A kind of water-soluble phosphate rock powder and preparation method thereof

A phosphate rock powder, water-soluble technology, applied in the field of phosphate rock powder, can solve the problems of inability to utilize phosphorus elements well, reduce the utilization rate of phosphate rock, complex process conditions, etc., and achieve a simple and controllable production process, water-soluble phosphorus The effect of increased content and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

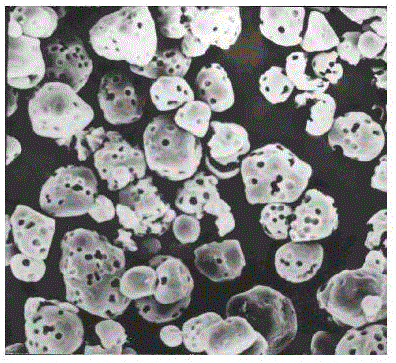

Image

Examples

Embodiment 1

[0033] A kind of water-soluble phosphate rock powder, its component is as follows, all by weight:

[0034] Fluorapatite powder: 100 parts,

[0035] Pentaerythritol esters: 5 parts,

[0036] Polyoxyethylene heptylamine: 5 parts,

[0037] Alkylphenol polyoxyethylene ether formaldehyde condensate: 5 parts

[0038] Its preparation method is as follows:

[0039] (1) Send 100 parts by weight of fluorapatite powder into the crushing chamber, and blow nitrogen gas (N 2 ), keep the indoor pressure at 400~500KPa, and use the gas phase pulverization method to refine the phosphate rock powder to a particle size of ≤10μm;

[0040] (2) Send the miniaturized phosphate rock powder obtained in step (1) into the pore-forming chamber, use the Nd:YAG laser drilling method, use the laser beam excited by diode pulses, and the laser power density is 800W / cm 2 , the drilling speed is 1000 holes / second, and the fine particles of phosphate rock powder are made into particles with a pore size of 18...

Embodiment 2

[0043] A kind of water-soluble phosphate rock powder, its component is as follows, all by weight:

[0044] Fluorapatite powder: 95 parts,

[0045] Glycerol polyoxyethylene ether: 10 parts,

[0046] Naphthalenesulfonate formaldehyde condensate: 5 parts,

[0047] Its preparation method is as follows:

[0048] (1) Send 95 parts by weight of fluorapatite powder into the crushing chamber, and blow nitrogen gas (N 2 ), keep the indoor pressure at 400~500KPa, and use the gas phase pulverization method to refine the phosphate rock powder to a particle size of ≤10μm;

[0049] (2) Send the miniaturized phosphate rock powder obtained in step (1) into the pore-forming chamber, use the Nd:YAG laser drilling method, use the laser beam excited by diode pulses, and the laser power density is 800W / cm 2 , the drilling speed is 1000 holes / second, and the fine particles of phosphate rock powder are made into particles with a pore size of 18-25nm porous structure;

[0050] (3), 10 parts of mo...

Embodiment 3

[0052] A kind of water-soluble phosphate rock powder, its component is as follows, all by weight:

[0053] Fluorapatite powder: 92 parts,

[0054] Polyoxyethylene hexyl alcohol amide: 7 parts,

[0055] Sodium methylene bis-naphthalene sulfonate: 5 parts,

[0056] Its preparation method is as follows:

[0057] (1) Send 92 parts by weight of fluorapatite powder into the crushing chamber, and blow nitrogen gas (N 2 ), keep the indoor pressure at 400~500KPa, and use the gas phase pulverization method to refine the phosphate rock powder to a particle size of ≤10μm;

[0058] (2) Send the micronized phosphate rock powder obtained in step (1) into the pore-forming chamber, use the Nd:YAG laser drilling method, and use the laser beam excited by diode pulses, and the laser power density is 1000W / cm 2 , the drilling speed is 1100 holes / second, and the fine particles of phosphate rock powder are made into particles with a pore size of 18-25nm porous structure;

[0059] (3), 7 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com