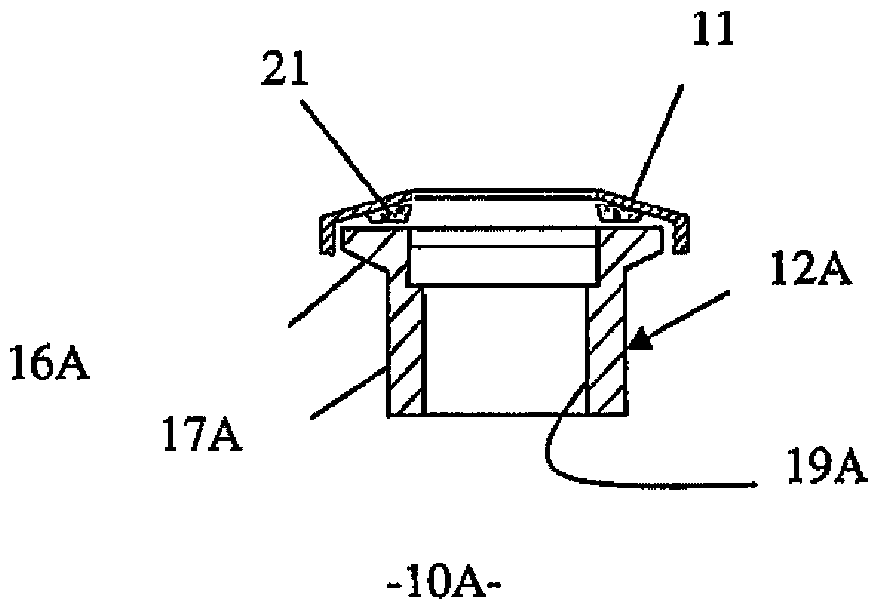

The invention provides a leak-proof fastening device and an assembly method thereof. The leak-proof fastening device comprises an annular base (15) and a washer (11) of a substantially cylindrical skirt (13) at the outer periphery of the annular base. The annular base comprising a central orifice (18) coaxial with the axis (14) of the skirt, characterized in that the annular base is at least partially covered with a layer (21) of a viscous composition capable of forming a liquid-tight coating through polymerization. When installing a nut having such a washer onto a male fastener such as a pin (33), the spreading of the viscous layer makes it possible to fill in the gaps (36) of the assembly, the polymerization of the composition ensuring its leak-tightness afterwards.

Owner:LISI AEROSPACE

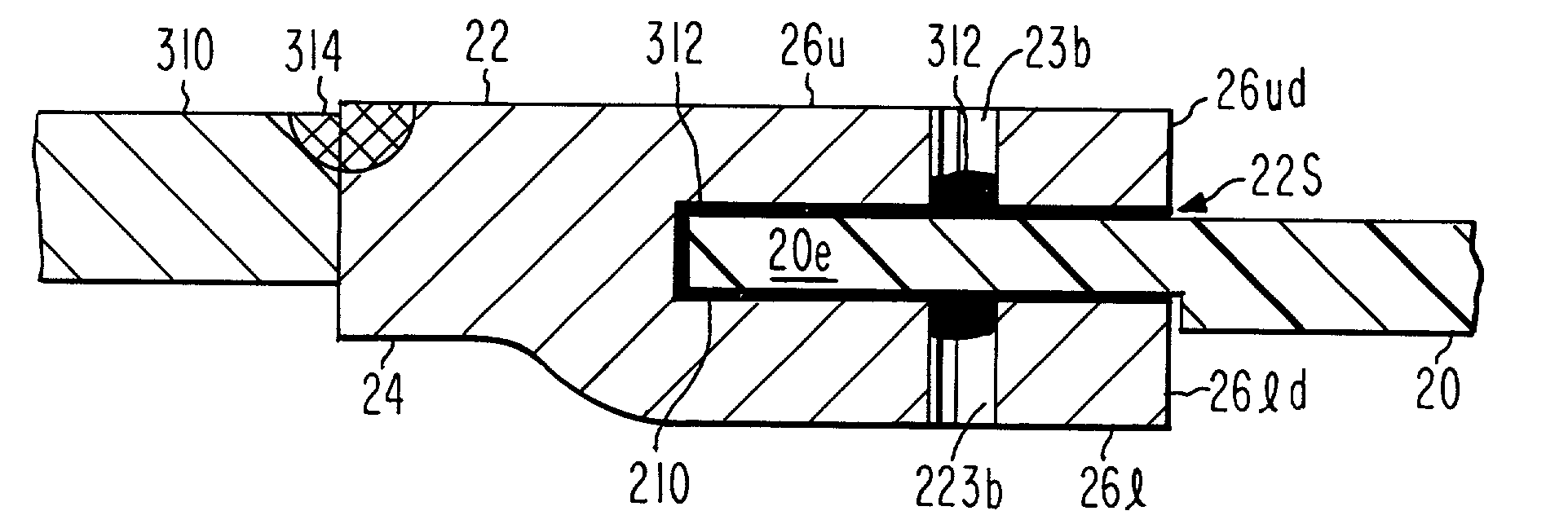

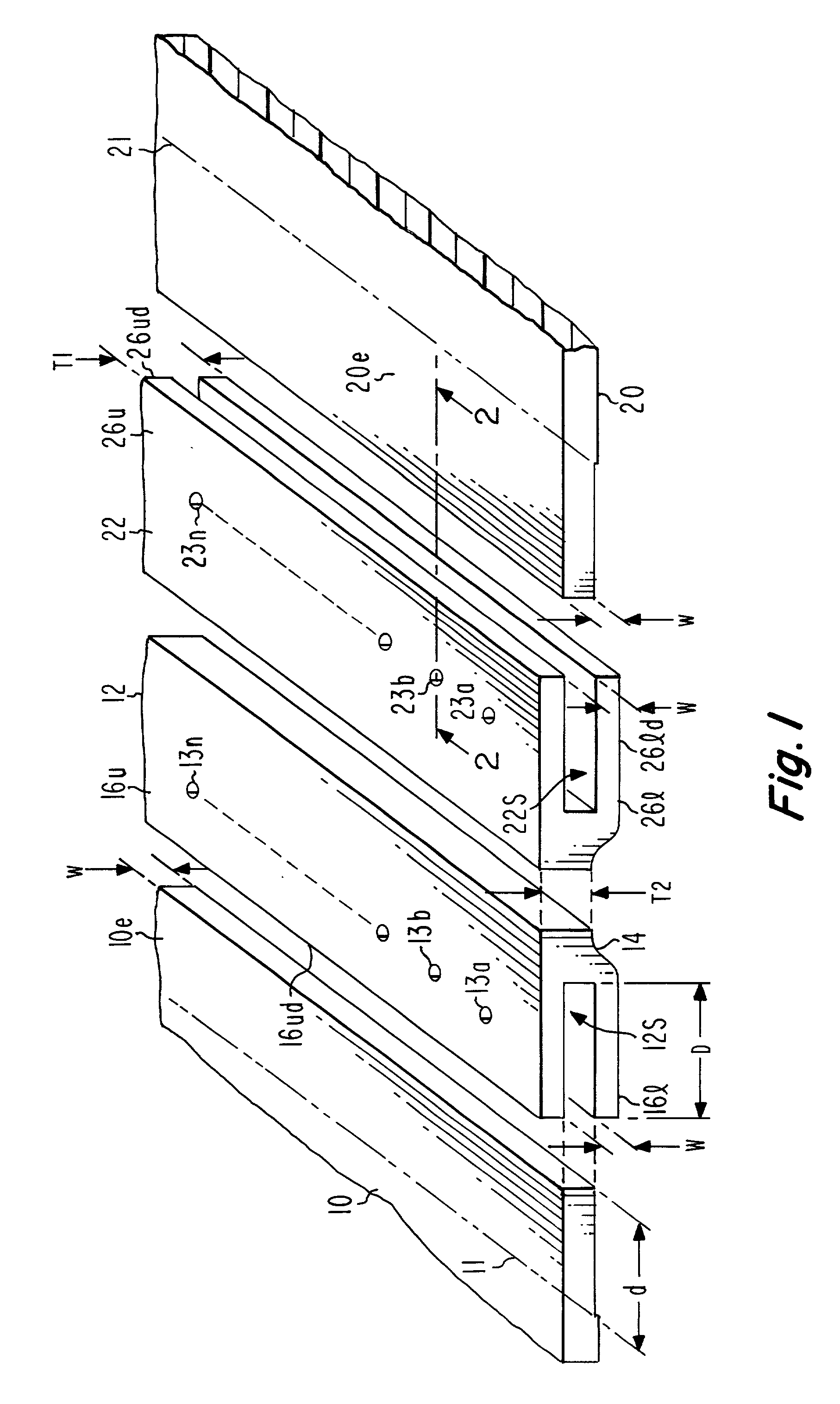

Method for making large composite structures without use of an autoclave

A method for fabrication or production of composite structures, which has particular advantages when fabricating large structures, includes the steps of procuring a composite panel, such as carbon-fiber-reinforced resin. The edge of the composite panel is adhesively fixed in the slot of a bifurcated metallic piece. After the composite panel is adhesively fixed to the metallic piece, the metallic piece is stir-friction welded to another metal piece. The stir-friction welding occurs at a lower temperature than fusion welding, and so the adhesive bond between the metallic element and the composite panel is less affected. When two composite panels are each adhesively fastened to a metallic element, the two metallic elements can, in turn, be stir-friction welded. Thus, large panels can be fabricated.

Owner:LOCKHEED MARTIN CORP

Multisecuring component

Owner:FIVETECH TECH INC

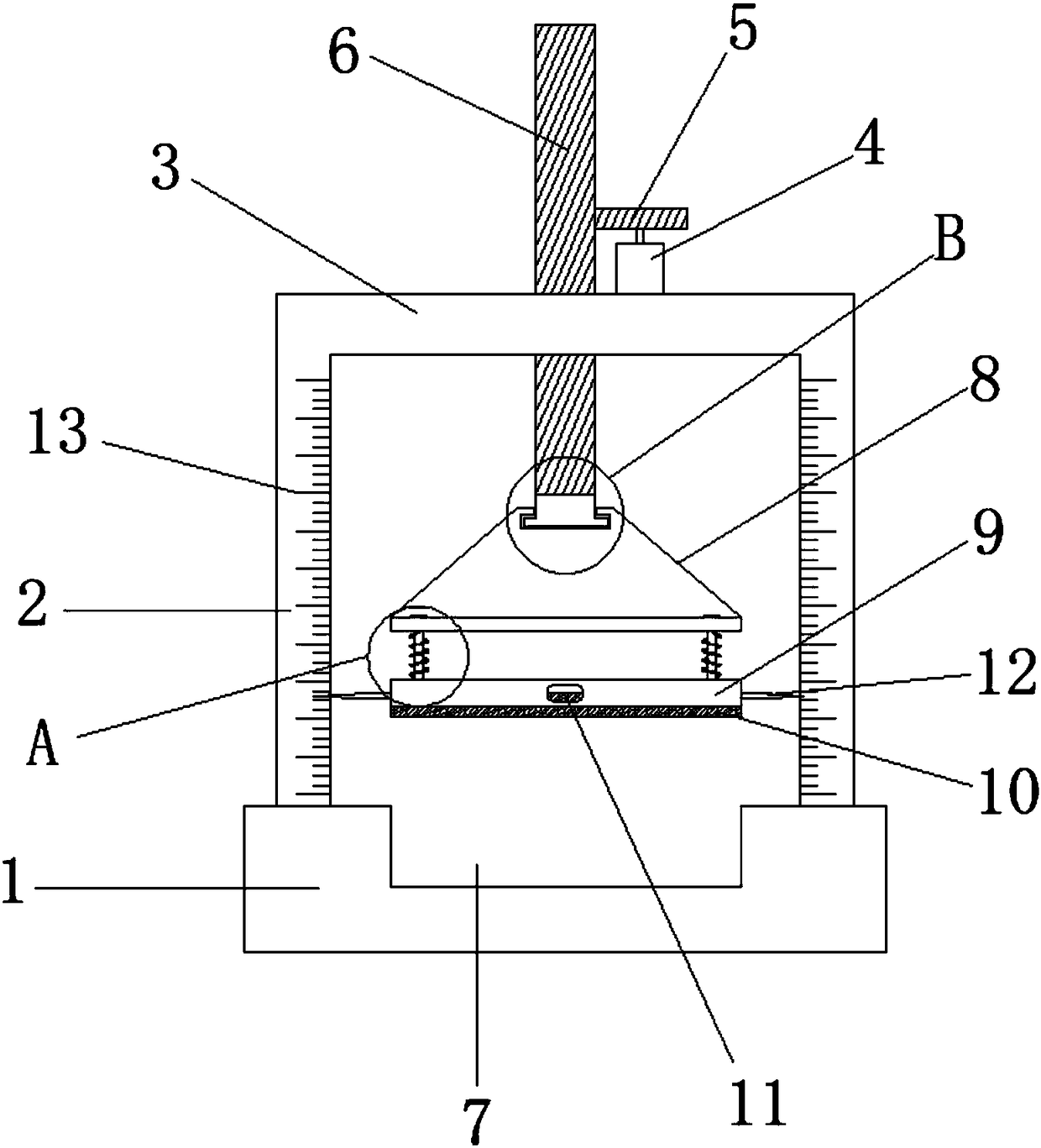

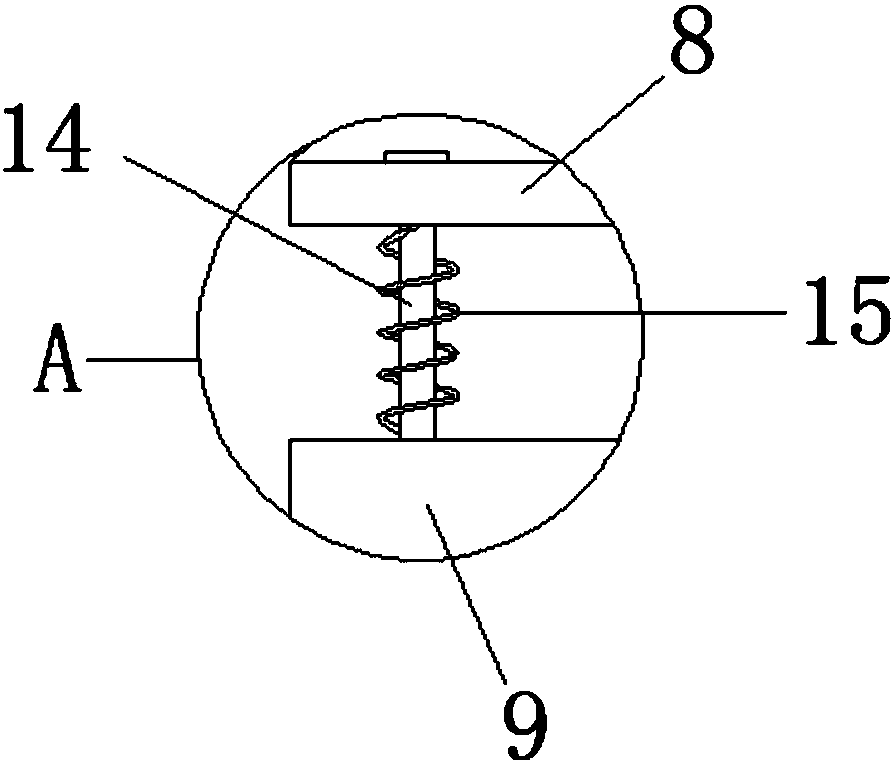

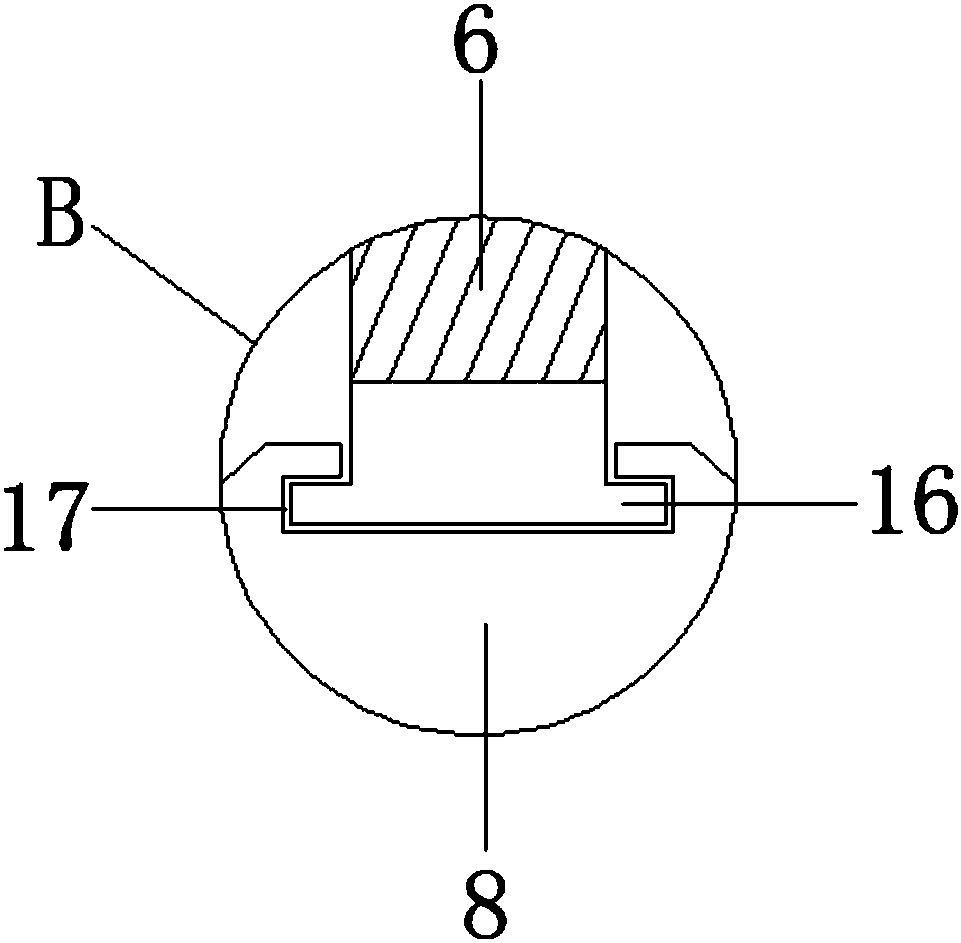

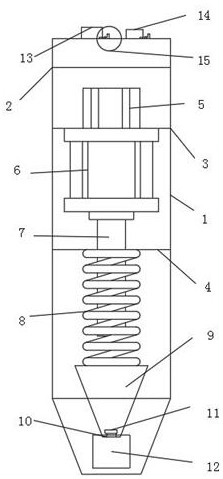

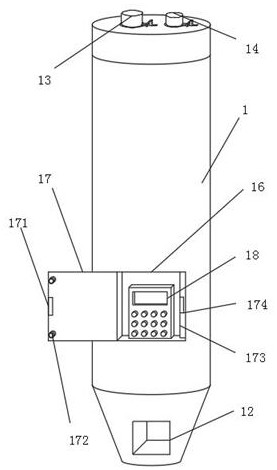

Pressure sensor patch pressurization device

InactiveCN108412867AAvoiding Zero Output InconsistenciesSimple structureCold pressureForce measurementTransverse planeEngineering

The invention discloses a pressure sensor patch pressurization device. The device comprises a base, two vertical plates are symmetrically arranged on the top wall of the base, the top ends of the twovertical plates are jointly provided with a transverse plate, a motor is arranged on the top wall of the transverse plate, a bevel gear is arranged at the driving end of the motor, the side wall of the bevel gear is meshed with a bevel gear rod, the bevel gear rod penetrates through the top wall of the transverse plate and extends to the lower side of the transverse plate, a trapezoid block is arranged at the bottom end of the bevel gear rod, a rotary groove is formed in the top of the trapezoid block, the bottom end of the bevel gear rod penetrates through the top wall of the trapezoid blockand extends into the interior of the rotary groove. According to the device, the structure is simple, the operation is convenient, by accurately controlling the pressure applied to a sensor patch, thesituation that zero-position output is inconsistent after the sensor patch is installed can be avoided, so that the sensor does not need to be corrected, and the cost output is saved.

Owner:江琴兰

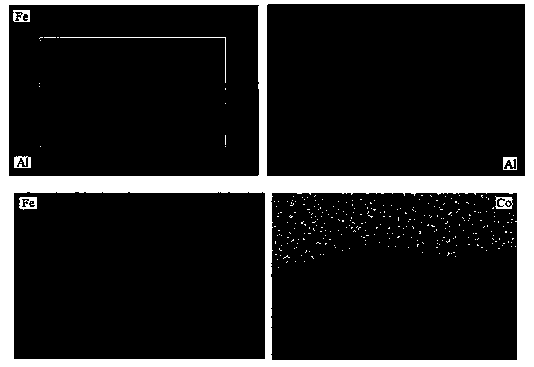

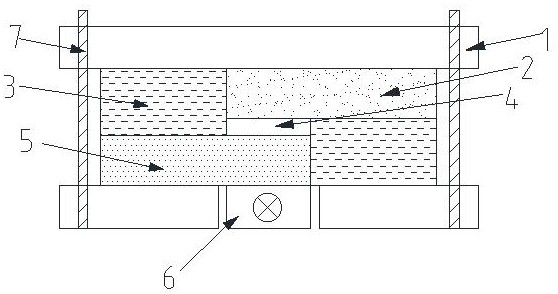

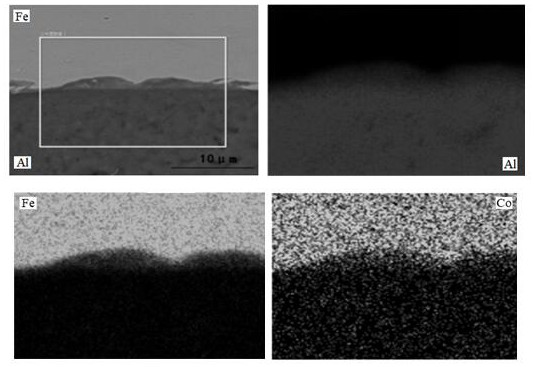

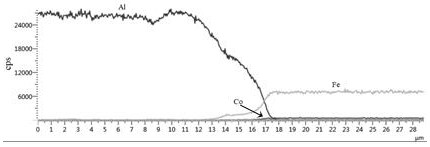

Method for improving corrosion resistance of welding joint between aluminum plate and steel plate

ActiveCN110666329AImprove performanceImprove corrosion resistanceCold pressureNon-electric welding apparatusLap jointWear resistance

The invention belongs to the technical field of application welding, and particularly discloses a method for improving the corrosion resistance of a welding joint between an aluminum plate and a steelplate. The method comprises the following steps that a layer of cobalt is plated on the to-be-welded surface of the steel plate for standby application; then the steel plate is used as a base plate,the aluminum plate is a compound plate, the aluminum plate and the steel plate are assembled on a welding clamp tool, and a certain lap joint length and a lap joint gap are kept between the aluminum plate and the steel plate; the plane formed through the lap joint between the aluminum plate and the steel plate is a to-be-welded surface; a coil is arranged below the aluminum plate, and a pressing plate is arranged above the steel plate; and finally, the aluminum plate and the steel plate are welded by using the electromagnetic pulse. According to the method, the corrosion resistance, the wear resistance and the high temperature resistance of the welding joint can be improved, the generation of aluminum and steel intermetallic compounds and mother material fragments can be effectively prevented, and the performance of the welding joint between the aluminum plate and the steel plate is improved.

Owner:CHONGQING UNIV OF TECH

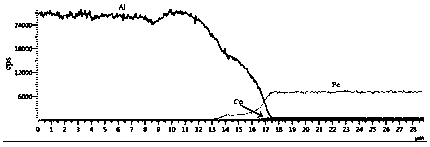

Cold welding process repairing method for oil field storage tank, without hot work

InactiveCN112524388AImprove mechanical propertiesHigh compressive strengthCold pressurePipe elementsCompressive resistanceHot work

The invention discloses a cold welding process repairing method for an oil field storage tank, without hot work, which comprises the steps that according to different construction conditions, surfacetreatment is conducted on the periphery of a leakage point of an oil field storage tank, and surface paint, rust, greasy dirt and a corroded loose layer on the periphery of the leakage point are completely removed; cold welding repair glue is prepared; gluing is conducted: the prepared cold welding repair glue is uniformly coated on the damaged leakage point part of the oil field storage tank, thedamaged part is firstly filled and leveled up, and then coated; bonding and curing are conducted; and after an expected leaking stoppage purpose is achieved through inspection, redundant viscose is ground, and the appearance of the bonding portion is kept attractive and smooth. The cold welding process repairing method for an oil field storage tank, without hot work, provided by the invention islow in repairing cost and short in repairing period, a special cold welding repairing glue bonding technology is adopted, good mechanical capacity and compressive strength can be provided, and for oilfield storage tank pipe wall damage repairing, the high grabbing force and adhesive force are achieved, and it is guaranteed that the repairing and reinforcing effect is effective for a long time.

Owner:郑州新锐石油工程技术有限公司

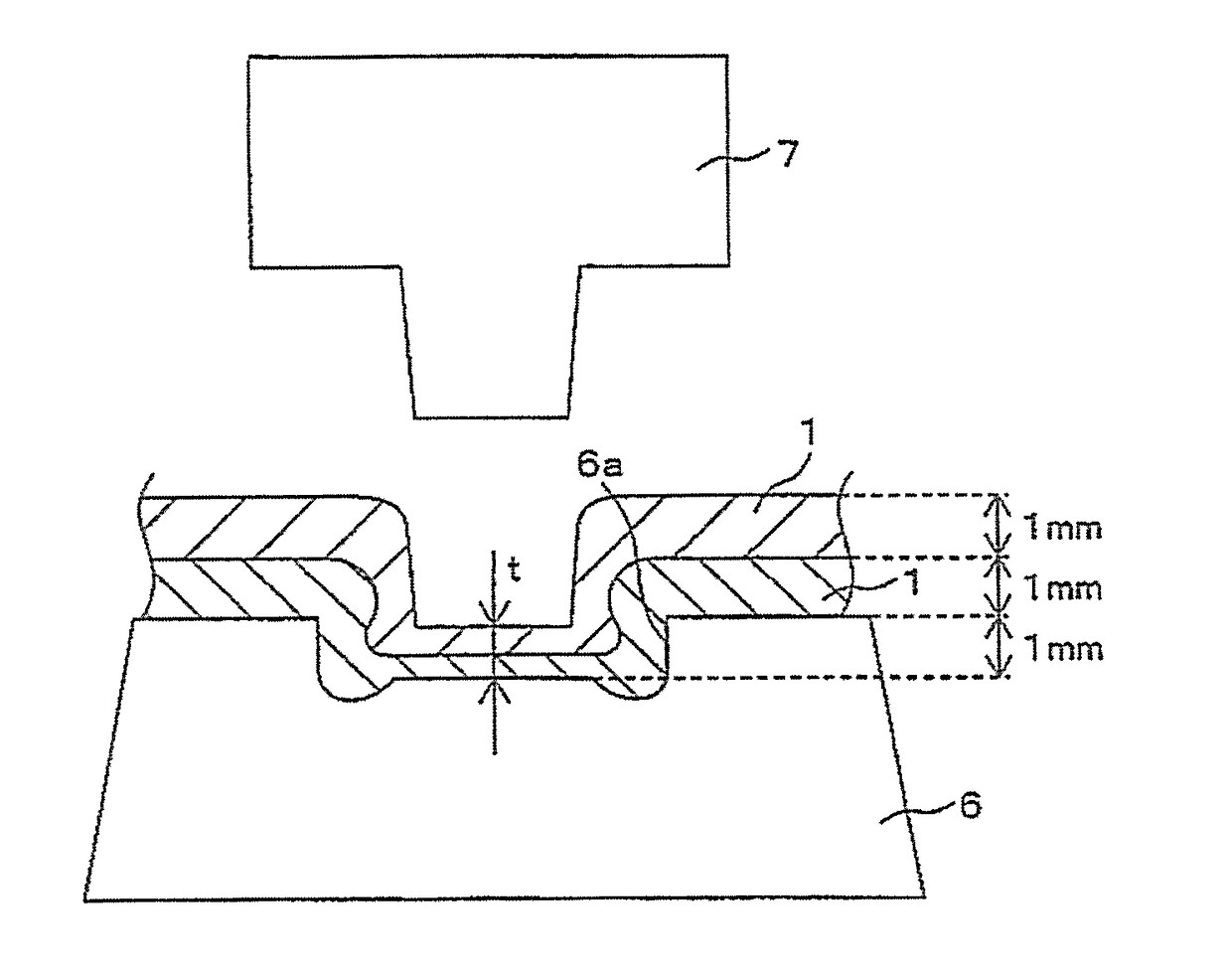

Metal joint and manufacturing method therefor

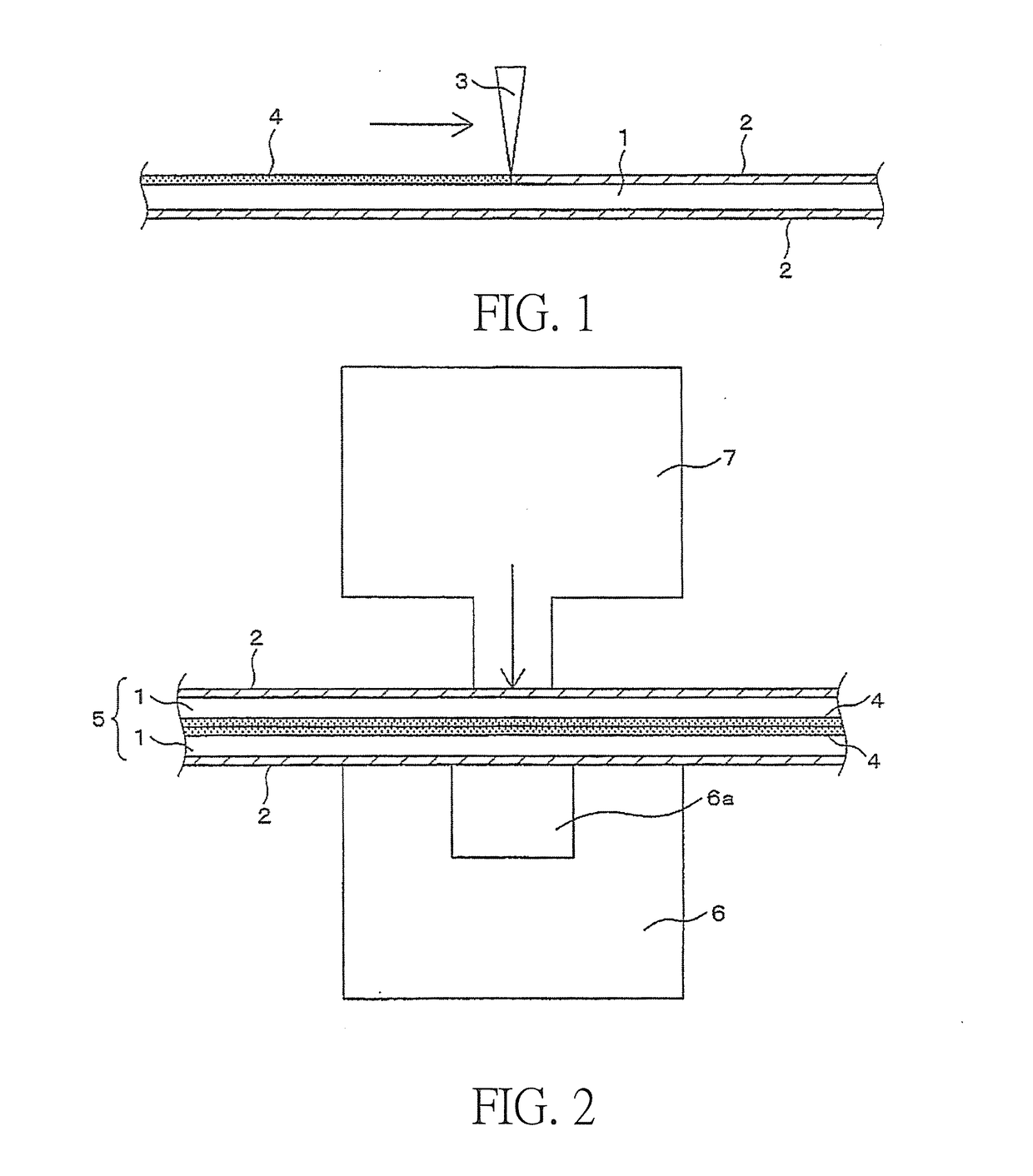

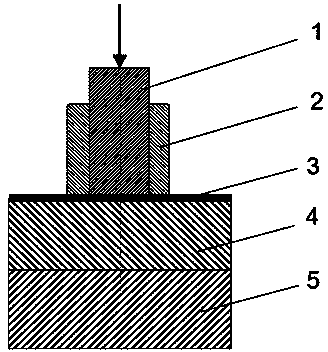

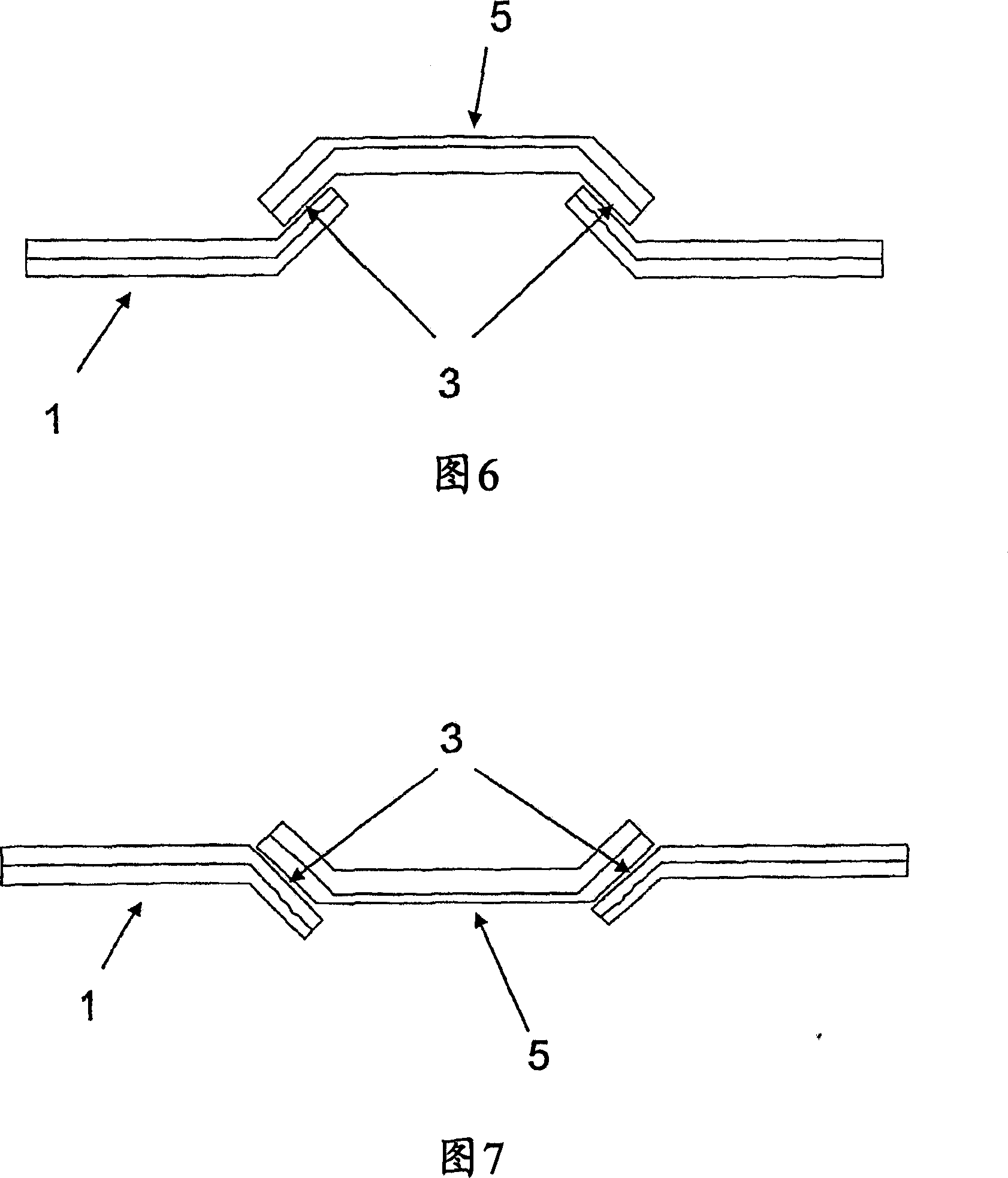

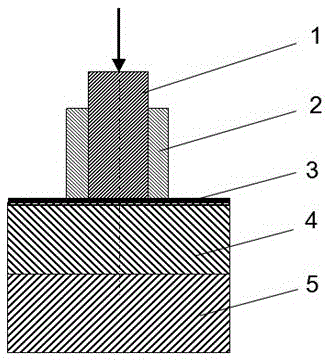

InactiveUS20170254348A1Improve joint strengthImprove adhesionCold pressureLamination ancillary operationsUltimate tensile strengthJoint surface

The present invention provides a method for manufacturing a metal joint that promotes adhesion between metallic joint surfaces to improve joint strength. Pulse lasers are illuminated to at least surface portions, where riveting is to be implemented, of surfaces of metal plates (1), so that the surface portions are molten and solidified to form surface modification thin films (4); and multiple metal plates (1) are stacked to form a laminated metal plate (5) by facing the surface modification thin films (4) to each other, and pressurized shaping is performed on the laminated metal plate (5) by using a punch (7) and a die (6) to implement riveting.

Owner:HONDA MOTOR CO LTD

Method for preparing block nanocrystalline alloy material

ActiveCN103506752AAvoid growing upLow costCold pressureNon-electric welding apparatusCold weldingNanocrystalline alloy

Owner:昊石新材料科技南通有限公司

Multisecuring component

Owner:FIVETECH TECH INC

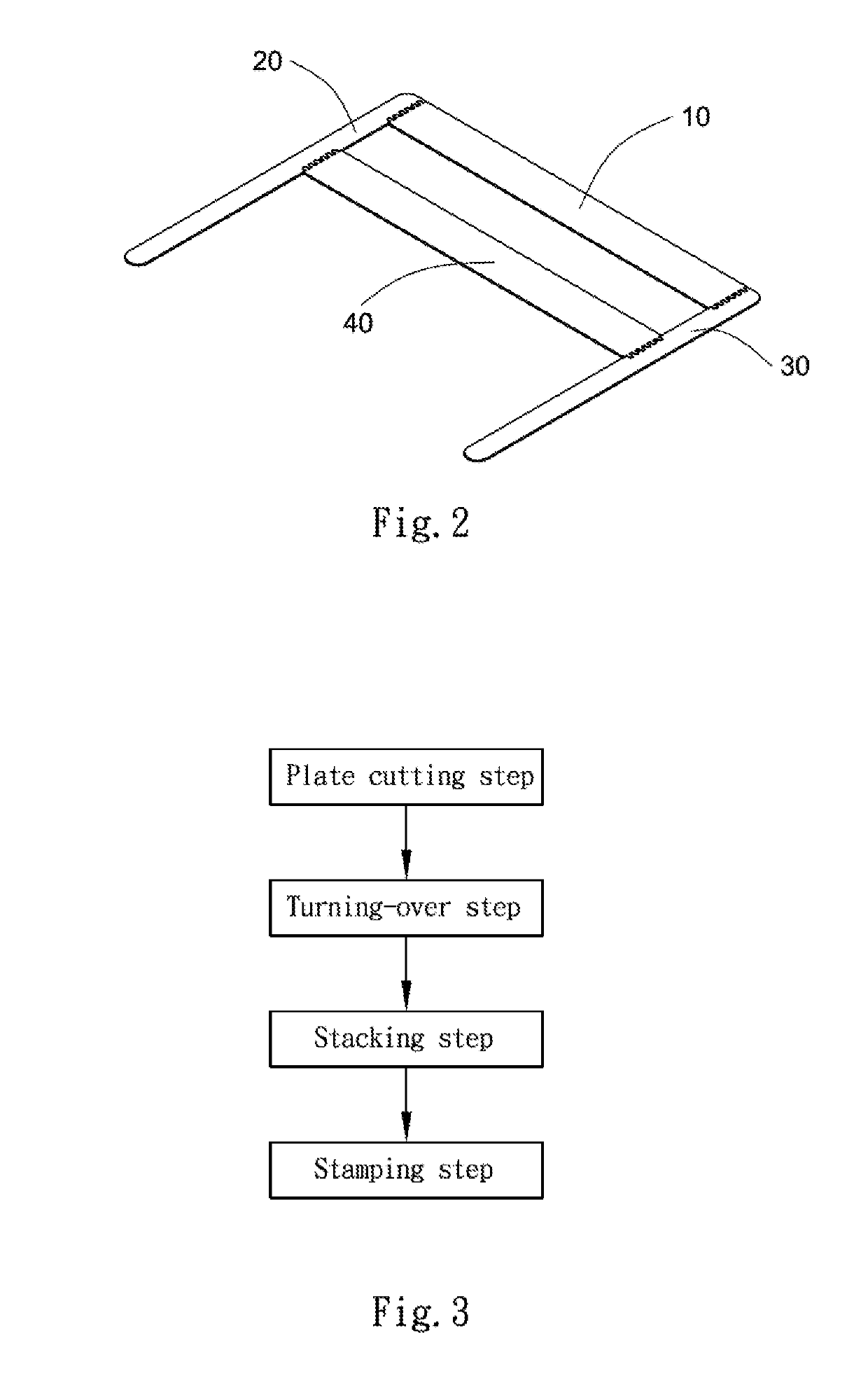

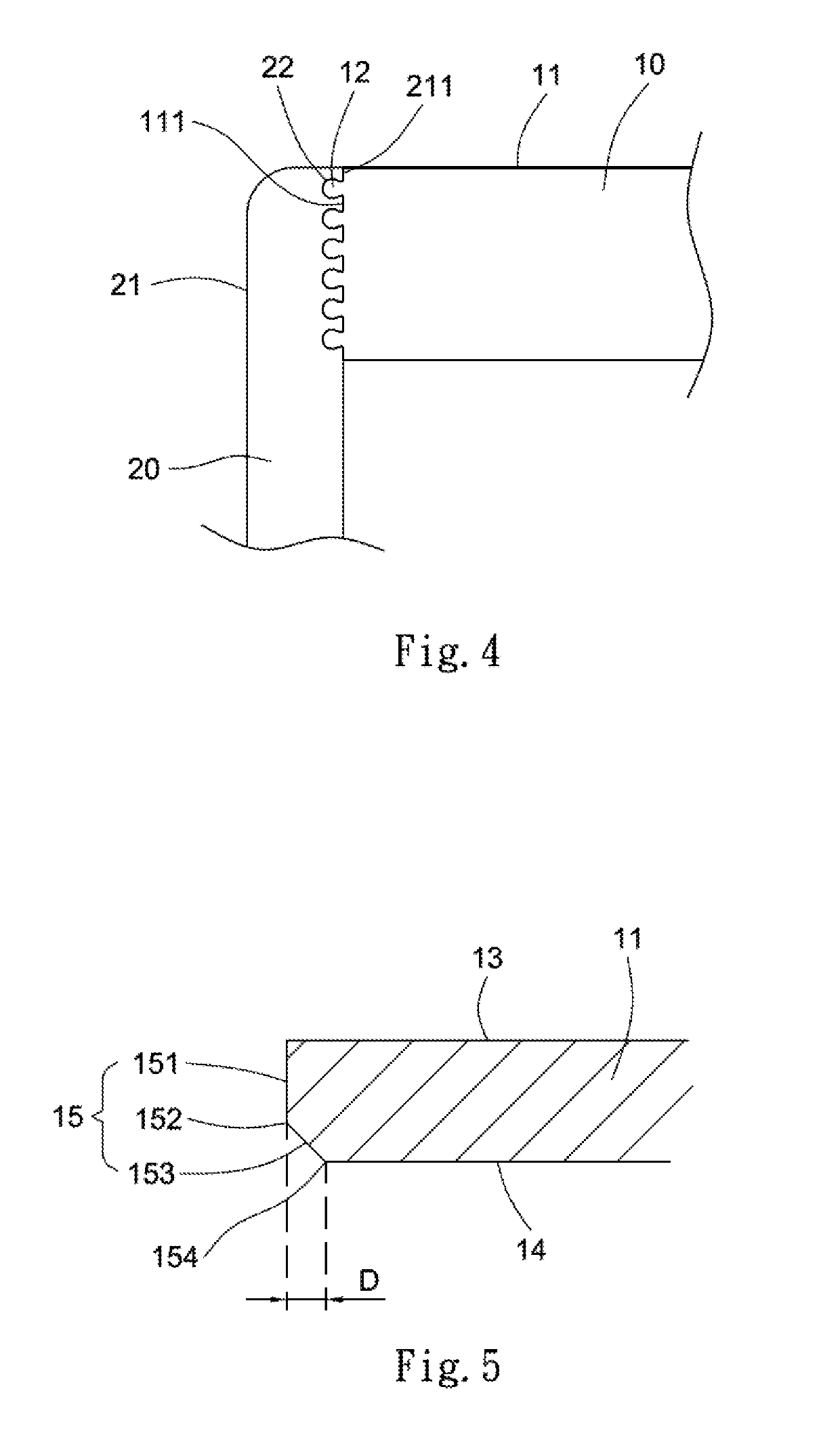

Jointed metal plates and manufacturing method thereof

InactiveUS20190178269A1Efficient productionEasy to controlCold pressureSheet joiningManufacturing cost reductionEngineering

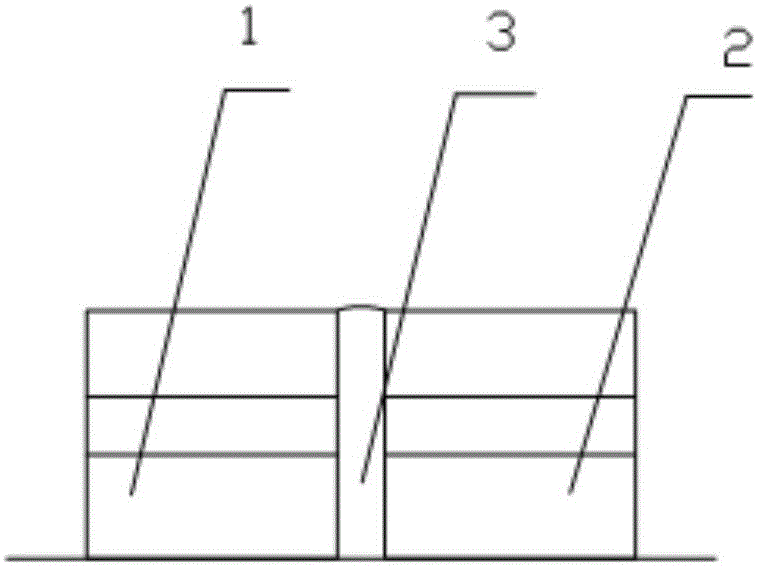

Jointed metal plates and the manufacturing method thereof are provided, in which a first plate can be end-to-end connected to a second plate. The first plate has protrusions on its jointing edge, while the second plate has recesses on its jointing edge. The protrusions of the first plate are embedded in the recesses of the second plate respectively in a manner that the first plate is fixed with respect to the second plate. Thereby, welding process can be omitted when two metal plates are to be fixed end-to-end. The disadvantages of the welding process can be prevented. The manufacturing efficiency can be increased, while the manufacturing cost can be reduced.

Owner:YANG PAI HSIEN

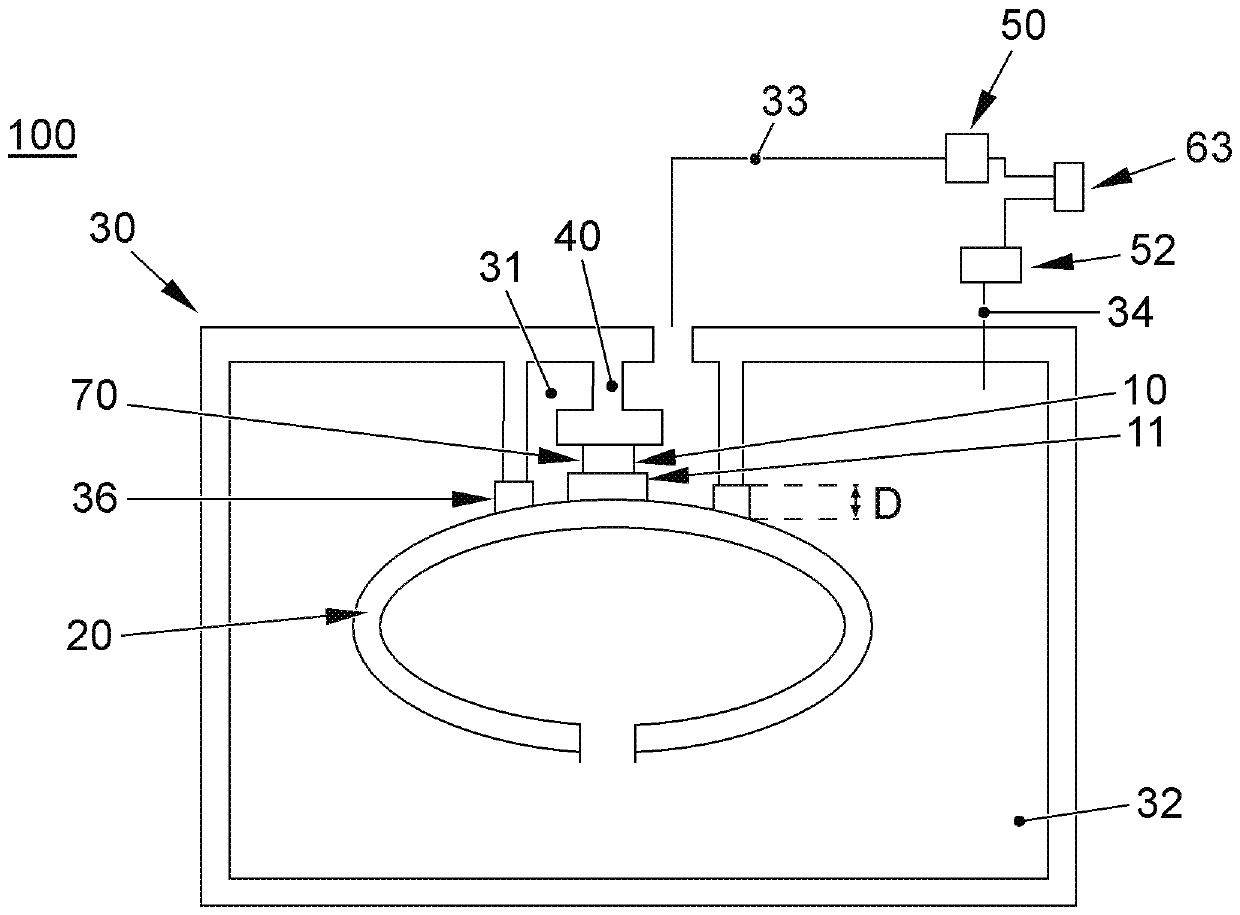

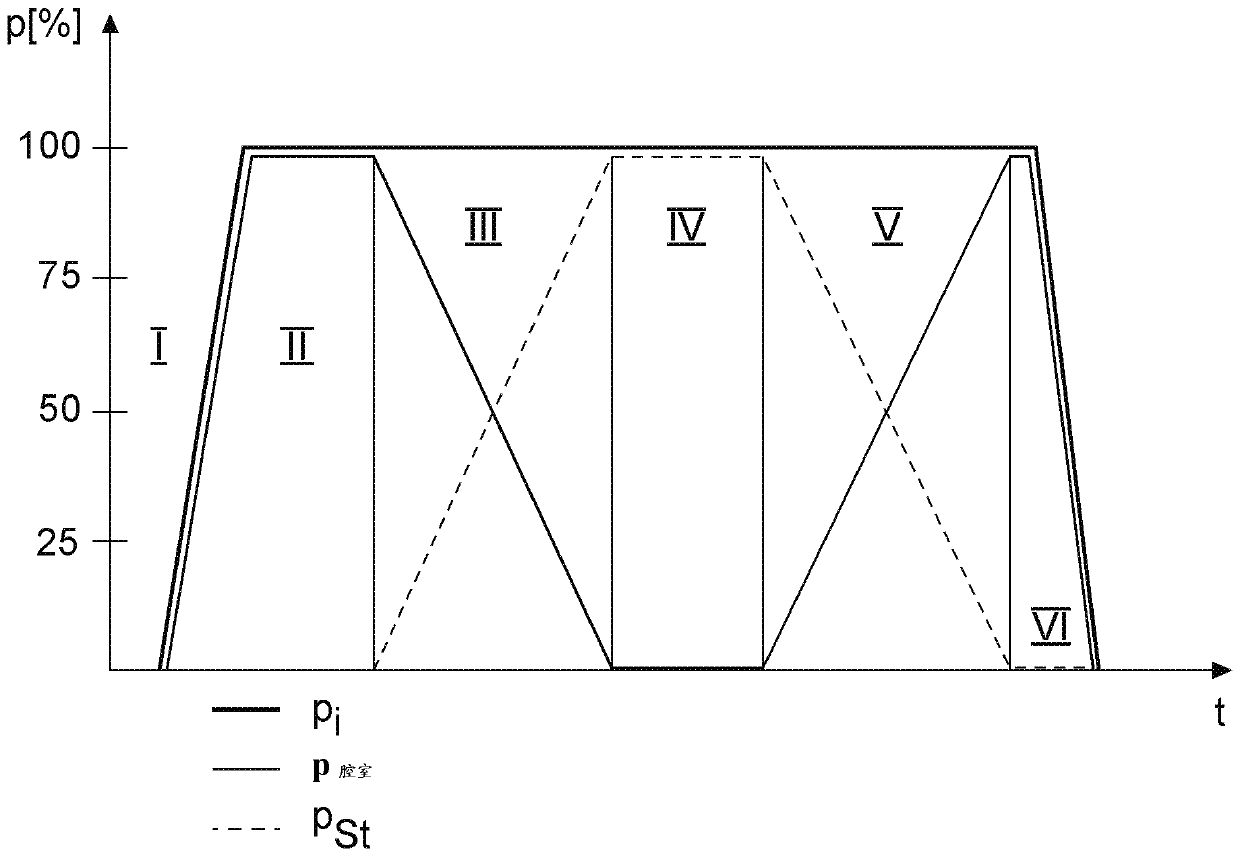

Joining method for connecting components

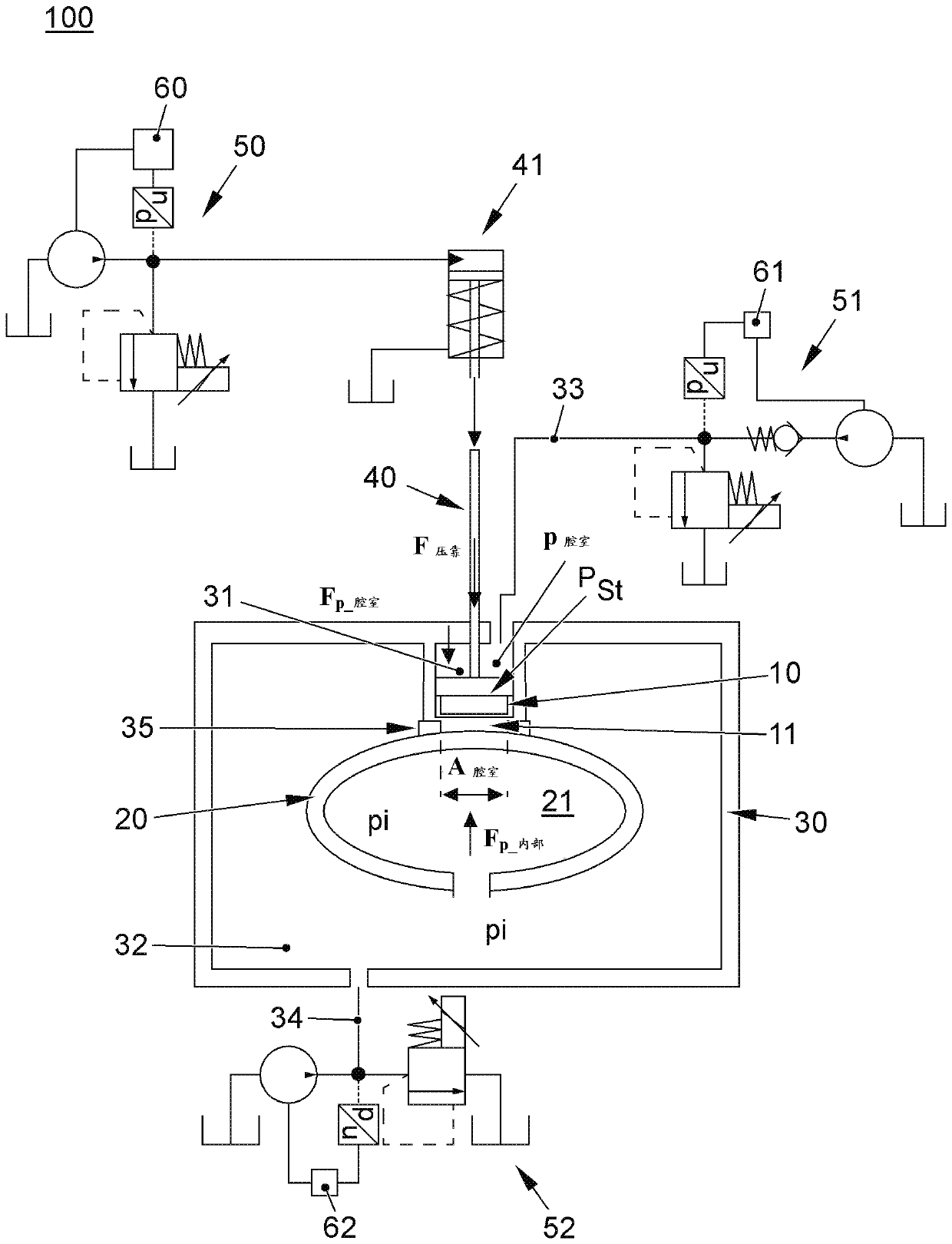

The invention relates to a joining method (80) for the positionally fixed connection of a first component (10) to a second component (20) under pressure loading, the first component (10) being arranged between a punch (40) and the second component (20), the ambient pressure (p-chamber) of the first component (10) and the ambient pressure (pi) of the second component (20) are synchronously increased to the working pressure, the working pressure is maintained for a defined duration or the ambient pressure (p-chamber) of the first component is continuously reduced after the working pressure is reached, thus generating a pressure difference. Further, a system (100) is disclosed.

Owner:VOLKSWAGEN AG

System for fastening two components on the motor fuel tank, method of fastening by means of this fastening system, and fuel system

A system for fastening, by welding, a component having a portion with a conical surface profile to a motor vehicle fuel tank that includes an opening whose perimeter has a conical surface profile. The welding is carried out between at least one portion of the conical surface of the perimeter of the opening in the tank and at least one portion of the conical surface of the component.

Owner:INERGY AUTOMOTIVE SYST RES (SA)

Connection and sealing method for gold material and silver material

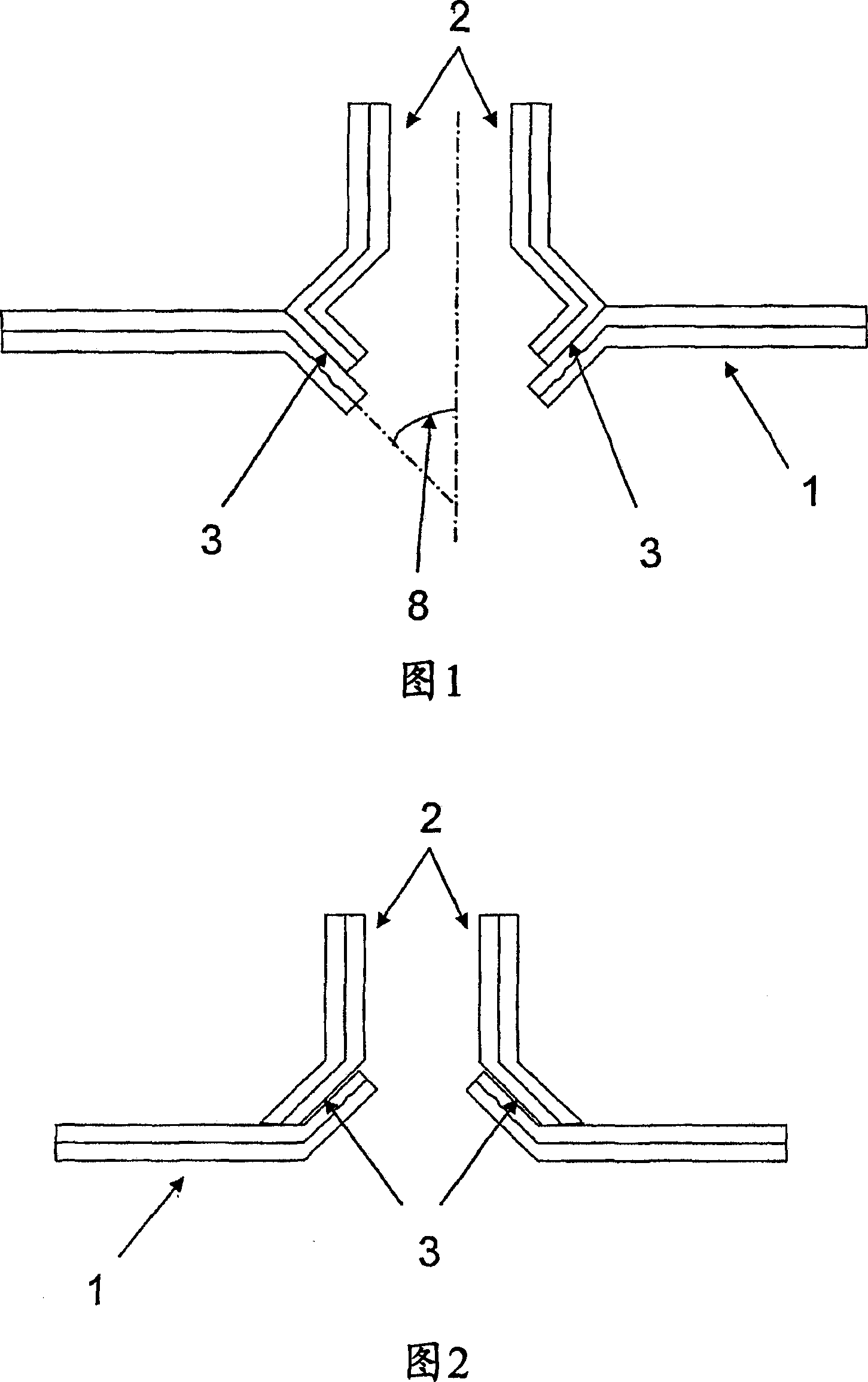

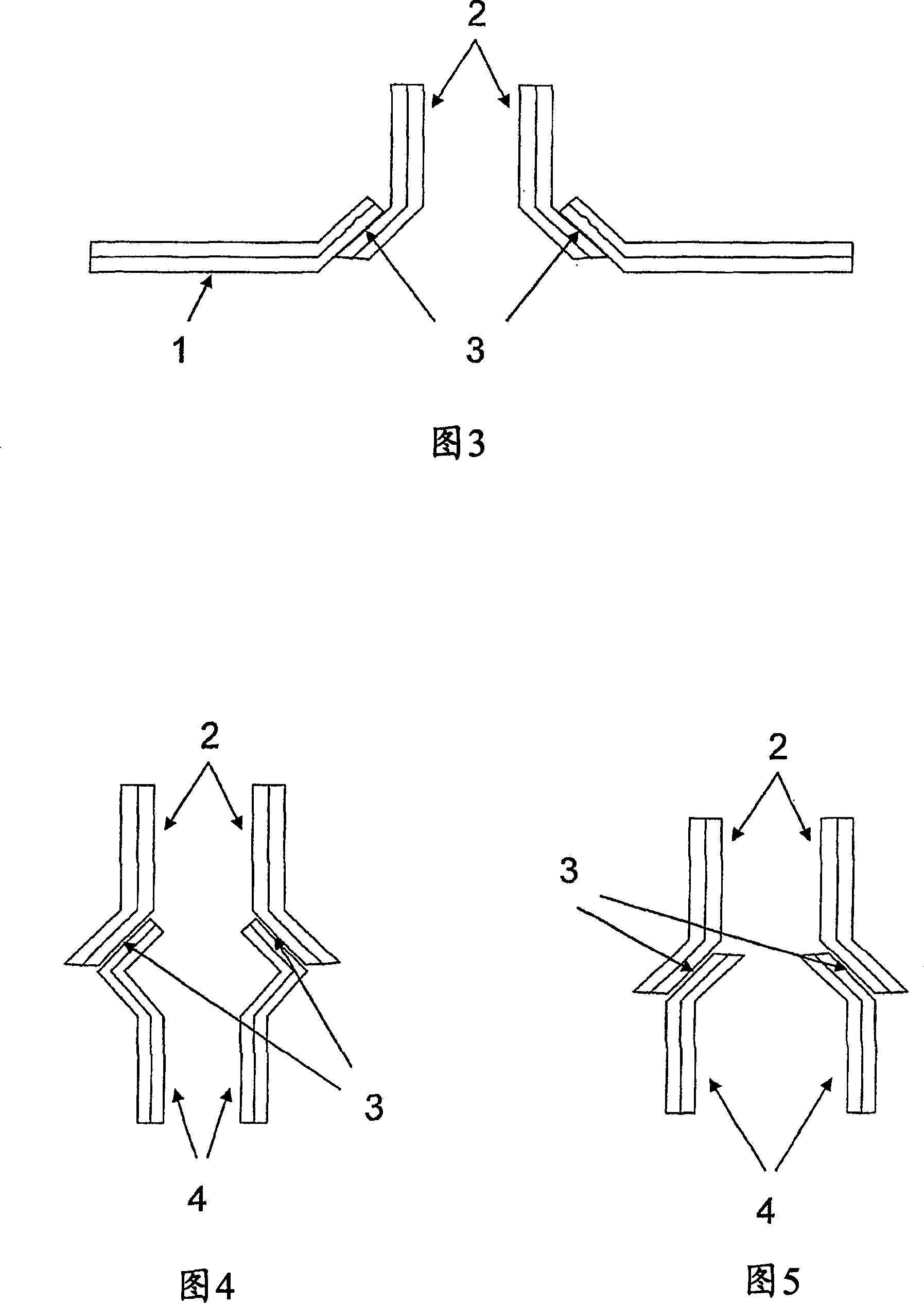

InactiveCN106041348AImprove connection tightnessSimple production processCold pressureWelding/cutting media/materialsAdhesiveMetal

The invention discloses a method for connecting and sealing gold and silver materials, which comprises the following steps: under normal temperature conditions, a ductile metal (3) is mechanically embedded in the gap between the two materials of gold (1) and silver (2), Use the hoarding board to enclose the joint surface formed by the three materials of gold (1), ductile metal (3) and silver (2) into a space area, and pour high-performance silicone structural adhesive on the substrate in the space area . The invention has good connection and sealing effect, and the whole production is carried out under the normal temperature condition, the production process is simple, the operation environment is improved, the labor intensity is reduced, and the production cost is reduced.

Owner:黄海娟

Connection and sealing method for steel material and magnesium material

InactiveCN106041349AImprove connection tightnessSimple production processCold pressureWelding/cutting media/materialsMagnesiumAdhesive

The invention discloses a connection and sealing method for a steel material and a magnesium material. The method comprises the following steps that ductile metal (3) is embedded into a gap between the steel material (1) and the magnesium material (2) in a mechanical manner at the normal temperature; a spatial area is defined by joint faces formed by the steel material (1), the ductile metal (3) and the magnesium material (2) through encircling plates; and high-performance silicone structural adhesive is poured on a substrate inside the spatial area. By means of the method, the good connection and sealing effect is achieved; in addition, the whole production process is conducted under the normal-temperature condition; the production technology is simple; the operation environment is improved; labor intensity is lowered; and production cost is lowered.

Owner:黄海娟

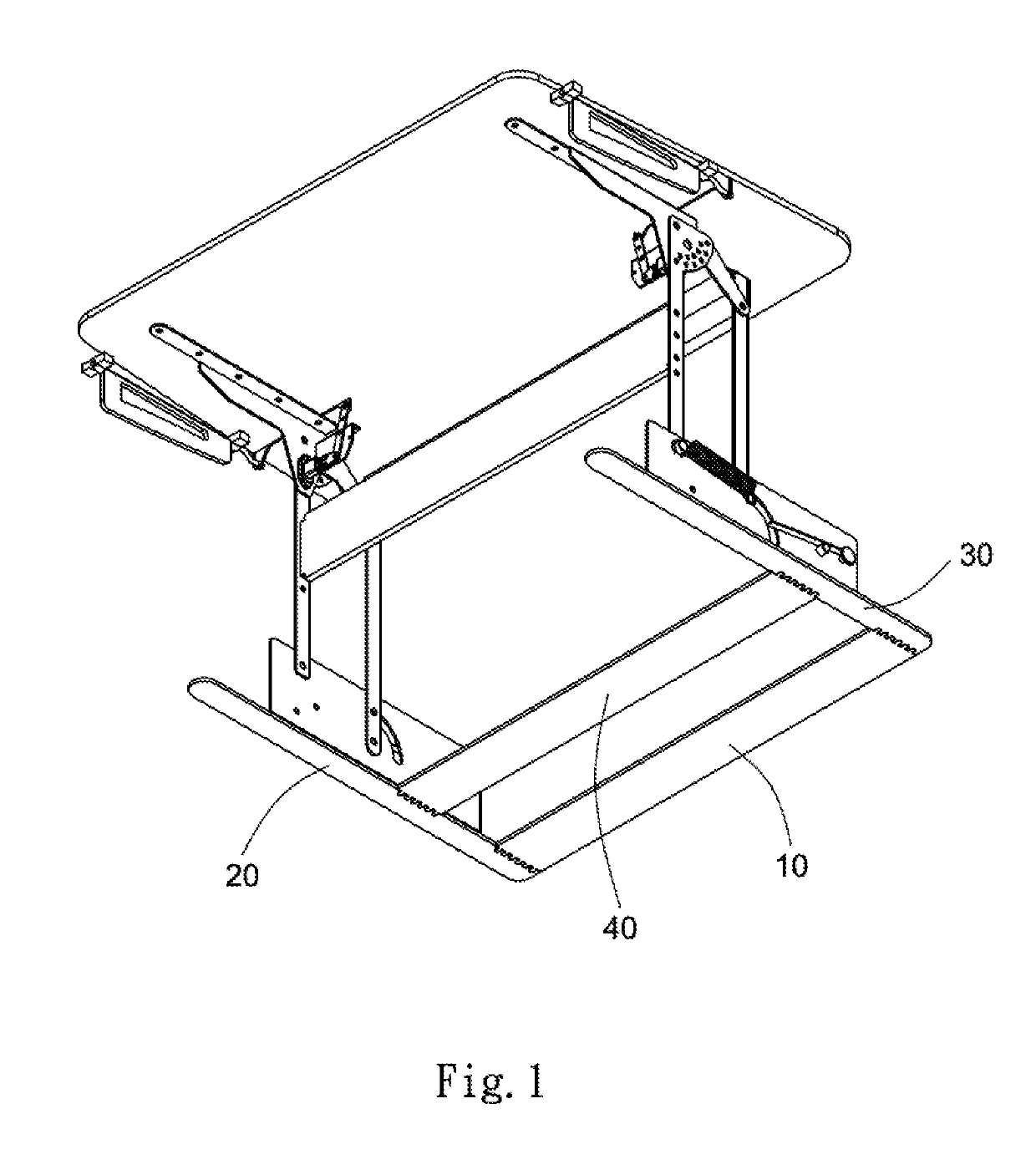

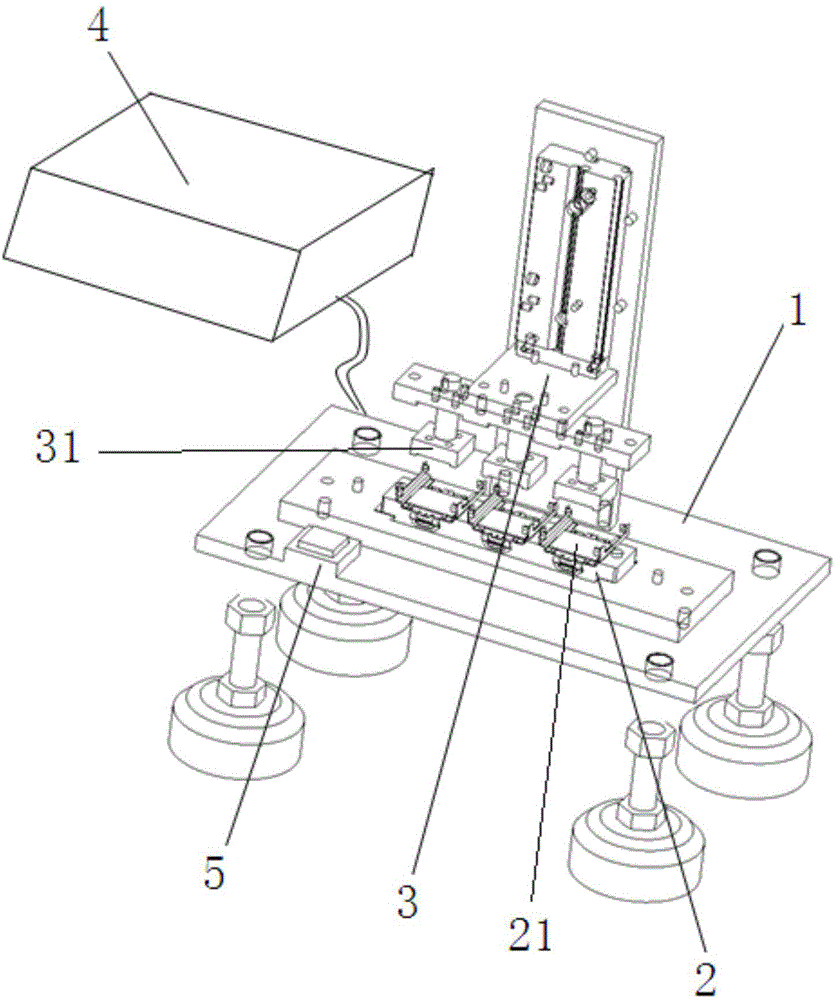

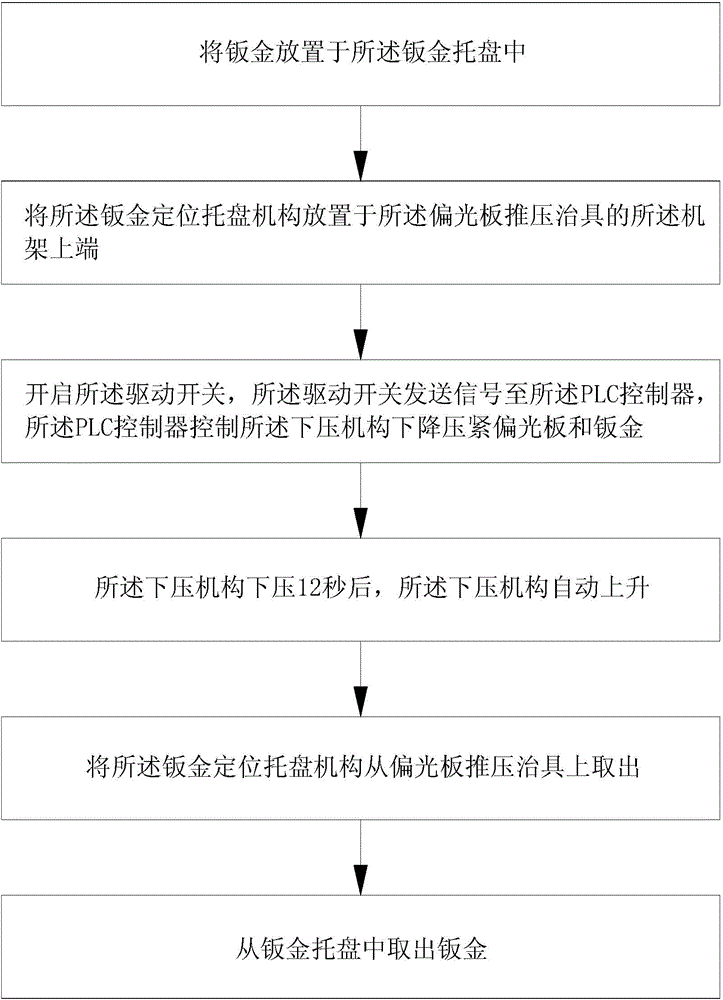

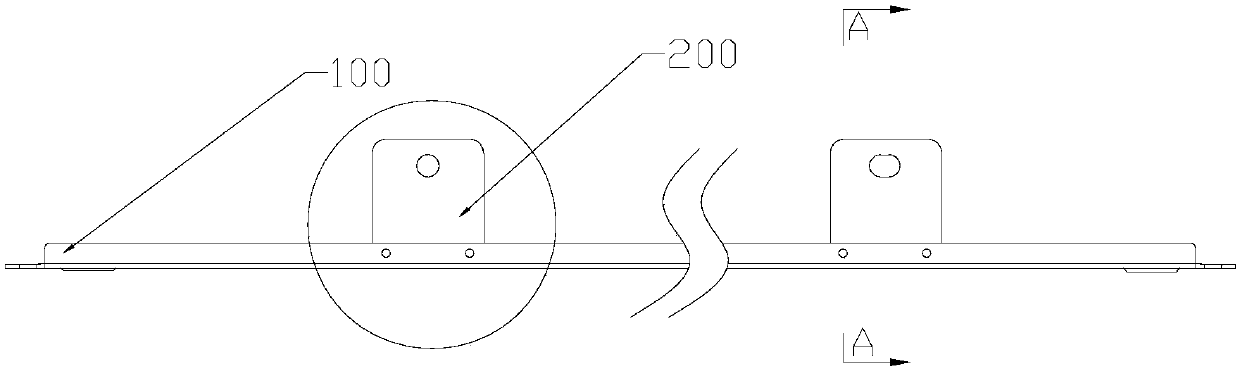

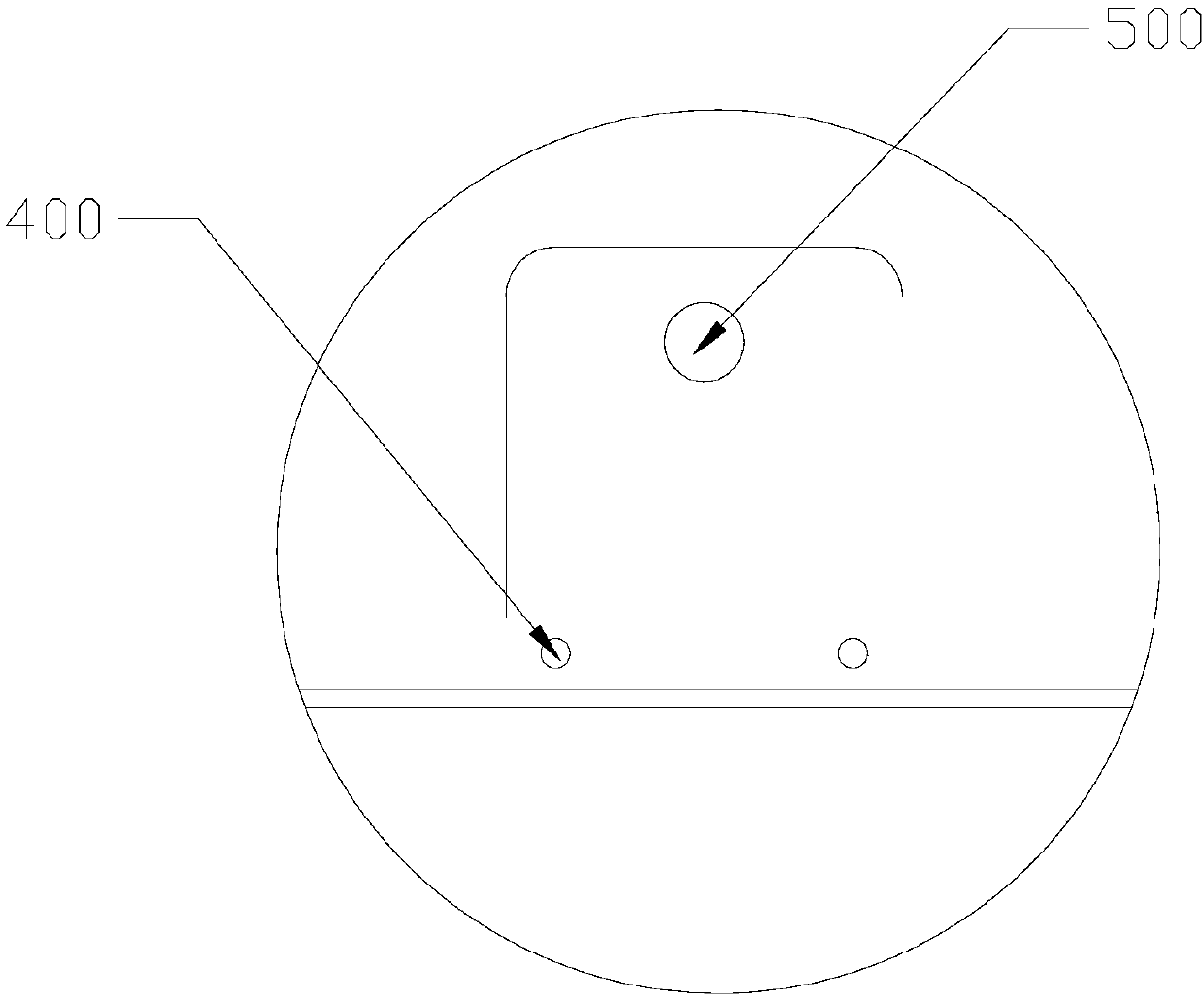

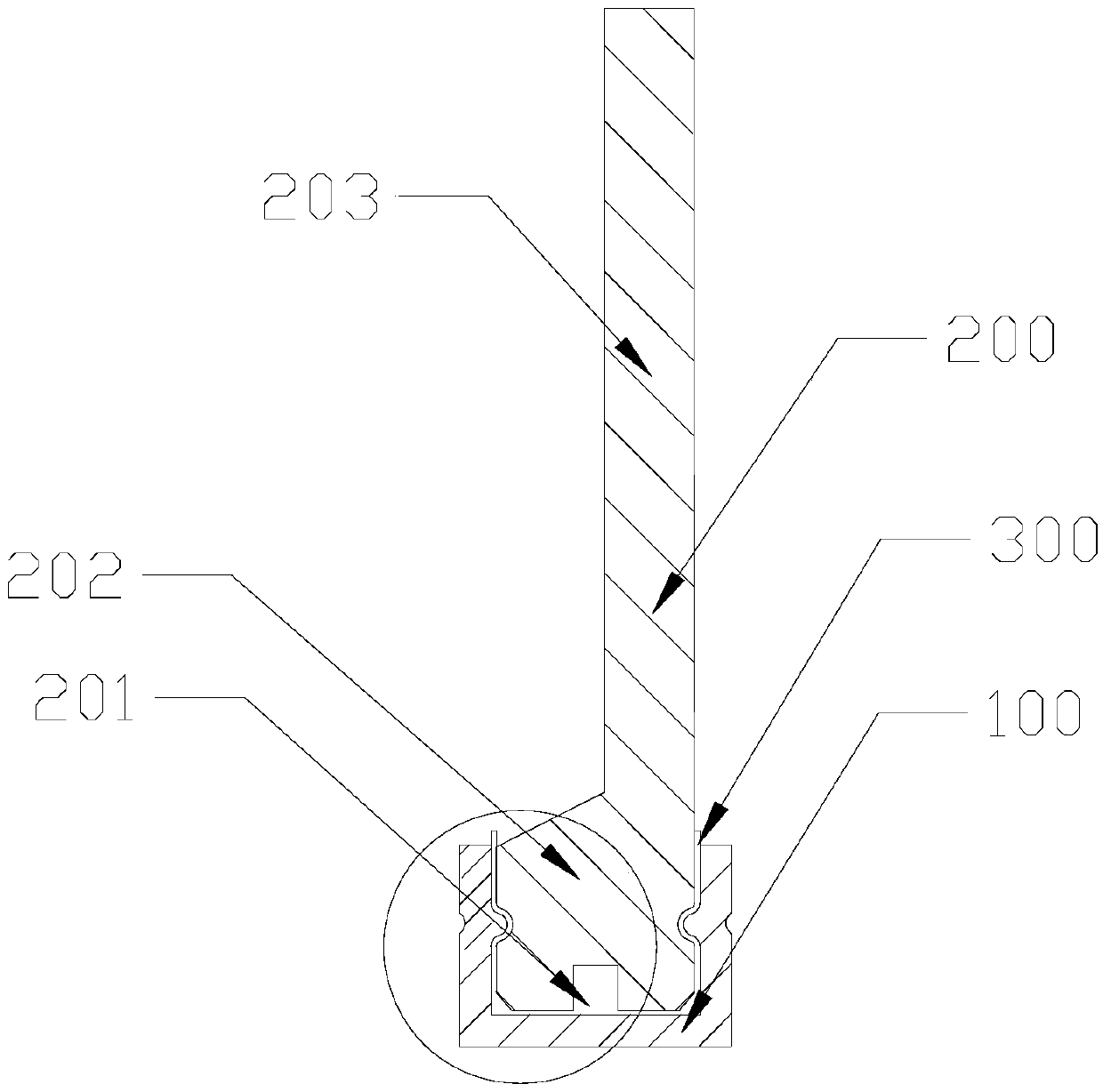

Polarizer push fixture and work mode thereof

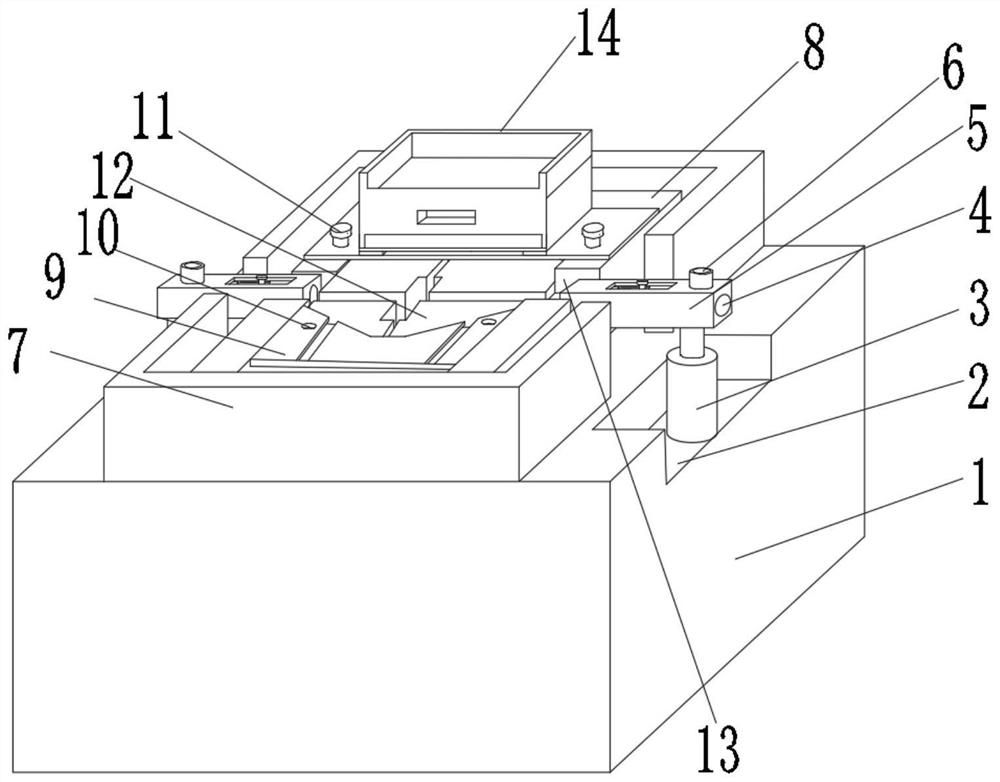

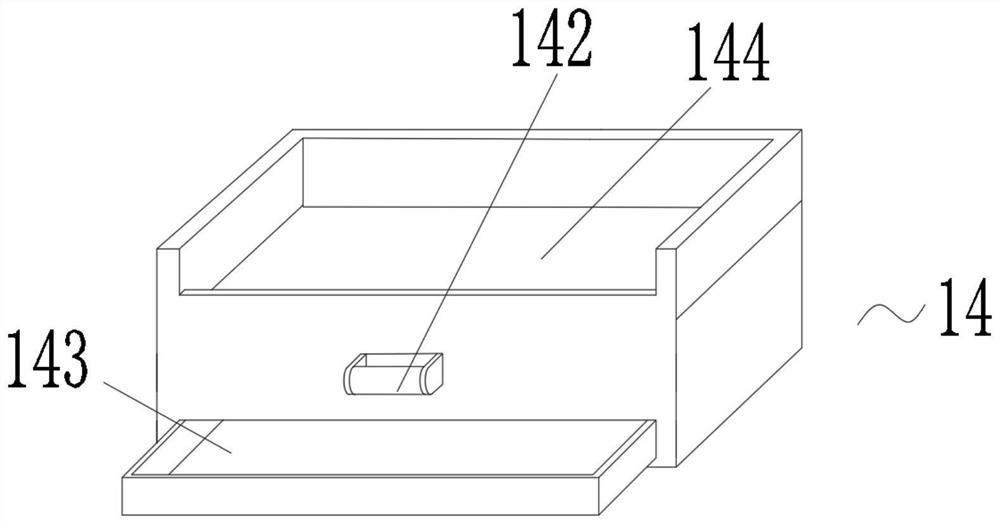

InactiveCN104653563AImprove adhesion firmnessAdhesion PreciseCold pressureProgrammable logic controllerEngineering

The invention discloses a polarizer push fixture and a work mode thereof. The polarizer push fixture comprises a rack, a metal plate positioning tray mechanism mounted at the upper end of the rack, a pressing-down mechanism located above the metal plate positioning tray mechanism, and a PLC (Programmable Logic Controller) in signal connection with the pressing-down mechanism. The work mode comprises the following steps: 1, placing a metal plate in a metal plate tray; 2, placing the metal plate positioning tray mechanism at the upper end of the rack; 3, opening a drive switch and controlling the pressing-down mechanism to descend and compress a polarizer and the metal plate by the PLC; 4, enabling the pressing-down mechanism to ascend automatically after the pressing-down mechanism performs pressing down for 12 seconds; 5, taking the metal plate positioning tray mechanism out from the polarizer push fixture; 6, taking the metal plate out from the metal plate tray. By adopting the polarizer push fixture and the work mode, a press-attaching rubber head of the pressing-down mechanism is in contact with the polarizer, so that the polarizer and the metal plate are fitted closely and adhered firmly, and the firm adhesion of the polarizer on the metal plate is ensured, and the whole operation is convenient and effective.

Owner:SHANGHAI SUOGUANG VISUAL PRODUCTS CO LTD

Method for embossing a component

The present disclosure concerns a method for embossing a component, and a method for connecting a component to a second component. The invention also relates to a device having such a component. The invention is based on the overall concept that at least one support groove is inserted and / or introduced into the peripheral region of a functional groove in order to reduce the flow of the material part of the component transversely to the imprint pressure application direction.

Owner:MAHLE INT GMBH

Magnesium and aluminum material connecting sealing method

InactiveCN106166641AImprove connection tightnessSimple production processCold pressureWelding/soldering/cutting articlesAdhesiveUltimate tensile strength

The invention discloses a magnesium and aluminum material connecting sealing method. The method comprises the following steps that under the normal temperature condition, ductile metal (3) is embedded into a clearance part of a magnesium material (1) and an aluminum material (2) in a mechanical mode, a spatial region is formed by enclosing joint faces of the magnesium material (1), the ductile metal (3) and the aluminum material (2) through an enclosing plate, and a high-performance silicone structural adhesive is poured on a substrate in the spatial region. According to the magnesium and aluminum material connecting sealing method, a good connecting sealing effect is achieved, the whole production is conducted under the normal temperature condition, the production technology is simple, the operating environment is improved, the labor intensity is reduced, and the production cost is reduced.

Owner:黄海娟

Nail-plier integrated type quick cold pressing pliers

PendingCN112696412ALabor-saving operationPrevent disengagementCold pressureEngineeringStructural engineering

The invention discloses nail-plier integrated type quick cold pressing pliers. The nail-plier integrated type quick cold pressing pliers comprise a device shell, a threaded cover plate is arranged at the top of the device shell, an upper partition plate is embedded in the device shell, a lower partition plate and a power supply assembly are arranged at the bottom of the upper partition plate, an electric control mechanism is arranged at the bottom of the power supply assembly, a sensing device is embedded in a conical push rod, a pressing plier groove is formed in the center of the bottom of the device shell in a penetrating mode, a first control switch is arranged at the top of the threaded cover plate, a second control switch is arranged on one side of the first control switch, a safety lock mechanism is arranged on the side, close to the second control switch, of the first control switch, the outer surface of the device shell is provided with a placing groove in a penetrating mode, a sealing cover is hinged to one side of the placing groove, a locking and unlocking mechanism is arranged on one side of the sealing cover, and a control panel is fixedly connected in the placing groove. According to the nail-plier integrated type quick cold pressing pliers, by means of the arrangement of the safety lock mechanism, an operator can be prevented from accidentally touching the control switches.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

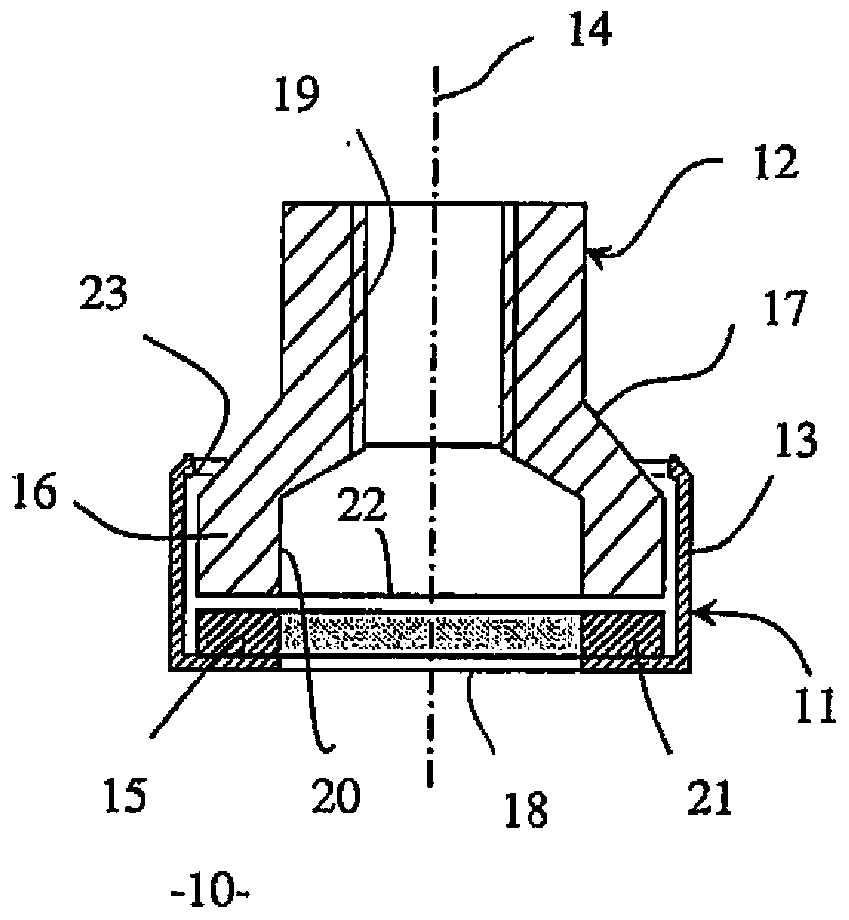

A leak-proof fastening device and assembly method

The assembly (10) has a washer (11) assembled on a female fastener that is designed as a fastening nut (12) or a collar. The washer comprises a cylindrical skirt (13) rigidly connected to an outer periphery of an annular base (15). The base is partially covered with a layer (21) of a viscous composition utilized for forming a liquid-tight seal through polymerization. The fastener is assembled onto the washer by adhering to the layer of the composition that comprises liquid polysulfide and reagent capable of releasing oxygen i.e. manganese dioxide. The viscous composition comprises liquid polysulfide and reagent capable of releasing oxygen i.e. manganese dioxide. An independent claim is also included for a method for assembling a leak-proof assembly for a fastening system.

Owner:LISI AEROSPACE

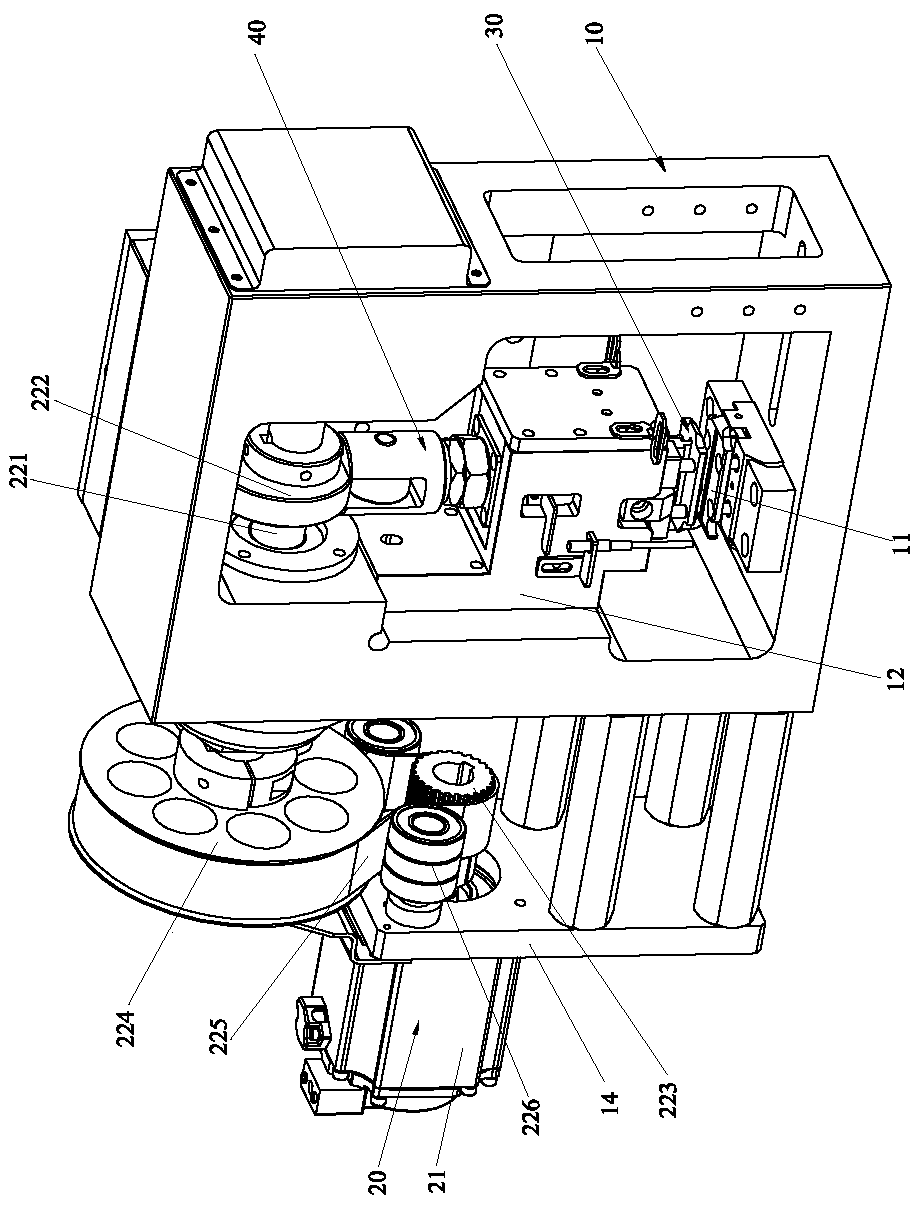

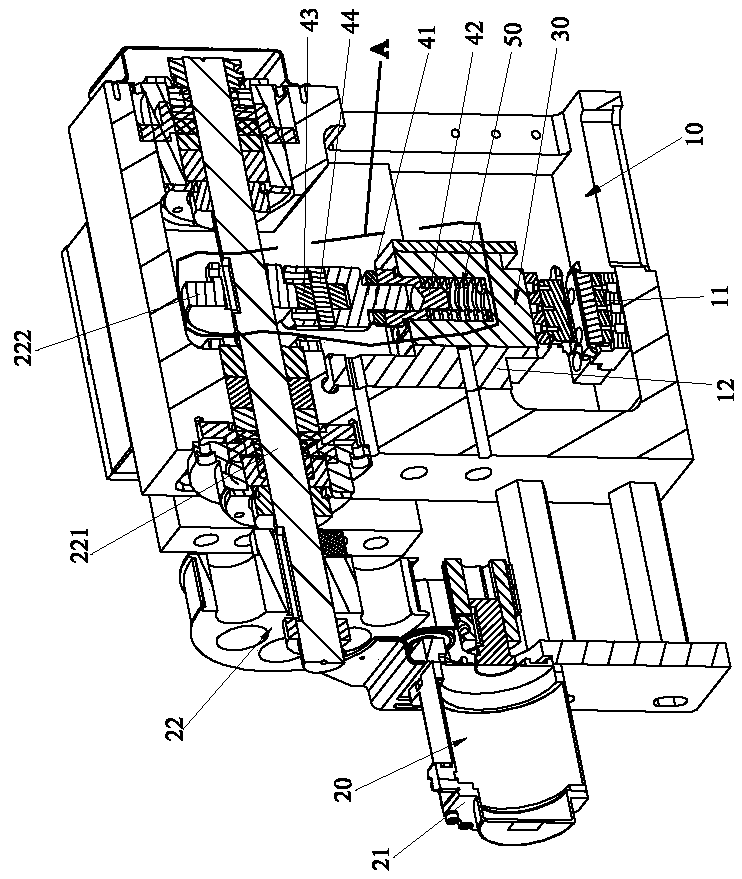

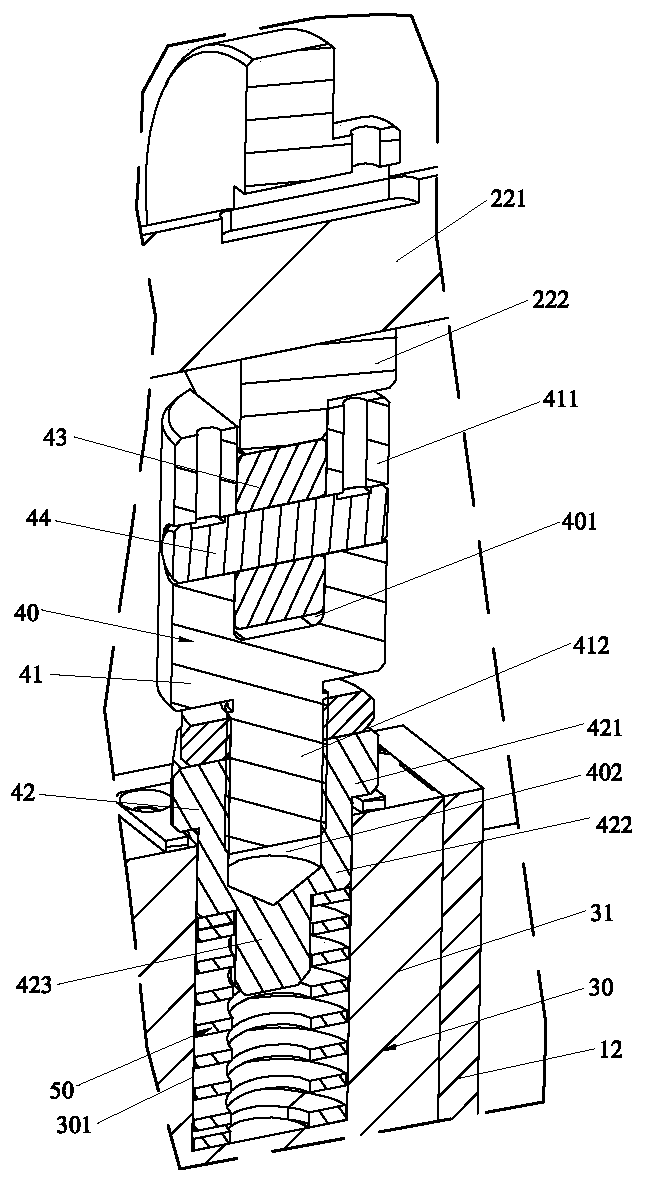

A CNC hydraulic automatic cold welding machine

ActiveCN112240333BAvoid scratchesGuarantee personal safetyCold pressureOther manufacturing equipments/toolsEngineeringMachine

Owner:杭州企诚净化科技有限公司

Motor support and shaft positioning and fixing method

InactiveCN106877602AEase of mass productionLow costCold pressureManufacturing dynamo-electric machinesHigh volume manufacturingCoupling

The invention discloses a method for locating and fixing a motor bracket and a shaft, comprising step 1: passing bolts through the casing of the motor bracket and a motor mounting plate; step 2: passing the components obtained in step 1 through threaded holes on the motor; 3: Tighten the nuts to get a simple motor bracket; Step 4: Install the coupling to the shaft of the motor; Step 5: Install the other end of the coupling to the shaft; Step 6, Weld the motor mounting plate. The motor bracket and the rotating shaft bracket are welded together by first positioning and then welding and fixing. In this way, the motor support can be produced according to the specifications of the motor, and the rotating shaft support can also be produced according to the required specifications, which is convenient for mass production of production parts, can reduce costs, and improve production efficiency.

Owner:袁祖六

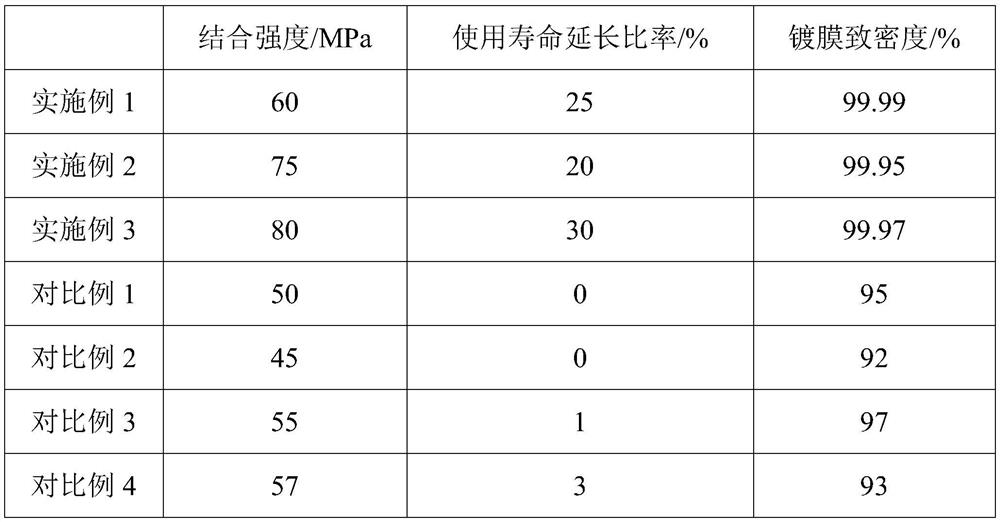

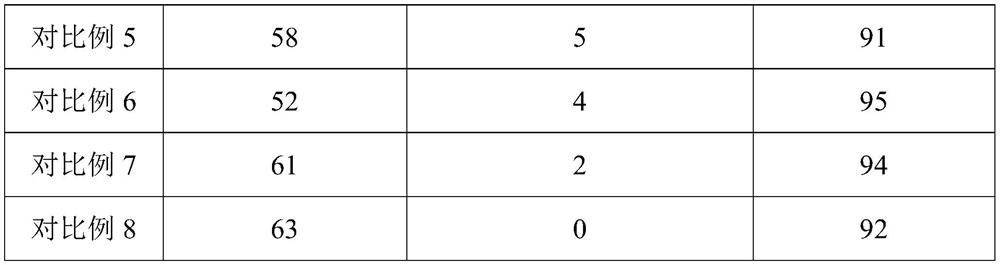

Welding method of tantalum target material assembly

The invention relates to a welding method of a tantalum target material assembly. The welding method comprises the following steps: carrying out sand blasting treatment on a welding surface of a tantalum target material, and then carrying out tin film plating treatment on the welding surface of the tantalum target material; carrying out copper film plating treatment on a welding surface of a back plate, then carrying out heating treatment on the tantalum target material plated with the tin film and the back plate plated with the copper film, then arranging mixed metal powder on the welding surface of the tantalum target material and the welding surface of the back plate correspondingly, and then carrying out infiltration treatment; and arranging copper wires on the back plate subjected to infiltration treatment, then assembling the welding surface of the back plate provided with the copper wires and the welding surface of the tantalum target material, and carrying out pressurizing and cooling, so that the tantalum target material assembly is obtained. Welding is carried out by adopting a film plating process and combining with specific mixed metal powder, then the welding bonding strength of the tantalum target material assembly is improved, meanwhile, the service life of the welded target material is prolonged by 20-30%, and when the welded target material assembly is sputtered, the thickness of a plated film obtained in the sputtering process is uniform.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Numerical control hydraulic automatic cold welding machine

ActiveCN112240333AReduce the chance of injuryAvoid scratchesCold pressureOther manufacturing equipments/toolsNumerical controlEngineering

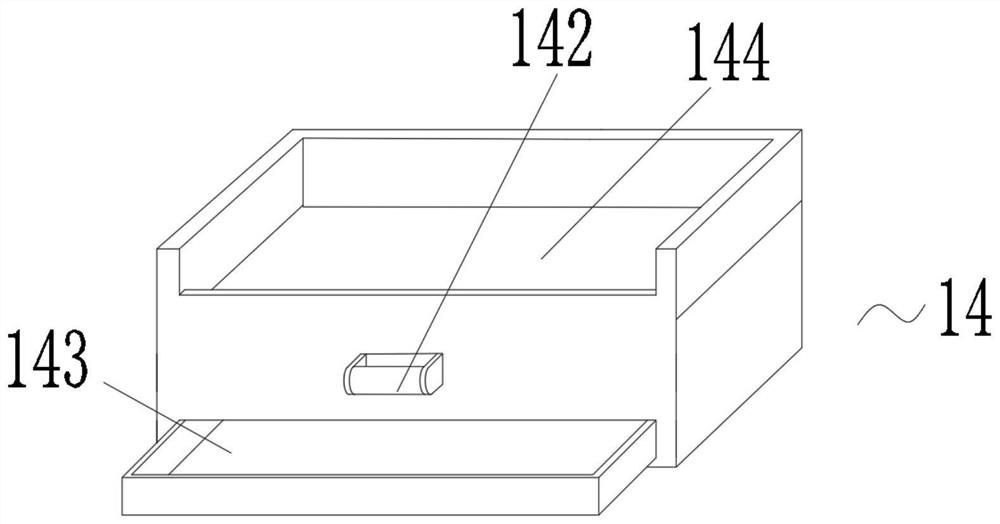

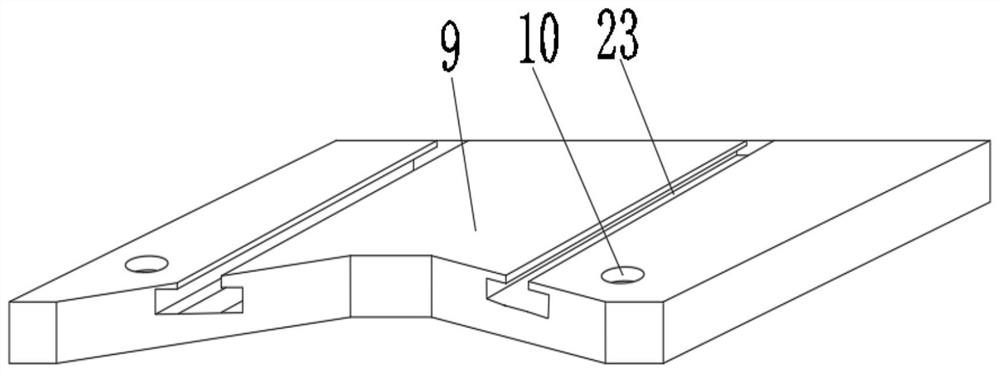

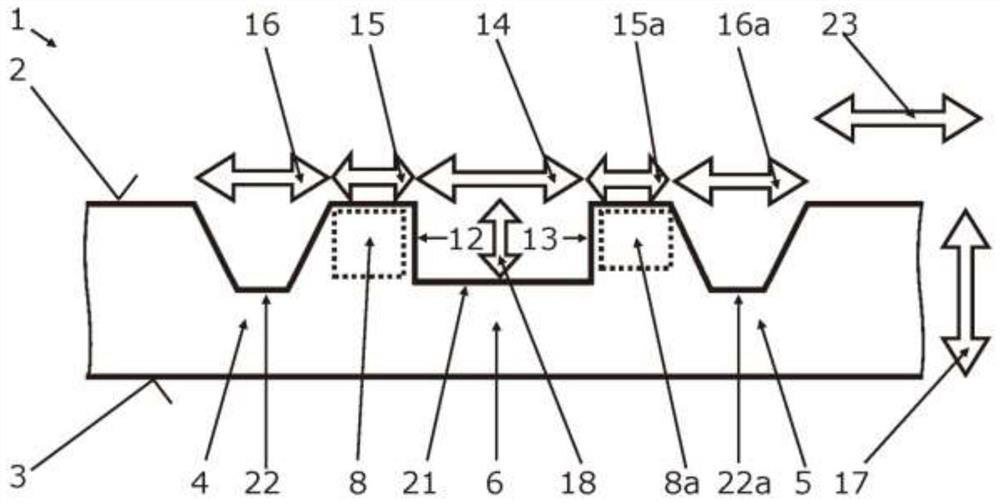

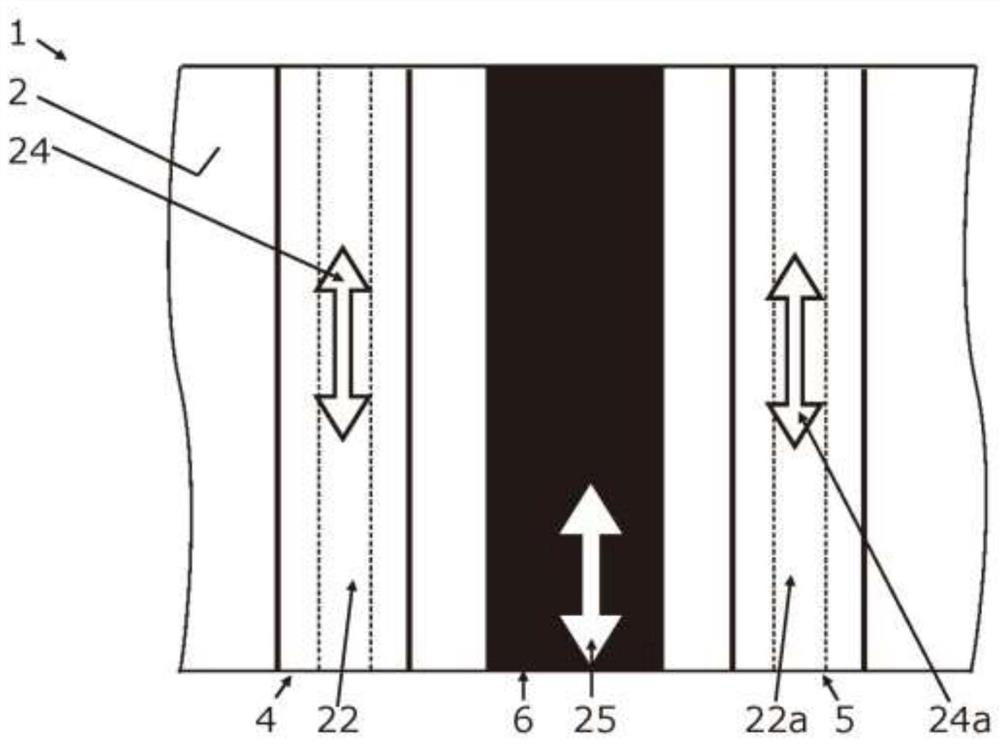

The invention discloses a numerical control hydraulic automatic cold welding machine. The numerical control hydraulic automatic cold welding machine comprises an upper main body and a base, wherein the base is located on the outer surface of the upper end of the main body and is fixedly connected with the main body, rectangular grooves are formed in the two sides of the outer surface of the upperend of the main body, the inner surfaces of the lower ends of the rectangular grooves are fixedly connected with hydraulic machines, the outer surfaces of the upper ends of the hydraulic machines arefixedly connected with limiting devices, baffles are fixedly installed at the edges of the front end and the rear end of the outer surface of the upper end of the main body, the outer surface of the upper end of the base is movably connected with a protective plate, a storage device is connected above the protective plate in a sliding mode, and grooves are formed in the joints of the outer surfaces of the two sides of the base and the limiting devices. According to the numerical control hydraulic automatic cold welding machine, a worker can quickly insert a welding part into a cold pressing mold, so that the problems that when the welding part is inserted, the welding part collides with the cold pressing mold, so that an inserting hole in the cold pressing mold is damaged and deformed, thewelding part is inconvenient to insert later, time is wasted, and the working efficiency is reduced are solved.

Owner:杭州企诚净化科技有限公司

Method for imprinting parts

Owner:MAHLE INT GMBH

Buffer type cold welding mechanism for preventing product crushing

The invention discloses a buffer type cold welding mechanism for preventing product crushing. The mechanism comprises a frame, a driving device and a cold welding device; the frame is provided with amachining base; the driving device is arranged on the frame; the cold welding device is arranged on the frame in a up-down reciprocating moving mode, and is opposite to the machining base; an abuttingpiece is connected between the cold welding device and the driving device; the driving device drives the abutting piece to press down; the abutting piece drives the cold welding device to press down;and an elastic buffer piece for preventing crushing or damage of a product is arranged in the connected place of the cold welding device and the abutting piece. The elastic buffer piece is arranged in the connected place of the cold welding device and the abutting piece; and through arrangement of the elastic buffer piece, the downward pressing acting force of the abutting piece is acted on the elastic buffer piece and the cold welding device in succession, and is effectively buffered when passing through the elastic buffer piece, so that the downward pressing acting force of the abutting piece is directly acted on the cold welding device to effectively prevent damage of the product due to higher downward pressing acting force of the cold welding device.

Owner:东莞和宏机械有限公司

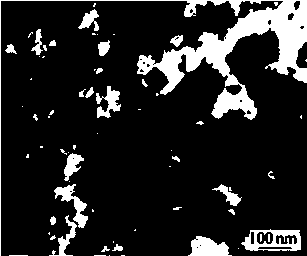

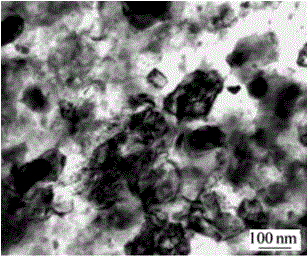

A kind of method for preparing bulk nanocrystalline alloy material

ActiveCN103506752BAvoid growing upLow costCold pressureNon-electric welding apparatusCold weldingNanocrystalline alloy

The invention relates to nanocrystalline alloys, in particular to a method for preparing bulk nanocrystalline alloy materials using cold pressure welding technology. The present invention utilizes the property that the strip-shaped or flake-shaped alloy material is combined with the base material through severe plastic deformation cold welding under huge pressure, and cold-welds the strip-shaped nanocrystalline alloy material into a block material. Due to the cold pressure welding process There is no obvious temperature rise phenomenon, so the grains of the finally obtained bulk material will not be significantly different from the original strips, that is, they are still nanocrystalline.

Owner:昊石新材料科技南通有限公司

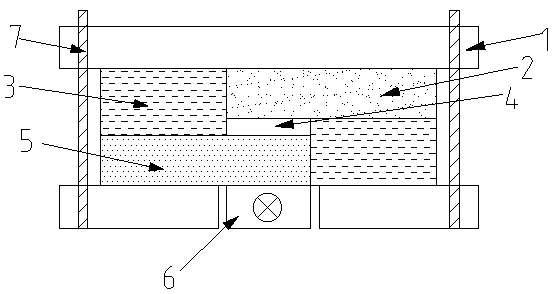

A method for improving the corrosion resistance of welded joints of aluminum plates and steel plates

ActiveCN110666329BImprove performanceImprove corrosion resistanceCold pressureNon-electric welding apparatusElectromagnetic pulseCorrosion resistant

The invention belongs to the field of applied welding technology, and specifically discloses a method for improving the corrosion resistance of welded joints between aluminum plates and steel plates. A layer of cobalt is coated on the surface of the steel plates to be welded for use; Assemble the aluminum plate and steel plate on the fixture tool, and keep a certain lap length and lap gap between the aluminum plate and the steel plate; the plane formed by the lap joint of the aluminum plate and the steel plate is the surface to be welded; there is a coil under the aluminum plate, and a coil above the steel plate. Press plates; finally aluminum and steel plates welded using electromagnetic pulses. The method can not only improve the corrosion resistance, wear resistance and high temperature resistance of the welded joint, but also effectively prevent the generation of aluminum-steel intermetallic compounds and base metal fragments, and improve the performance of the welded joint of the aluminum plate and the steel plate.

Owner:CHONGQING UNIV OF TECH

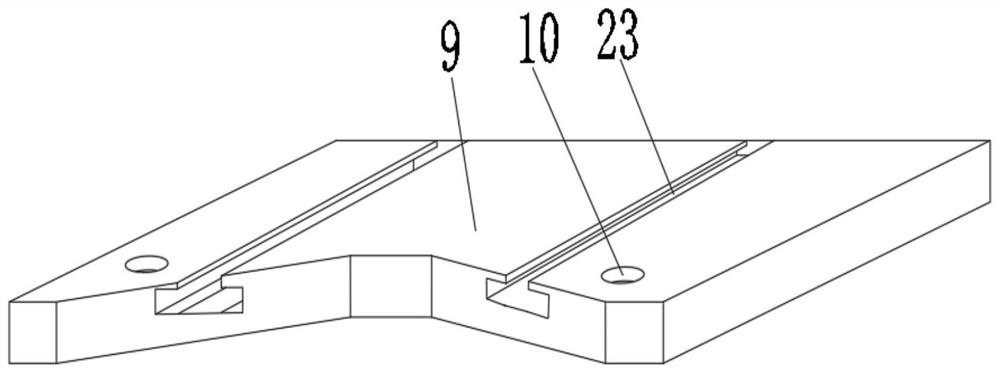

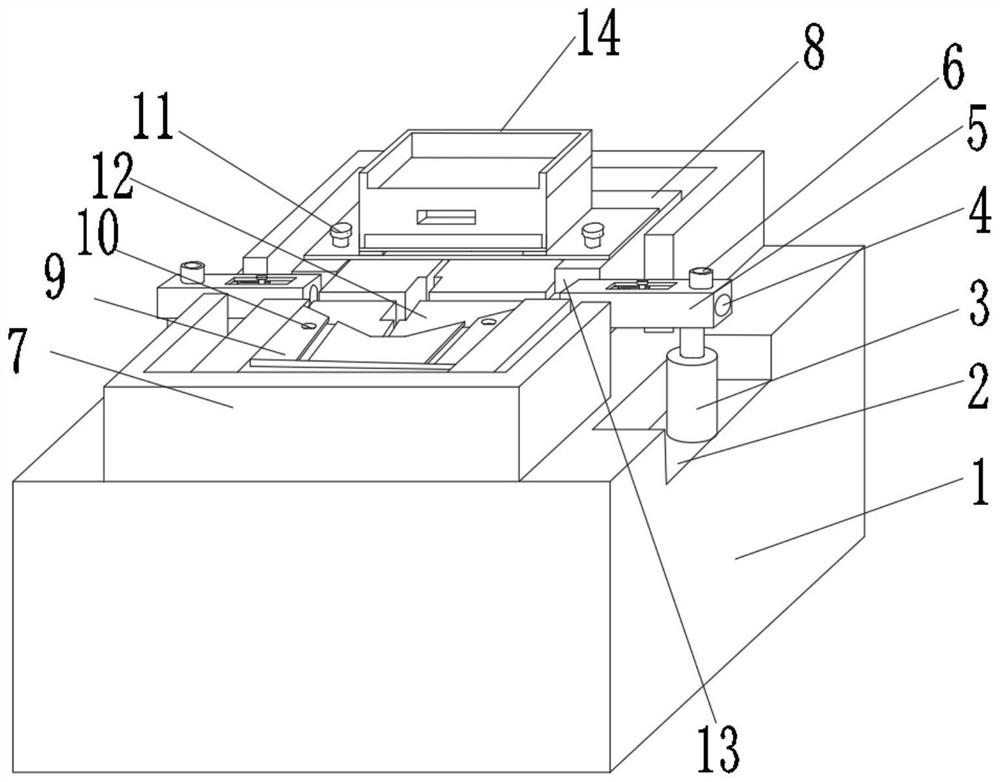

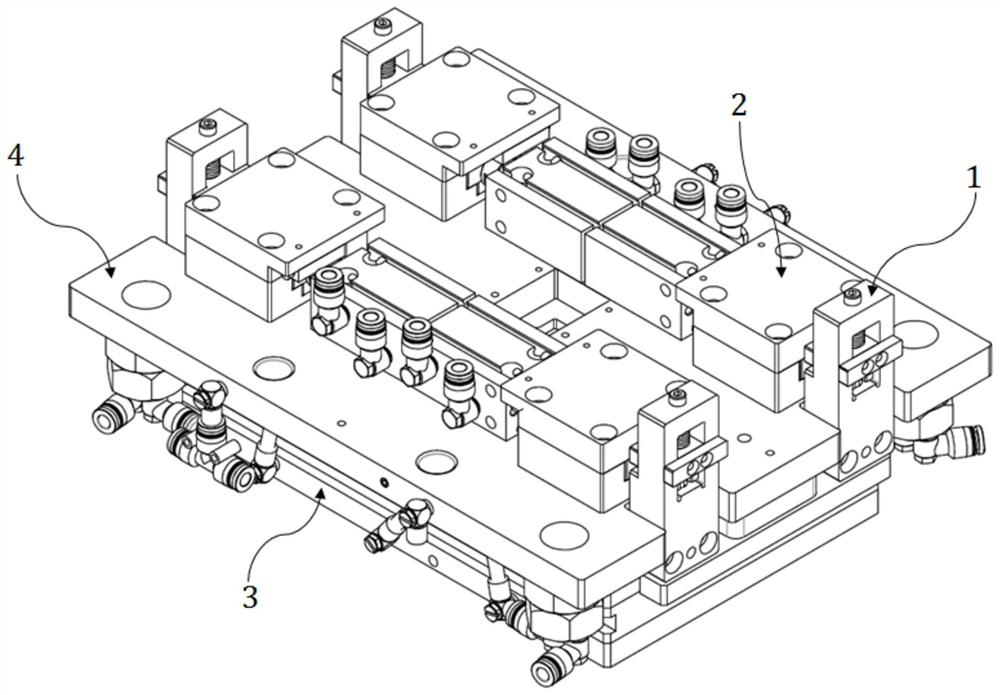

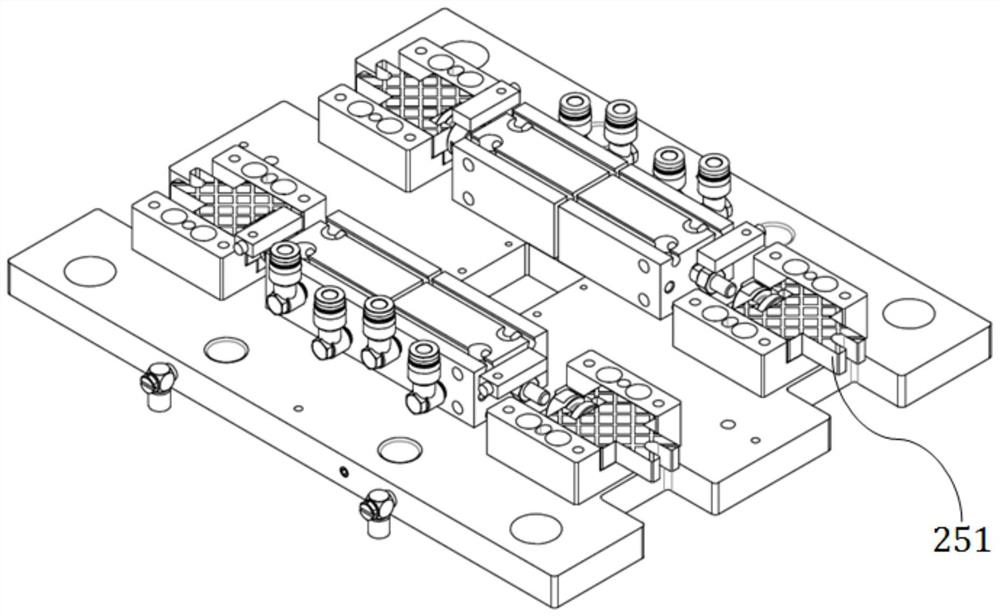

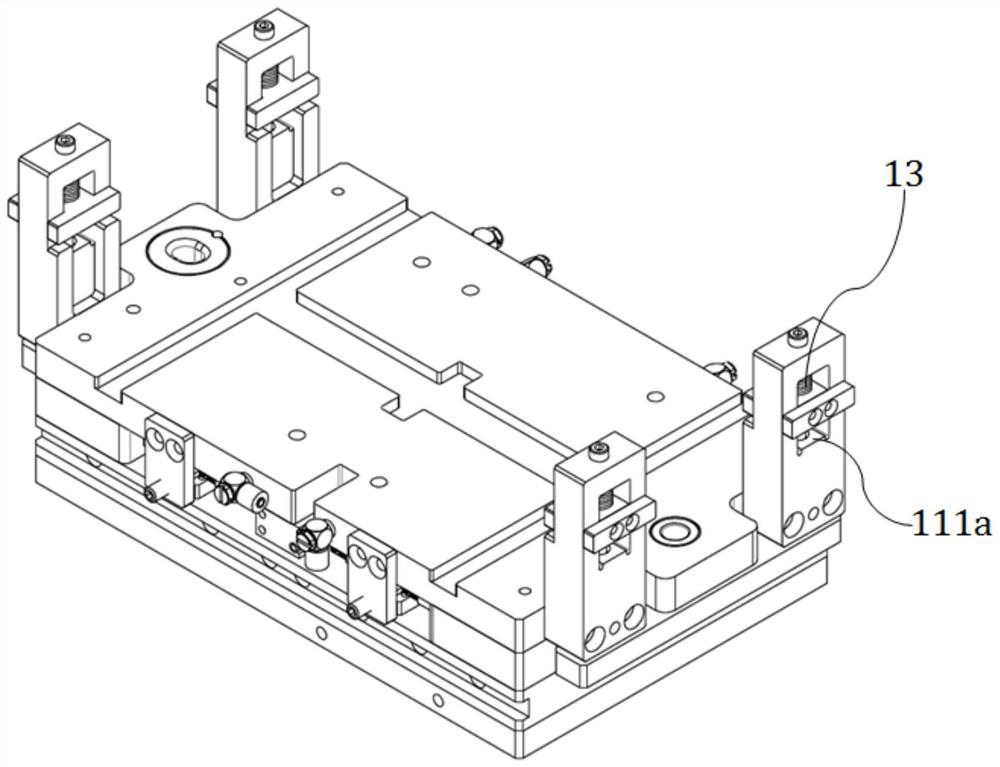

Quick upper die changing structure and related equipment and method

PendingCN113752620AImprove fitQuick changeCold pressurePressesStructural engineeringMechanical engineering

The invention provides a quick upper die changing structure and related equipment and method. The structure comprises a telescopic mechanism and a locking mechanism, wherein the telescopic mechanism is connected to a lifting mechanism and comprises a telescopic end capable of stretching out and drawing back in the horizontal direction; the locking mechanism is connected to an upper die and comprises a force applying part and a first surface; and when the telescopic end is inserted between the force applying part and the first surface, the force applying part can provide vertically downward force to enable the lower surface of the telescopic end of the telescopic mechanism to be attached to the first surface. Through the vertically downward force provided by the force applying part, the lower surface of the telescopic end of the telescopic mechanism is attached to the first surface of the locking mechanism, thus the upper die is attached to a lower die easily, and the requirement for the structural precision is lowered. Meanwhile, quick changing of the upper die can be achieved, and the machining requirements of different products are met.

Owner:苏州威达智科技股份有限公司

Connecting structure of side plate and accessory

PendingCN108679059ALow costDoes not change the chemical compositionAir-treating devicesCold pressureChemical compositionSoldering

The invention provides a connecting structure of a side plate and an accessory and relates to the technical field related to heat dissipaters. The connecting structure comprises the side plate and theaccessory, wherein a slot is formed in the side plate, and one end of the accessory is arranged in the slot; and a soldering lug is arranged between the accessory and the side plate. According to theconnecting structure of the side plate and the accessory provided by the invention, one or more point connecting side plates and the accessories are riveted to the upper and lower surfaces of a C-shaped side plate, so that the cost of a material is not increased basically. As the connecting mode is implemented by means of deformation, the chemical components of the material are not changed, so that the corrosion resistance of a product is not affected. The product is good in riveting consistence and attractive in appearance; the surfaces of the side plate and the accessory entering a furnaceto be brazed are tightly welded together by means of brazing filler metal, so that the stress areas of the accessory and the side plate of the product in the vibrating process are increased, and the vibration resistance is guaranteed.

Owner:重庆超力电器有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com