3D printing device and 3D printing method by utilizing supercritical carbon dioxide as solvent

A carbon dioxide and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of inability to make filamentary consumables and inapplicability, and achieve the effect of meeting actual industrial requirements, avoiding emissions, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

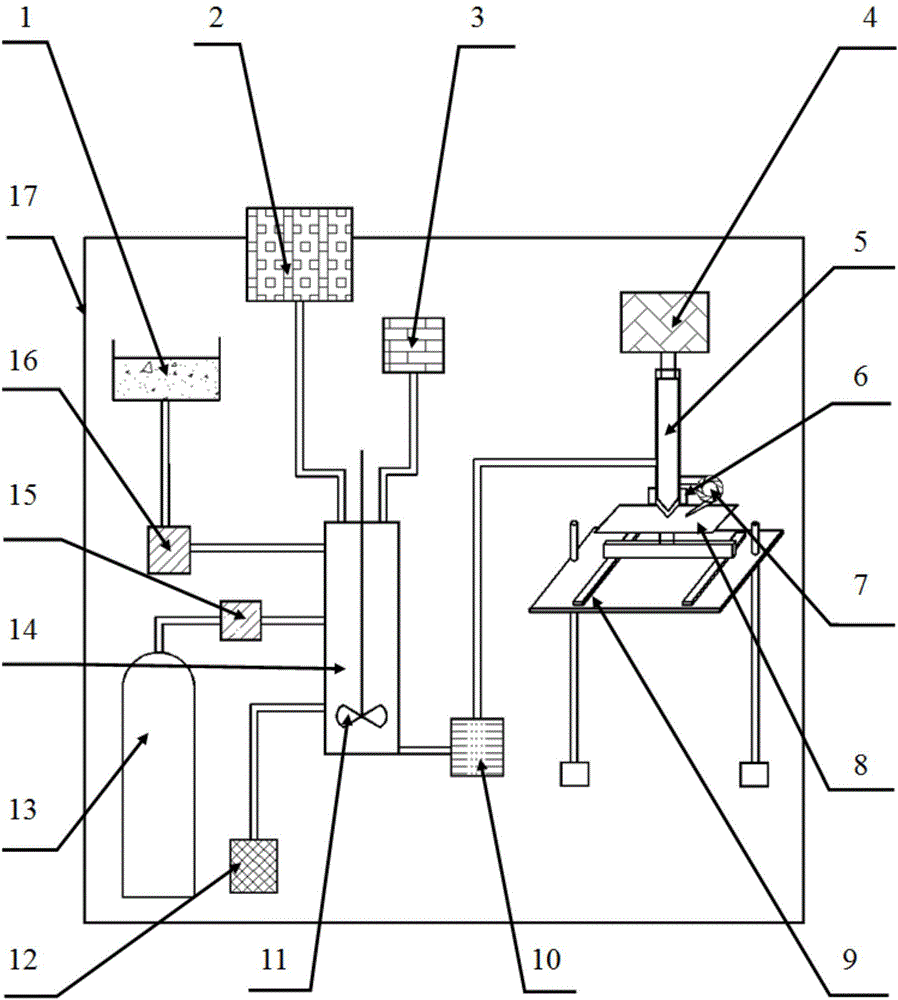

[0014] The present invention uses supercritical carbon dioxide as a 3D printing device as a solvent, such as figure 1 As shown, it is composed of a material preparation unit, an injection unit, a three-dimensional modeling platform unit, and a raw material recovery unit; the material preparation unit includes a polymer material powder 1, a carbon dioxide gas cylinder 13, a mixing tank 10, a liquefaction booster pump 3, a stirring impeller 11, Refrigerator 2, liquid pump 10, gas pump 15, and powder pump 16; wherein the injection unit includes an air pump 4, a pneumatic needle valve 5, a cooling fan 7, and a resistance heater 6; wherein the three-dimensional forming platform includes a forming platform 8 and a three-dimensional ball screw Slider module 9; wherein the raw material recovery unit includes a gas recovery pump 12 and a closed box 17.

[0015] In a 3D printing device using supercritical carbon dioxide as a solvent in the present invention, the carbon dioxide gas is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com