High-strength and ultra heat-resistant high entropy alloy (HEA) matrix composites and method of preparing the same

a technology of high entropy alloy and composite material, which is applied in the field of high-strength and ultra heat-resistant high entropy alloy (hea) matrix composite material and a method of preparing the same, can solve the problems of reduced powder yield, contamination by balls, and severe reduction of yield, so as to enhance mechanical properties and heat resistance of alloys, the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

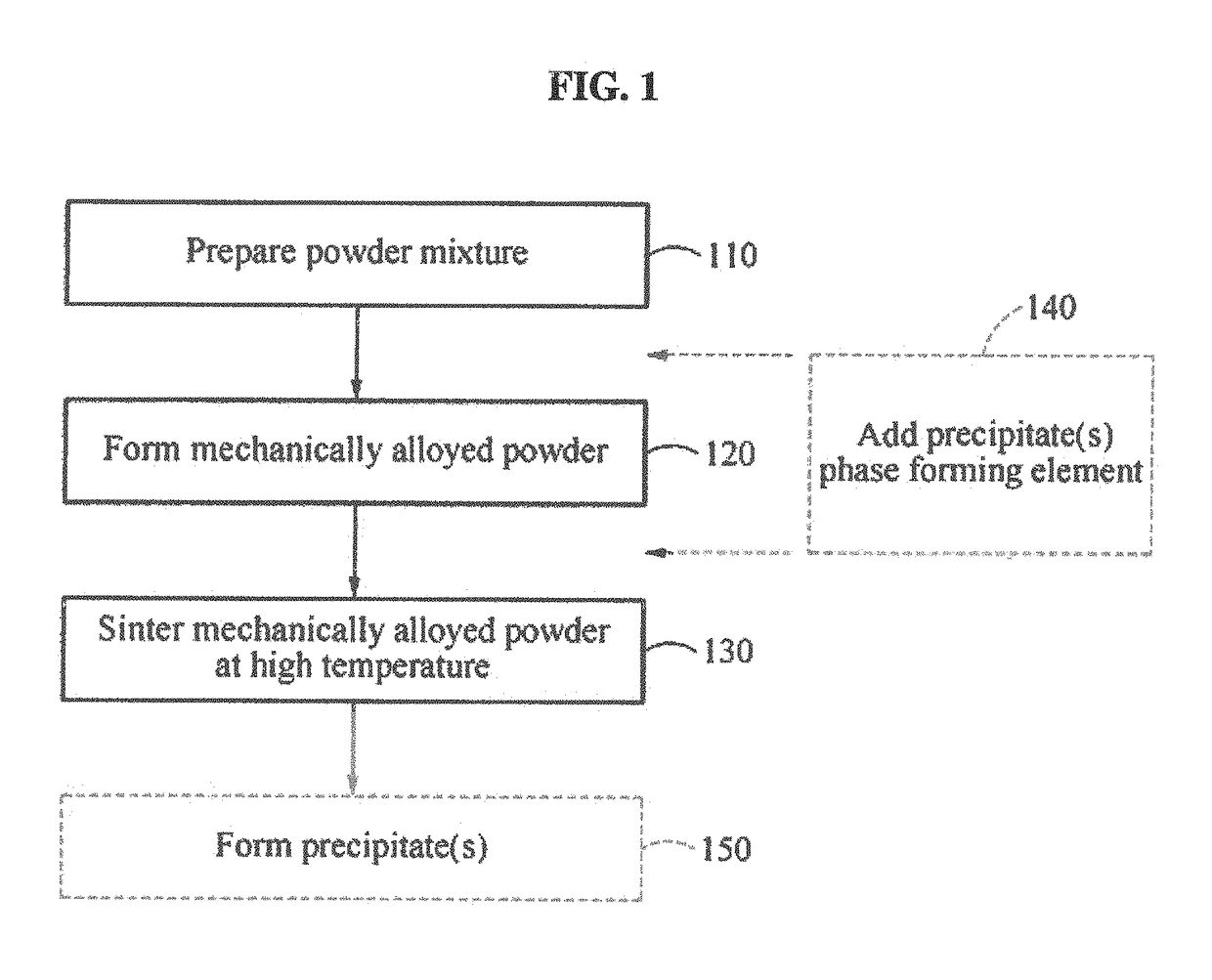

Method used

Image

Examples

example 1

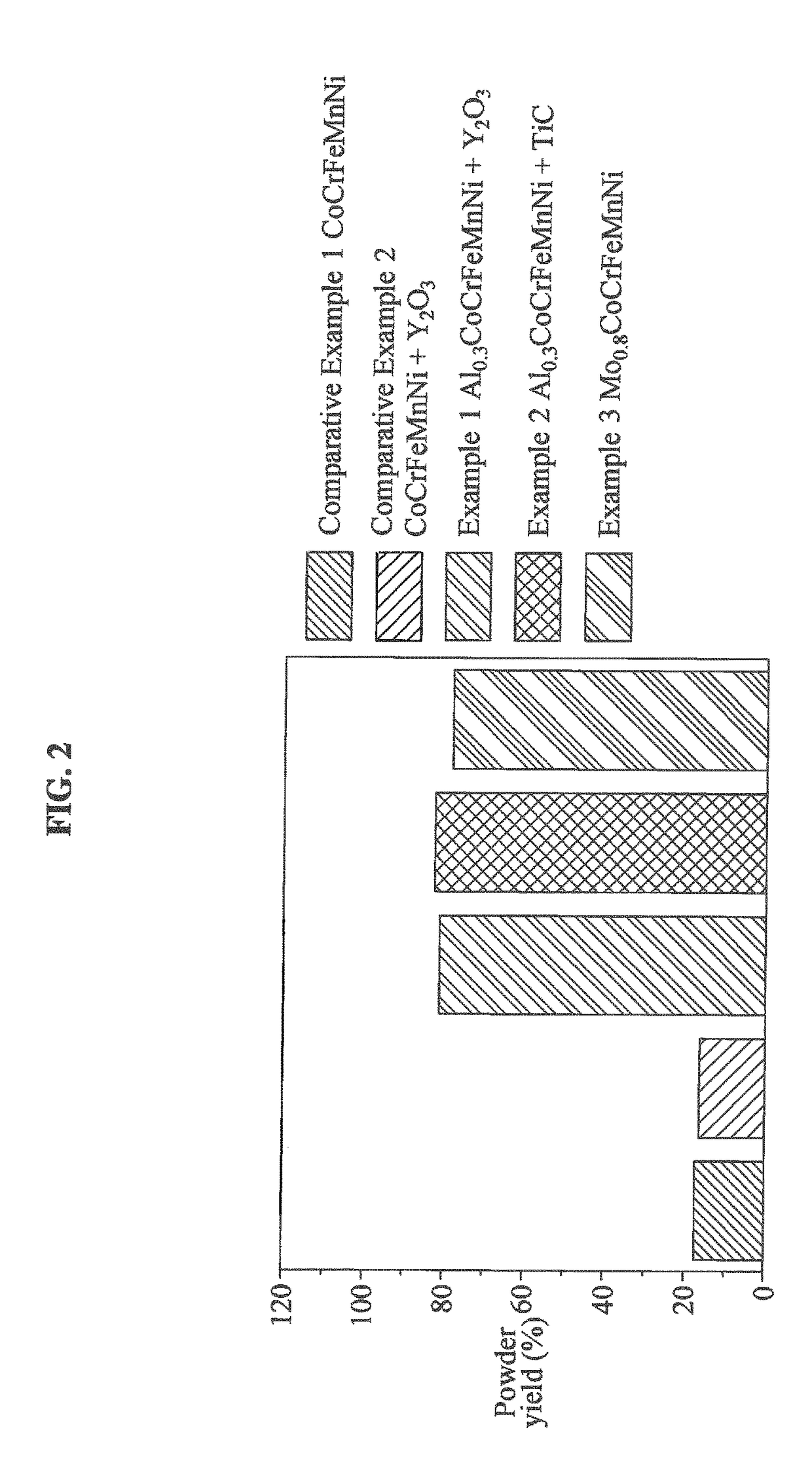

[0067]Mechanical alloying was performed using a planetary mill for 24 hours, to prepare an Al0.3CoCrFeMnNi HEA powder to which 3 vol % of Y2O3 was added. About 5.7 mol % of Al was added as a BCC forming alloy element. A yield of the prepared Al0.3CoCrFeMnNi HEA powder is shown in FIG. 2.

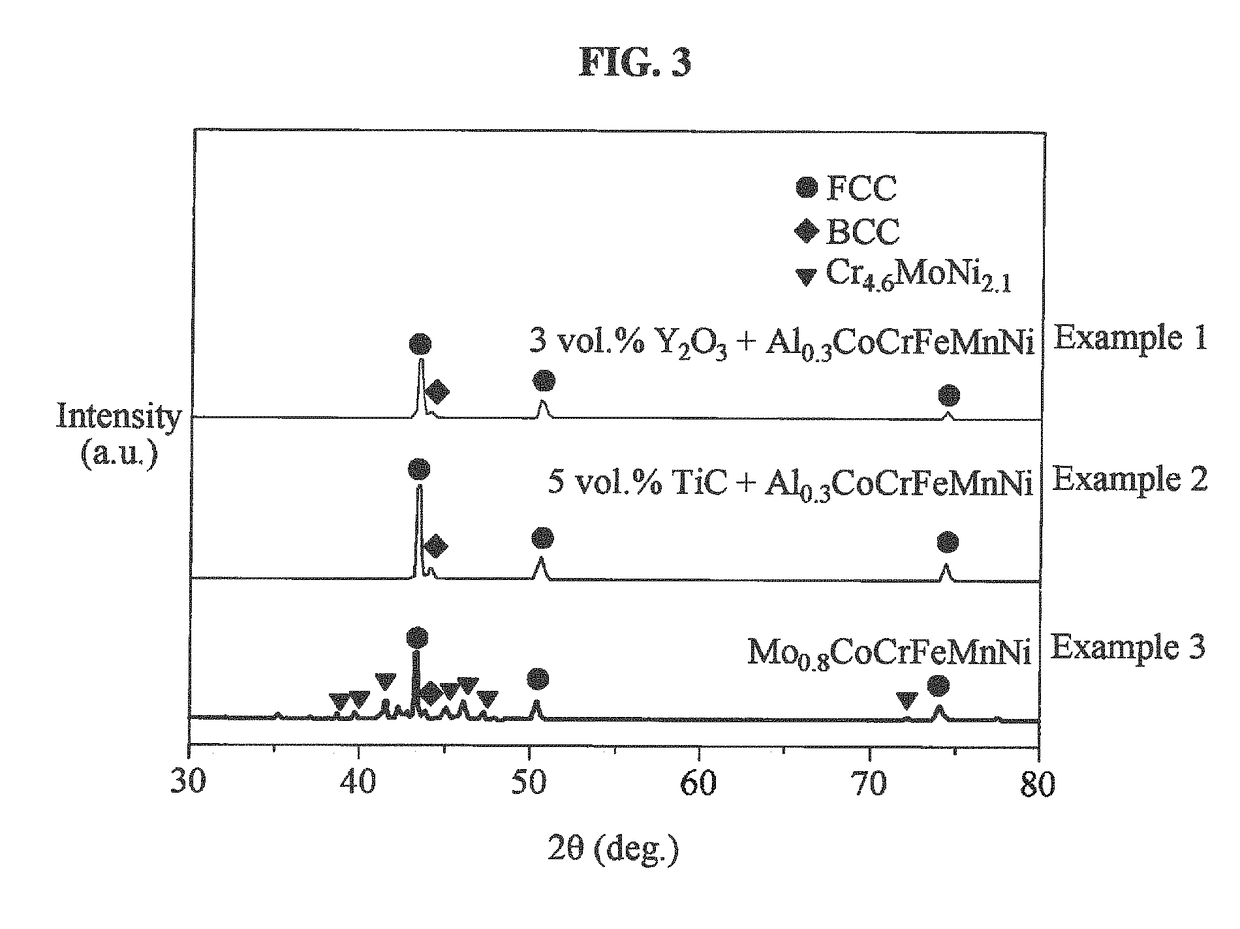

[0068]The prepared 3 vol % Y2O3 / Al0.3CrCrFeMnNi HEA powder was sintered at 900° C. for 5 minutes using a spark plasma sintering method, to prepare a sintered alloy. A phase and a microstructure of the sintered alloy were analyzed and a hardness and a compressive strength of the sintered alloy were measured as shown in FIGS. 3 to 6. The microstructure was obtained by a scanning electron microscope (SEM).

example 2

[0069]Mechanical alloying was performed using a planetary mill for 24 hours, to prepare an Al0.3CoCrFeMnNi HEA powder to which 5 vol % of TiC was added. About 5.7 mol % of Al was added as a BCC forming alloy element. A yield of the prepared Al0.3CoCrFeMnNi HEA powder is shown in FIG. 2.

[0070]The prepared 5 vol % TiC / Al0.3CoCrFeMnNi HEA powder was sintered at 900° C. for 5 minutes using a spark plasma sintering method, to prepare a sintered alloy. A phase and a microstructure of the sintered alloy were analyzed and a hardness of the sintered alloy was measured as shown in FIGS. 3 to 5.

example 3

[0071]Mechanical alloying was performed using a planetary mill for 24 hours, to prepare a Mo0.8CoCrFeMnNi HEA powder. About 13.8 mol % of Mo was added as a BCC forming alloy element. A yield of the prepared Mo0.8CoCrFeMnNi HEA powder is shown in FIG. 2.

[0072]The prepared Mo0.8CoCrFeMnNi HEA powder was sintered at 900° C. for 5 minutes using a spark plasma sintering method, to prepare a sintered alloy. A phase and a microstructure of the sintered alloy were analyzed and a hardness of the sintered alloy was measured as shown in FIGS. 3 to 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com