Magnesium and aluminum material connecting sealing method

A technology of magnesium-aluminum and aluminum materials, applied in the field of connection and sealing of magnesium-aluminum materials, can solve the problems of poor sealing and complicated connection process, and achieve the effects of reducing labor intensity, simple production process and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for connecting and sealing magnesium, copper, and aluminum materials, comprising the following steps:

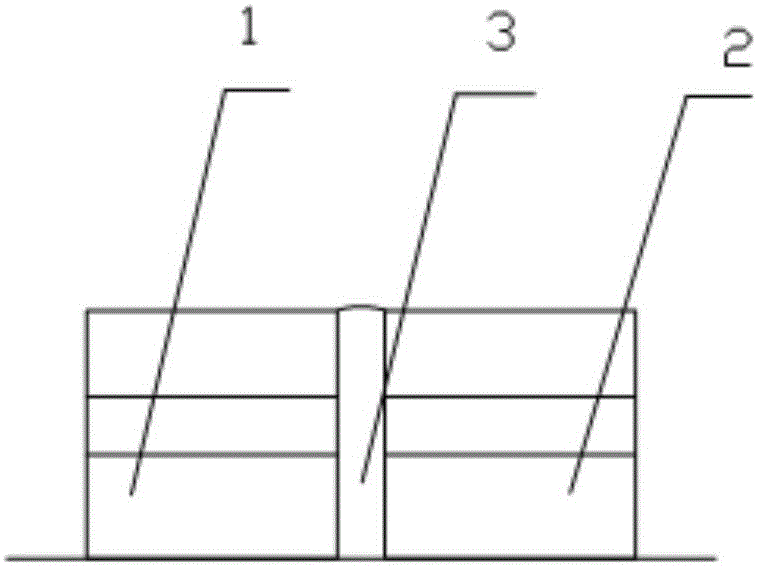

[0023] Step 1: If figure 1 As shown, under normal temperature conditions, the copper material 3 with a thickness of 2mm is embedded in the gap between the connected magnesium material 1 and the connected aluminum material 2 by cold pressure welding;

[0024] Step 2: Use the hoarding board to enclose the joint surface formed by the three materials of magnesium material 1, aluminum material 2, and copper material 3 into a space area, and apply a 2mm thick polyurethane primer on the substrate of the space area as a primer Coating to remove the oxide layer residing on its surface;

[0025] Step 3: After 10 minutes, pour high-performance silicone structural glue on the substrate of the enclosed space area, and the product is ready.

Embodiment 2

[0027] A method for connecting and sealing magnesium, chromium, and aluminum materials, comprising the following steps:

[0028] Step 1: If figure 1 As shown, under normal temperature conditions, the chromium material 3 with a thickness of 4mm is embedded in the gap between the connected magnesium material 1 and the connected aluminum material 2 by cold pressure welding;

[0029] Step 2: Enclose the joint surface formed by the three materials of magnesium material 1, aluminum material 2, and chrome material 3 with a hoarding board to form a space area, and apply a 5mm thick polyurethane primer on the substrate of the space area as a primer Coating to remove the oxide layer residing on its surface;

[0030] Step 3: After 15 minutes, pour high-performance silicone structural glue on the substrate of the enclosed space area, and the product is ready.

Embodiment 3

[0032] A method for connecting and sealing magnesium, zinc, and aluminum materials, comprising the following steps:

[0033] Step 1: If figure 1 As shown, under normal temperature conditions, the zinc material 3 with a thickness of 3 mm is embedded in the gap between the connected magnesium material 1 and the connected aluminum material 2 by cold pressure welding;

[0034] Step 2: Use the hoarding board to enclose the joint surface formed by the three materials of magnesium material 1, aluminum material 2, and zinc material 3 into a space area, and apply a 3mm thick polyurethane primer on the substrate of the space area as a primer Coating to remove the oxide layer residing on its surface;

[0035] Step 3: After 12 minutes, pour high-performance silicone structural glue on the substrate of the enclosed space area, and the product is ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com