High-strength and high-toughness molybdenum alloy and preparation method thereof

A high-toughness molybdenum and high-strength technology, applied in the field of powder metallurgy, can solve the problems of low-temperature brittleness and high-temperature oxidation resistance, and limit the use of molybdenum alloys, and achieve the effects of easy control, reasonable design and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh La 2 o 3 10g, ZrH 2 11g, TiH 2 5.4g, carbon powder 0.6g, Si powder 5g, B powder 10g, molybdenum powder 1kg;

[0024] TiH 2 , ZrH 2 , C, Si, and B powders were mixed in a three-dimensional mixer for 2 hours, and then added La 2 o 3 Powder, milled for 6 hours with a planetary ball mill, the ball-to-material ratio is 1:10, and the rotating speed is 220r / min;

[0025] (2) The alloy powder after ball milling is subjected to isostatic pressing with a pressure of 5.0t / cm 2 , the holding time is 30s, pressed into a billet;

[0026] (3) The blank was sintered at 1900° C., the atmosphere was vacuum, and segmented sintering was adopted. The sintering time was 17 hours and cooled with the furnace to obtain a high-strength and high-toughness sintered molybdenum alloy material.

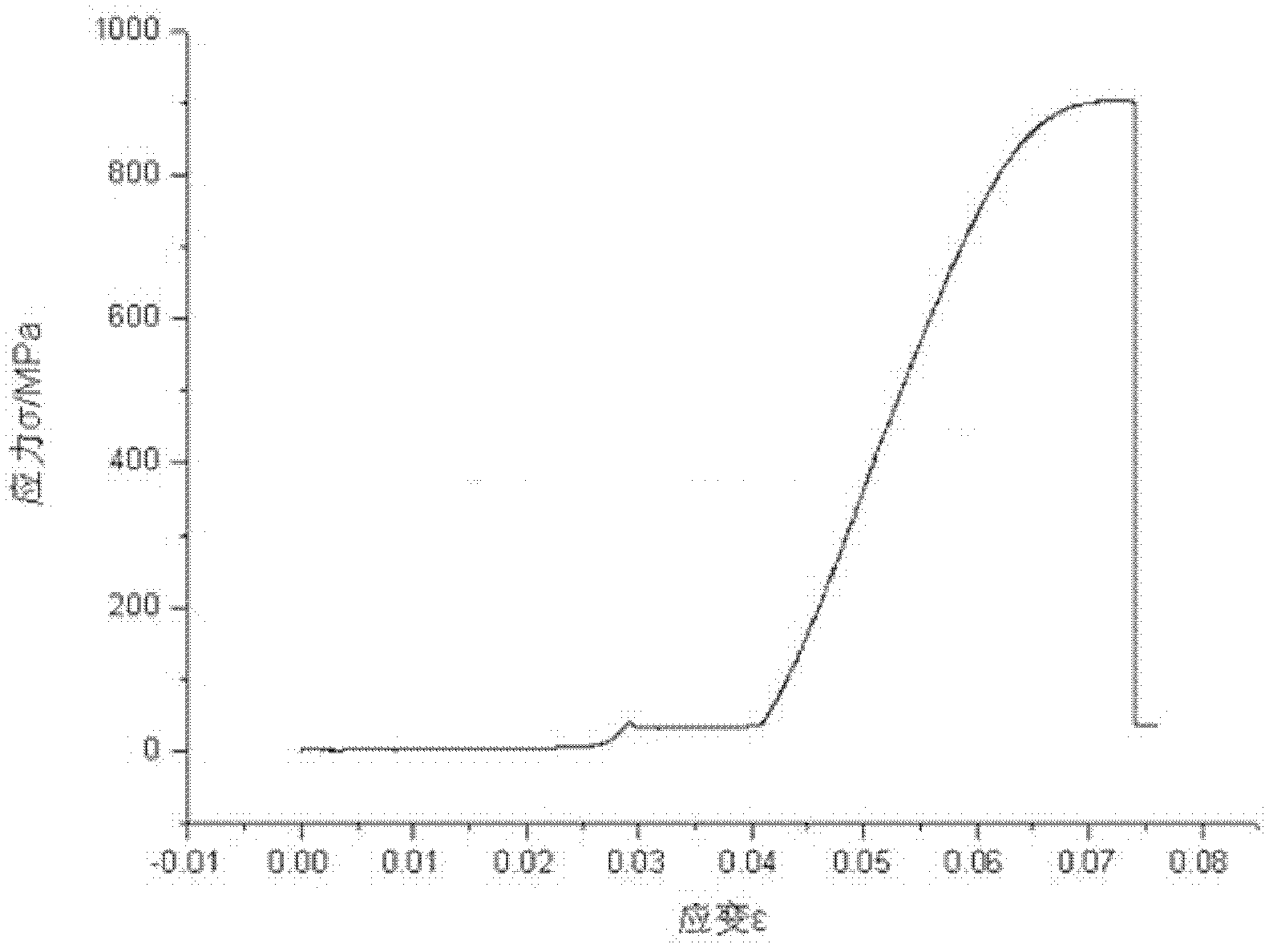

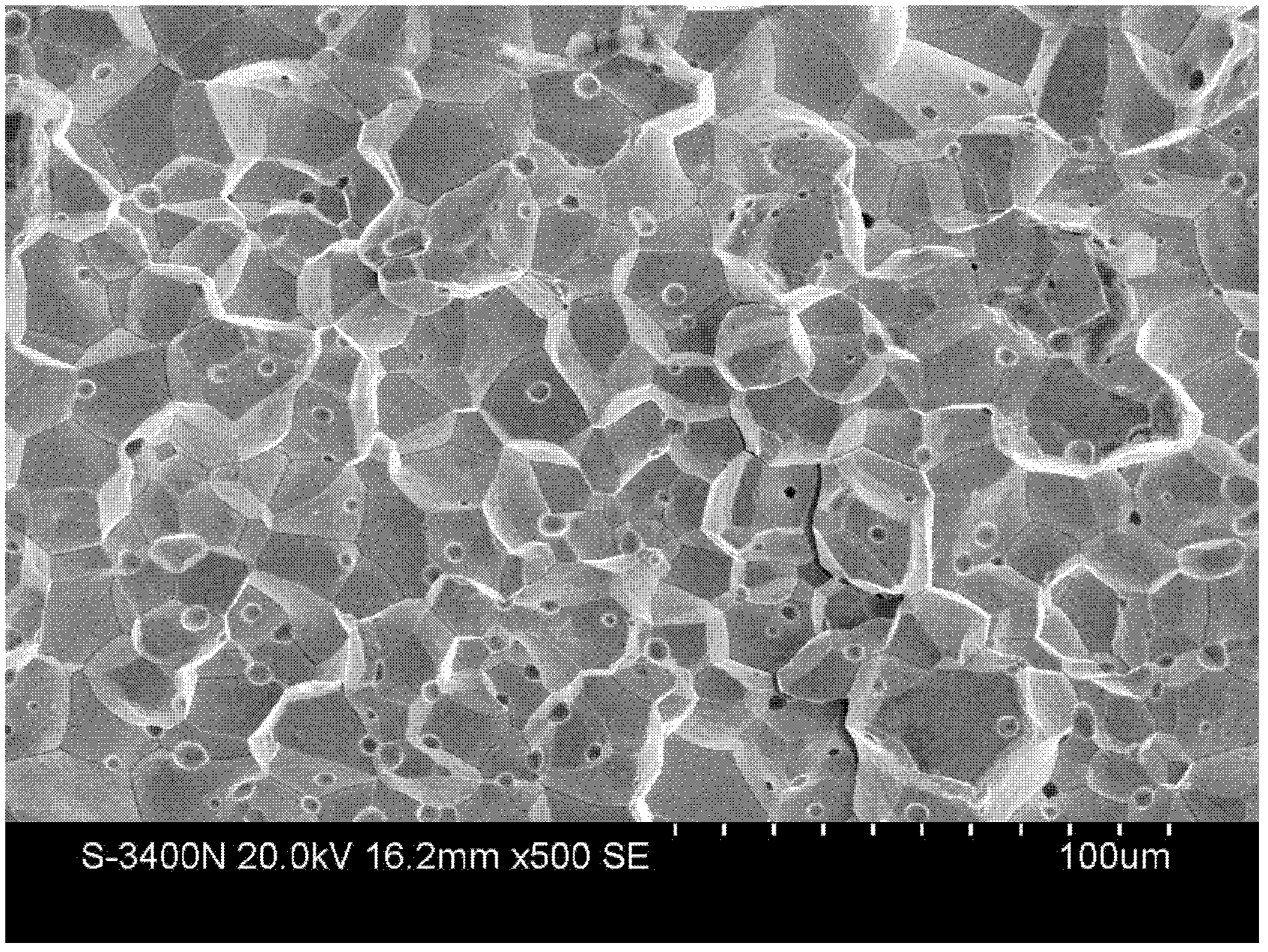

[0027] The high-strength and high-toughness molybdenum alloy stress-strain curve figure and scanning electron microscope photo prepared by the present embodiment are as follows respecti...

Embodiment 2

[0029] (1) Weigh La 2 o 3 8g, ZrH 2 10g,TiH 2 6g, C powder 0.8g, Si powder 4g, B powder 7g, molybdenum powder 1kg;

[0030] TiH 2 , ZrH 2 , C, Si, B powder and molybdenum powder were mixed in a three-dimensional mixer for 3 hours, and then added La 2 o 3 Powder and 100mL alcohol, after stirring evenly, dry at 200°C for 8 hours;

[0031] (2) Ball milling with a planetary ball mill for 8 hours, the ball-to-material ratio is 1:10, and the rotating speed is 220r / min;

[0032] (3) The alloy powder is pressed into shape by cold isostatic pressing, and the pressure is 4.0t / cm 2 , the holding time is 1min, and pressed into a billet;

[0033] (4) The blank was sintered at 2100° C., the atmosphere was hydrogen, and sintered in sections for 20 hours, and cooled with the furnace to obtain a high-strength and high-toughness sintered molybdenum alloy material.

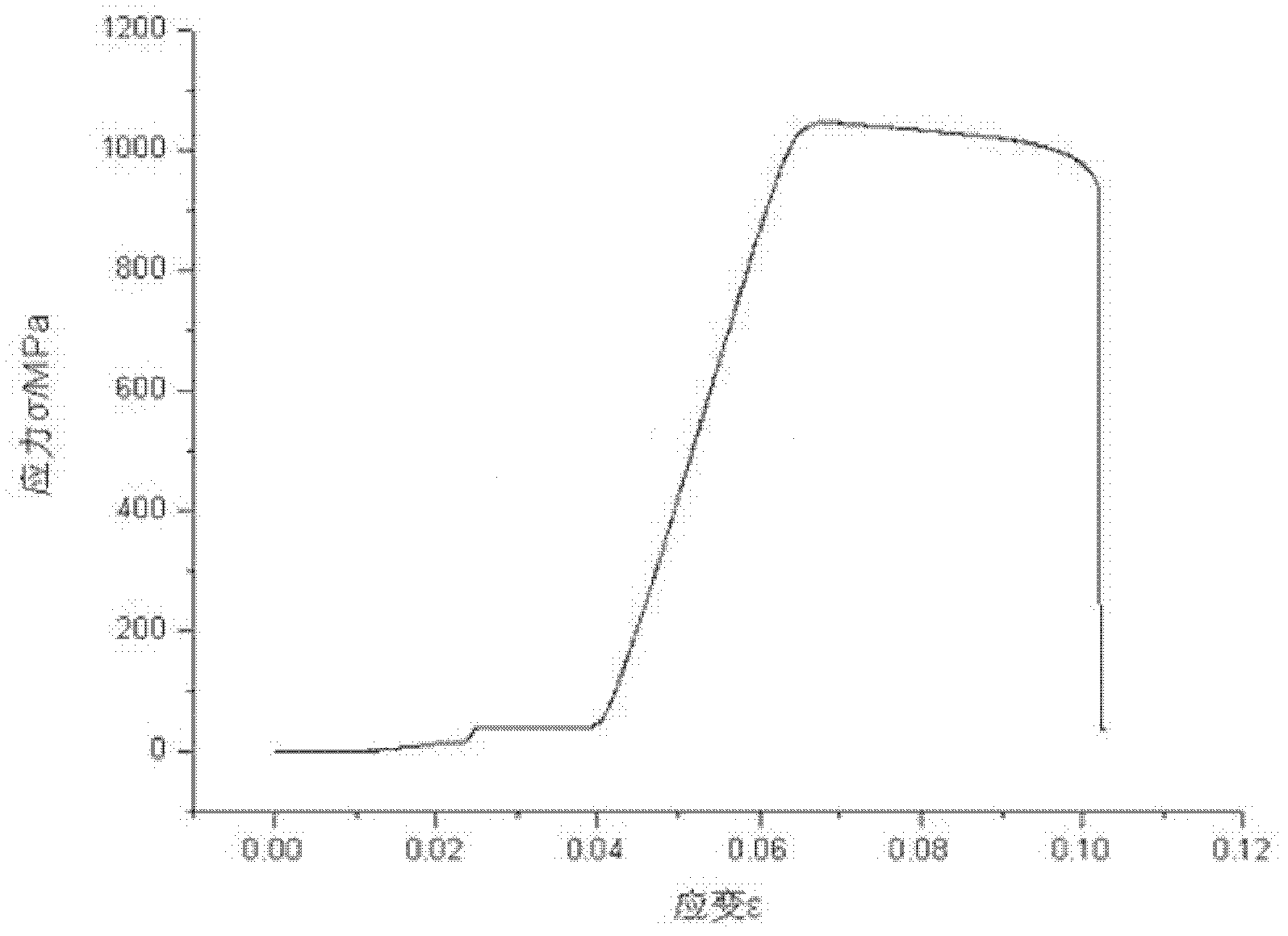

[0034] The high-strength and high-toughness sintered molybdenum alloy material obtained above is further rolled, the ...

Embodiment 3

[0036] (1) Weigh La 2 o 3 9g, ZrH 2 12g, TiH 2 5g, C powder 0.5g, Si powder 6g, B powder 8g, molybdenum powder 1kg;

[0037] TiH 2 , ZrH 2 , C, Si, B powder and molybdenum powder are mixed, mixed in a three-dimensional mixer for 10 hours, and then mixed with La 2 o 3 Powder and 100mL alcohol, stir evenly, and then dry at 150°C for 8 hours;

[0038] (2) ball milling with a high-energy ball mill for 2 hours, the ball-to-material ratio is 1:10, and the rotating speed is 500r / min;

[0039] (3) The alloy powder is molded with a pressure of 3.0t / cm 2 , the holding time is 2min, pressed into a billet;

[0040] (4) The blank was sintered at 2400° C., the atmosphere was inert gas, and segmented sintering was adopted for 10 hours, and then cooled with the furnace to obtain a high-strength and high-toughness sintered molybdenum alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com