Methanol steam reforming hydrogen production reactor for fuel cell car

A steam reforming and hydrogen production reactor technology, applied in the field of reactors, can solve problems such as uneven heating, difficult volume reduction, slow system response speed, etc., achieve uniform heating, avoid local high temperature areas, and improve energy efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

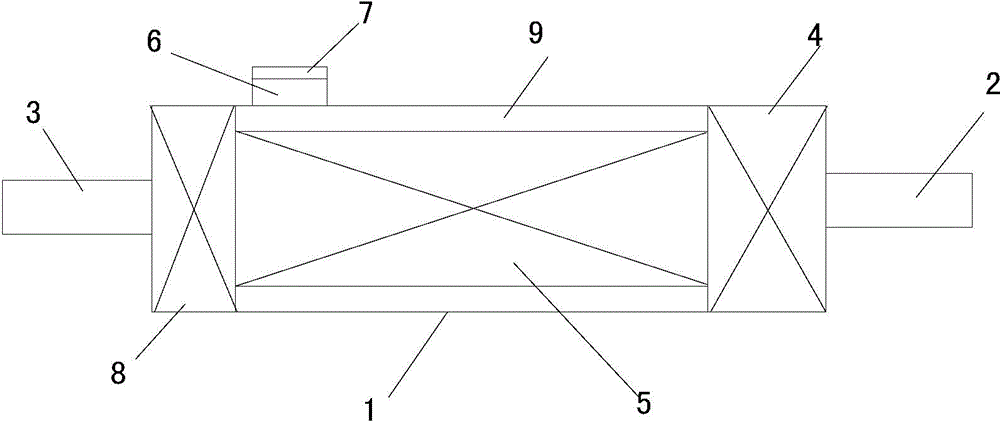

[0022] see figure 1 , the methanol steam reforming hydrogen production reactor used for fuel cell vehicles in the present invention comprises a shell 1, the right end of the shell is provided with a methanol and aqueous solution inlet pipe 2, the left end is provided with a gas production outlet pipe 3, and the shell is composed of two A dividing plate is divided into right chamber, middle chamber and left chamber; an evaporator 4 is arranged in the right chamber; a catalytic converter 5 is arranged in the middle chamber, and a connecting middle chamber is installed on the pipe wall of the middle chamber. The waveguide 6 is provided with a magnetron 7 on the waveguide; a condenser 8 is provided in the left chamber.

[0023] Cu / Al is filled in the catalytic converter among the present invention 2 o 3 Catalyst, the catalyst is made into a cylindrical shape of 1mm×1mm. The catalyst material is alumina ceramics.

[0024] In the present invention, a space is provided between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com