Superhard composite material and method for preparation thereof

A composite material and superhard technology, which is applied in the field of combined metal composition, can solve problems such as performance limitations and poor variability in composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

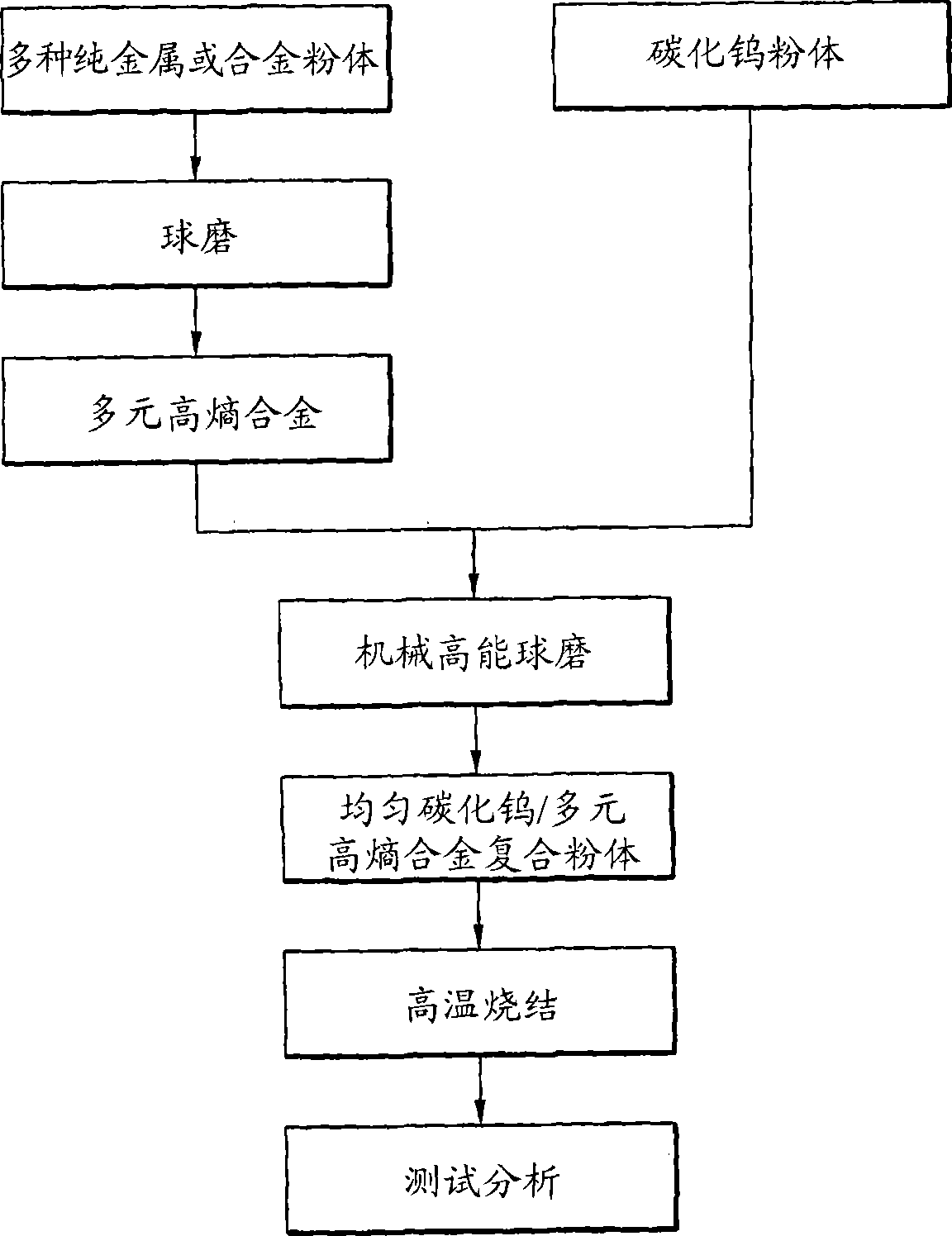

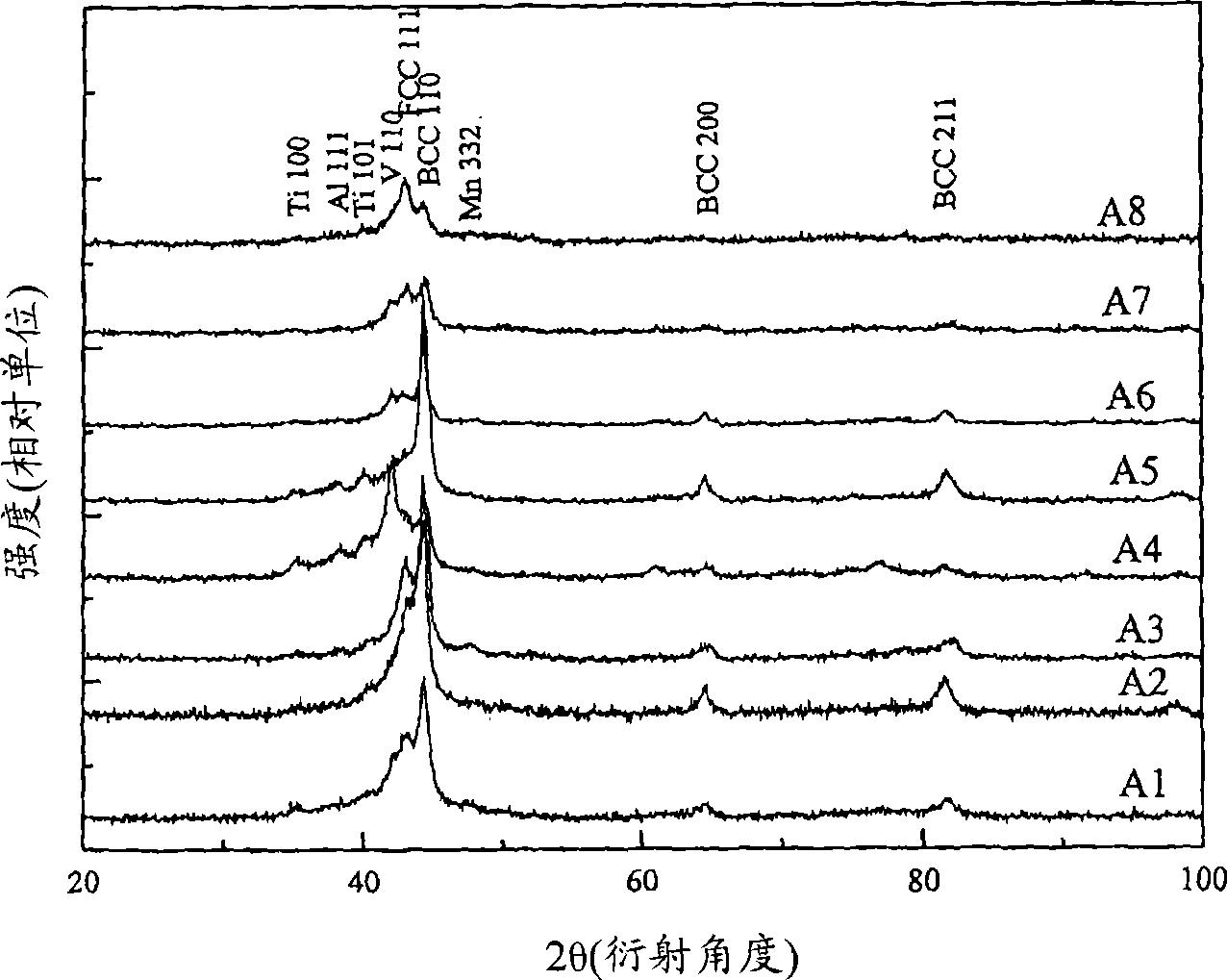

[0023] The experimental process of this embodiment is as follows figure 1 As shown, a variety of pure metal or alloy powders are mechanically milled to form multi-element high-entropy alloy powders. Then, the multi-element high-entropy alloy and tungsten carbide powder are mixed and ball-milled in different proportions to make it a uniformly mixed composite material powder. Then the uniform tungsten carbide-multivariate high-entropy alloy mixed powder is pressed and sintered at high temperature to make a superhard composite material sintered body, and finally the sintered body is tested and analyzed. In this embodiment, seven kinds of pure metal powders of aluminum, chromium, copper, iron, manganese, titanium and vanadium are used to produce multi-element high-entropy alloy powder. Using the Taguchi method L 8 2 7 Orthogonal tables are used to prepare A series alloys, as listed in Table 1.

[0024] Table I

[0025]

[0026] Note: The difference in the second decimal pl...

Embodiment 2

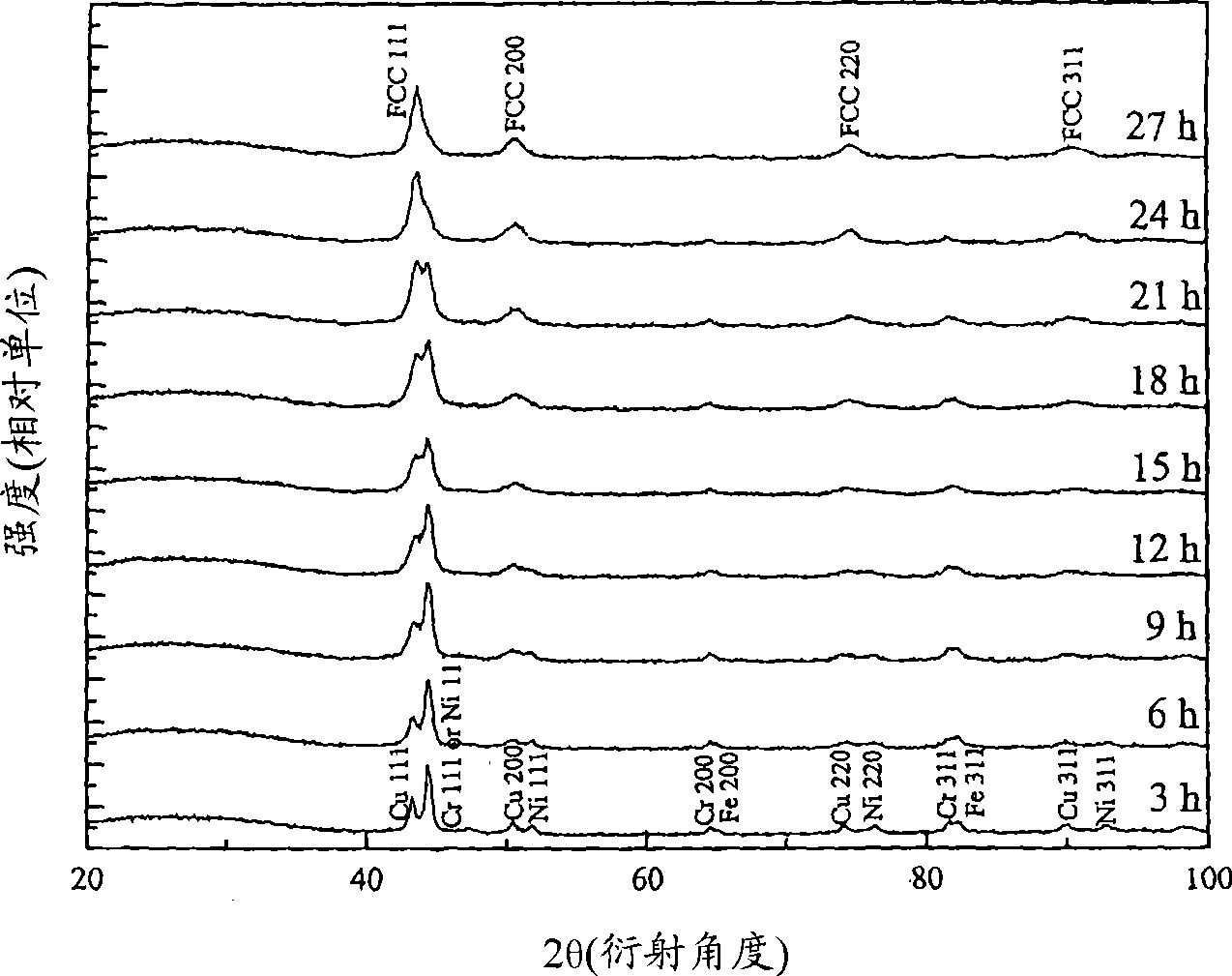

[0031] The experimental process of this embodiment is also the same figure 1 As shown, six metal element powders of aluminum, chromium, cobalt, copper, iron, and nickel were mixed and ball-milled into multi-element high-entropy alloy powder, and the configuration ratio was the B series alloy shown in Table 3. Taking B2 powder as an example, the relationship between different ball milling times and the crystal structure of multivariate high-entropy alloys is as follows: image 3 As shown in the X-ray diffraction analysis, it is shown that ball milling for more than 24 hours can obtain complete alloying and form a single FCC phase solid solution.

[0032] Table three

[0033]

[0034] Table 4 is an example of the code of its powder configuration. The X-ray diffraction analysis of the mixed powder after the three alloys in this table are mixed with WC powder and ball milled is as follows: Figure 4 As shown, it can be seen that there is only a mixed phase structure of WC pha...

Embodiment 3

[0045] The experimental process of this embodiment is also the same figure 1 As shown, carbon, chromium, nickel, titanium, and vanadium element powders are ball-milled to form a multi-component high-entropy alloy, and its configuration ratio is the C1 alloy shown in Table 7; Figure 6 It is the X-ray diffraction analysis of the high-entropy alloy C1 powder, which shows that the powder after ball milling is completely alloyed and forms a single BCC solid solution phase.

[0046] Table seven

[0047]

[0048] Table 8 shows the densities and room temperature hardness of sintered bodies of C1 alloy powders and WC powders in different proportions at different sintering temperatures. For example, the hardness of tungsten carbide-20% C1 alloy sintered body can reach Hv 1825. The room temperature hardness of the tungsten carbide-15% C1 alloy sintered body is as high as Hv 1972. The difference in hardness range also shows that it can be controlled by adjusting the ratio to provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com