Cold welding process repairing method for oil field storage tank, without hot work

A repair method and cold welding technology, applied in the direction of cold-pressed connections, connecting components, pipes/pipe joints/fittings, etc., can solve the problems of difficulty and danger of repair, difficulty in continuous production, cracking of welds, etc., and achieve low repair costs. , the effect of good mechanical ability and compressive strength, strong grip and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

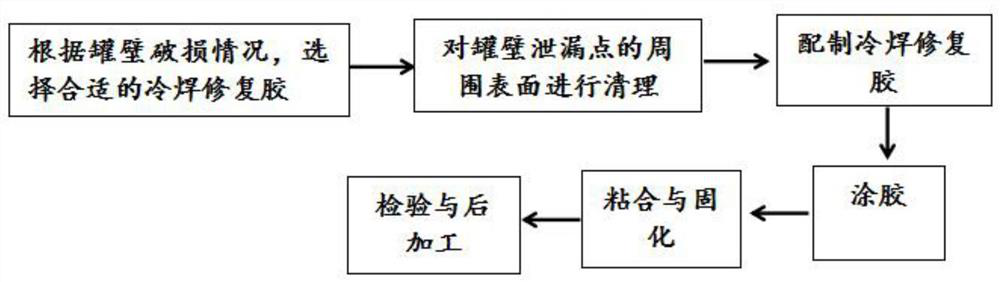

[0036] S1: Select the suitable glue; S2: Clean the surface paint, rust, oil stain and corroded loose layer around the leakage point; S3: Prepare cold welding repair glue according to the formula and weight ratio, and prepare 100kg of cold welding repair Glue, the formula of specific weight part is as follows: 35kg of bisphenol A type epoxy resin, 5kg of bisphenol F type epoxy resin, 10kg of ethyl cyanoacrylate, 50kg of silicon micropowder; The repair glue is evenly applied to the damaged leakage point of the oil field storage tank, and the damaged part is first filled and then applied. When applying the glue, it should move in one direction, and the speed should not be too fast; S5: bonding and curing; after steps S4 After glue application, wait for the bonding between the cold welding repair glue and the damaged pipe wall and the curing of the cold welding repair glue; S6: Inspection and post-processing: after the inspection achieves the expected plugging purpose, polish the e...

Embodiment 2

[0038]S1: Select the suitable glue; S2: Clean the surface paint, rust, oil stain and corroded loose layer around the leakage point; S3: Prepare cold welding repair glue according to the formula and weight ratio, and prepare 100kg of cold welding repair Glue, the formula of specific weight part is as follows: 40kg of bisphenol A type epoxy resin, 10kg of bisphenol F type epoxy resin, 10kg of ethyl cyanoacrylate, 40kg of silicon micropowder; The repair glue is evenly applied to the damaged leakage point of the oil field storage tank, and the damaged part is first filled and then applied. When applying the glue, it should move in one direction, and the speed should not be too fast; S5: bonding and curing; after steps S4 After glue application, wait for the bonding between the cold welding repair glue and the damaged pipe wall and the curing of the cold welding repair glue; S6: Inspection and post-processing: after the inspection achieves the expected plugging purpose, polish the e...

Embodiment 3

[0040] S1: Select the suitable glue; S2: Clean the surface paint, rust, oil stain and corroded loose layer around the leakage point; S3: Prepare cold welding repair glue according to the formula and weight ratio, and prepare 100kg of cold welding repair Glue, the formula of specific weight part is as follows: 37kg of bisphenol A type epoxy resin, 10kg of bisphenol F type epoxy resin, 8kg of ethyl cyanoacrylate, 45kg of silicon micropowder; The repair glue is evenly applied to the damaged leakage point of the oil field storage tank, and the damaged part is first filled and then applied. When applying the glue, it should move in one direction, and the speed should not be too fast; S5: bonding and curing; after steps S4 After glue application, wait for the bonding between the cold welding repair glue and the damaged pipe wall and the curing of the cold welding repair glue; S6: Inspection and post-processing: after the inspection achieves the expected plugging purpose, polish the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com