Thermal treatment process capable of reducing microsegregation of directionally-solidified high-niobium TiAl alloy

A titanium-aluminum alloy, directional solidification technology, applied in the field of high-performance alloy material preparation, can solve the problems affecting the comprehensive mechanical properties of directional solidified TiAl alloy, equipment requirements and energy consumption, recrystallization and grain growth, etc., to achieve improvement The effect of room temperature brittleness, improving mechanical properties and eliminating β segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

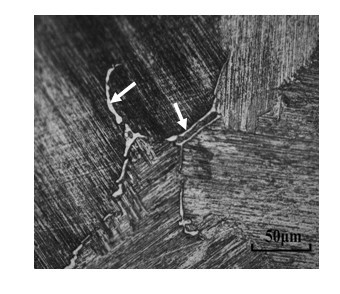

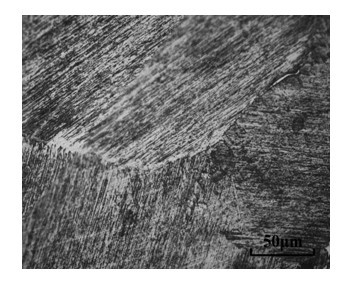

[0034] The high-niobium titanium-aluminum alloy button ingot with the composition of Ti-44Al-6Nb-(0~2)(W, Mn)-(0~0.5)(B, Y) was smelted by arc melting method, and the button ingot was melted by suction casting method. Cast into a cylindrical test rod of Ф4×L50mm. Put the test rod into the alumina tube coated with yttrium oxide, and pull it by Bridgeman method at the holding temperature of 1650oC and the pulling rate of 5 μm / s to obtain the directionally solidified high niobium titanium aluminum alloy sample. Cut out the middle section of the directional solidification sample, put it into an alumina crucible coated with a protective layer of yttrium oxide, place it in an electric furnace, evacuate to 0.01Pa, then pass in argon gas to 600Pa, and the heating rate is 10oC / min, Raise the temperature to 1250oC and keep it warm for 24h. Set the temperature of the electric furnace to 910oC, and cool the sample with the furnace. After the temperature drops to 910oC, keep it warm for 3...

Embodiment 2

[0036] The high-niobium titanium-aluminum alloy button ingot with the composition of Ti-45Al-7Nb-(0~2)(W, Mn)-(0~0.5)(B, Y) was smelted by suspension melting method, and the button ingot was melted by suction casting method. Cast into a cylindrical test rod of Ф7×L80mm. Put the test rod into the alumina tube coated with yttrium oxide, and pull it by Bridgeman method at the holding temperature of 1680oC and the pulling rate of 20μm / s to obtain the directionally solidified high niobium titanium aluminum alloy sample. Cut out the middle section of the directional solidification sample, put it into an alumina crucible coated with a protective layer of yttrium oxide, place it in an electric furnace, evacuate to 0.02 Pa, and then pass in argon gas to 620Pa, with a heating rate of 11oC / min. Raise the temperature to 1270oC, keep it warm for 12 hours, set the temperature of the electric furnace to 900oC, cool the sample with the furnace, keep it warm for 32min after the temperature dro...

Embodiment 3

[0038] The button ingot of high niobium titanium aluminum alloy with the composition of Ti-46Al-9Nb-(0~2)(W, Mn)-(0~0.5)(B, Y) was smelted by arc melting method, and the button was made by suction casting method. The ingot is cast into a cylindrical test bar of Ф10×L100mm. Put the test rod into the alumina tube coated with yttrium oxide, and pull it by Bridgeman method at the holding temperature of 1700oC and the pulling rate of 100μm / s to obtain the directionally solidified high niobium titanium aluminum alloy sample. Cut out the middle section of the directional solidification sample, put it into an alumina crucible coated with a protective layer of yttrium oxide, place it in an electric furnace, evacuate to 0.03Pa, and then pass in argon gas to 650Pa, with a heating rate of 12oC / min. Raise the temperature to 1290oC, keep it warm for 6 hours, set the temperature of the electric furnace to 890oC, cool the sample with the furnace, keep it warm for 35min after the temperature d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com