Buffer type cold welding mechanism for preventing product crushing

A cold welding and product technology, applied in the field of capacitor manufacturing equipment, can solve the problems of product crushing, high processing accuracy and high cost, and achieve the effects of convenient replacement, reduced processing difficulty and reduced processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

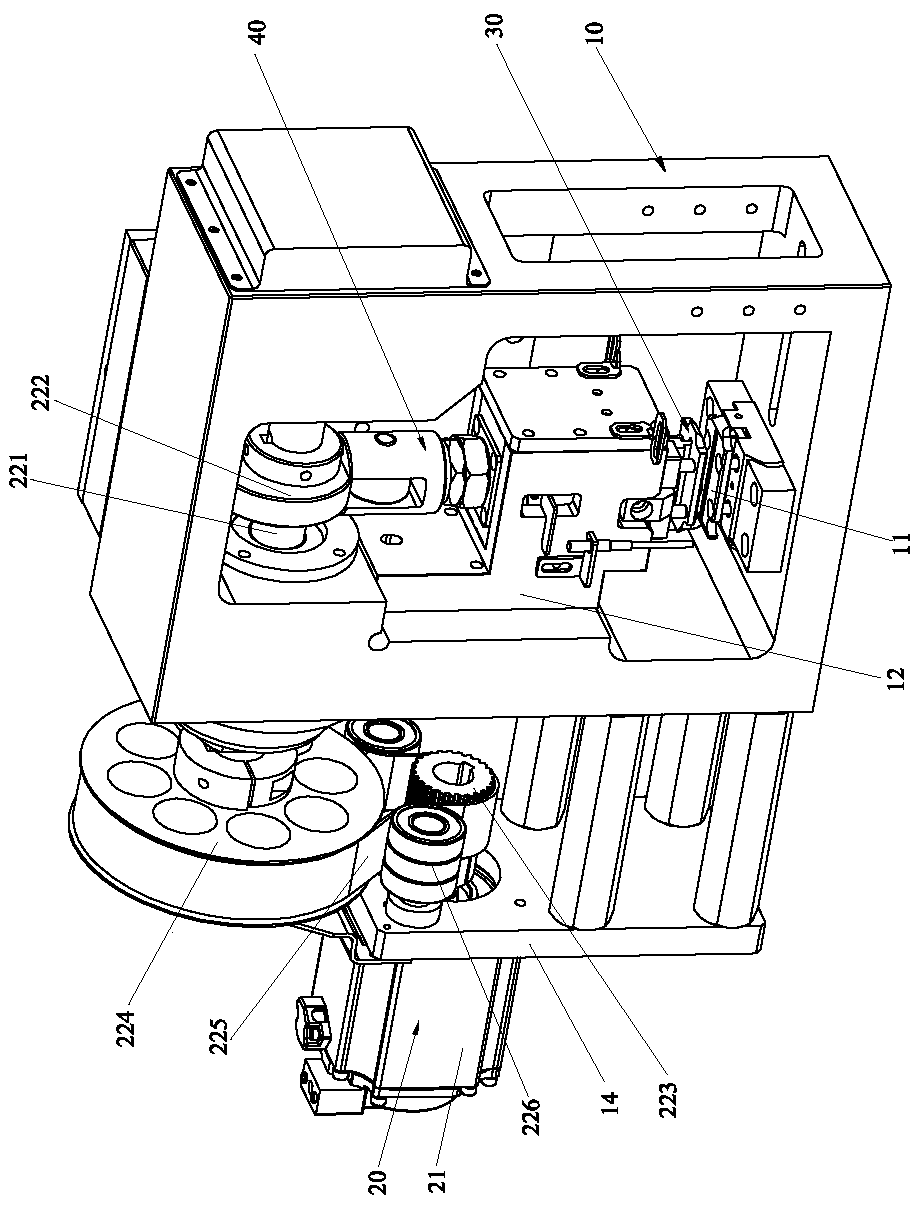

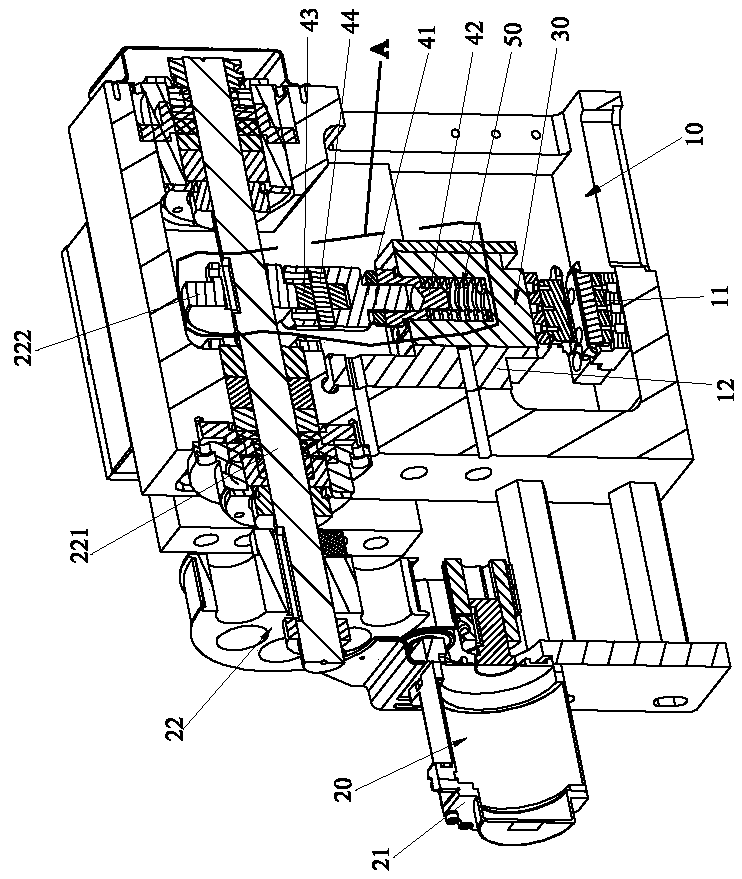

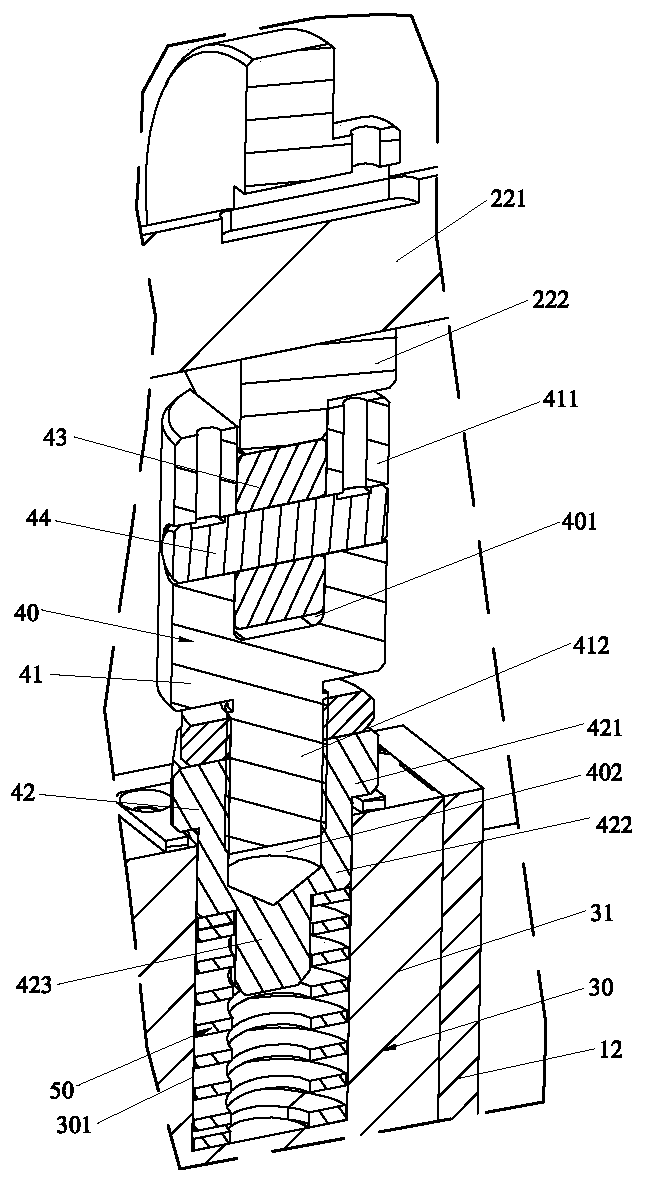

[0041] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10, a driving device 20 and a cold welding device 30.

[0042] The frame 10 is provided with a processing seat 11, which is used to place the lead strips, aluminum foil and negative foil. The driving device 20 is disposed on the frame 10 .

[0043] The cold welding device 30 can be movable up and down on the frame 10 and is opposite to the processing seat 11. A resisting member 40 is connected between the cold welding device 30 and the driving device 20, and the driving device 20 drives the resisting member 40 to press down. , the conflicting member 40 drives the cold welding device 30 to press down, thereby realizing cold welding riveting. The connection between the cold welding device 30 and the conflicting member 40 is provided with an elastic buffer 50 to avoid crushing or crushing the product. On the cold welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com