Process for a high efficiency and low emission operation of power stations as well as for storage and conversion of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

OF APPLICATION

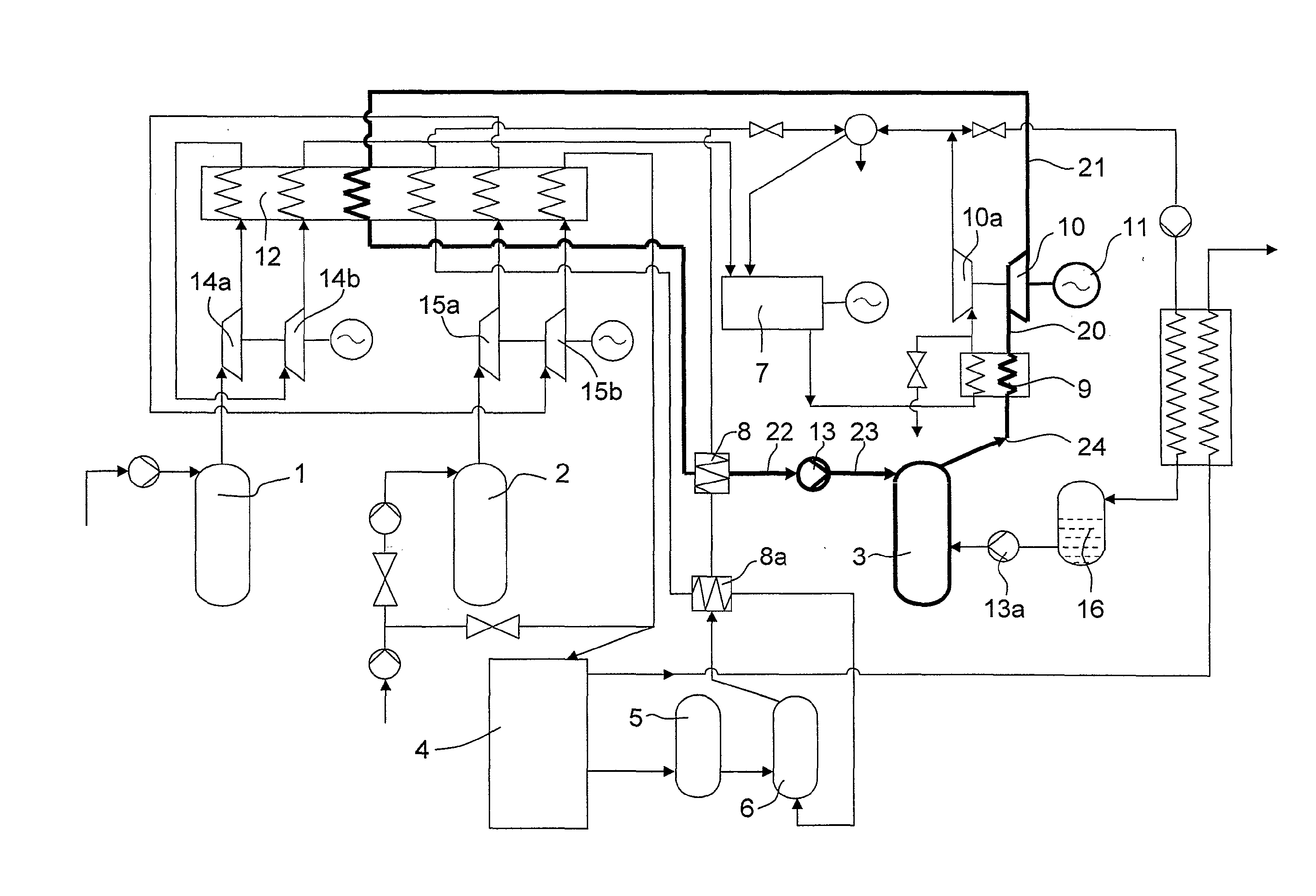

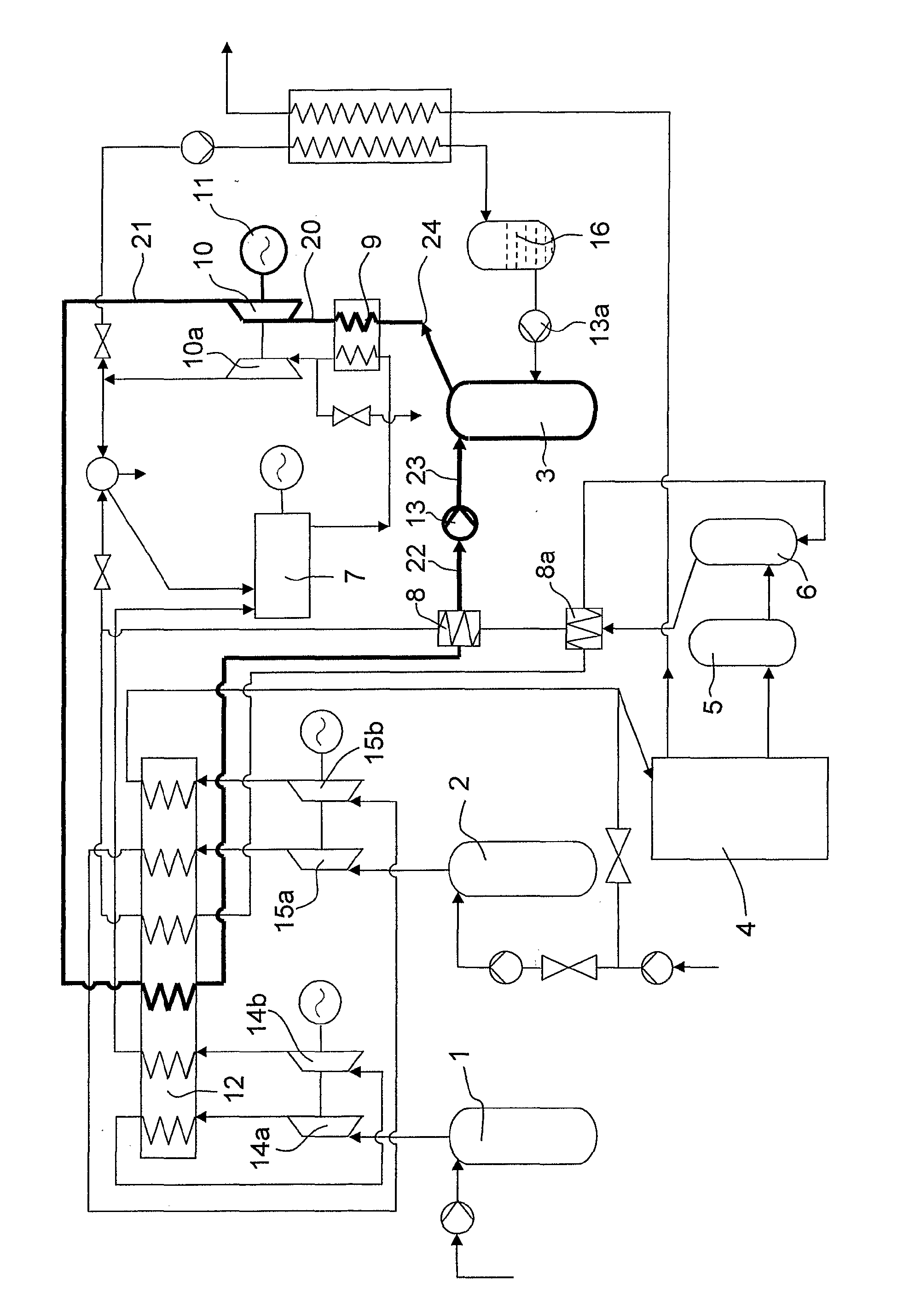

[0033]Further advantages are given by the description of an example of application of the invention by different temperatures of the using of heat with and without the using of a geothermic potential at 301 K as well as the connected figure and table with different modifications.

[0034]In the figure the principle of the construction of the device for the application of the process with using the geothermal potential is given schematically.

[0035]In the following example of the application the using of the decisive thermal potential is put into the centre of interest. The corresponding, with the numbers 20 to 24 characterized duct circuit is marked by increased lines. All of the other advantages are to understand by specialists direct and without other commentaries.

[0036]The most important parameters as transferred heats, temperatures and powers are given in the table in clearly visible form for the two temperatures 423 K and 473 K. The great advantage of the combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com