Plasma spraying method used for preparing titanium-silicon-carbon composite coating layer

A plasma and carbon composite technology, applied in coating, metal material coating process, melting spray plating, etc., to achieve the effect of fine grain, good wear resistance, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

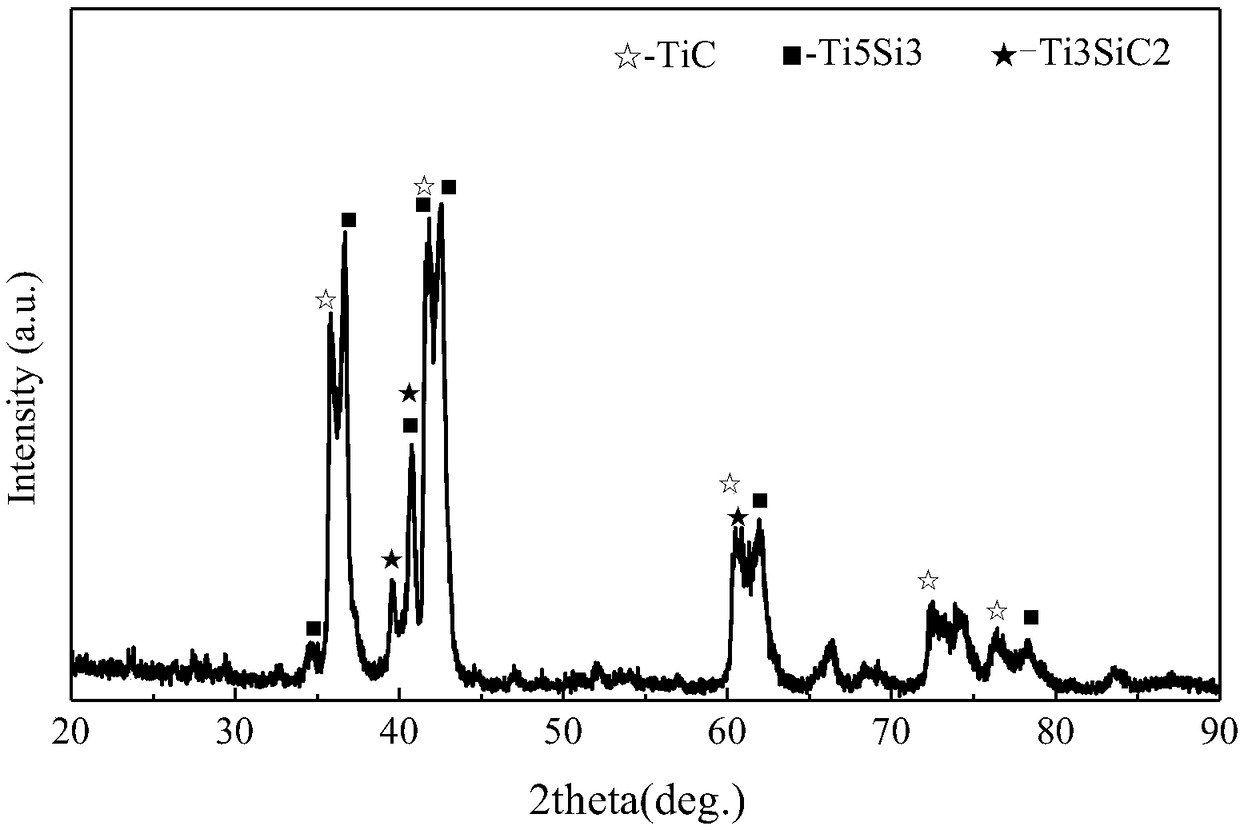

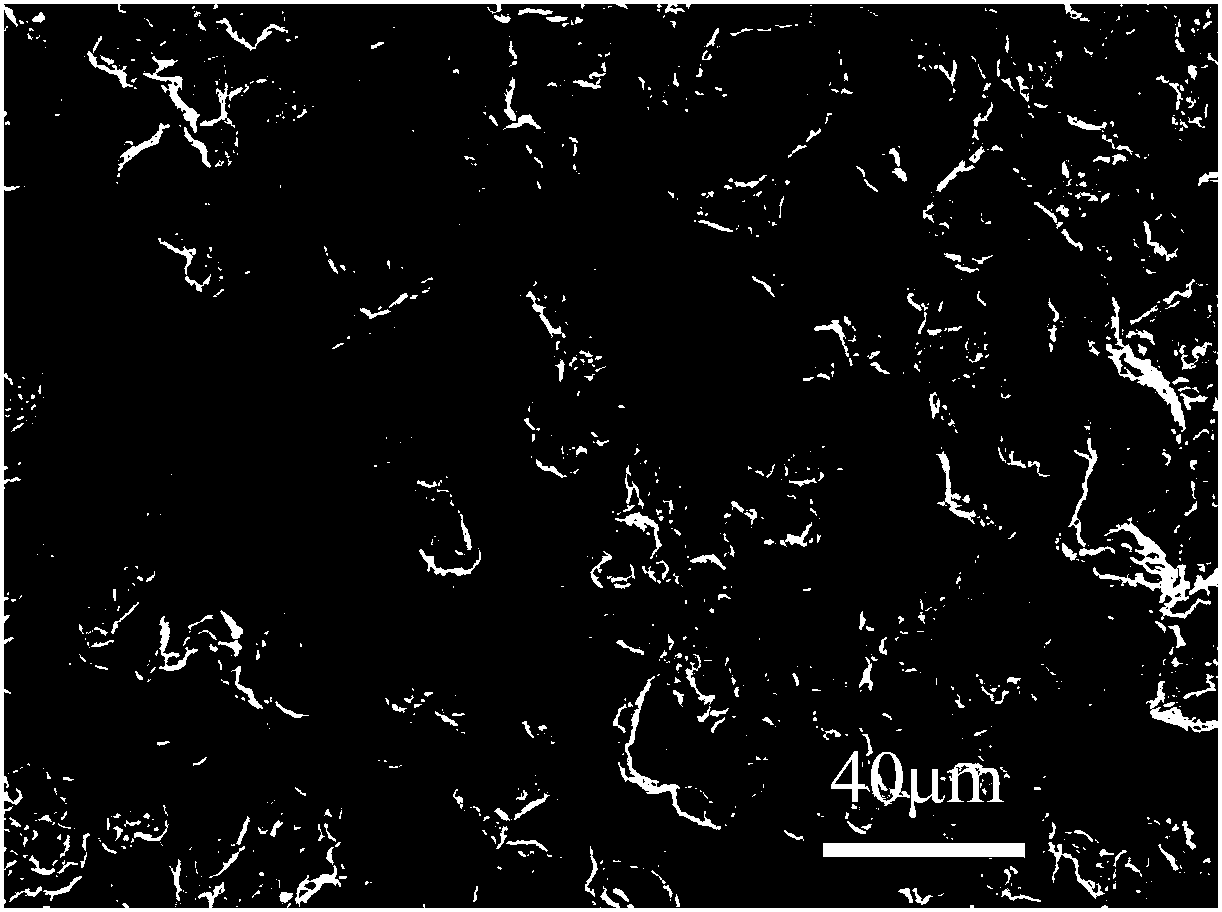

[0032] In this embodiment, a method for preparing a Ti-Si-C cermet composite coating by reactive plasma spraying based on agglomerated powder modification comprises the following steps:

[0033] Step 1, according to Ti powder 73.5wt%, silicon powder 14.3wt%, graphite powder 12.2wt% take raw material respectively, and purity is 99.9%; Wherein, the particle size of Ti powder is 325 mesh~500 mesh, and the particle size of Si powder is 2000-4000 mesh, the particle size of graphite powder is 8000-15000 mesh.

[0034] Step 2. Add deionized water and gel to the raw material powder (the gel is mixed according to the mass ratio of water: sodium carboxycellulose = 100:1. The composition of the gel is the same in the following examples), and then add the total raw material powder 1% of the mass of PVP is used as a dispersant, mixed, and mechanically stirred for 3 hours to obtain a slurry; wherein, the mass ratio of original powder, deionized water, gel = 2:2:1;

[0035] Step 3. Spray dr...

Embodiment 2

[0047] In this embodiment, a method for preparing a Ti-Si-C cermet composite coating by reactive plasma spraying based on agglomerated powder modification comprises the following steps:

[0048] Step 1, according to Ti powder 64.5wt%, silicon powder 25wt%, graphite powder 10.5wt% take raw material respectively;

[0049] Step 2. In addition, according to the total mass of raw powder, the mass of deionized water, and the gel mass ratio of 2:2:1, add 1% of the total mass of raw powder PVP as a dispersant, mix, and mechanically stir for 3 hours to obtain a slurry;

[0050] Step 3. Spray drying: Spray the mixed slurry into the drying chamber for atomization, and quickly dry to form agglomerated particles. The inlet temperature of the spray dryer is 260°C, and the outlet temperature is 110°C;

[0051] Step 4. Use a sieve to select the agglomerated particles with a size of 100 mesh to 300 as spray feed;

[0052] Step 5. Polish the 45# steel substrate with sandpaper, and then perform...

Embodiment 3

[0062] In this embodiment, a method for preparing a Ti-Si-C cermet composite coating by reactive plasma spraying based on agglomerated powder modification comprises the following steps:

[0063] Step 1, taking raw materials respectively according to Ti powder 57wt%, silicon powder 30wt%, graphite powder 13wt%;

[0064] Step 2. In addition, according to the total mass of raw powder, the mass of deionized water, and the gel mass ratio of 2:2:1, add 1% of the total mass of raw powder PVP as a dispersant, mix, and mechanically stir for 3 hours to obtain a slurry;

[0065] Step 3. Spray drying: Spray the mixed slurry into the drying chamber for atomization, and quickly dry to form agglomerated particles. The inlet temperature of the spray dryer is 260°C, and the outlet temperature is 110°C;

[0066] Step 4. Use a sieve to select the agglomerated particles with a size of 100 mesh to 300 as spray feed;

[0067] Step 5. Polish the 45# steel substrate with sandpaper, and then perform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com