Packaging pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

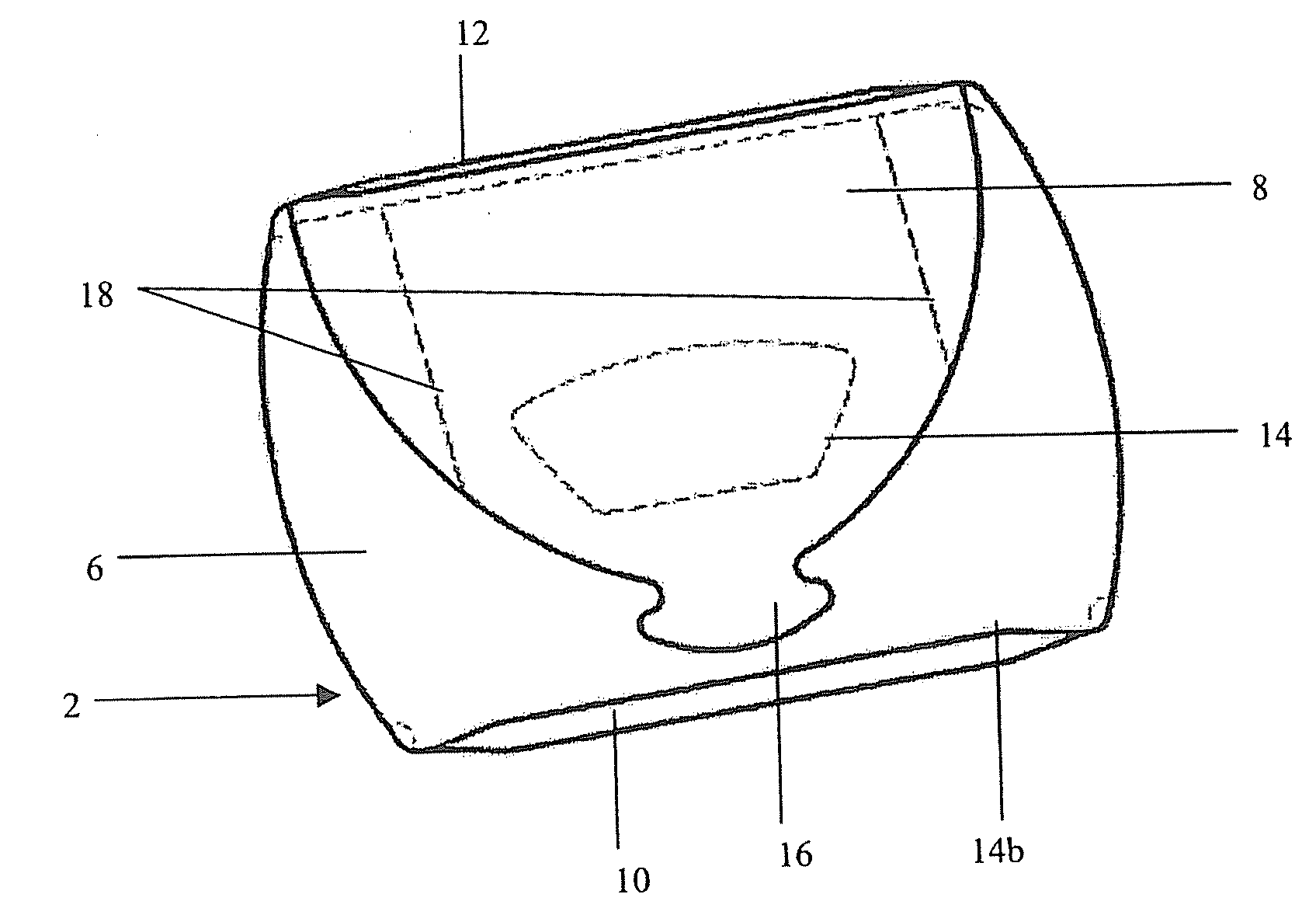

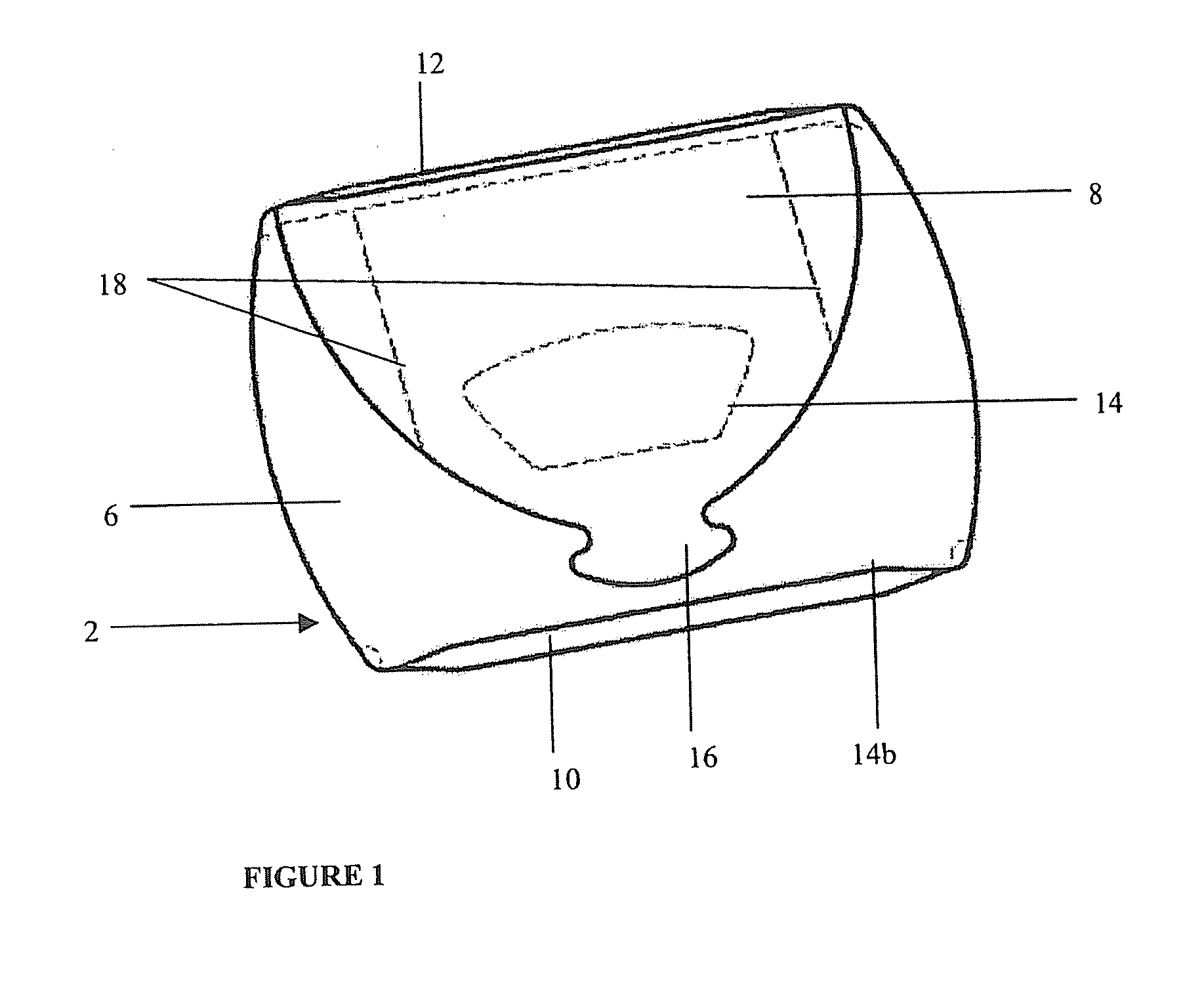

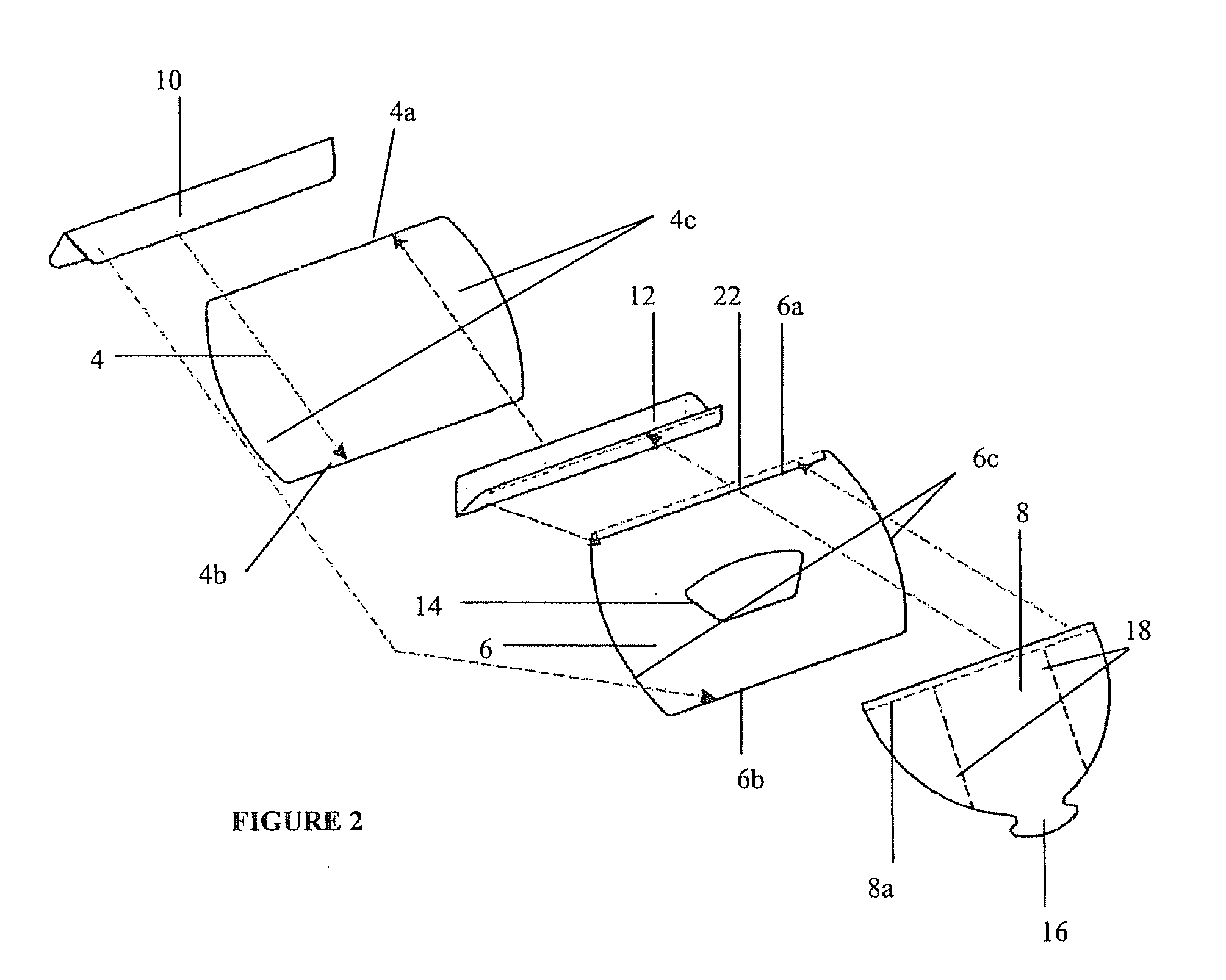

[0017]FIGS. 1 and 2 show a first exemplary embodiment of a packing bag 2 according to the invention, formed from films composing the back face 4, the front face 6, the flap 8, the lower gusset 10 and the upper gusset 12 of the packing bag 2. These films are multilayer films and include a heat-sealable internal layer made for example of polyethylene, an intermediate barrier layer such as aluminium, and an external layer made of a plastic material such as PVC, polypropylene or PET which can be printed (by screen printing, photogravure, flexographic printing etc.). According to this provision, only the internal layers can be heat-sealable together.

[0018]The back 4 and front 6 faces have a substantially rectangular shape. They each have two upper 4a, 6a and lower 4b, 6b rectilinear edges, as well as two slightly curved side edges 4c, 6c, in the utilisation position. The internal layers of the side edges 4c, 6c of the back 4 and front 6 faces are welded together. The internal layers of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com