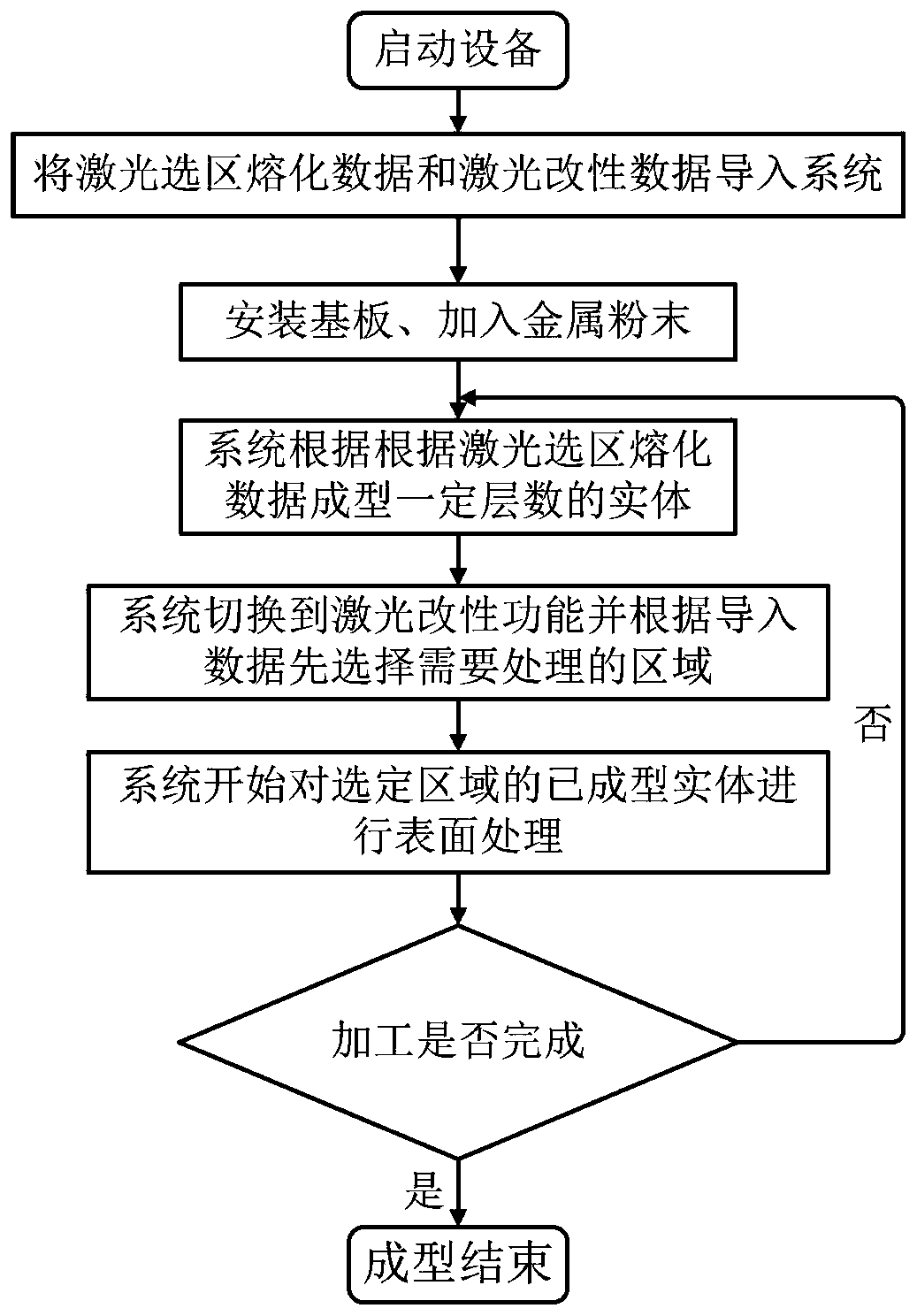

A method for interlayer laser-modified laser selective melting to form gradient materials

A laser selective melting and gradient material technology, applied in additive processing, process efficiency improvement, additive manufacturing, etc., can solve problems such as micro-cracks and voids, and achieve higher density, higher surface quality, and elimination of voids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

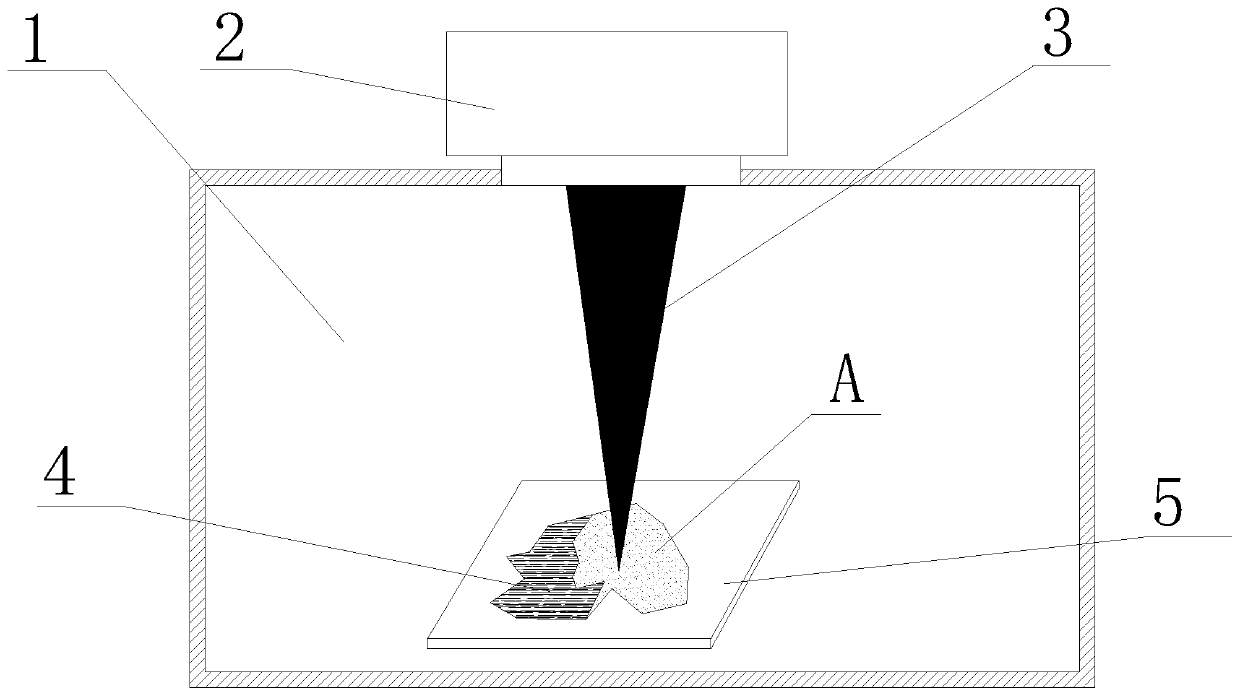

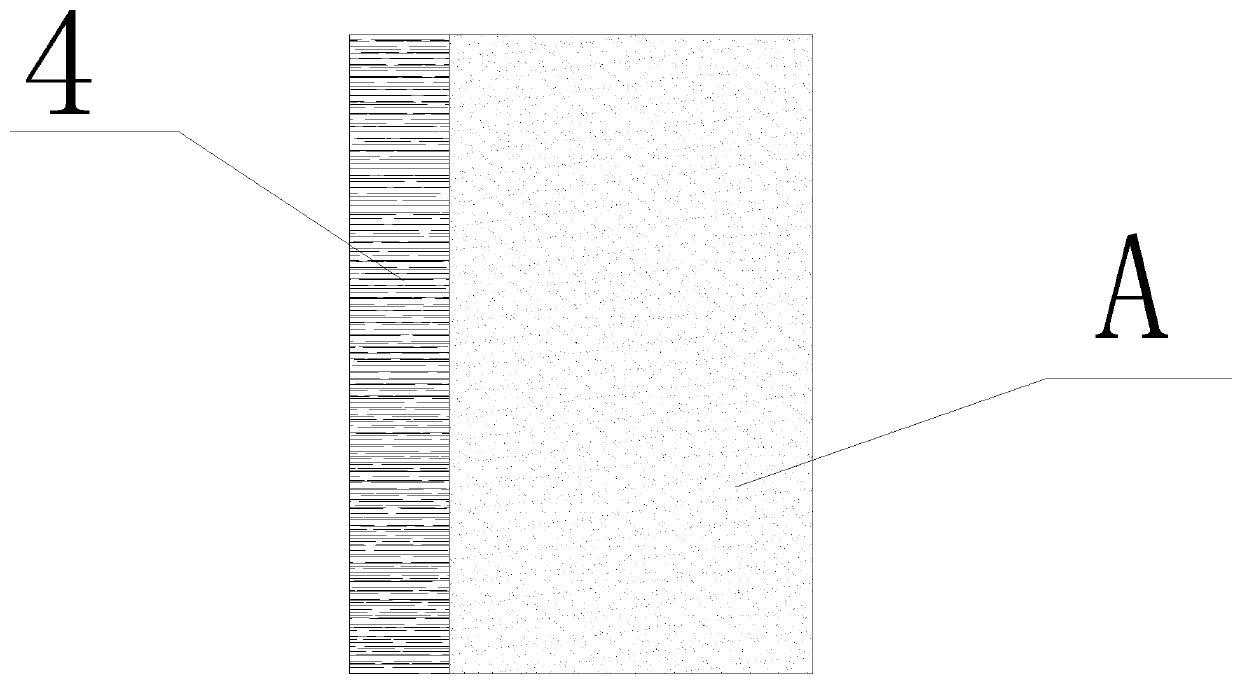

[0035] The typical feature of SLM technology is layered superposition manufacturing, with the thickness of each layer being 20-50 μm, which provides the possibility to change the properties of parts in the micron range. Combining the characteristics of laser surface modification technology to change the properties of surface materials and the characteristics of laser selective melting technology for micron-level layered superposition manufacturing, a new type of gradient material with different properties can be obtained by changing the process parameters of the two. With the development of science and technology, complex environments have higher and higher requirements for functional parts. In order to realize SLM printing of metal parts with special functions and special requirements, a device based on interlayer laser modification technology for laser selective melting to form gradient materials And methods will surely bring new innovations and breakthroughs. Laser modifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com