Transparent conductive layer, target for transparent conductive layer and a process for producing the target for transparent conductive layer

A technology of a transparent conductive film and a manufacturing method, which is applied to the conductive layers, oxide conductors, non-metallic conductors and other directions on an insulating carrier, can solve problems such as the influence of component characteristics, and achieve stable resistivity, improved conductivity, and low resistance characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

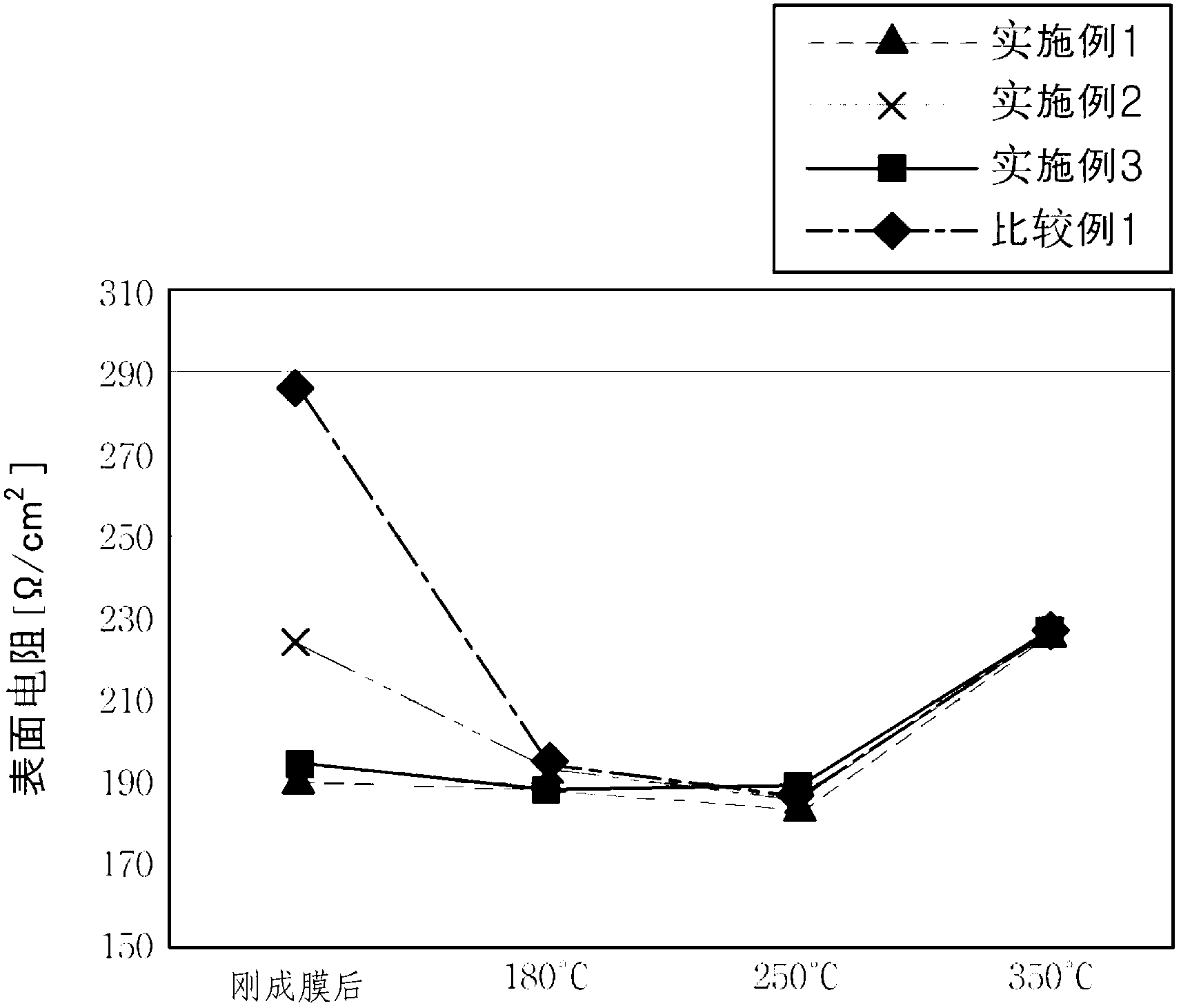

Embodiment 1 to Embodiment 3 and comparative example 1

[0076] Example 1 to Example 3 and Comparative Example 1: Manufacture of sputtering target

Embodiment 1

[0078] Indium nitride (In(NO 3 ) 3 ·6H 2 O) 1730g and green tin (SnCl 4 ·3H 2 After O) 36.5 g was dissolved in 60 ml of ethanol, ultrapure water was added as a pH adjuster and stirred at 50° C. for 12 hours to obtain a solution of pH 3.

[0079] Next, to the above solution was added NH 4 OH aqueous solution to bring the pH to 9. Thereafter, the reaction was carried out at 40° C. for 20 hours to produce a precipitate. After the above-mentioned precipitate was separated, it was washed three times with ultrapure water, and then dried with hot air at 120° C. to obtain a powder. Afterwards, the above powder was put into an electric furnace and heat-treated (calcined) at a temperature of 750° C. for 2 hours to obtain ITO.

[0080] In addition, the average particle diameter and specific surface area of the above-mentioned ITO are shown in Table 1 below.

[0081] 【Table 1】

[0082]

[0083] Next, 2 g of tantalum oxide and 0.07 g of polyvinyl alcohol were added to 998 g of ...

Embodiment 2

[0090] A sputtering target was prepared in the same manner as in Example 1 except that 5 g of tantalum oxide was added to the above-mentioned ITO995 g. The ICP component inspection results of the above-mentioned sputtering targets showed a weight ratio of Ta:In:Sn=4.902:92.37:2.728. In addition, the density and surface resistivity of the said sputtering target are shown in Table 3 below.

[0091] 【table 3】

[0092]

[0093] Next, the above-mentioned sputtering target was installed in the RF magnetron sputtering machine and the initial vacuum degree in the chamber was adjusted to 1×10 -6 Torr below. Thereafter, an In—Sn—Ta—O-based thin film was deposited on the above-mentioned glass substrate at atmospheric temperature to a thickness of 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com