Austenitic heat-resistant stainless steel and processing method thereof

A technology of heat-resistant stainless steel and processing method, which is applied in the field of austenitic stainless steel and can solve the problems of high nickel content and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

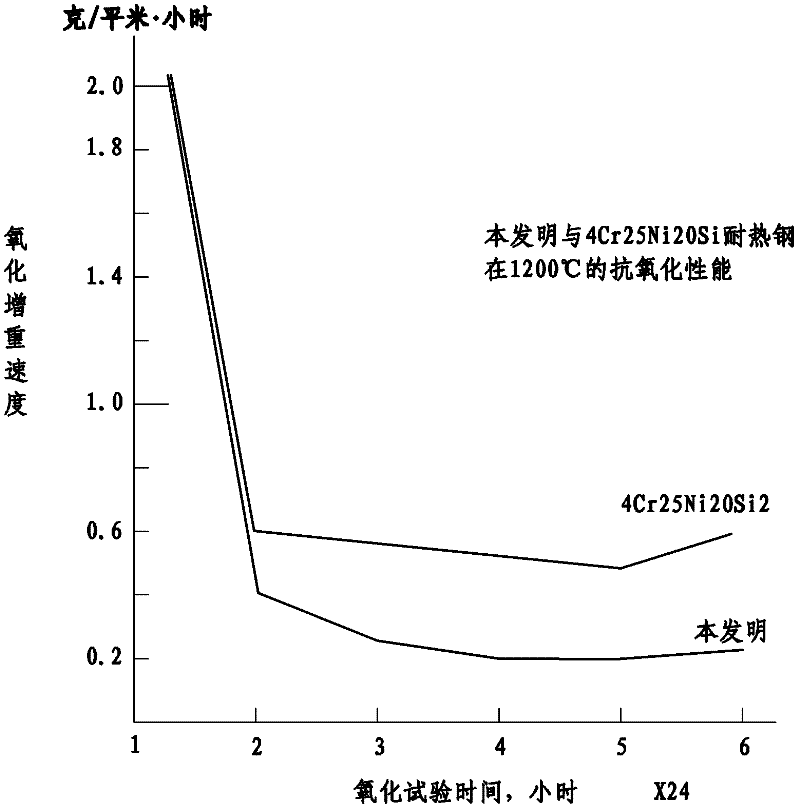

[0020] The invention is an austenitic heat-resistant stainless steel, including carbon, silicon, manganese, chromium, nickel, nitrogen and rare earth elements, and the components are: carbon: 0.25-0.45%, silicon: 0.5-2% by mass percentage , manganese: 0.5-2%, chromium: 23-27%, nickel: 6-10%, nitrogen: 0.15-0.3%, rare earth elements: 0.1-0.5%, and the balance is iron.

[0021] Three heats of steel were cast in an intermediate frequency induction furnace, and their chemical compositions are shown in Table 1:

[0022] Table 1 enumerates the proportioning of three groups of different qualities within the scope of the present invention

[0023] C Cr Ni Si mn N RE Fe NO.1 0.33 26.20 8.62 1.50 1.23 0.21 0.42 margin NO.2 0.38 25.98. 8.40 1.43 1.30 0.17 0.44 margin NO.3 0.35 26.13 8.51 1.61 1.28 0.19 0.40 margin

[0024] After the furnace steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com