Method for producing high purity organic amine tantalum compound

A technology of tantalum compounds and production methods, which is applied in the field of high-purity organic amine tantalum compounds, can solve the problems of low concentration, poor operating conditions, and high requirements for equipment materials, and achieve the effects of simple equipment, friendly production environment, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

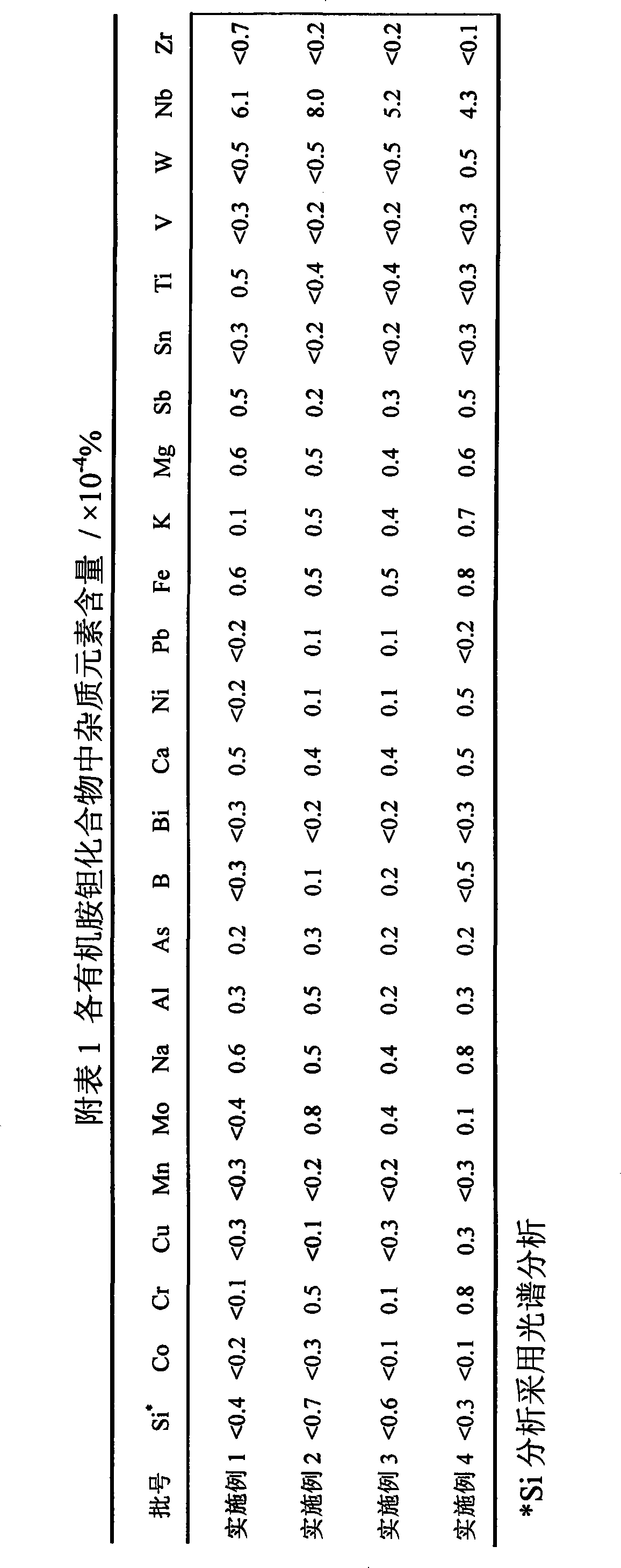

Embodiment 1

[0023]Get 12L of diethylamine, add 0.04mol / L conductive agent (CH 3 ) 4 NCl is the electrolyte, the tantalum plate is the anode, the area is 44cm×34cm, the stainless steel is the cathode, the area is 44cm×34cm, the distance between the cathode and the anode is 2cm; the constant current density is 140A / m 2 , the starting temperature is normal temperature, slowly and automatically heat up to boiling, the tank voltage is 20-35V, the volatilized diethylamine is returned to the electrolysis by cooling and reflux, and the diethylamine is continuously added to maintain the solution volume, and the electrolysis is continued for 4 days (96h) . The mixed solution of diethylamine tantalum-diethylamine obtained by electrolysis, first slowly raise the temperature under normal pressure, distill to above the boiling point of diethylamine, make diethylamine volatilize from the solution, and then raise the temperature to At about 90-100°C, a small amount of impurity organic amines are distil...

Embodiment 2

[0025] Get 1.2L of dipropylamine, add 0.02mol / L conductive agent (CH 3 ) 4 NHSO 4 As the electrolyte, the tantalum plate is the anode, the area is 12cm×12cm, the stainless steel is the cathode, the area is 12cm×12cm, the distance between the cathode and the anode is 8cm; at a current density of 400A / m 2 , The tank voltage is 100-120V, and the temperature is electrolyzed under the condition of boiling. The volatilized dipropylamine is returned to the electrolysis by cooling and reflux, and the dipropylamine is continuously added to maintain the solution volume, and the electrolysis is continued for 2 days (48h). The mixed solution of dipropylamine tantalum and dipropylamine obtained by electrolysis, first slowly raise the temperature under normal pressure, distill to above the boiling point of dipropylamine (109°C), make the dipropylamine volatilize from the solution, and then raise the temperature At about 140°C, a small amount of impurity organic amines are distilled off, a...

Embodiment 3

[0027] Take 1.2L of dibutylamine, add 0.1mol / L conductive agent NH 4 Br is the electrolyte, the tantalum plate is the anode, the area is 12cm×12cm, the stainless steel is the cathode, the area is 10cm×12cm, the distance between the cathode and the anode is 2.0cm; at a current density of 50A / m 2 , The cell voltage is 15-20V, and the temperature is electrolyzed at room temperature. The volatilized organic amine is returned to the electrolysis by cooling and reflux, and the electrolysis is continued for 5 days (120h). The mixed solution of organic amine tantalum compound obtained by electrolysis-organic amine, first slowly raise the temperature under normal pressure, distill to above the boiling point of dibutylamine (159°C), make dibutylamine volatilize from the solution, and then raise the temperature When the temperature reaches about 180°C, a small amount of impurity organic amines are distilled off, and dibutylamine is cooled and recovered. Turn on the vacuum pump while it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com