High-entropy alloy-base composite material and preparation method thereof

A technology of high-entropy alloys and composite materials, applied in the field of alloy-based composite materials and their preparation, can solve the problems of no reports of high-entropy-based composite materials, limited alloys of high-entropy alloys, etc., and achieves easy implementation, simple operation, compressive strength and compression strength. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

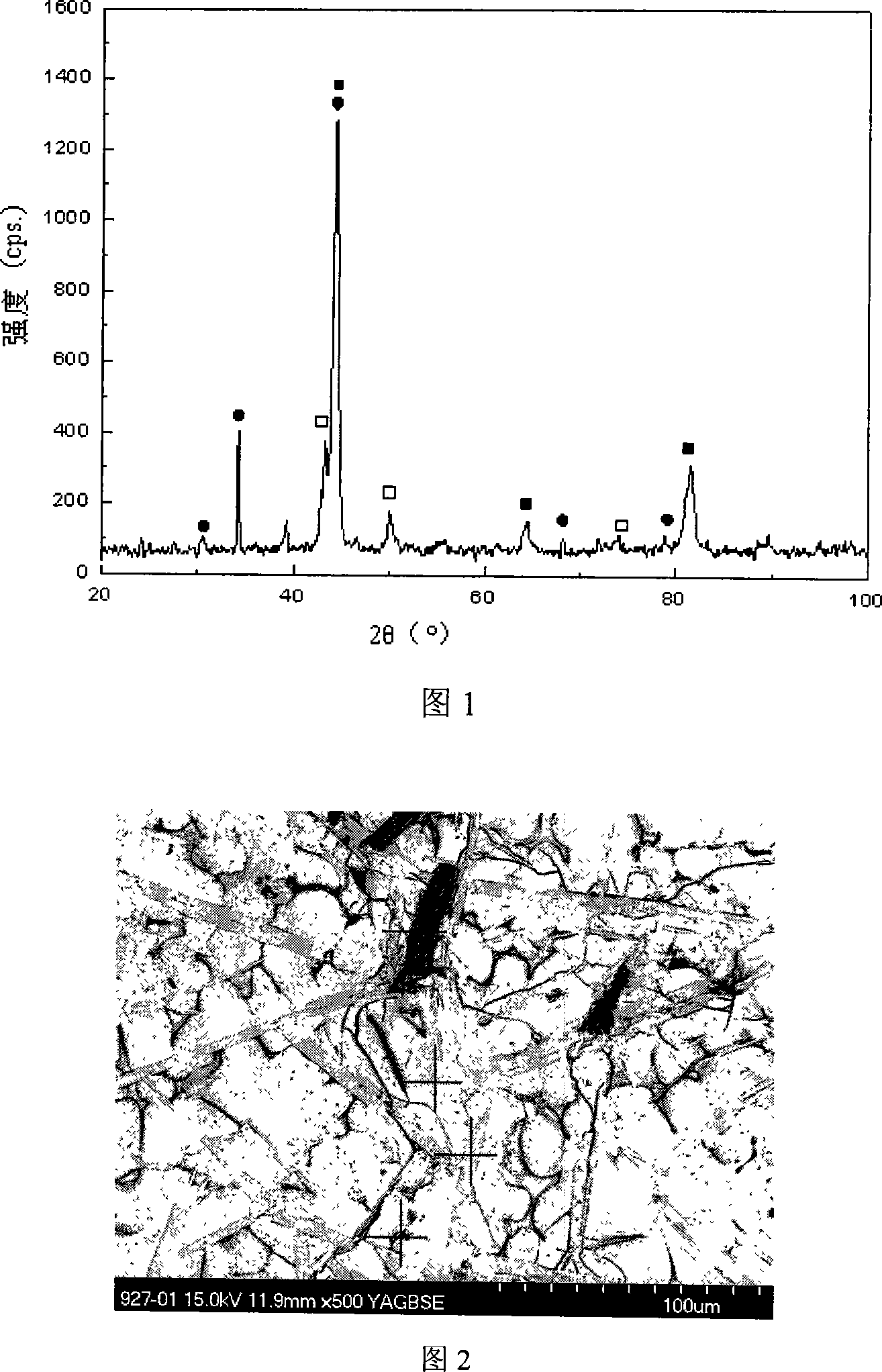

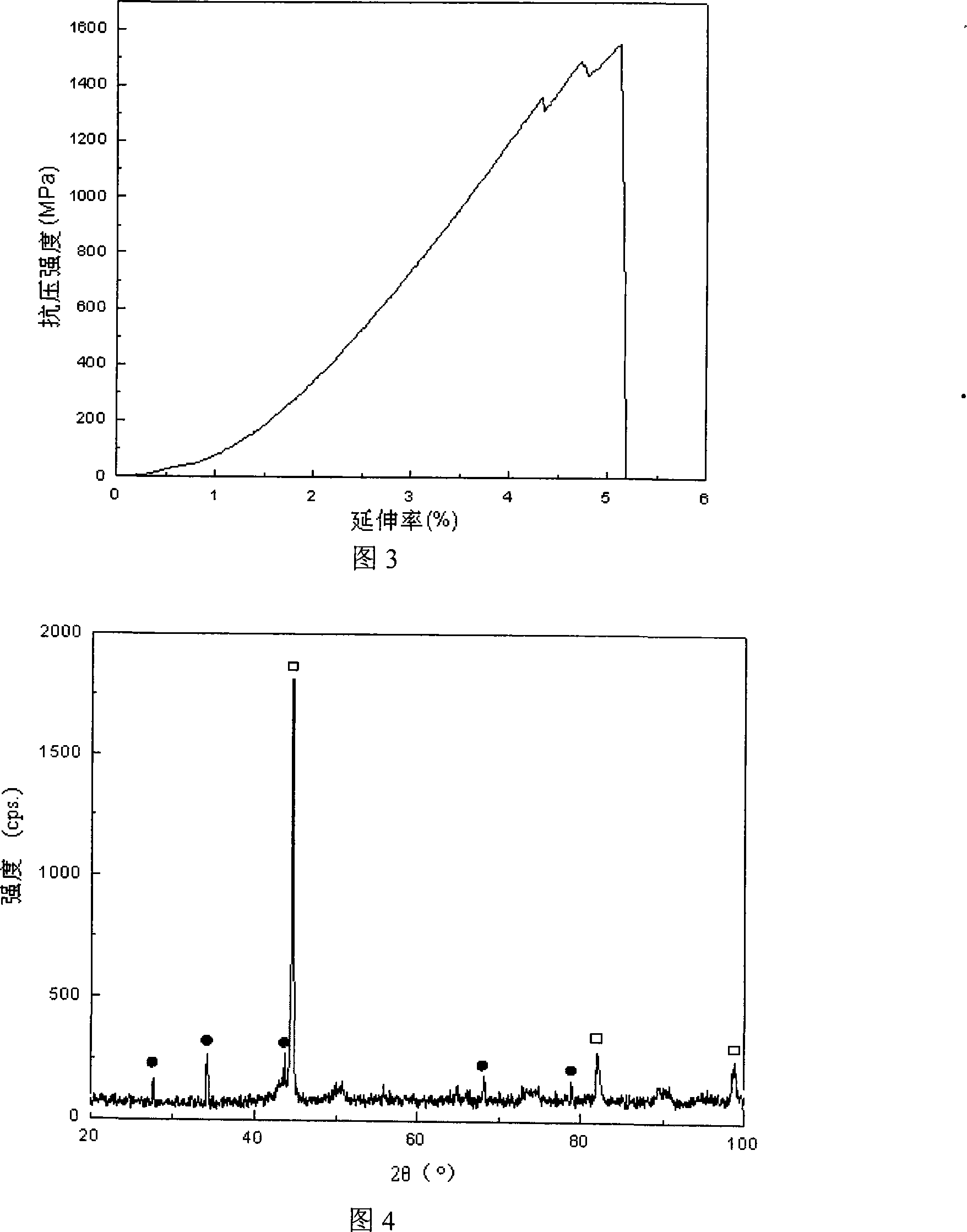

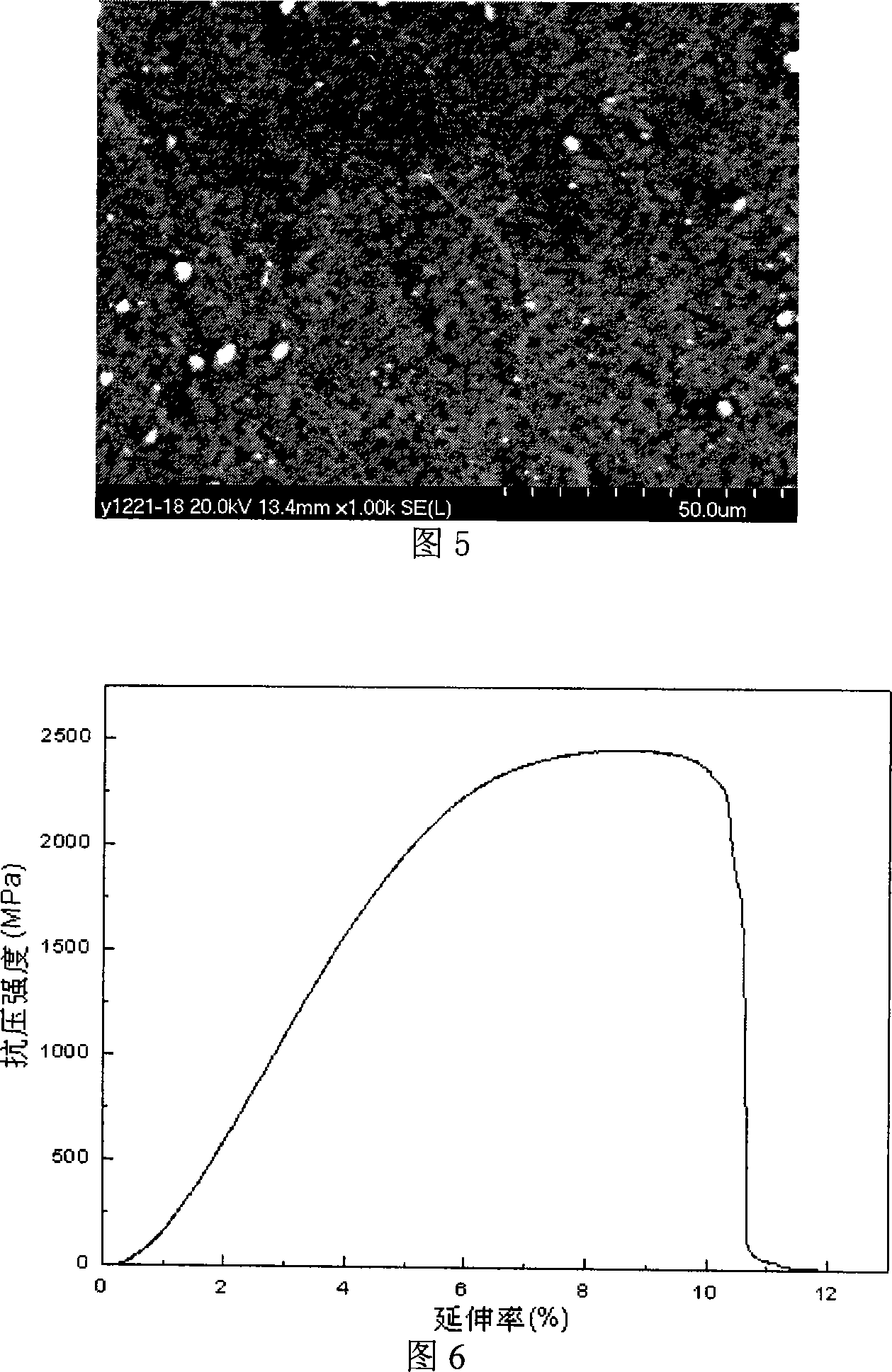

[0016] Specific Embodiment 1: The high-entropy alloy-based composite material in this embodiment is made of 1% to 45% of the reinforcement phase and 55% to 99% of the high-entropy alloy matrix by volume percentage; wherein the reinforcement phase is TiC, TiB 2 , TiB, B 4 C. Al 2 o 3 、Ti 3 Al, TiAl, Ti 5 Si 3 、Zr 2 o 3 , AlN or TiN.

[0017] In order to make the alloy form a simple solid solution structure, non-metallic elements must not be introduced into the high-entropy alloy; the invention breaks through this limitation and introduces non-metallic elements into the reinforcing phase. In the present invention, there is a relatively large negative mixing enthalpy among elements of the reinforcing phase, so the reinforcing phase tends to form a cermet phase.

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the high-entropy alloy matrix is a 5-element, 6-element, 7-element, 8-element, 9-element, 10-element, 11-element, 12-element or 13-element alloy A system in which the elements are composed in equimolar ratios. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the matrix of the high-entropy alloy is 6 elements, and each element is composed in an equimolar ratio. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Vickers hardness value | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com