Method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current

A technology of low-carbon aluminum-killed steel and low-pressure pulse, which is applied in the field of improving hot-delivery cracks in slabs, can solve problems such as high production costs, heat loss of slabs, and reduced production efficiency, and achieve environmental protection and safety of slab defects and improve high-temperature mechanical properties. Performance, effect of reducing slab defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

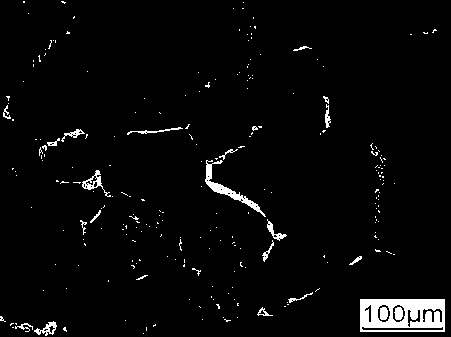

[0027]In order to compare and illustrate the significant effect of the present invention on improving the cracks of low-carbon aluminum-killed steel slabs during hot delivery, a comparative test without pulse current treatment was carried out. The material of this comparative example is 16Mn steel (its main chemical composition is: 0.102%C, 0.384%Si, 1.40%Mn, 0.019%P, 0.007%S, 0.031%Al, 0.0055%N), first use the intermediate frequency vacuum induction furnace Smelt and cast the slab with 16Mn composition, then cut the slab into small pieces, put the sample into a box-type resistance furnace, keep it at 1200°C for 1 hour, then lower the temperature at a rate of 6°C / min, when the temperature When the temperature dropped to 750°C, the sample was taken out and quenched in an aqueous solution with a NaCl concentration of 10%. Its microstructure is as figure 1 shown.

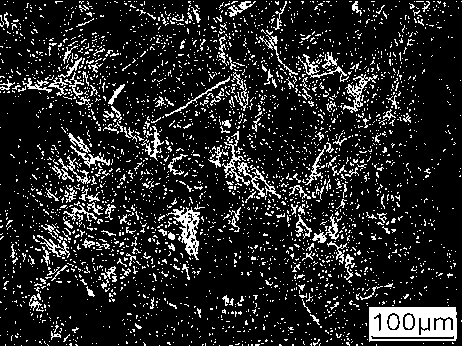

[0028] Depend on figure 1 and figure 2 It can be clearly seen that without pulse current treatment, white pro...

Embodiment 2

[0031] Example 3

Embodiment 3

[0033] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com