Process and device for using of low temperature heat for the production of electrical energy

a technology of low temperature heat and electrical energy, which is applied in the direction of mechanical power devices, machines/engines, steam engine plants, etc., can solve the problems of high-toxic and environmentally dangerous ammonia emissions at possible leakages, lowering the cycling time of little proved plants, and increasing material and control effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

OF APPLICATION

[0017]Further advantages are given by the description of examples of application of the invention as well as the connected picture and table.

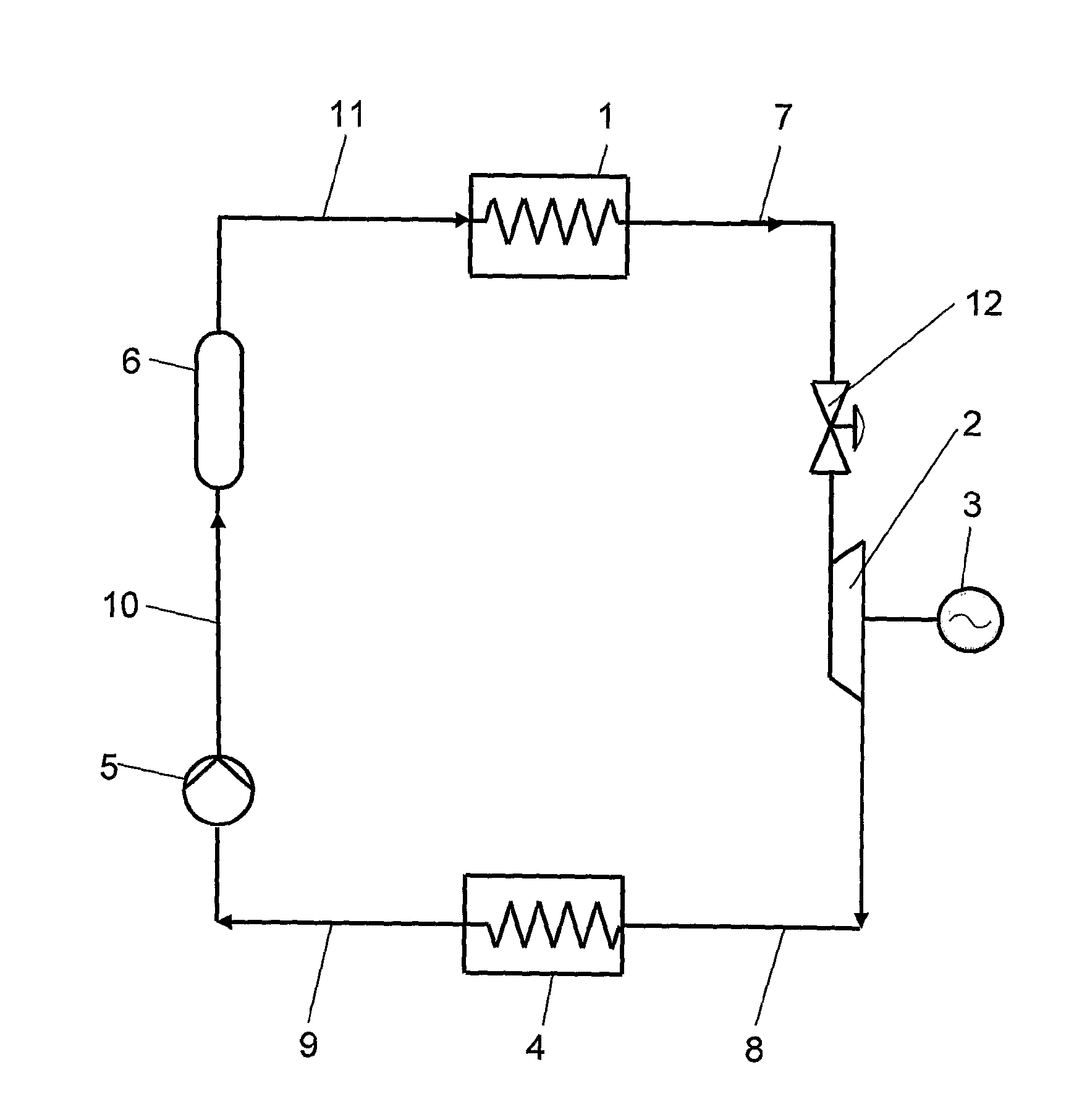

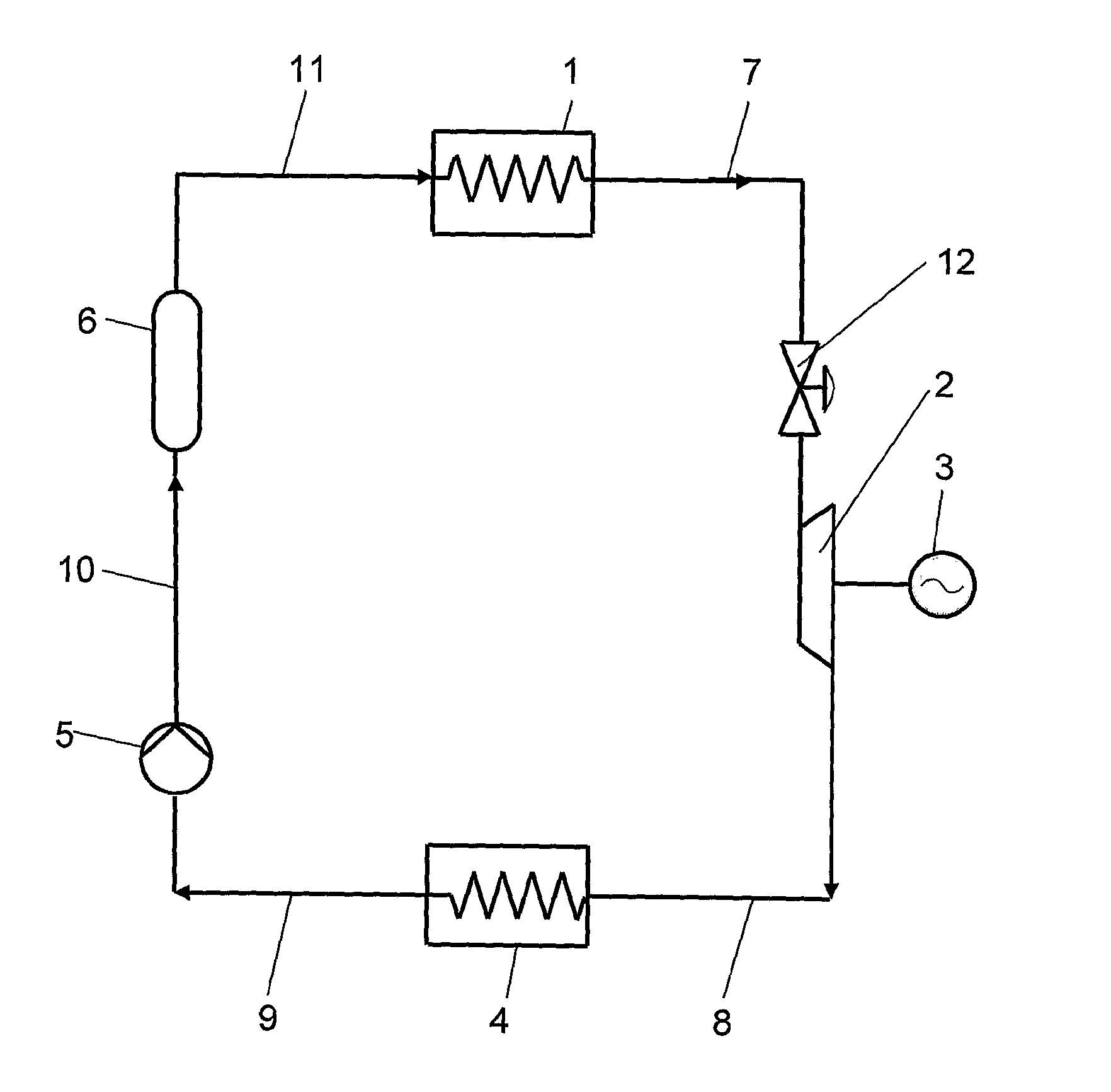

[0018]The fundamental principle of the application of the process and the device for using of the waste energy of an energy generation plant by using the earth as cooling source for condensation of the working fluid carbon dioxide is shown in the picture. Three different heat potentials at 363 K, 373 K und 623 K are used exemplary as heat sources at the working pressure at 15 MPa in the examples I to III. As expansion machine (2) is used an expansion turbine. The earth heat potential in the depths of 8 to 30 meters is used as cold source (4) for the condensation of the working fluid carbon dioxide which was expanded to 4.5 MPa. A pressure chamber (6) will used as a temporary storage. The pipes for the carbon dioxide circuit are the lines 7 to 11 according to the picture. The calculation of the examples was made with the program EB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com