Polarizer push fixture and work mode thereof

A polarizing plate and jig technology, which is used in cold-pressed connections, connecting components, mechanical equipment, etc., to achieve the effects of convenient operation, simple structure, and improved adhesion firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

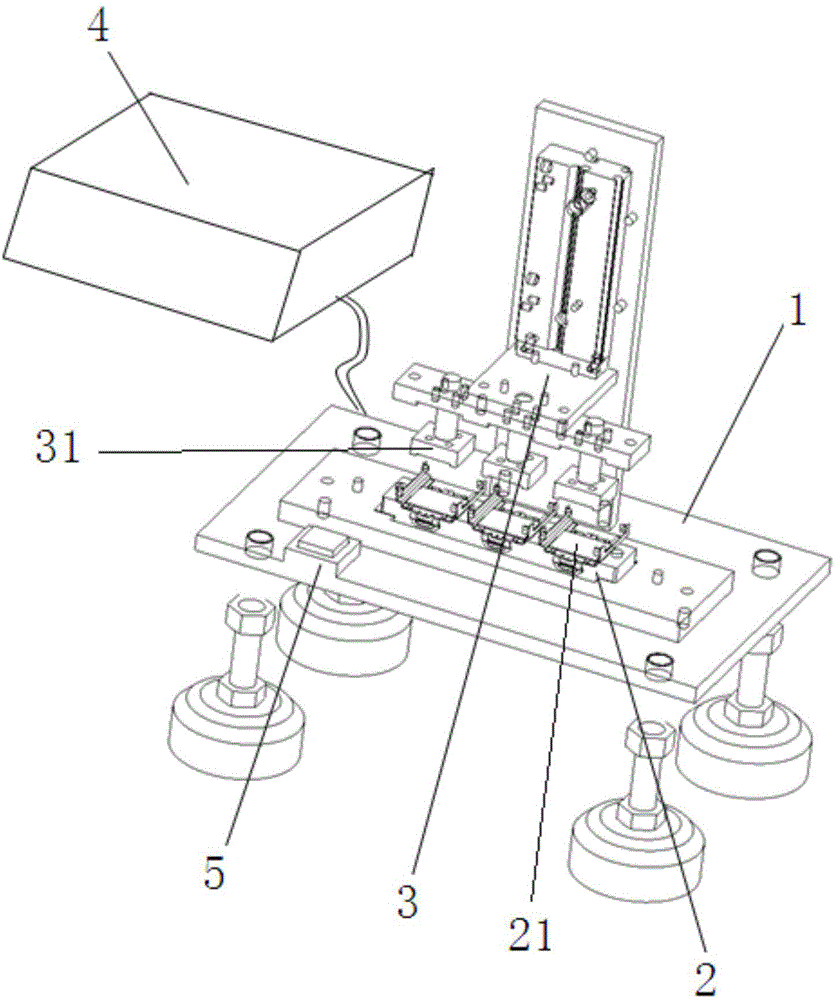

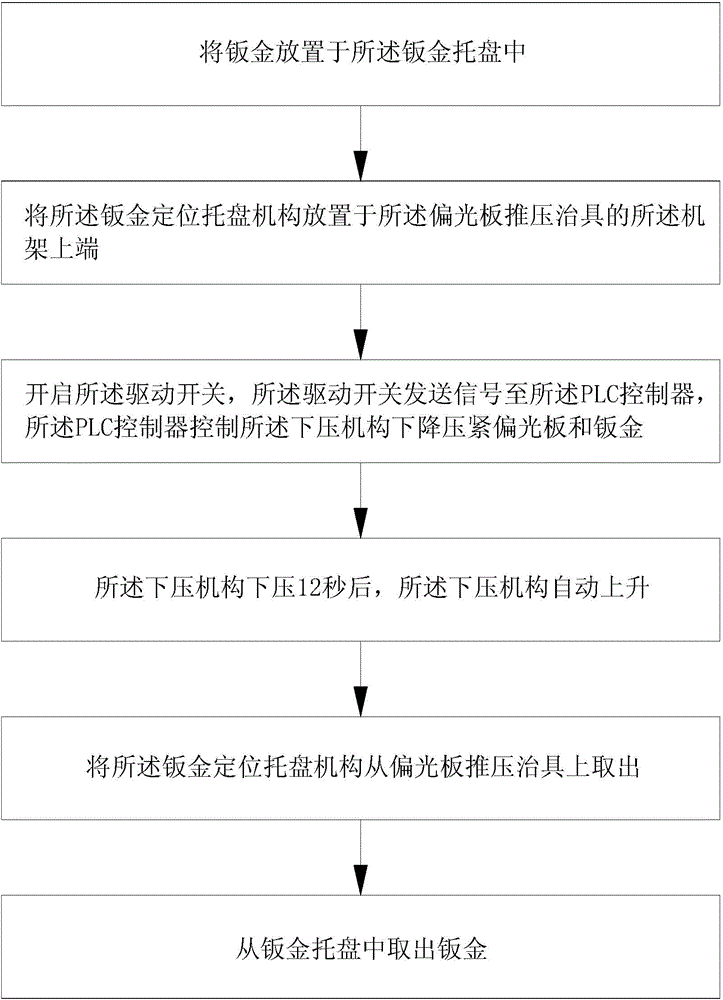

[0024] In further embodiments of the present invention, please continue to refer to figure 1 and figure 2 shown. The pressing mechanism 3 has a driving device, and the PLC controller 4 is connected with the driving device signal, so that the PLC controller 4 sends a signal to the driving device, and the driving device drives the pressing mechanism 3 to realize the up and down pressing action.

[0025] In a further embodiment of the present invention, taking a preferred embodiment as an example, the driving device is a double-rod cylinder, specifically an SMC double-rod cylinder. The pressing down mechanism 3 realizes the pressing down action through the double-rod cylinder, so as to press down a plurality of sheet metal trays 21 of the sheet metal positioning tray mechanism 2 .

[0026] In a further embodiment of the present invention, the pressing mechanism 3 has several pressing rubber heads 31, each pressing rubber head 31 faces each sheet metal tray 21, and each pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com